modeller_masa

NRG Member-

Posts

950 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by modeller_masa

-

If you haven't resolved the issue yet, I recommend resetting the browser app. Go to the control panel and uninstall the browser. Otherwise, you can see a "user data reset" or similar button. Once you reset the browser app, you should go to Google Play and update it to the newest version. Also, your favorite webpage list will be removed. If you want to keep browser info, backup the favorite list before resetting.

-

https://www.keranova.es/categoria-producto/modelismo-naval/?product_brand=5638 Have you ever heard about the company? It looks like a new company in Spain. https://www.scalemates.com/kits/keranova-51201-pilar--1494376 This is the most expensive kit from the company. New companies and kits are always welcome. By the way, Carthago Nova is a historic city in Spain. https://www.worldhistory.org/Carthago_Nova/

-

Help for blocks with hoop required.

modeller_masa replied to Tony28's topic in Masting, rigging and sails

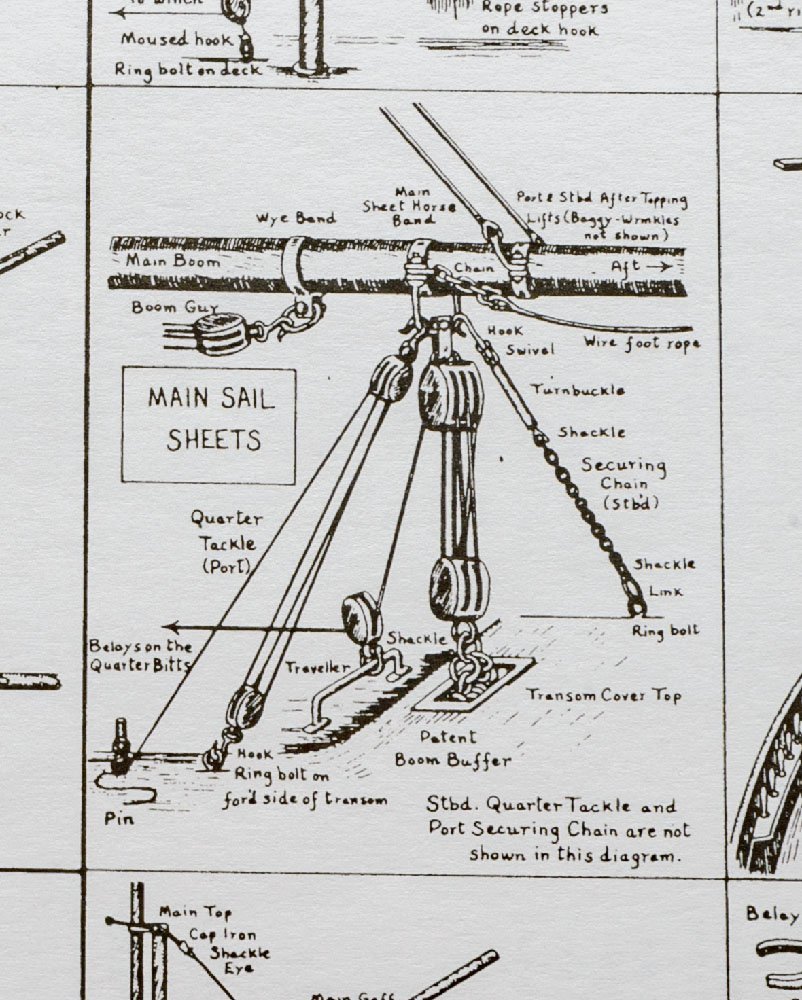

I guess you are making Bluenose from Amati. This book may help your understanding. https://www.amatimodel.com/en/models-amati-classic/product-bluenose-b1447.html These are examples by Amati. -

The silkspan is the brand marketing name of an original paper that was invented in China in the B.C. 50s. The modern paper we use every day is refined by machine and chemicals. The old and original paper have low density and higher tensile strength. The original paper is so popular in the East Asia region. Asians use the original paper for many purpose, such as windows and wallpaper. I can find and buy the silkspan paper at every stationery shop in South Korea. The original paper has different name by country. - Chinese paper in China, Korean paper in Korea, Japanese paper in Japan, or Japanese rice paper, etcs. Wefalck introduced industrially refined original paper made by a German company. The refined paper is optimized for the model project; longer fibers and evenly patterns. I guess it is hard to find the original paper in the Western region, The different names may help you find the "Silkspan". (When I saw the word first, I purchased "silk and span fabric," literally. 😆 )

-

Light table question

modeller_masa replied to GrandpaPhil's topic in Modeling tools and Workshop Equipment

