-

Posts

600 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by ERS Rich

-

-

Hello Bill, greetings from Central Mass. Always around if you need a hand.

- JeffT, mtaylor and Keith Black

-

3

3

-

7 hours ago, AntonioT said:

Thank you Rich. I will start with kits taking more care in research than follow instruction booklet.

Will you continue with the Puritan? The hull looks ok. Completion of any ship is a huge step.

Checkout Tom Lauria’s channel on YouTube. He recently posted videos of how he restored a ship, Emma C Berry, built from a kit that may be similar to yours. Tom is an awesome mentor, his videos show how to do the work in simple practical ways.

Find and study with the masters, they are here, the people doing the work, not just talking about it. Lookup Mr. Kevin Kennedy. @Kevin Kenny

Next steps? Learn how to sharpen a chisel and your tools. Grab the book, https://www.amazon.com/Ship-Modeling-Simplified-Techniques-Construction/dp/0071558675. Tips and techniques useful when building any ship.

Look at Model Shipways, Armed Virginia Sloop and the practicum by Bob Hunt. https://www.lauckstreetshipyard.com/product-page/armed-virginia-sloop

This practicum is remarkable, Bob shows how to rig every line. And the kit is a larger scale and easy on older eyes.

Best

- mtaylor and Keith Black

-

2

2

-

Hello Antonio and welcome to the World of Model Ships.

Kits and Scratch building?

Scratch build an entire ship.

Add scratch built components to a kit.

Every wood kit, even the simplest, requires skills used in scratch building.

Wood model shipbuilding, scratch or kit, is using a plan, and measuring, marking the wood, and removing the waste with a tool. A saw, a rasp, a knife, a chisel, a file.

Kits save time by providing pre shaped parts, that even so, typically must be worked to final shape, and the wood stock: dowels that must be shaped into masts and spars, strip wood that must be cut into planks that must be spilled and tapered.

What you do in your “shipyard” is up to you. Like a real shipyard, your yard is an assembly point, which components come from kits (vendors in real life) or are scratch built by you (fabricated by the yard in real life) is up to you.

A motto here is better modeling through research. The plan and the research bound creative imagination.

Real creativity or imagination, is needed to devise ways to accomplish the work, to use tools and paint to transform a log, or a pile of wood components and stock, into a convincing rendering of the ship.

It’s all about skill and execution, in the end kit or scratch build doesn’t matter.

All the best.

-

On vacation, resume in about 2 weeks. Up ahead is ship’s boats, anchors, rigging, and the case.

Hope your summer is relaxing where you are…..

