Rick310

NRG Member-

Posts

833 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick310

-

Nice job Jared, looking really good! Rick

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Rich, to raise the topsail for furllng, would necessarily mean having to loosen the chain sheets of the topsail first before the sail could be raised. Much simpler and faster to lower the topsail yard first so the reef points could be drawn up to the yard by the reef tackle and then furl the sail. Rick

-

Agree Rob, Her topsail yards have been lowered to the lowest reef points, her reef tackles are pulled in tight and the billowing part of the topsail will be furled on top of the yard. The crew is in the process of furling the topsails. To furl the topsail, the yard has to be lowered first, therefore the billowing sails. What a great picture!!! Rick

-

Rich, Rob, In reference to the location of the water closets/ companionways on the Flying Fish, I think the location and design make sense. Possibly the companionways were up against the aft end of the forecastle, as seen on other ships. It doesn’t make sense for the water closets to be below deck where they would be difficult to access for the crew working on deck. As no one knows for sure, I assume that Ben Langford, Erik Ronnberg, and the others who worked on the 1979 revision of the Flying Fish plans, resorted to placing them in a common location. Don’t underestimate the knowledge and experience these people brought to this reconstruction. While each ship was unique as far as hull design, and to some extent, the rigging ,ect. deck equipment was fairly standard in function and location. This doesn’t mean that there weren’t differences. Keep up the good work!! Rick

-

Keith, some more pictures of Cangarda. Tried to focus on the metal frame work for the awning (Bimini?). I have a feeling that she will be departing soon. If there are any other photos you need, especially on board, let me know and I’ll see if I can get back on board, or at least get to the top of the stairs.

-

Thanks you ClipperFan for your kind words and encouragement! I too am at a loss about Buttersworth’s work. While I believe his paintings are incredible, there are features in his paintings that make me question the accuracy, such as a furled sail on the forestay on the FF painting, and his painting of the Westward Ho, he depicts both Spencer sails and staysails set at the same time. Maybe this is correct? As far as the bow of the Flying Fish, I also wasn’t sure how to model it and ended up trying to come up with something that was close to the painting. Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

USS Cairo by Zetec - FINISHED - 1/50 scale

Rick310 replied to Zetec's topic in - Build logs for subjects built 1851 - 1900

WOW!! Great job!! Rick -

Thanks Rob, I take inspiration from your work! Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks George, really anxious to start rigging. Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

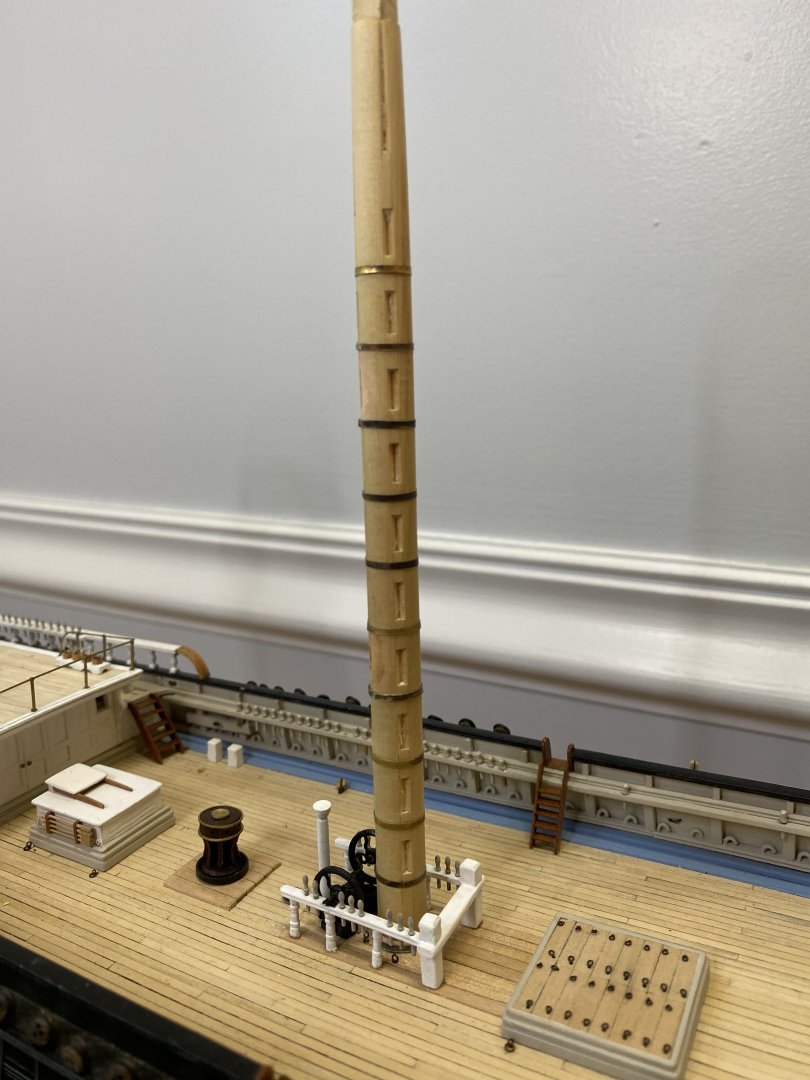

Finished the lower main and fore masts. The mast bands are .05 brass, approximately .055 inches in width. The futtock band and the lower yard truss band are .02 inches thick copper, approximately 1/16 inch wide. These were made with the hounds clamped in place, then when the hounds were glued and shaped, the bands were pushed the into place. The jackstay eyebolts are28 gauge copper, formed around the .02 inch diameter brass rod used for the jackstay. All eyebolts and block straps will be made with 26 gauge copper wire from now on. I’ve had a devil of a time with the 28 gauge copper wire breaking when blocks are put in place. I know this is out of scale, but it’s not that noticeable and the 26 gauge copper wire seems to be significantly stronger. The lizard and the bullseye for the mizzen stay are 2.5 mm ( approximately 3/32 or 9 scale inches). These are the smallest ones I could find that are commercially available . The upper bullseyes are smaller and I will try to make them. now, onto the tops and top masts.

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.