-

Posts

7,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Build log part 38 poopdeck handrail Prior to sanding and varnishing wheel to auxiliary rudderstand decks nearly completed nav sight-bearing devices on pods next to the raft containers handrails complete all around poopdeck mizzen mast top shroud wire chords a few hundred blocks (in total) for all the sail operating running rigging spanners for the upper shrouds of foremast Build log part 39 to follow... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Popeye, the railing assembly is always quite a fiddeling session, and when those thin stanchions are bent too often they simply break off. I consider about 5-10% spare when purchasing... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Michael, in total it must have been appr. 1600 manhours, but not continously building, because the Pamir was pulled up inbetween, whilst the Gorch Fock stood waiting, so that both ships nearly had the same sequence Level and I could do common practice withe the sailmaking, etc... Cheers Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 37 the anchorchain-stoppers choke type, with spindle in combination with electric spills and Spill band-brake device forecastle deck now ready for operation Crew in Trial positions because of the Motor there must be an machine telegraph operator poopdeck railing nearly completed continous Progress.... Build log part 38 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Mirabell61 replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Doris , Thanks so much for those Close up pics of those absolutely fantastic mystic figures, its like in fairyland even with my 66 years Nils- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

congrats Karl, a great tool that Proxon lathe, someday I think I will invest in such myself Nils

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

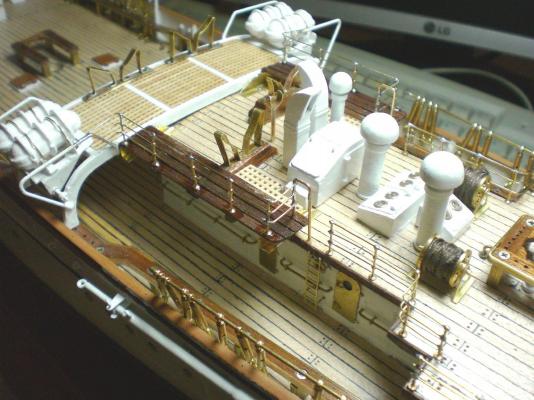

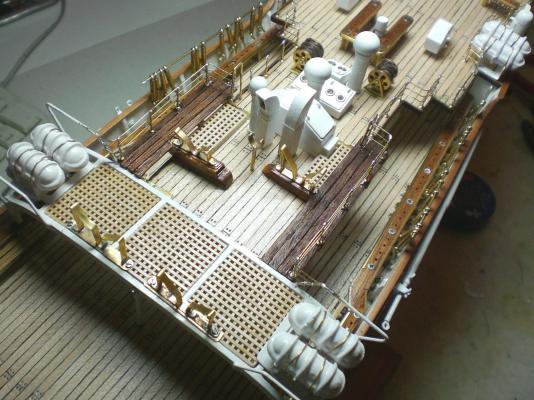

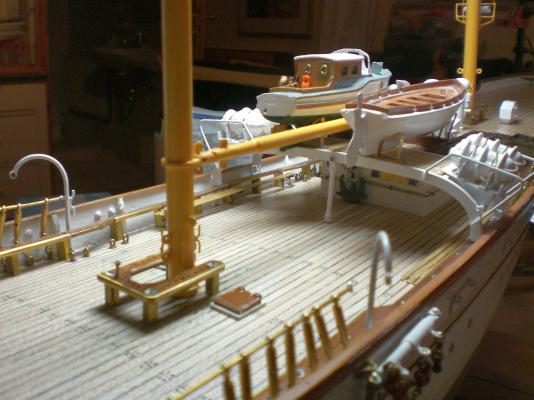

Build log part 36 the forecastle stairs will not be permanently fixed until the frontmast rigging in that area is done, due to Access Problems otherwise view without the boats uncomplete forecastle deck, the portside only bears an nostalgic admiralty type anchor shortcut Access to boatstations also directly possible from welldeck portside welldeck Forward view the stairs to poopdeck shall be integrated into the railing Build log part 37 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Mauro, Plankings Looks good are you going to fill the plank gaps in some way when the Planks are all laid down ? Nils