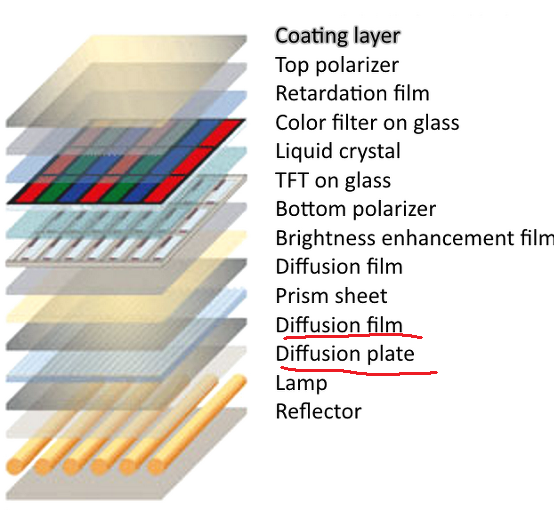

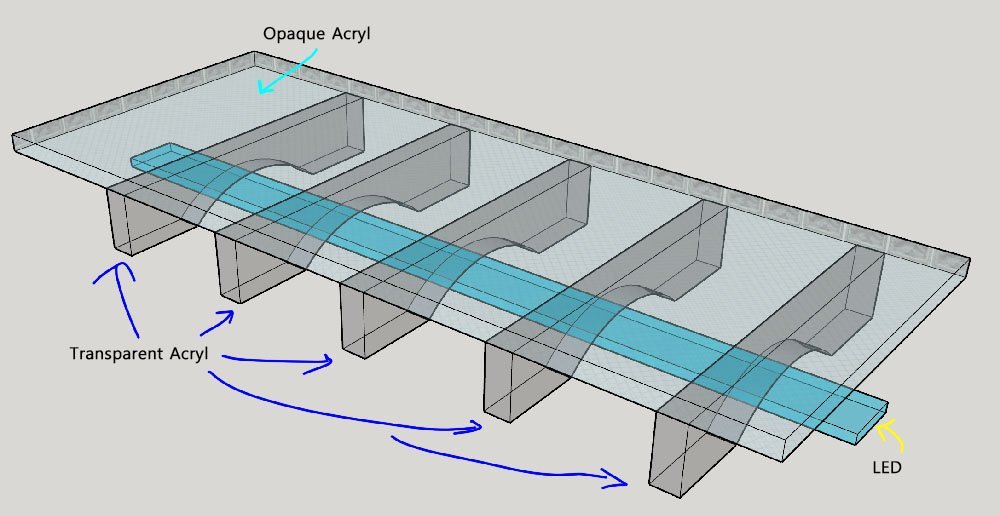

Lamp = LED strip Diffusion plate = Laser engraved acrylic panel https://en.kohacraft.com/archives/make-a-flat-light-emitting-lighting-by-processing-acrylic-into-a-light-guide-plate-with-a-laser-cutter.html https://aliexpress.com/item/1005006156384485.html Diffusion film = translucent PET film https://aliexpress.com/item/1005006059186279.html -

Light table question

modeller_masa replied to GrandpaPhil's topic in Modeling tools and Workshop Equipment

Technically, the best light diffuser panel is the part in the LCD screen for TVs and smartphones. There is a thin LED light strip at the bottom of the display, and the thin layer emits and spreads light to the entire screen equally. It seems like the light pad has a similar structure. The video shows how he modified a monitor into a light pad. https://aliexpress.com/item/1005004799141286.html I'll try this diffuser film. -

Light table question

modeller_masa replied to GrandpaPhil's topic in Modeling tools and Workshop Equipment

-

Thank you so much, Baker. Although It's not as good as I expected, I wish to improve next time with your kind comment. Thanks, Jeff.