- Canute, Keith Black, mtaylor and 2 others

-

5

5

-

- wemattson, Keith Black, Ryland Craze and 7 others

-

7

7

-

3

3

-

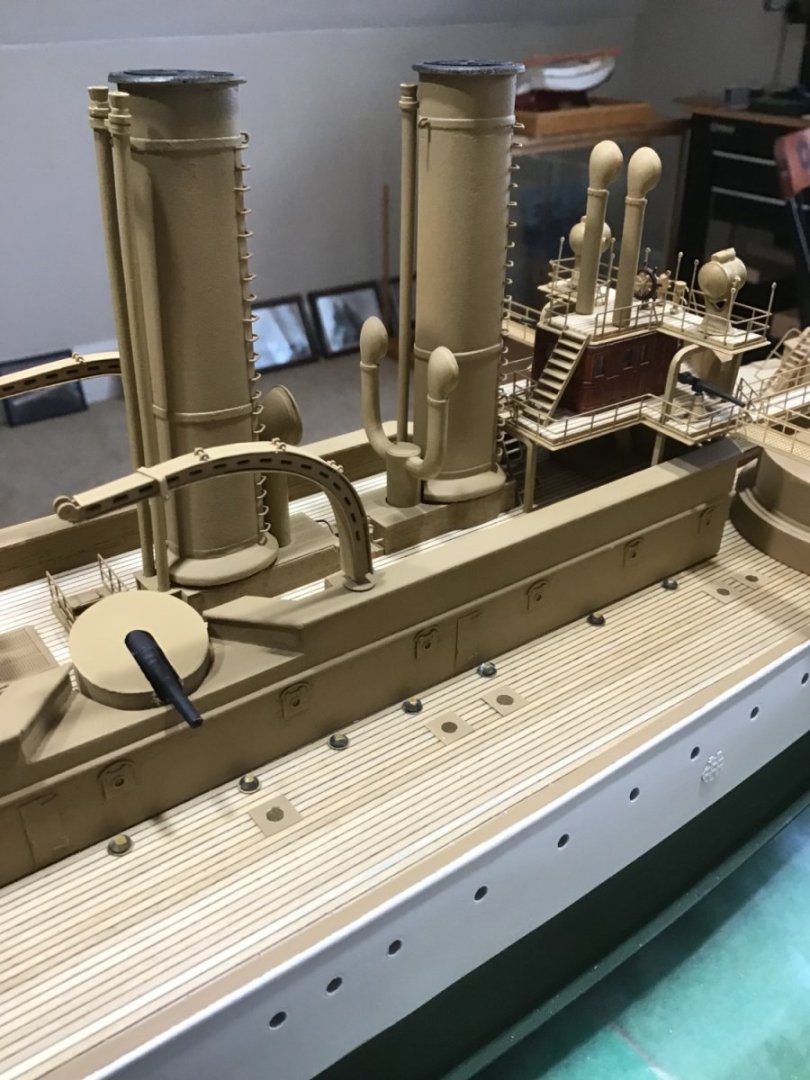

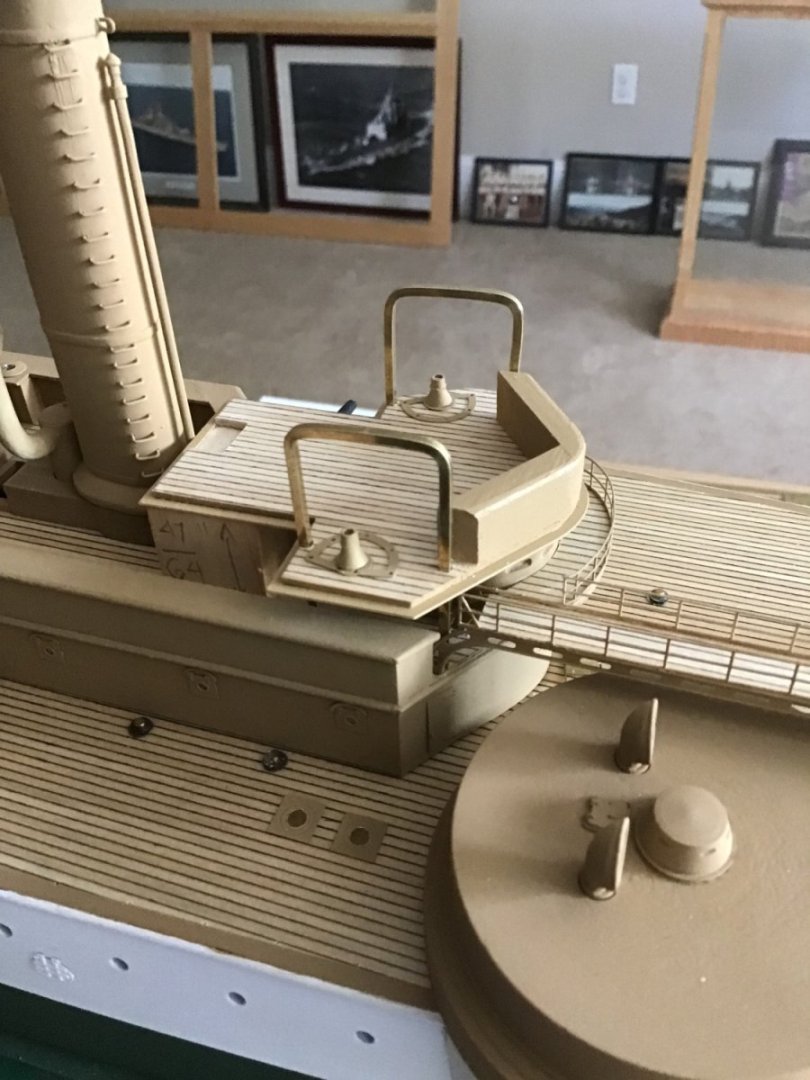

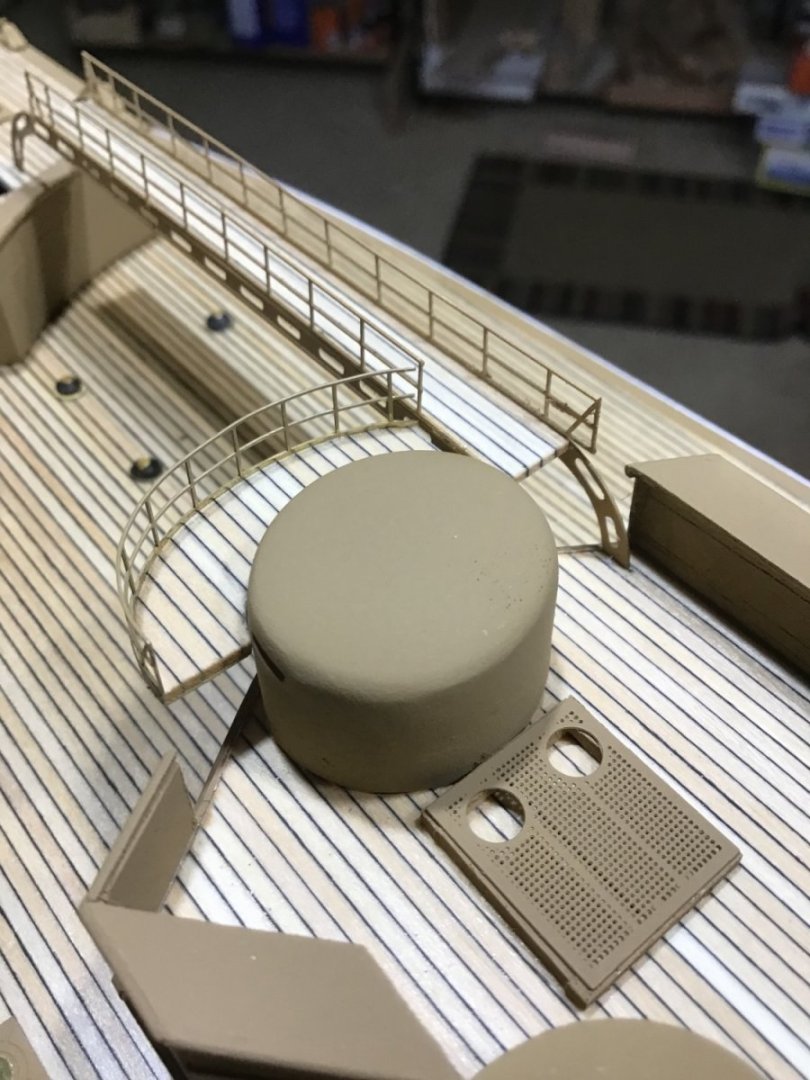

Progress Photo

Have been telling myself “next week it will be done”, for about the last six weeks.

Itching to start something new….

Here is where we are. Notice the bridge wings were installed off the wrong deck, they were higher off the Flying Bridge, now relocated off the navigation deck…

Brass frets just about empty, running out of parts to install, it’s all about the journey…..

-

20 minutes ago, MrBlueJacket said:

Yes, I make them out of .010 annealed wire.

Nic

That’s the ticket!

Thanks

- Keith Black and chris watton

-

2

2

-

8 hours ago, MrBlueJacket said:

Upper topsail yard prepped and ready for its sail.

Hi Nic, could you share a few thoughts on how to get the foot ropes to lay so easy? They look just right….

Thanks

-

3 hours ago, Bruma said:

Campbell's plans show a flag on top of it:

My interpretation of the illustration is a single line attached slightly above the pole midpoint, passed through a block, to raise the pole, then, not shown, a single line attached to the pole bottom for tension.

Cheers!

-

Welcome to Model Ship World!

- Ryland Craze and Keith Black

-

2

2

-

-

Welcome! Always available to answer a question.

-Rich

- mtaylor and Keith Black

-

2

2

-

9 hours ago, aliluke said:

Please keep the updates coming Rich, I'm loving this log and build!

Thanks for joining, appreciate your kind words, and will keep the updates coming.

Cheers!