- 111 replies

-

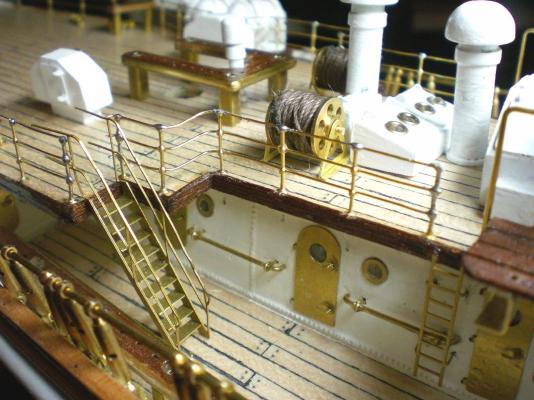

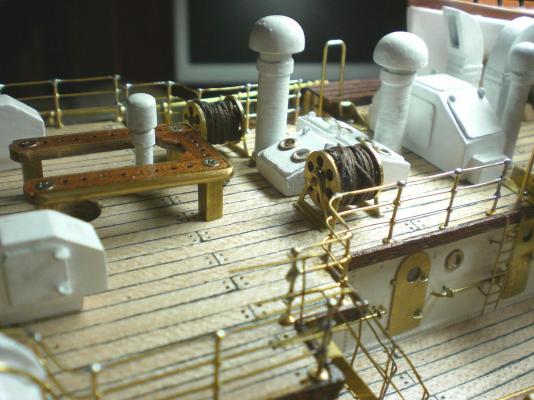

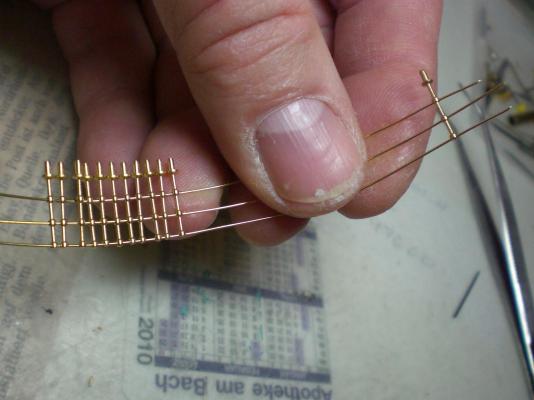

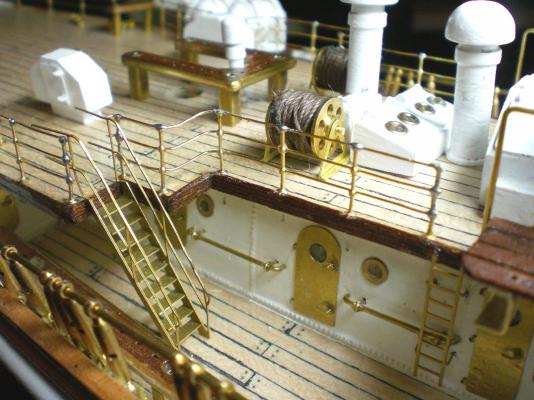

Build log part 35 starting the brass railings with 3 hole stachions and 0,4mm wire from the spool shaping a duct for the potside anchor ...and on towards the boatstations front mast goes through the deck here the two boats are hanging outwards but also can be swung inwards fit in the forcastle stairs (to be soldered with the railing, later on ropedrums attached railing continued around the boatstations and up to the liferaft containments Build log part 36 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 34 Davits fitted on poopdeck walking Planks at boatstation again the wheelstand portside boat rigged all boats on... Build log part 35 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

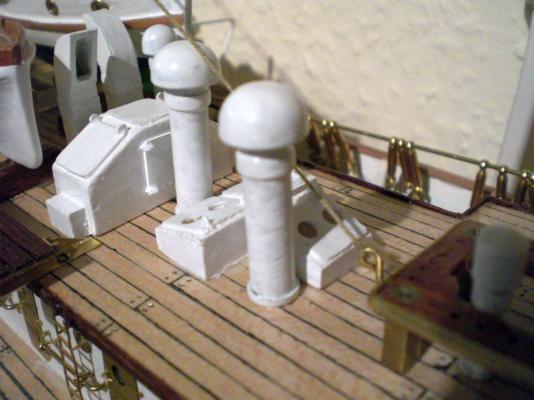

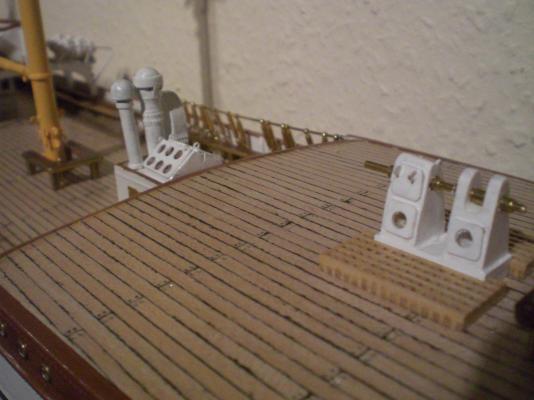

Build log part 33 nav. light containments mushroom type vents on the deckhouse top slowly having all deck Fitting-out placed front of poopdeck with main wheelstand two additional raft containers still lots of space on the welldeck the White round item is not the cooking pot, its the mother gyro-compas containment White tipped Ends... Builg log part 34 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