- 13 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

Focus Stacking

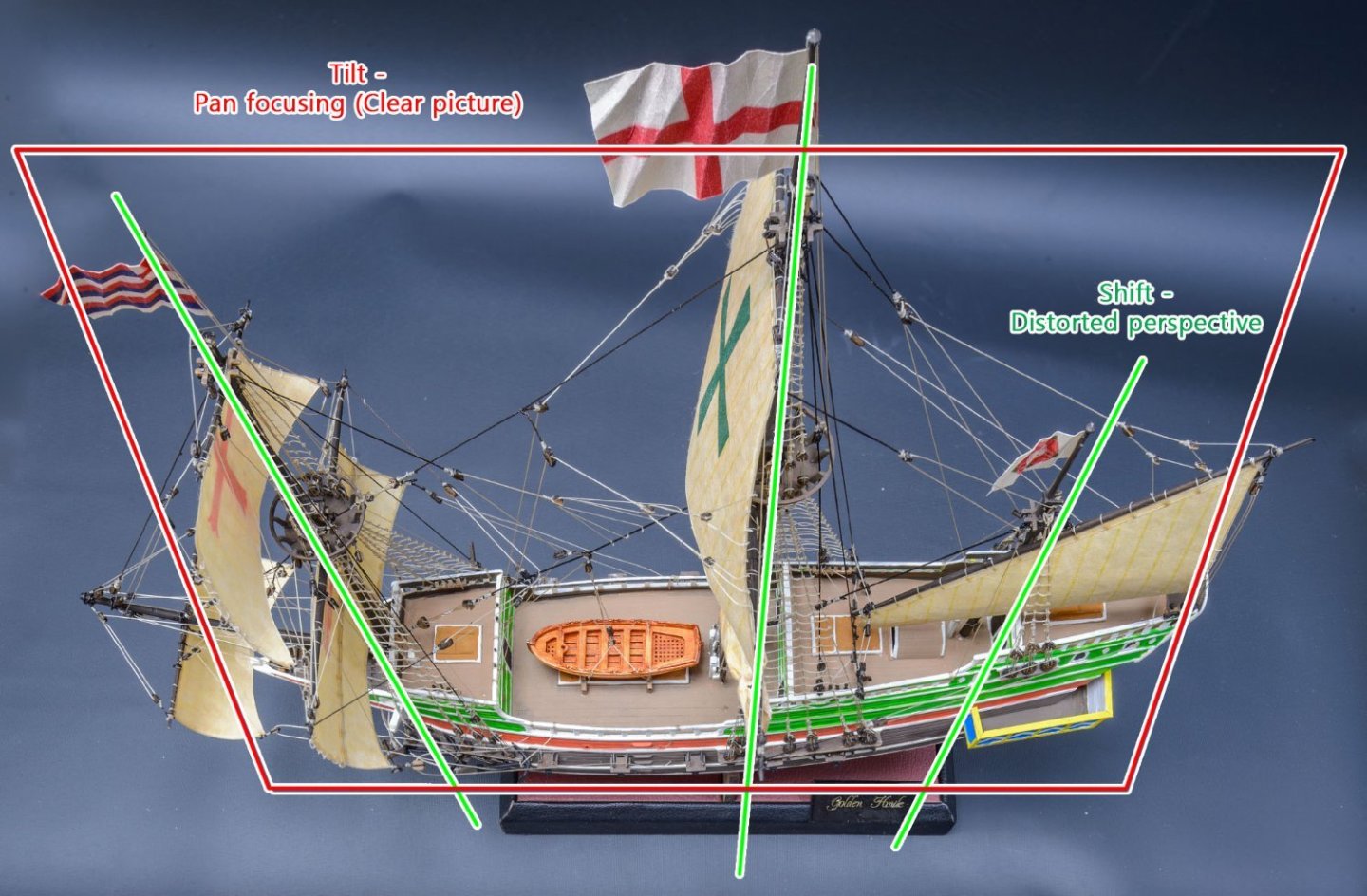

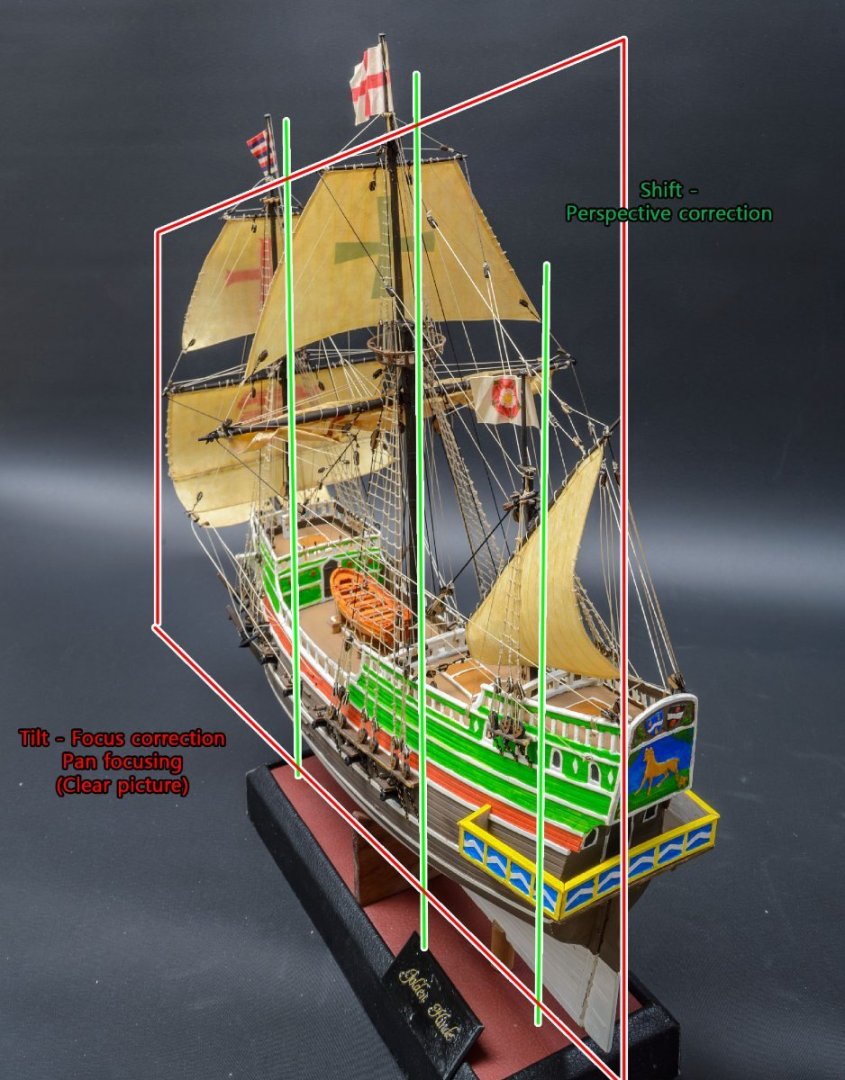

modeller_masa replied to Dennis P Finegan's topic in Photographing your work. How to do this.

These are sample pictures that I took with a Samyang 24mm F3.5 Tilt-Shift lens. In a general situation, I may need an ultra wide angle lens with a F22 slow speed aperture or the focus stacking method to take the same picture. I took only a picture. Beautifully simple and works well. It is a case of "a practice is worth a thousand words." Another example. I can get the same perspective correction with an ultra wide angle lens and photoshop crop option, but the picture resolution will be lower than this. Difficulties with the focus stacking method have already been commented on here. Before the slim mirrorless camera age, the TS lens cost more than $2,000. The high price was a reason we had difficulties using the lens. Now we can get the old vintage lens for $300. 😎 -

Thank you for your guidance, Darivs. I didn't expect the result, but I thought the straight standing rigging line is better than the zigzag line. I'll pay more attention to it next time.

- 13 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

Thank you again for your comments, Steven. I appreciate very much!

- 13 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

I used my 24mm F3.5 Tilt-Shift lens. The lens makes interesting pictures using perspective and depth-of-field control. I hope you enjoyed my build log. See you next month.