- mtaylor, Canute and Keith Black

-

3

3

-

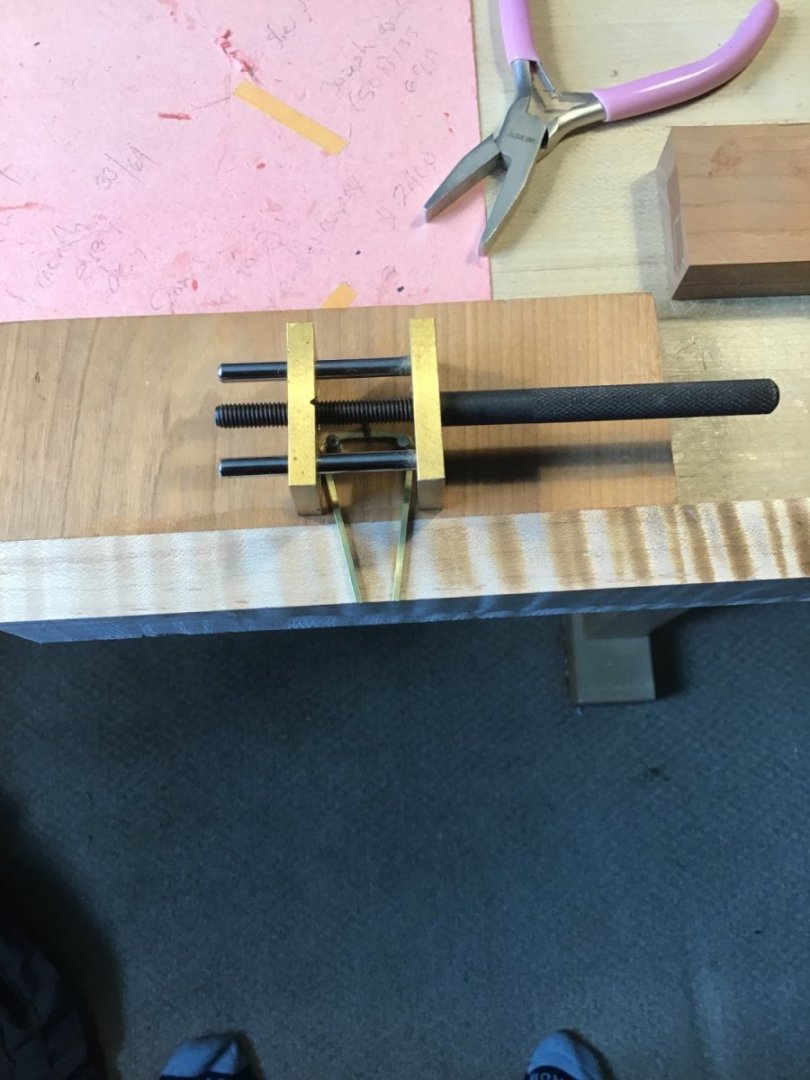

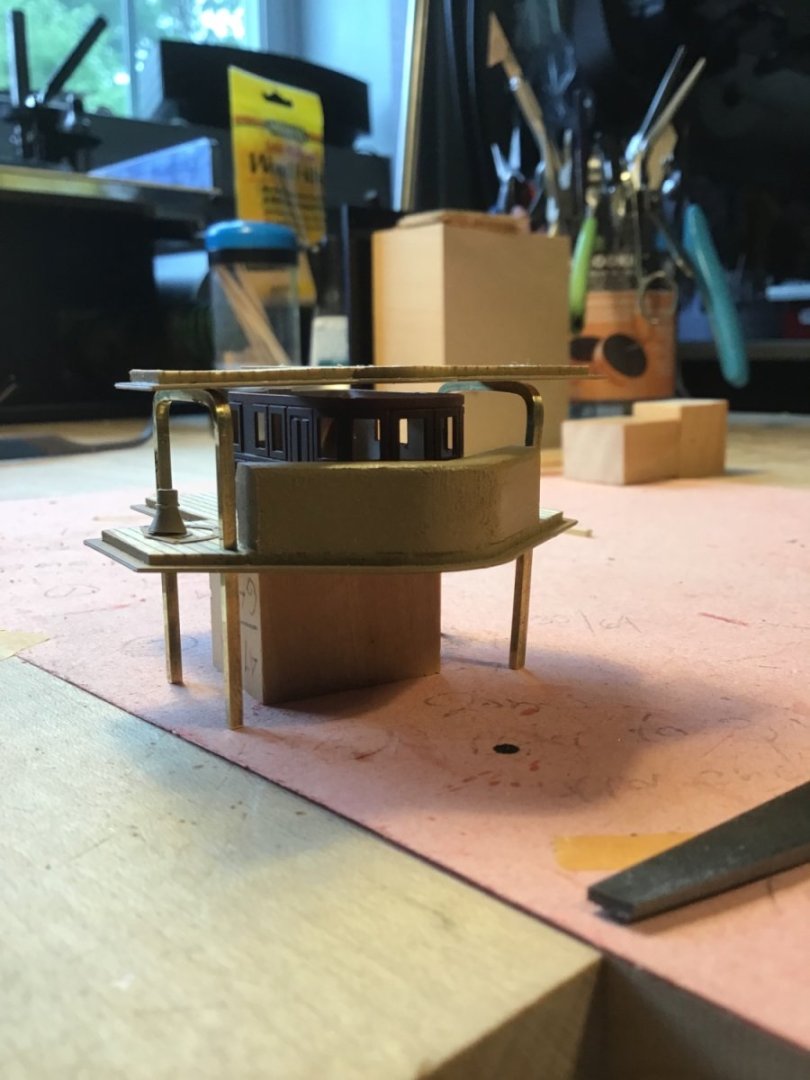

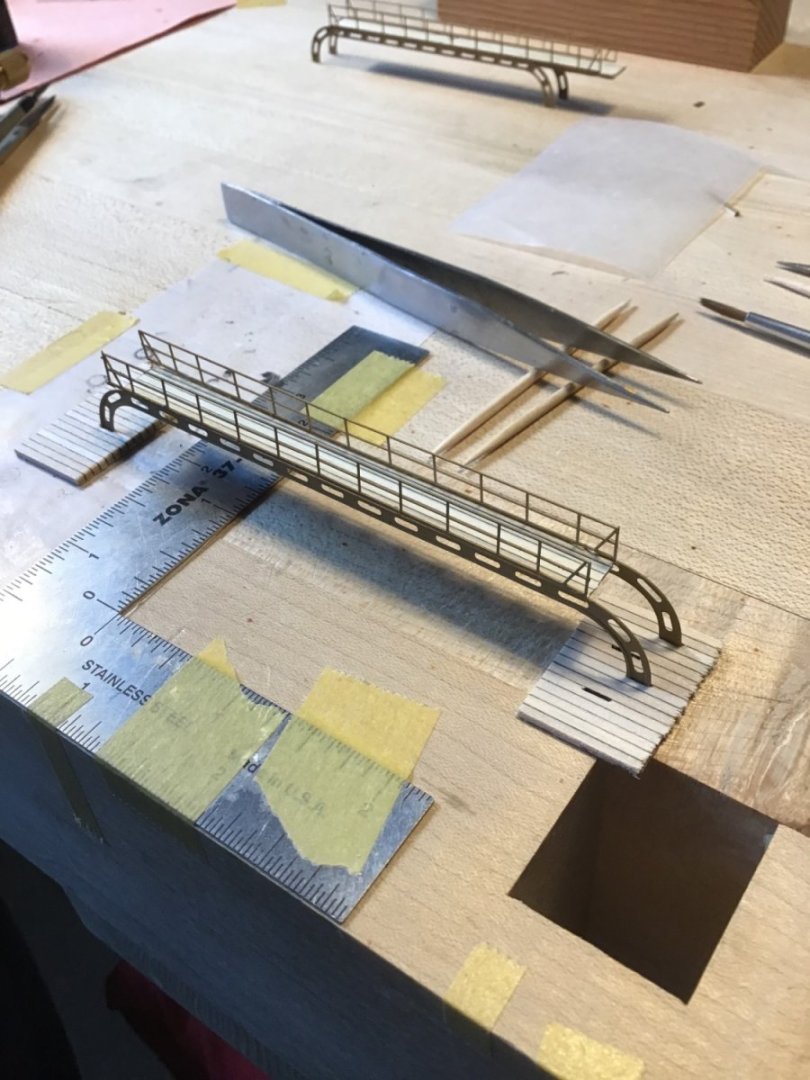

Flying Bridge Supports

Had to give this some thought as these supports need to fit exactly through square holes in the Navigation Bridge. Precise bends are required. The supports are 1/16” brass rod. Note my first attempt was not successful and needed more bar stock. Called Bluejacket and the crew helped and sent out additional stock right away for a reasonable charge.

