Rick310

NRG Member-

Posts

811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick310

-

That’s a beautiful rigging job Rob!! The foot ropes look great!! I see what you mean about the length of the stirrups. I’m going to try painting the foot ropes black also. Rck

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

I really like the idea of placing the foot ropes first, that way they are the same length . Harder to do when threading the foot ropes through the stirrups. Rick

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

I really like that technique! I think I’m going to try it as my results with the varnish have been somewhat inconsistent. Rick

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Amazing work!! Really enjoy following along! Rick

- 299 replies

-

- lightship

- Feuerschiff Elbe 1

-

(and 1 more)

Tagged with:

-

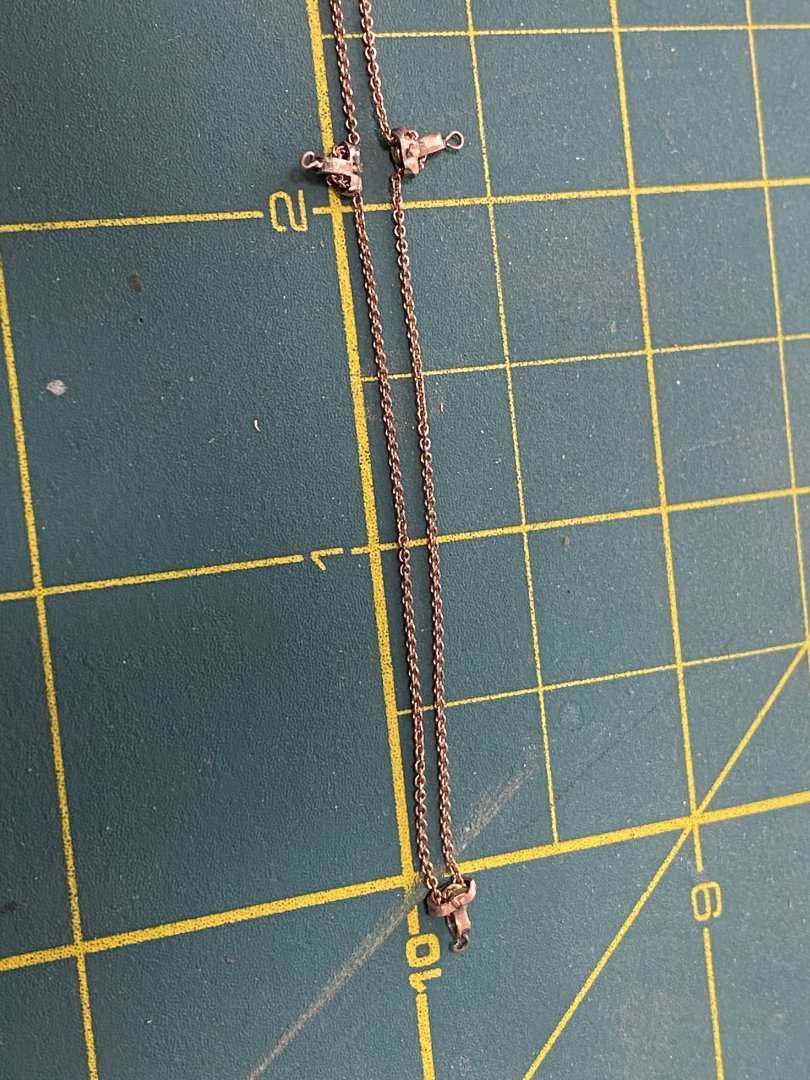

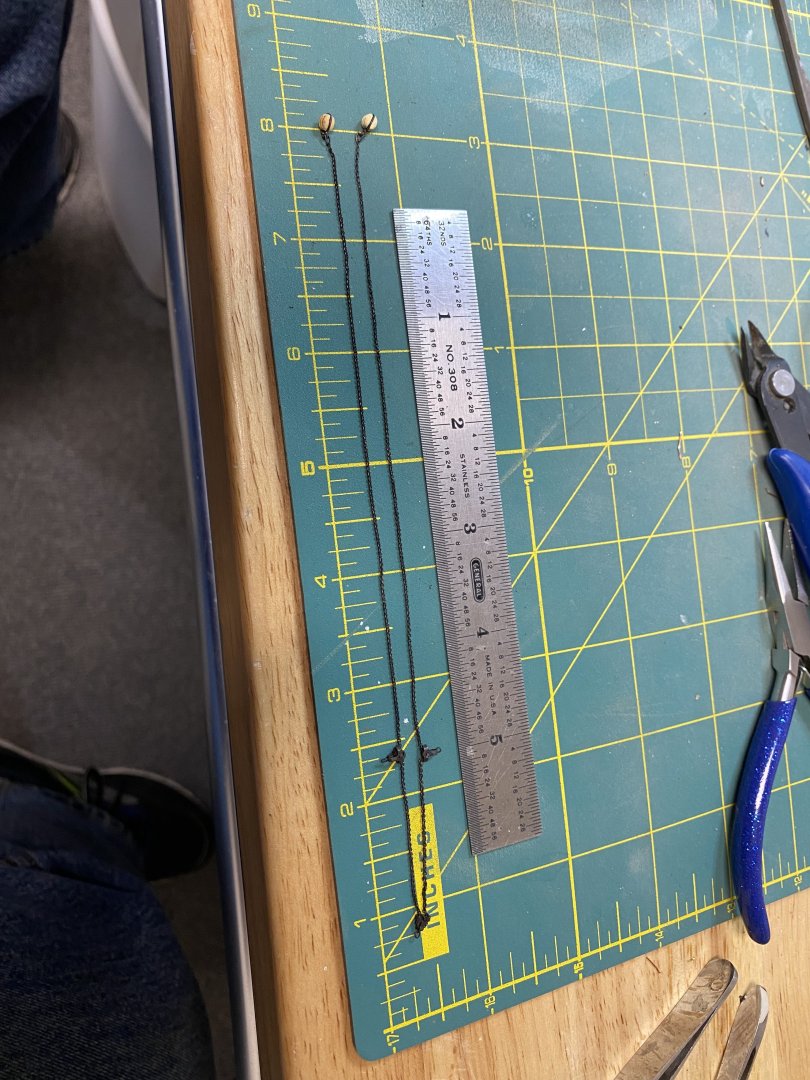

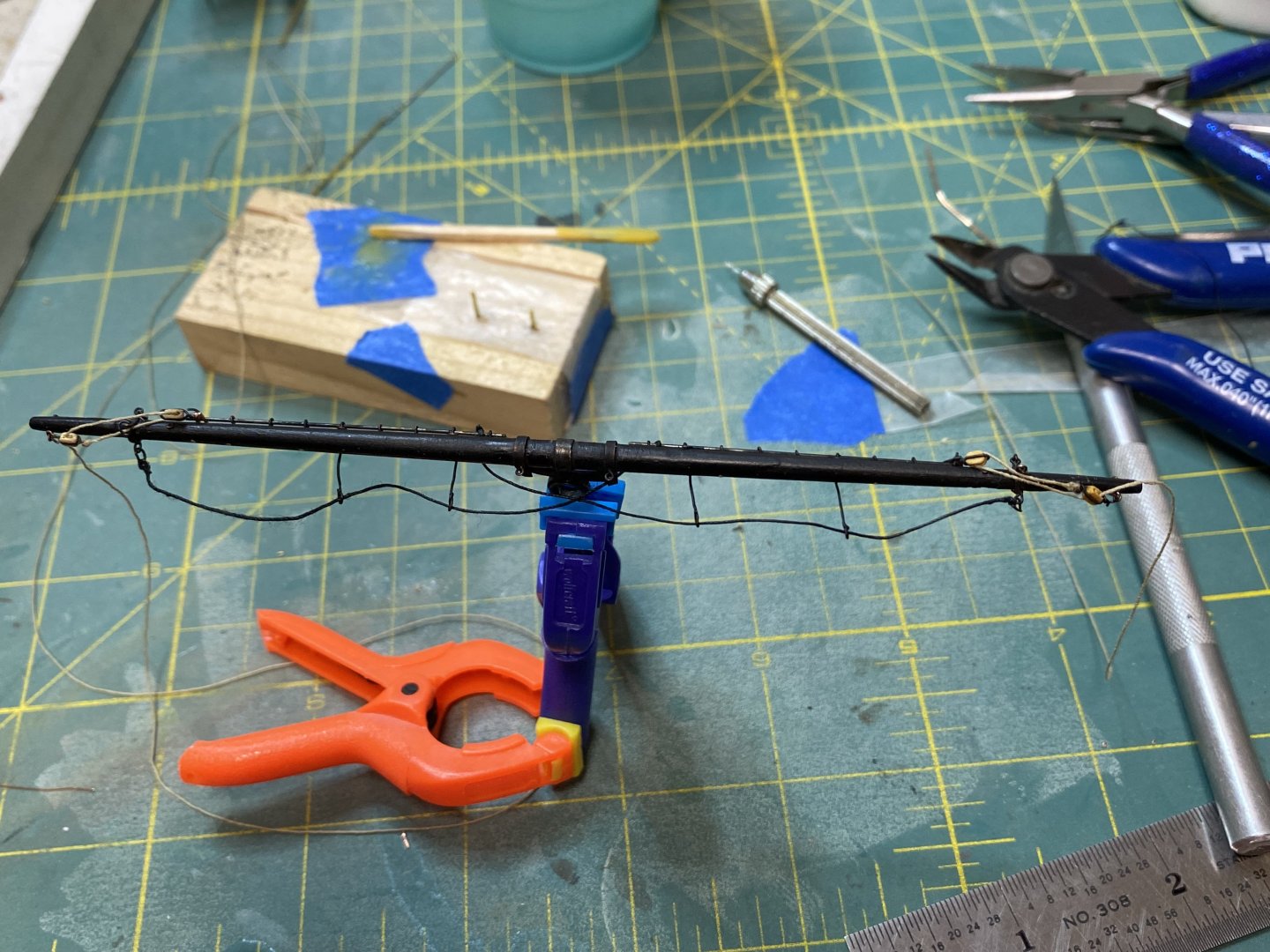

Ic, I used 28 ga copper wire for the stirrups and .012 black thread for the foot ropes. My intention is to apply Matt varnish to the foot ropes and shape them to the proper shape after I finish the rest of the work on the topsail yard.I’ll see if that works Rick

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Rob and George for your input. I am currently out of town helping my daughter plan her wedding (my input not required, just my approval). I will check everything when I get back. Rick

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks for the input Rob, really appreciated! I’ll go back and re-measure the stirrups, they’re supposed to be approximately 3 1/2 ft. Rick

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

John, Red Jacket is looking really good!! Bluejacket’s fittings are really well done! Rick