- 13 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

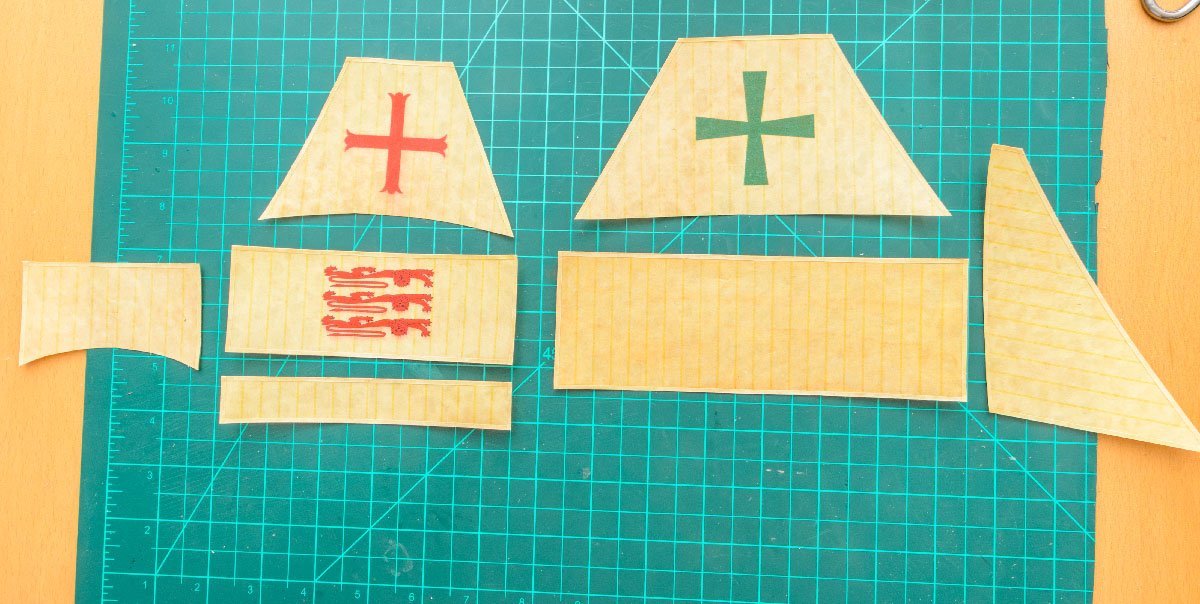

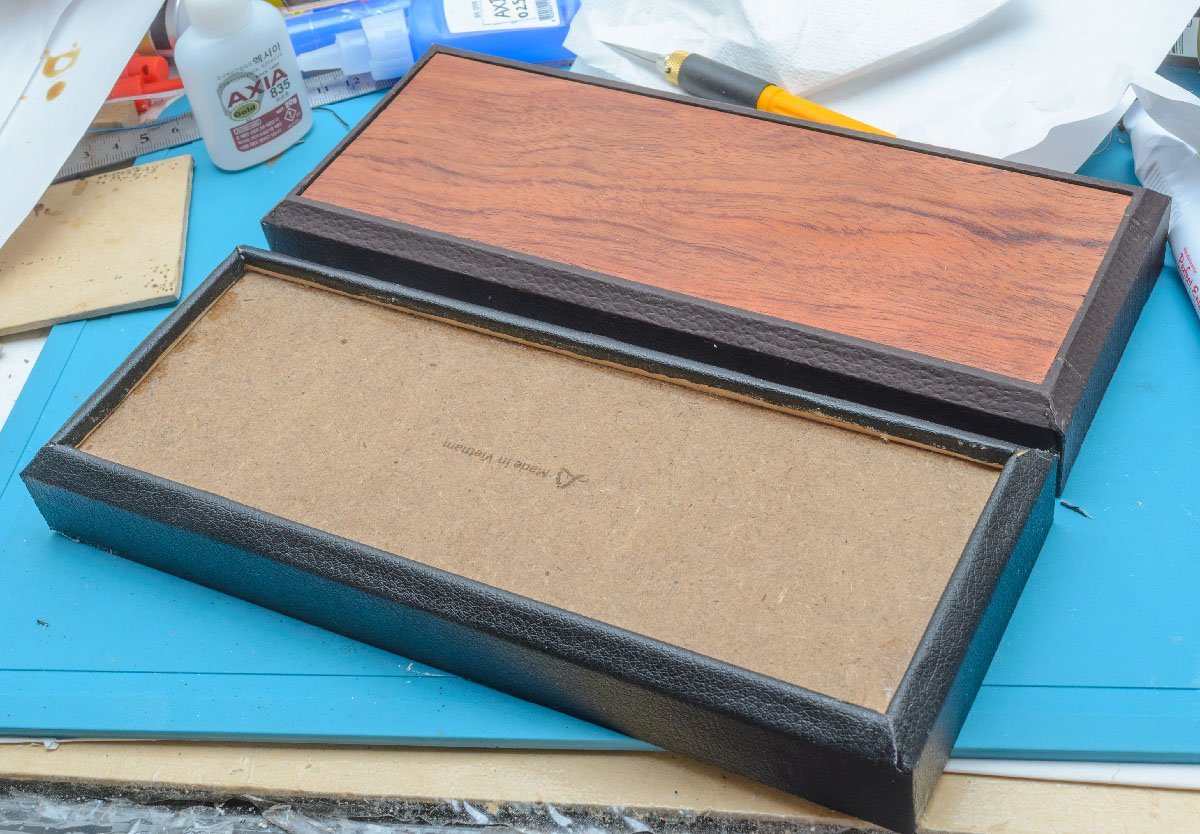

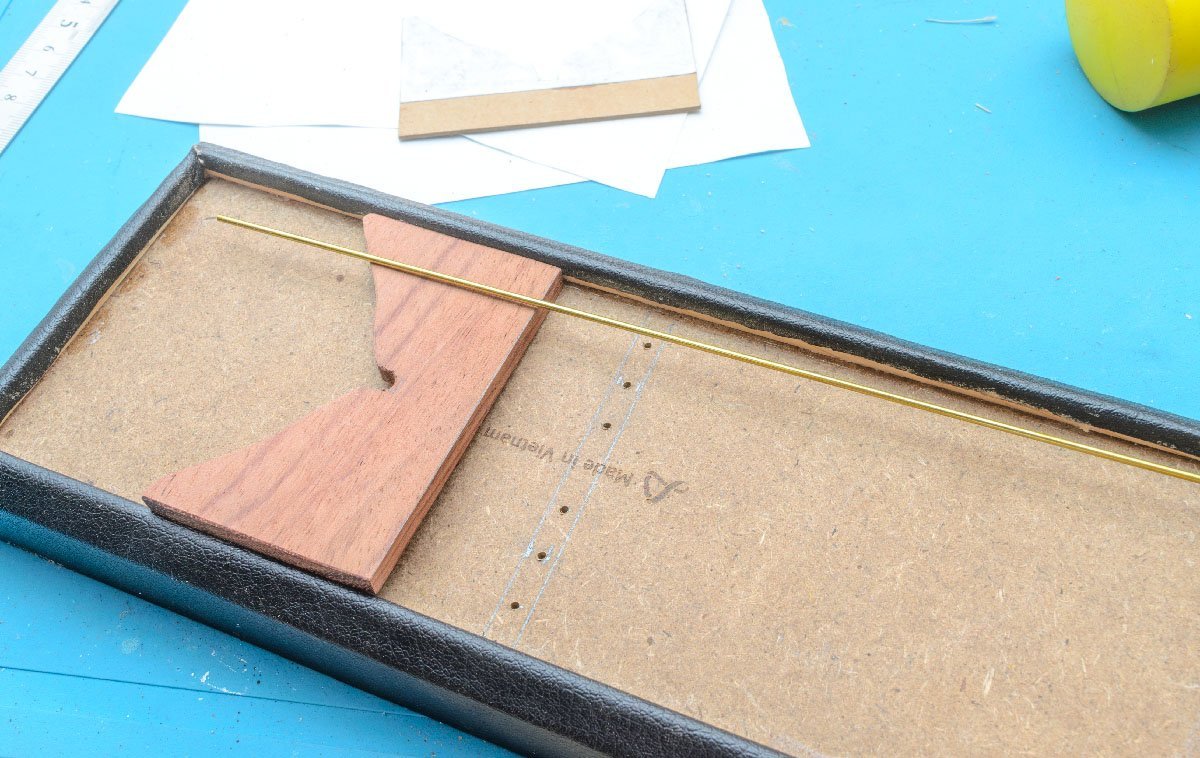

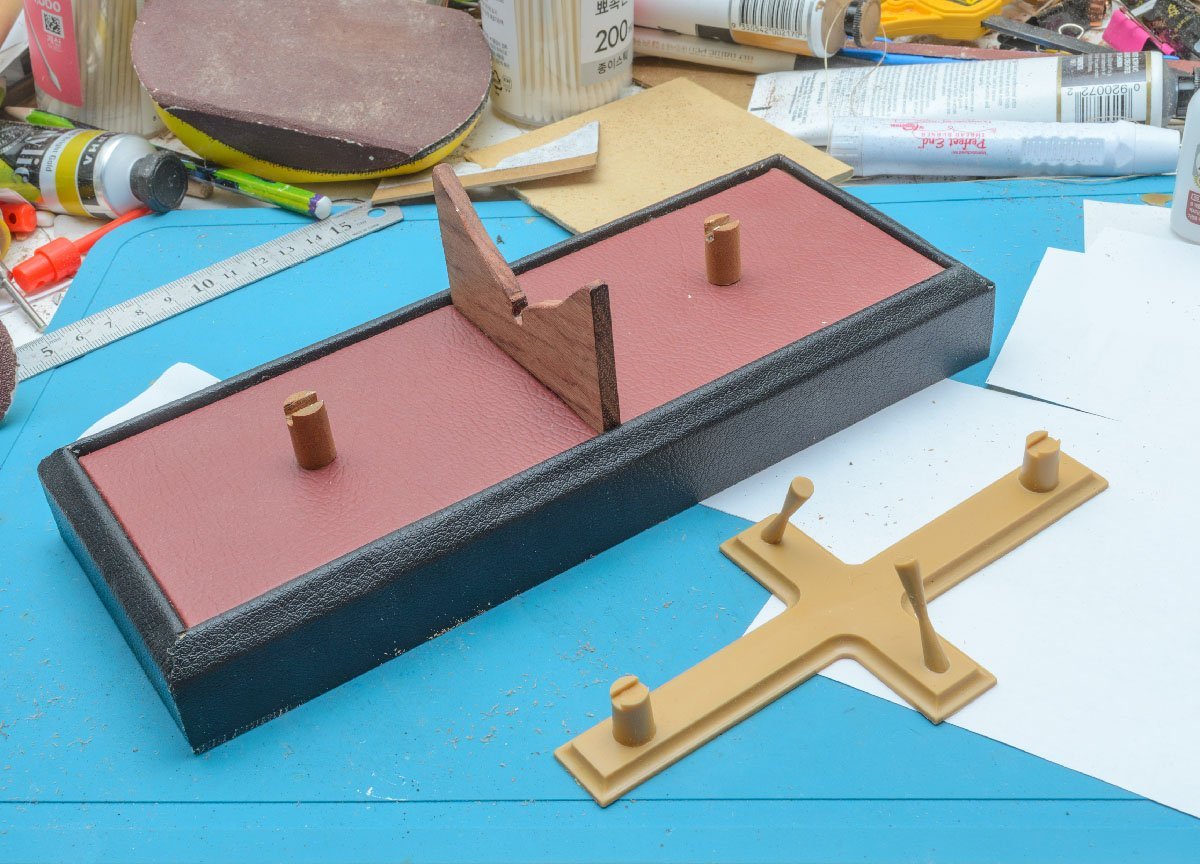

The standing rigging section was fun and solid. However, the running rigging was pretty difficult. HISmodel's running rigging plan was confusing and inaccurate. The plan includes two different Golden Hinds, so it led me to install duplicated rigging threads to the same place. I don't have enough skill and experience to fix them, so I just added all the riggings. The result was spagetti rigging. 🤣 I made sails using Han-ji. (In other words, Korean paper, silkspan, Japanese rice paper, or Chinese paper.) I used an inkjet printer to print them. I used synthetic leather to wrap a wooden tray. This was an ambitious project, but the HISmodel rigging plan made my model impractical. In the future, I'll stick to more formal references, such as the AotS book series. 😁

- 13 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

I would like to express my sincere condolences on the death of James William Byrnes... https://byrnesmodelmachines.com/

-

Focus Stacking

modeller_masa replied to Dennis P Finegan's topic in Photographing your work. How to do this.