Decided to make a jig, shown below. The instructions call for 1/8” radius bends. So measured the inside spacing of the square holes in the Navigation Bridge, and drilled 1/8” holes in the board so the distance between the outside edges of the bits correspond to the measurement - 25/32”. Also installed a third bit, to minimize the upward bow, midway between the 1/8” bits. Make a mark on the piece to bisect it’s length, and register the mark on the middle bit, to help get even legs.

I used the vise (available at Micromark) to make sure the bar as fully wrapped around the 1/8” bits.

Dry fit….

Stacked up the superstructure to get an idea of the leg length.

First pass, about a 1/16” gap between the pilot house roof and the flying bridge deck.

Used wire cutters to take a nibble off the legs. Evened up the legs with the Ultimation disk sander and a file. Dry fit on the model….

- GrandpaPhil, mtaylor, yvesvidal and 4 others

-

7

7

-

20 hours ago, Rick310 said:

Beautiful!! I’ve really enjoyed learning how you solve the inevitable problems that arise during a build. I know Nic and Al at Bluejacket will be impressed with your build.

Rick

Thank you Rick, tried to gear the information to show that ship modeling is doable. Cheers!

- Keith Black, Canute and mtaylor

-

3

3

-

- Keith Black, Nunnehi (Don), yvesvidal and 6 others

-

5

5

-

4

4

-

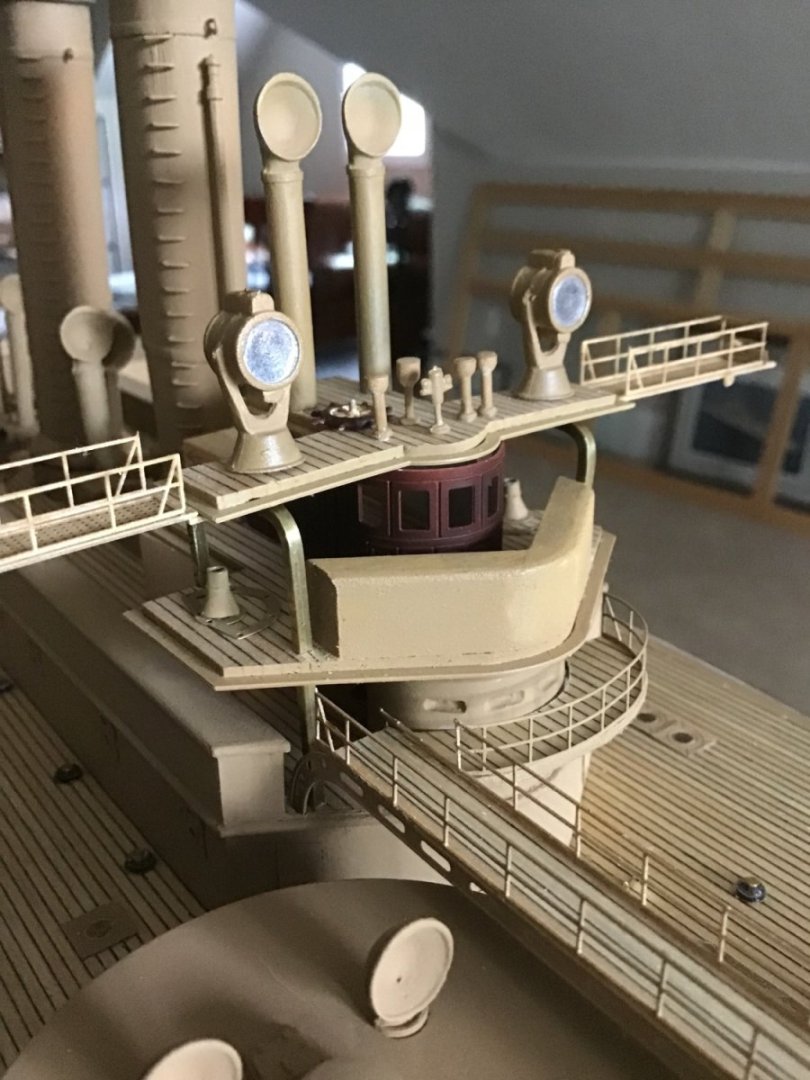

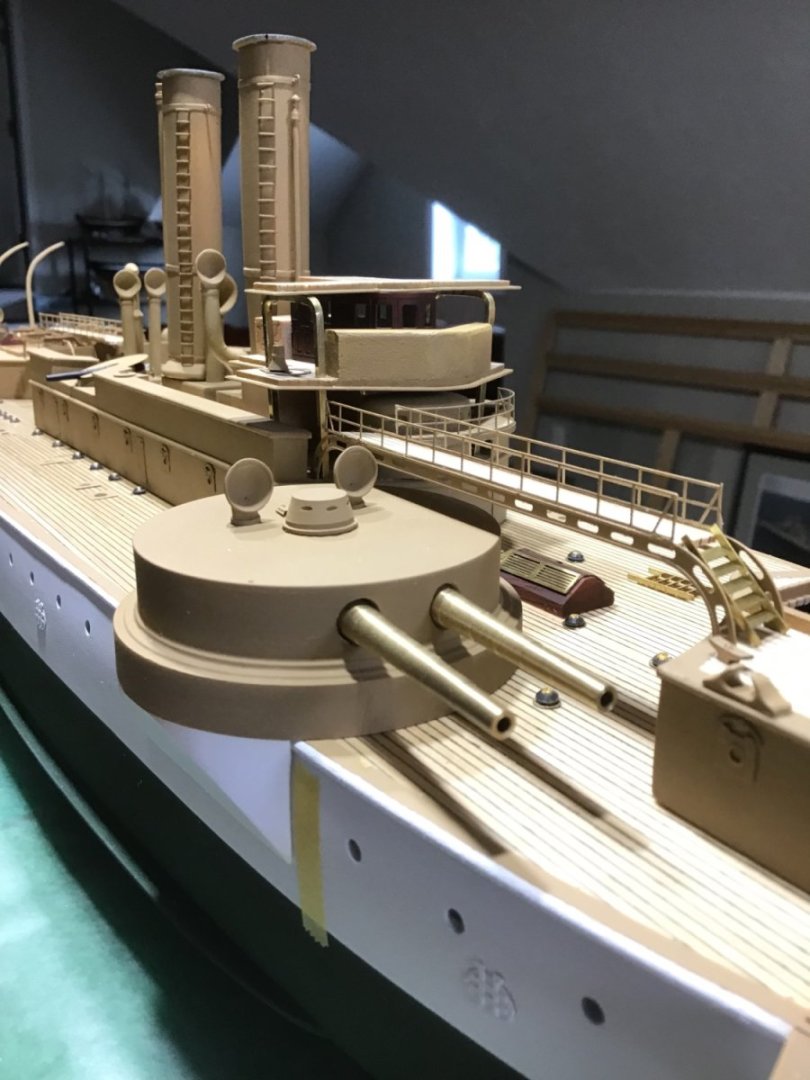

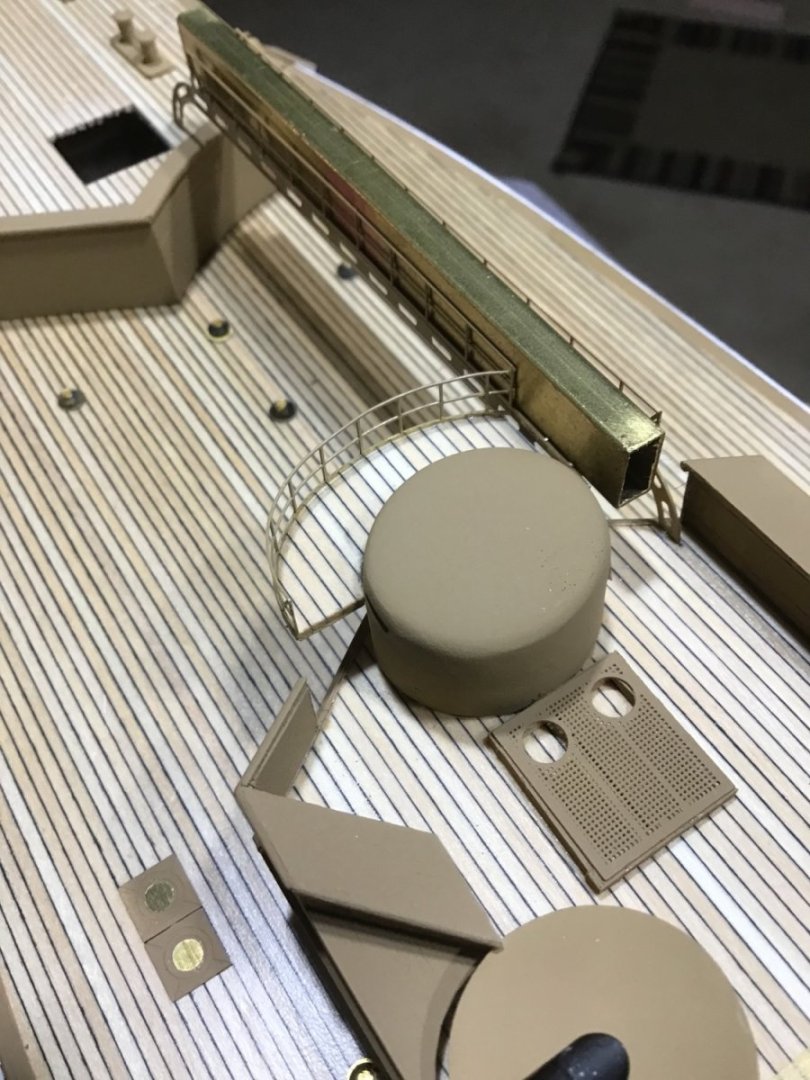

Forward and Conning Tower Catwalks

It turns out I was too aggressive when flattening the conning tower. So during the dry fit found, rather than the two catwalks being flush, the catwalk deck was about 3/32” higher than the conning tower catwalk.