very nice hull Bob, with her slightly higher aft deck, the fine elegant lines she reminds me of the gloucester fisher boats, as well as the fast Pilot schooners of that time in all great looking ! Nils

- 420 replies

-

very nice work Mike, clean accurate and wonderful joining. I like the answer you gave as to your intended Planking already, and expect your model to be one of the great ones at MSW. Well done Nils

- 175 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Build log part 32 Walking Planks at the boat stations, and further vents funnel, vents, wheelstand, two compas stands, Skylight and rudderposition indicators, the boat is just for checking available space in length nav light Towers (here still without lanterns) Forward vents, radar-bar, fog horn and forecastle raft Containments mounted cradle device for strapping raft containers navlight containments Build log part 33 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Mirabell61 replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

candy for eyes and soul Doris, you put so much love into every Detail... even the Little stand plate withe the Name and those great modelled (unicorns ?), do you have a Close up view ? Nils- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

David, when the GF2 log is done I shall have to switch back to online actual-progress-posting. Unfortunately, when I built the live swedish museum Steamer "Bohuslän" I think Digit-cameras were not available at that time, so no pics from that build except for the last stage Fitting out ones. David sorry I did`nt answer the first part of your question..., it took me 1,5 years to make Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

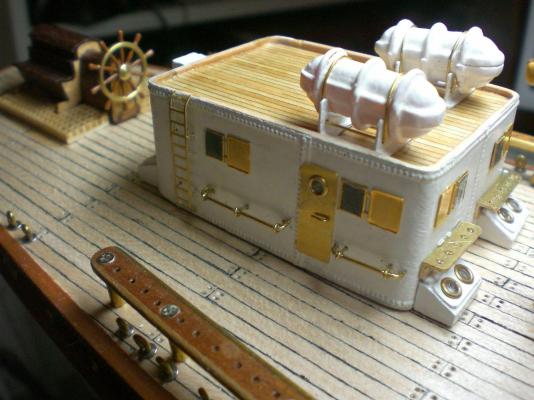

Build log part 31 aft deckhouse (command cabin and nav- and Chart-room) and spare aft anchor. the blue guy had always become too much Porridge as a Baby already and now has to leave the Crew for his size chest-cover to sit on, for the auilliary rudder mechanics, here still without wheel some brass pinrails to the deckhouse, and the main rudderstand saddle for the 3 steering wheels, this rudderstand (the wheels) is operated manualy if necessary by up to 6 men the Long boom outside starboard bulwark is swivible and required for fastening the boats in water (when rigged 90° square to the hull). The brass wire through the top spanner-eyelets is only preliminary and prevents the spanners from tilting down between bulwarks and inboard pinrails vents and Skylight added on top of the small well-deckhouse Build log part 32 to follow..... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

very nice words David, makes me feel good this morning, thank you Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

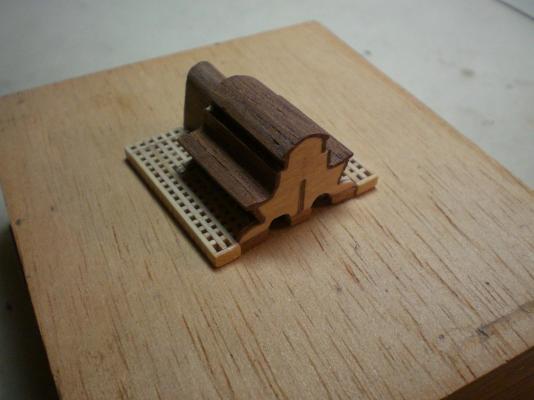

Build log part 30 check for cutter on the boats rack captain`s pinnace goes besides the cutter first deck Skylights.... Build log part 31 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Build log part 29 decks ready for Fitting out Stern and bow of hull so far done checking backstays alignment with regular Cotton thread strings first set of masts and Yards painted Build log part 30 to follow.... Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Thanks Popeye, your comment is well appreciated Nils

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.