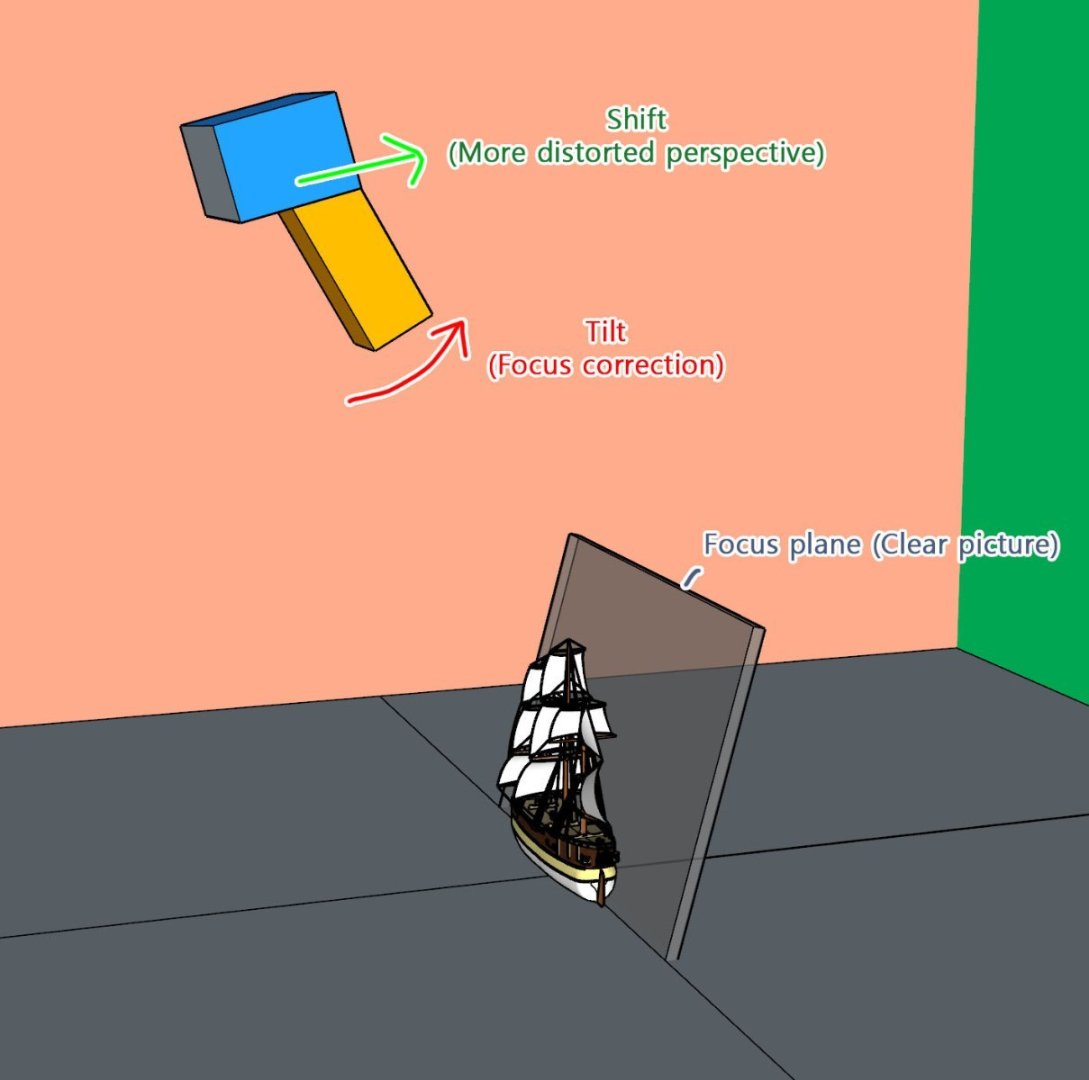

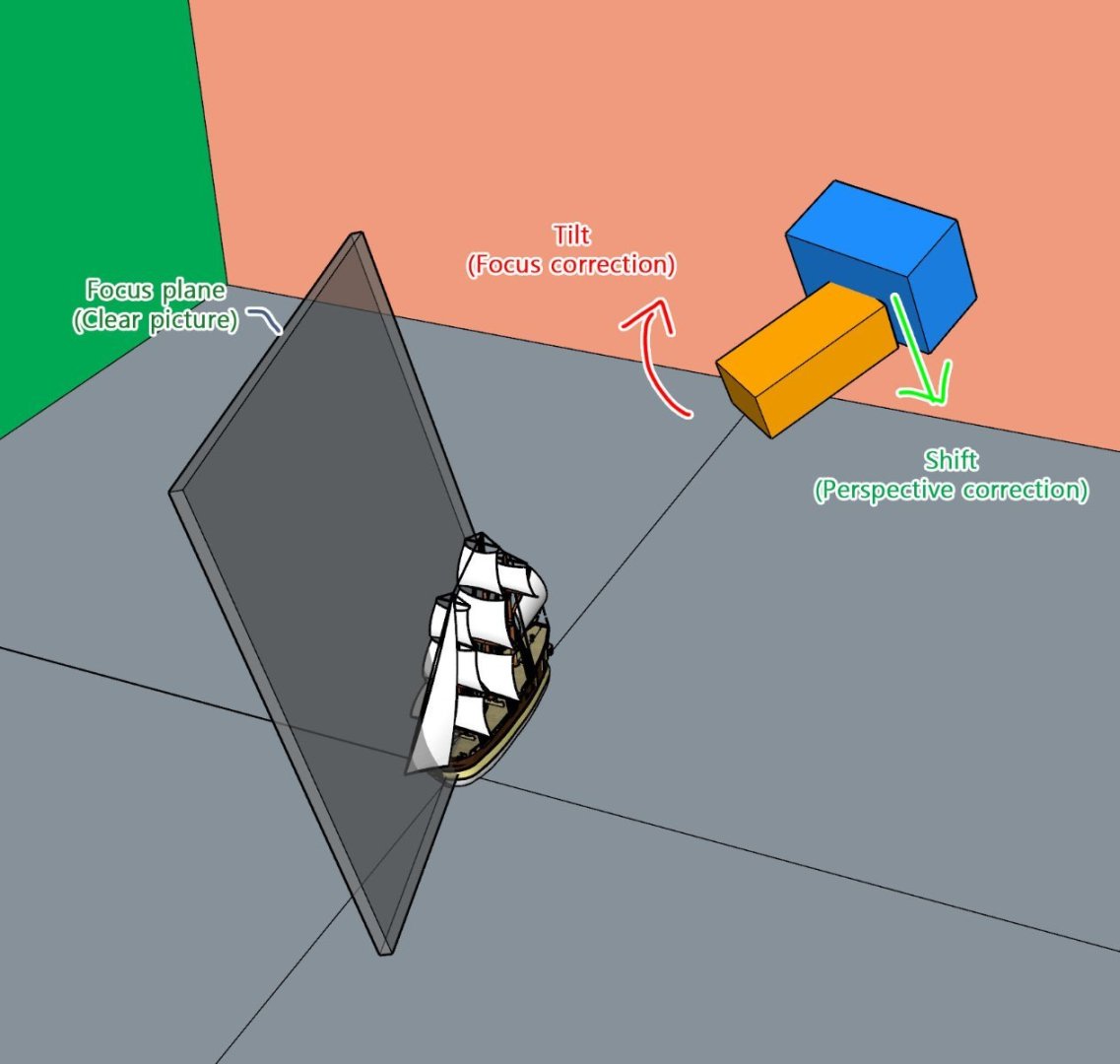

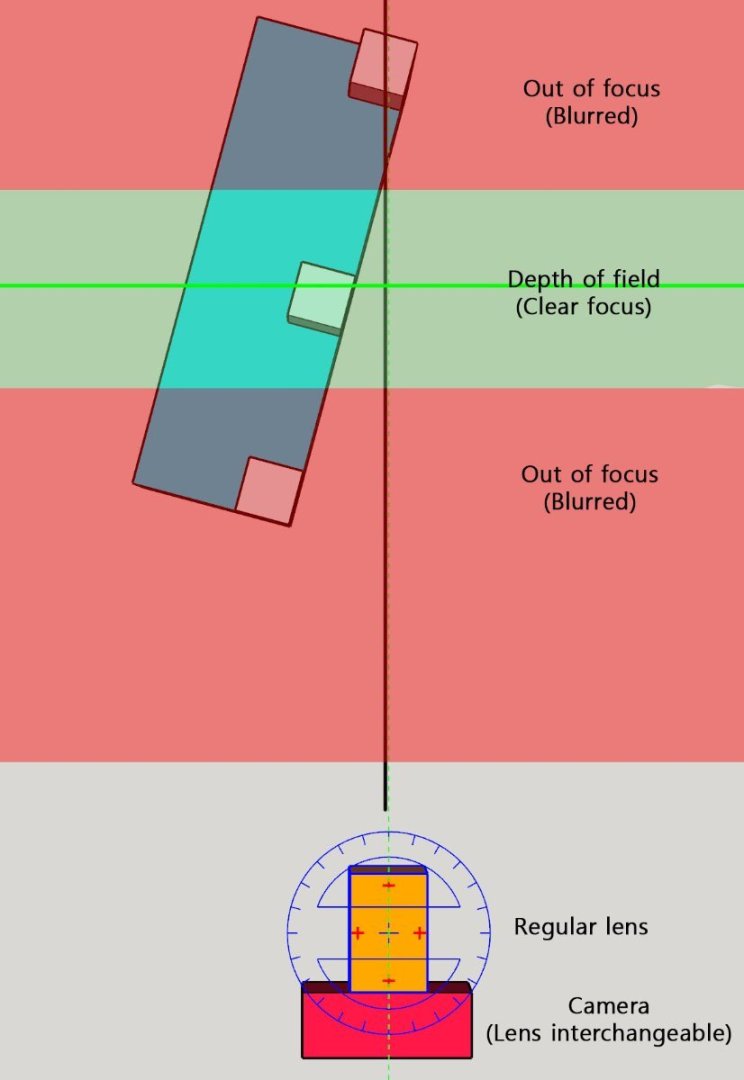

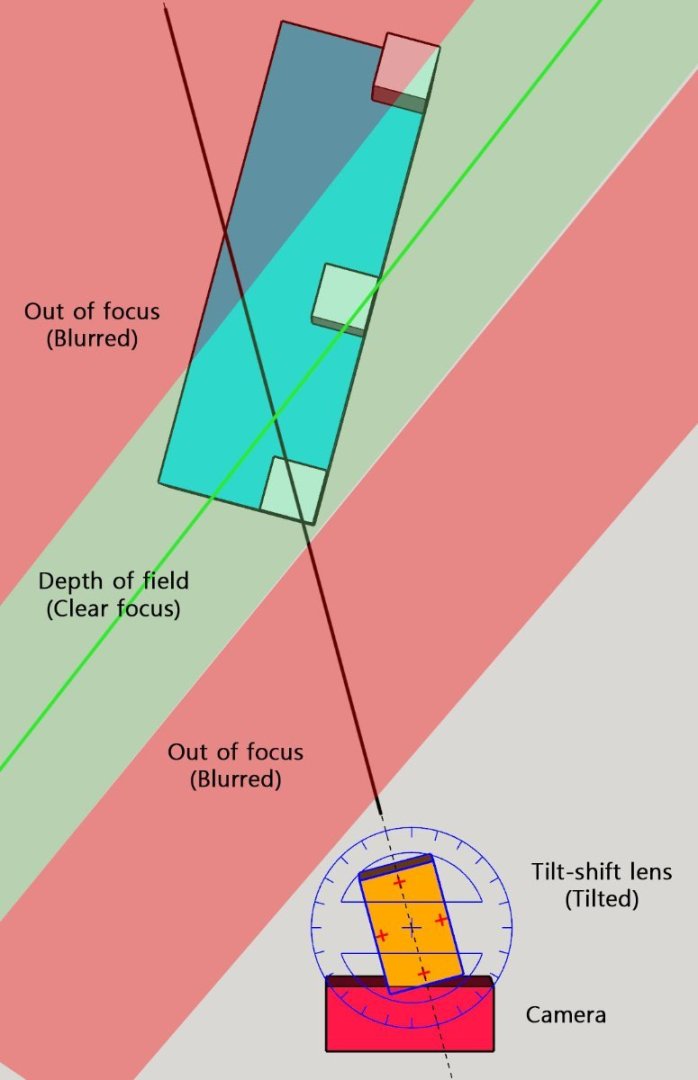

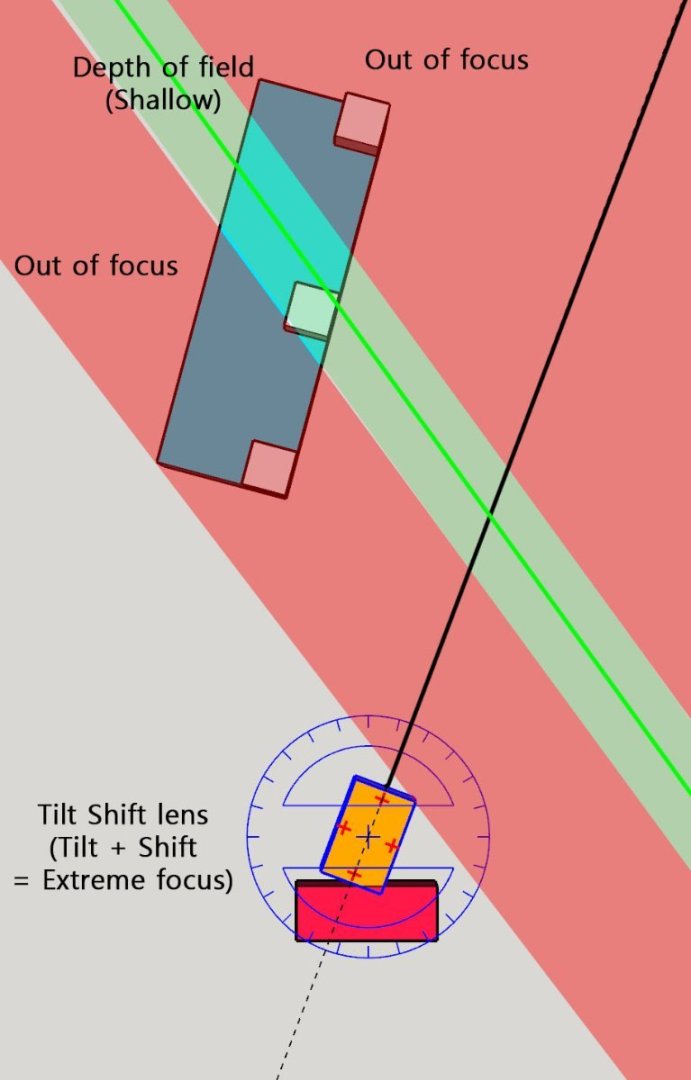

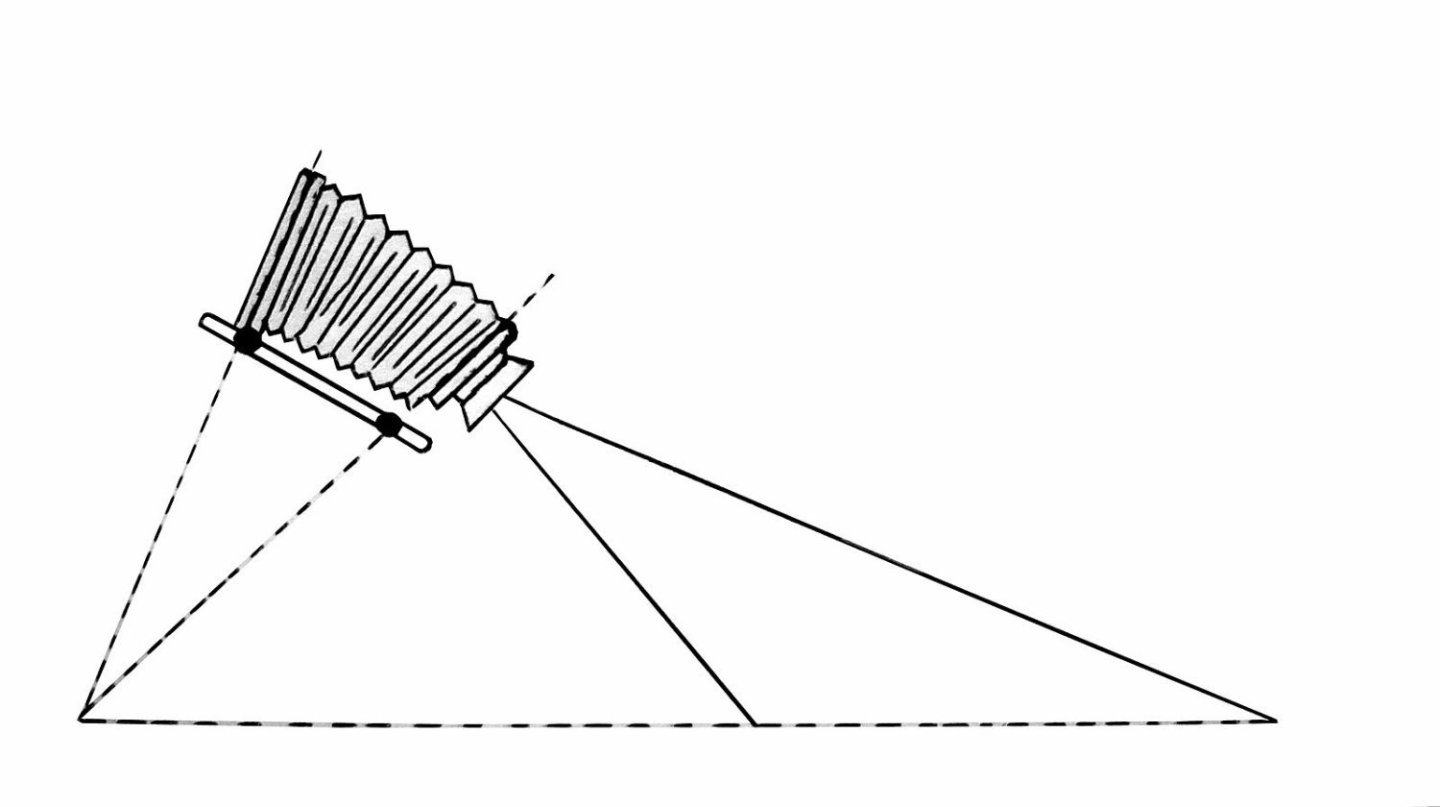

Wow, the camera is newer than me! I've been using a Nikon D4 for ten years. The built-in focus stacking became popular in the next generation. Sorry about the confusing sample pictures. I would like to show an example of the controlling depth of field. Here is a diagram of the depth of field in the case of a normal lens. There are two ways to get clear focus on the entire subject (Blue) in the given situation. 1. Small aperture - Cons: Slow shutter speed, loss of detail 2. Software photo stacking - Cons: Needs multiple pictures, frequent