I was able to reduce, but not eliminate the step, by making the grooves to accept the catwalk girders, as shown in the previous post deep.

Here is the setup to check the dry fit. The long board in the catwalk is to square up the rail. And the block under the conning tower catwalk establishes the height, where the deck is 1/16” below the conning tower portals.

It took many iterations of deepening the grooves, fitting the catwalks, and trimming the conning tower catwalk railing to get it nice.

Blocks removed.

Slight gap where the railings meet. Will try to close it up, but hardly noticeable and don’t want to snap off the catwalk railing, since that glue joint is hard to work with.Decided to use this brass bar to apply pressure to close the gap, then hit the joint with liquid CA.

- Javelin, Ryland Craze, GrandpaPhil and 5 others

-

8

8

-

28 minutes ago, JacquesCousteau said:

That said, I think I over-thinned the paint for my first few coats. This made it harder to keep from bubbling or from building up in the corners (of which there are many on the interior). It also meant that it still looked patchy after the third coat. Subsequently, I thinned it less. Despite the frustrations, I think the interior turned out pretty well.

Hi Jacques,Your boat looks nice. A couple of ideas to consider. It is all about the finish.

Wood fibers, in particular pine, because of sap, absorb paint differently across the board grain. So unprimed wood can appear blotchy, again pine in particular. There are products to “pretreat” pine prior to finishing, meant to even out the finish.

However, blotching or uneven finish absorption, may not be a bad thing, depending what you are going for.

This is a wood kit, if the wood is say completely primed and painted so evidence of wood disappears, the finished product can look plastic.

On the other hand, evidence of wood, meaning the grain is visible, tells the observer they are looking at wood.

I like both of the pictures above, the first looks like a boat that’s been in service a while, the second looks like the boat is new.

Thanks

-

Checkout Tamiya masking tape….

Cheers

-

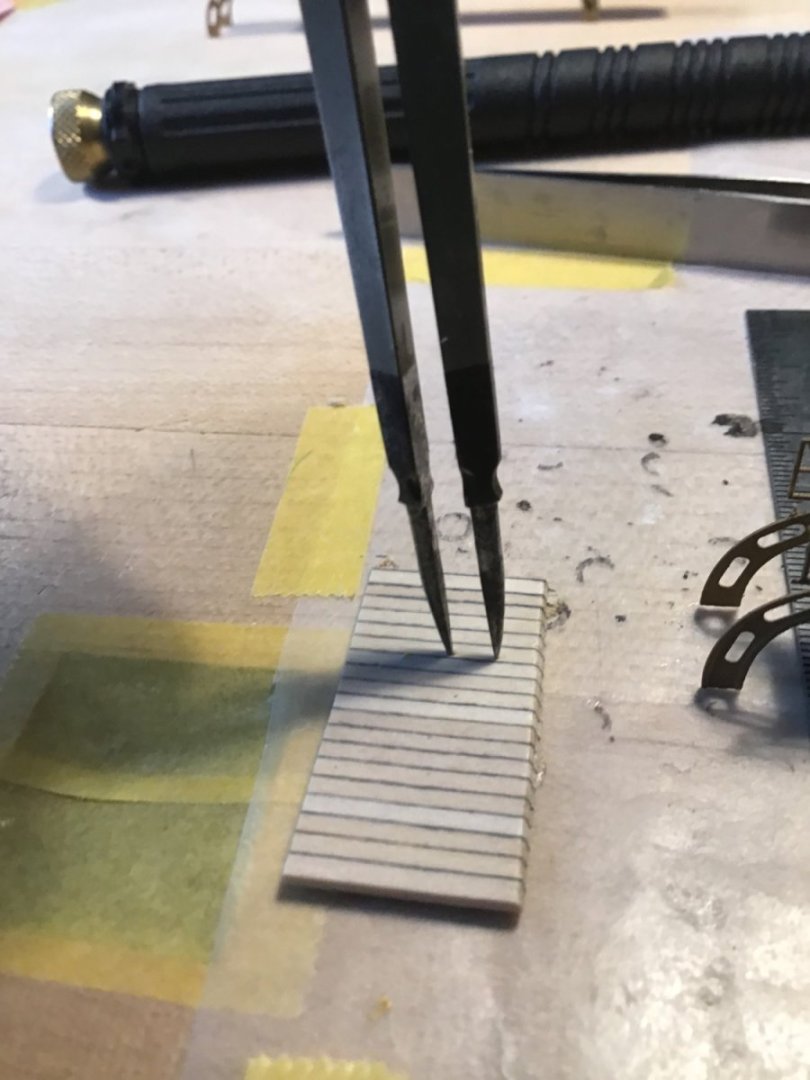

Installing the Catwalks

Inevitably both catwalk legs are not entirely level, fore and aft, and side to side, and the deck is slightly uneven as well, so need to level the assembly on the deck. This assembly is fragile to say the least.

Decided to tackle the problem by making a groove in the deck and recessing the legs.

Practiced with a couple of pieces of scrap deck.

First made a dimple in the deck on the outboard side of each leg.