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

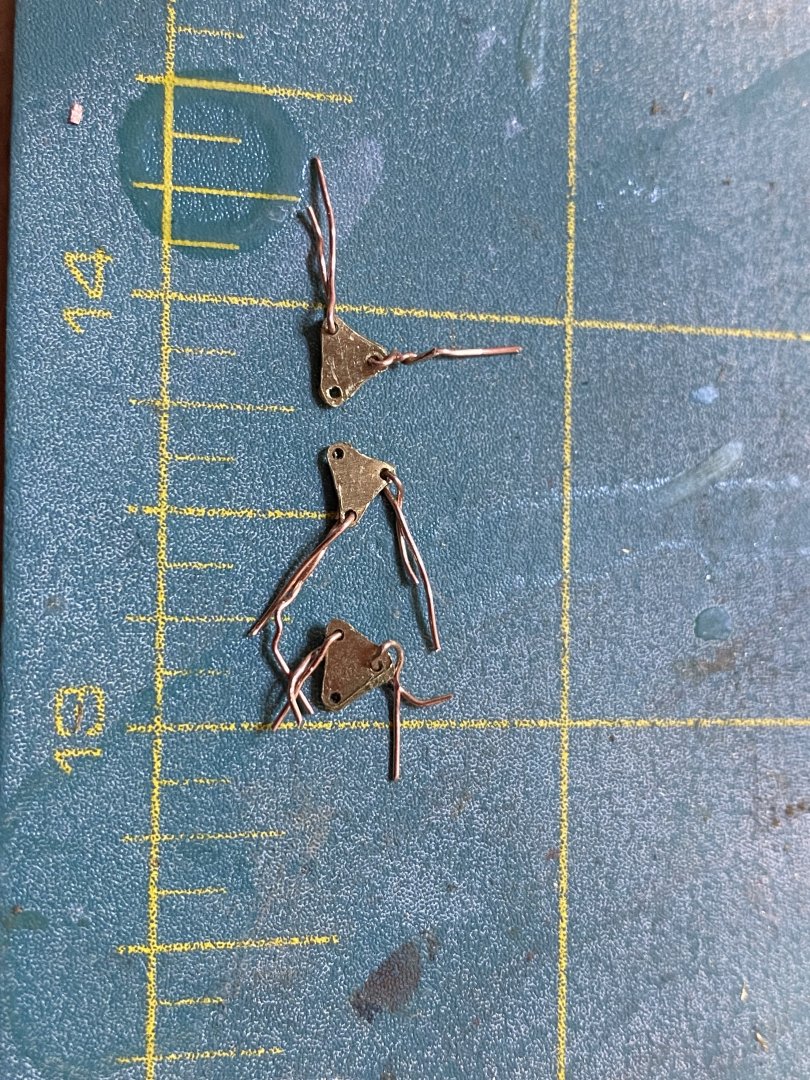

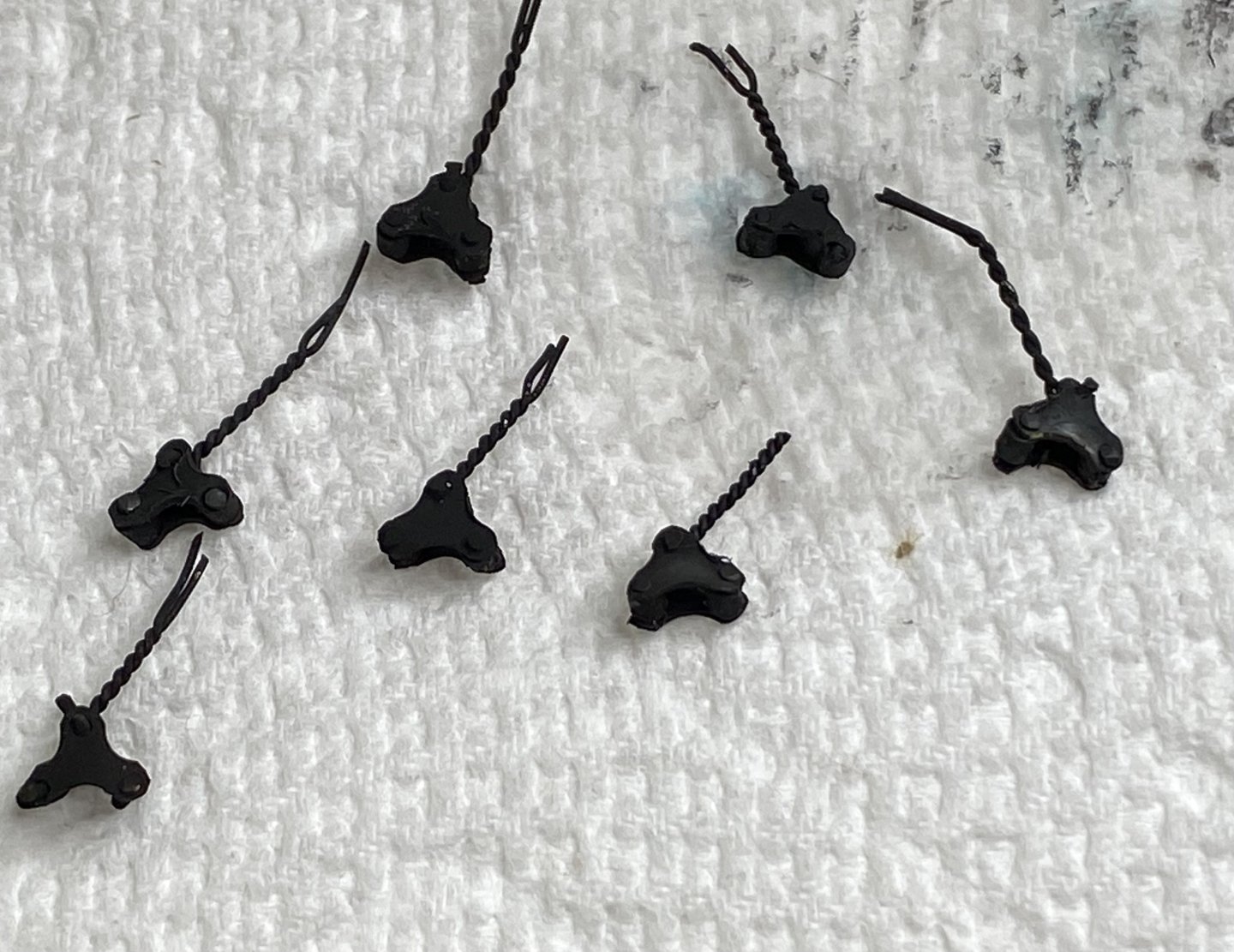

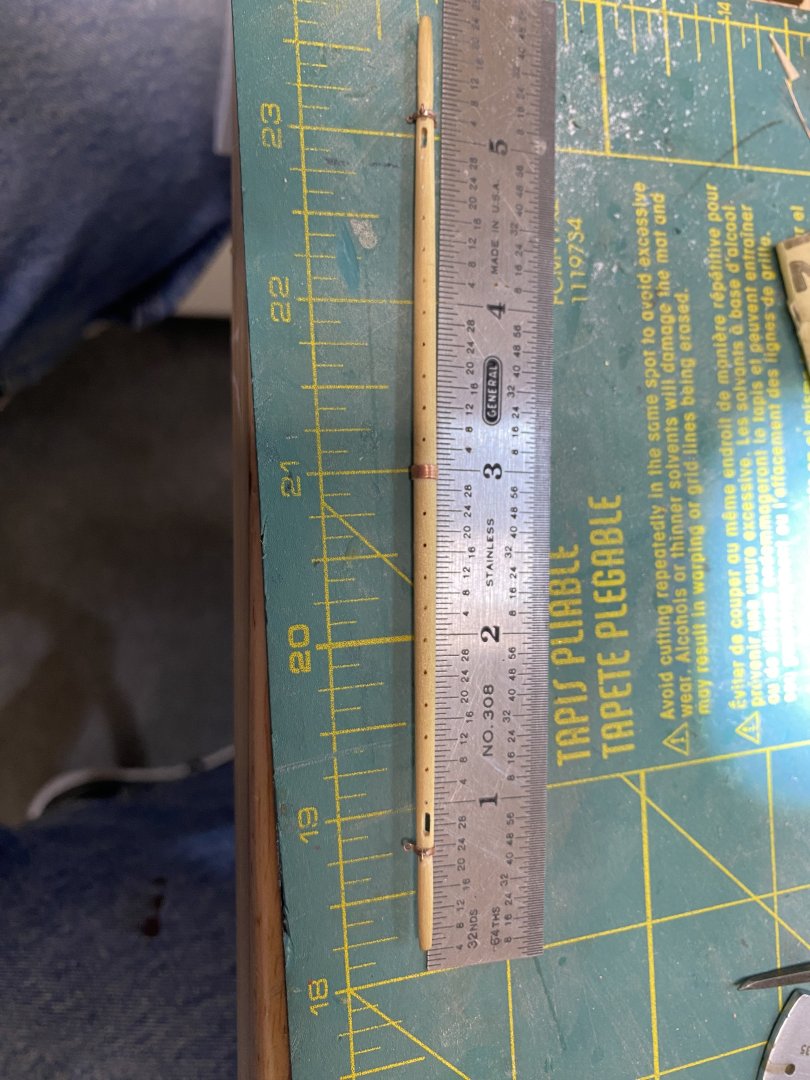

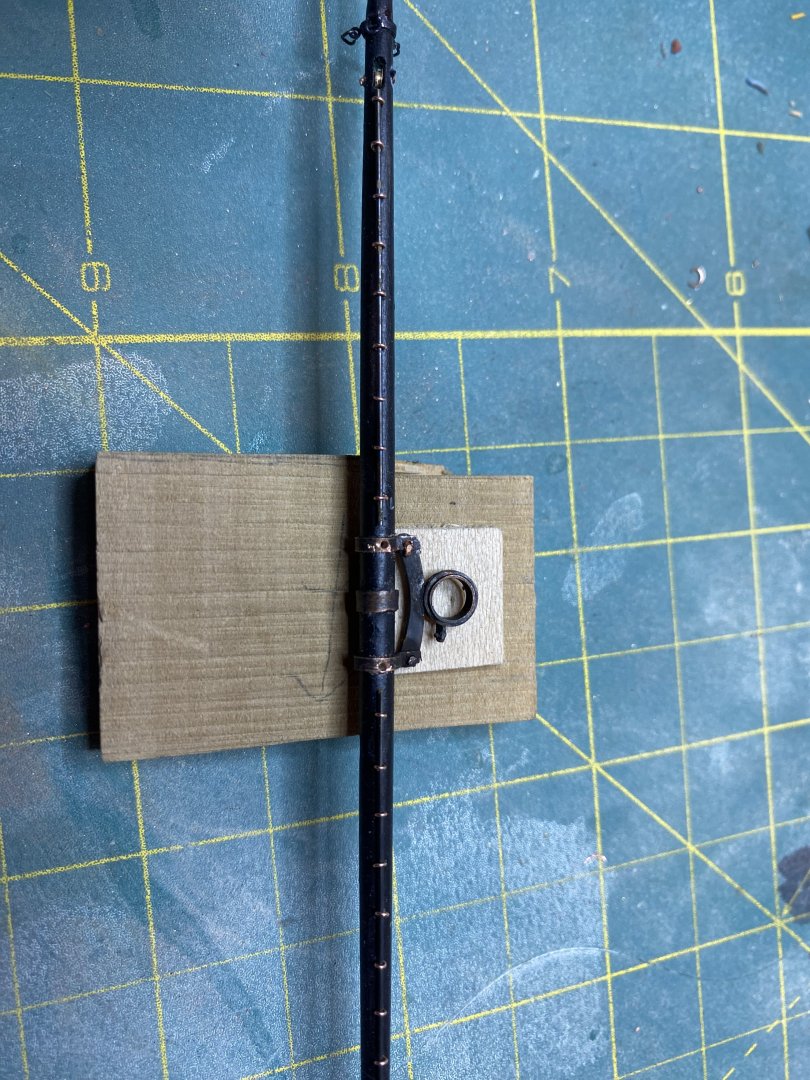

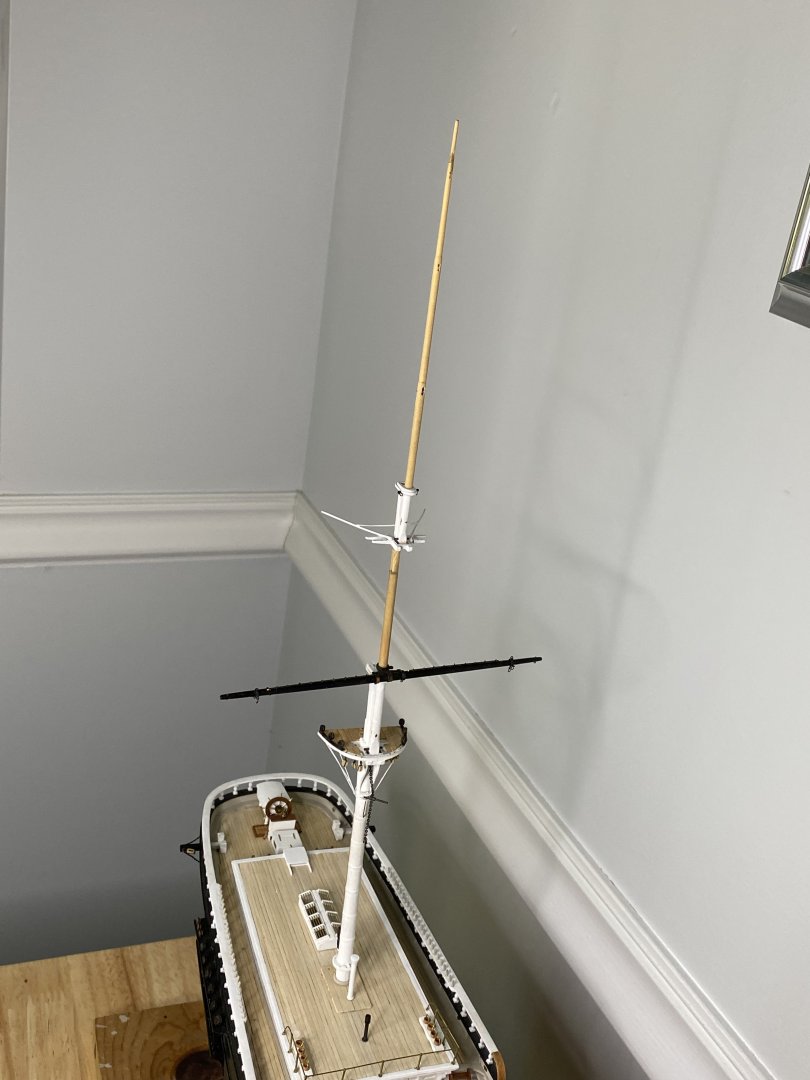

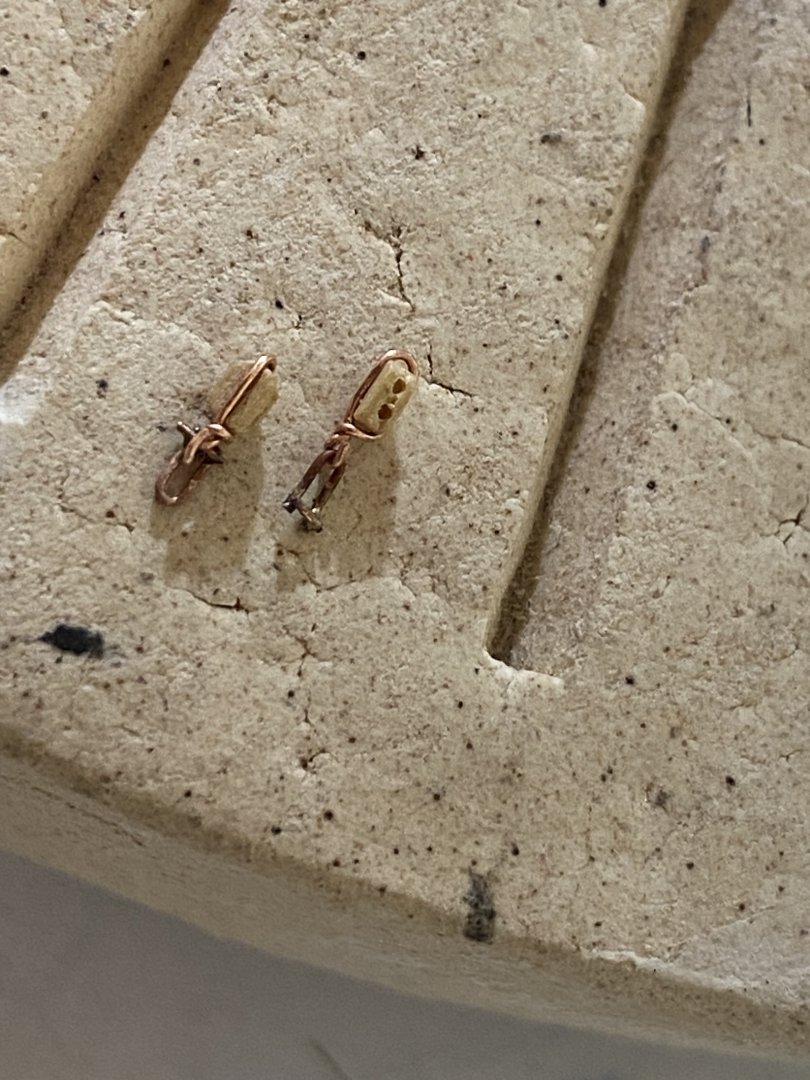

I While still down the rabbit hole, I decided to make the cloverleaf blocks for the topsail and topgallant chain sheets, 6 of them. They should be 2 different sizes but I made them all the same size for convenience as the difference is small and I wasn’t sure I could make them