software rendering error - Ex: rigging threads This diagram shows how the tilt-shift lens makes a clear picture of the subject. If I tilt the lens in the opposite direction, the subject looks like a miniature. The best lens for tilt and shift control is for large format cameras. You can find cheap vintage lens on eBay. I once made a flat-bed scanner-large format camera 15 years ago. I won't use the lens because the whole device holds too big place. -

Focus Stacking

modeller_masa replied to Dennis P Finegan's topic in Photographing your work. How to do this.

-

Focus Stacking

modeller_masa replied to Dennis P Finegan's topic in Photographing your work. How to do this.

I'll buy a 24mm F3.5 Tilt Shift lens for my DSLR today. ($250) It is cheaper than an electric dolly rail. I thought the lens is the most simple solution for given budget. -

https://www.subchaser.org/model-anchor-chain According to the US Submarine Chaser archive site, this is the the optimal scale of railing anchor chain in the WW I era. 1:24 16 LPI (Links per inch) 1:32 21.5 LPI 1:48 32 LPI 1:64 43 LPI 1:74 49 LPI 1:96 64 LPI https://floatingdrydock.com/more.htm#CHAIN I found this site is selling the 50 LPI chains, but I don't guarantee it because I've never bought anything at the site. https://www.labellemodels.com/chain-p-295.html https://www.builders-in-scale.com/bis/parts-chain.html Another 40 LPI chain.

-

I don't know the story behind it, but I would say that it seems to kill the goose that lays the golden eggs...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.