any smaller. They were fabricated per EdT. Two 0.010 inch strips of brass sheet, 1/4 inch wide, were clamped together and the 3 holes drilled in the milling machine ( EdT used 4 holes). I modified the spacing for my convenience and ease and the holes were drilled with a #68 drill which corresponds to a 22ga copper wire bolt. The sheaves were made from 2mm brass tube cut to a 1/16 inch length. The sides of the blocks were cut from the brass sheet. This was all fairly straightforward. The real difficulty came in trying to preen the copper wire bolts. I first preened a small head on one end of the wire bolt, assembled the parts the cut off the bolt. Preening the other end turned out to be a nightmare as the head didn’t want to flatten and the block wanted to distort. I finally got 7 made( 1 spare). These were filled to shape using a jeweler’s drill. Since then I have been working on the mizzen topsail yard. Yard bands were made from copper tube and sheet, jackstay eyebolts from 28 ga copper wire and the jackstay from.02 brass rod. The stirrups are 28 ga copper wire and the foot ropes are.012 black thread. Tried to make the stirrups out of thread also , but no luck. The blocks for the reefing tackles are from Syren, their 2 mm blocks. Still need to add the chain sheets and halyard, as well as the bowlines.

- 351 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

A great place to visit!! I live 6 miles away and try to stop in frequently. Nic is a wealth of information, their fittings are top notch and I love to see their display of finished models!! Well worth the trip! Rick

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

Really nice Keith!! Would never have noticed the deadeye if you hadn’t pointed it out! I’ve come to realize that over time I don’t see the mistakes that I once thought were obvious. Rick

-

On my Flying Fish build, I’m trying to make as many of the parts as possible, vs using the parts supplied with the kit. I think anything you can make will be much better and you will be much happier with the results. Rick

- 193 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Congratulations Nic!! Well deserved!! Rick

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Good advice Rob! Flying Cloud is coming along well! Rick

- 193 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.