Then set the dividers to the leg width and made a second dimple.

Then drilled out the dimples with a 1/64” bit, drilled several other holes in between and cleaned out the waste.

Nice fit!

- GrandpaPhil, ccoyle, Canute and 4 others

-

7

7

-

-

Deck Lights Revisited.

The deck light rings filled with clear glue did not turn out very well, so decided to do something else.

A picture of Maine on page 53 of the instructions shows the light housings protrude above the deck.

So I decided to simulate this by using a rhinestone on the brass base ring. The rhinestone are from Walmart, and have a flat top and bottom. Glued the rhinestone to the ring, gave it a wash to cutdown on the shine, then painted the top brass.

The first attempt on the left, with the new on the right.

- Canute, yvesvidal, GrandpaPhil and 4 others

-

7

7

-

Coal Scuttle Installation

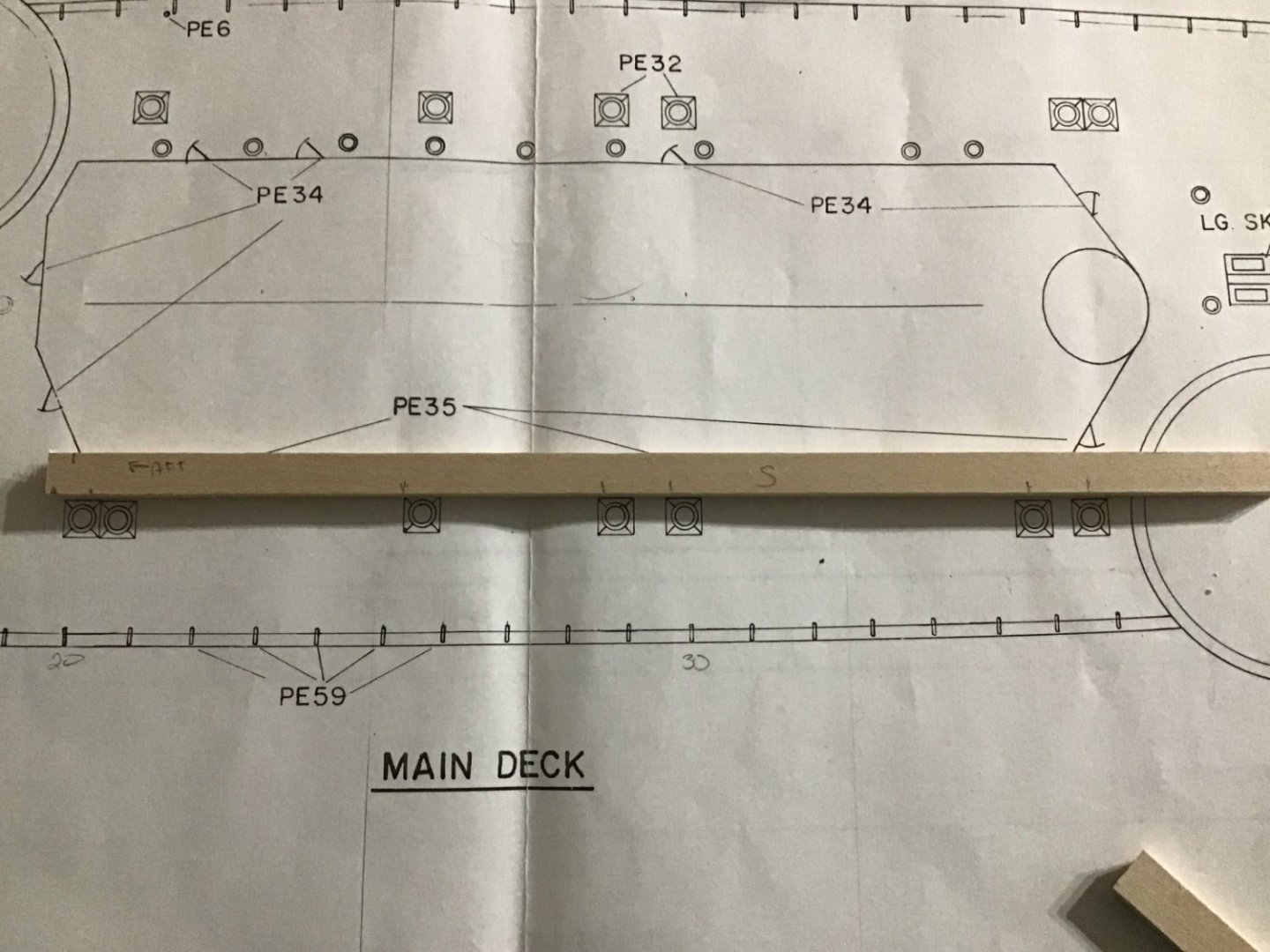

A “story stick” is commonly used in cabinet making. In this case we can use the plan to make marks on a stick to help with locating the scuttles on the deck.

Here the stick, of the correct width between the superstructure and the scuttles, is shown on the plan, with a pencil mark at the aft end of the superstructure and marks at each scuttle.

Then it’s a simple matter of positioning the stick on the deck and installing the scuttles with CA.

- yvesvidal, Keith Black, GrandpaPhil and 3 others

-

6

6

-

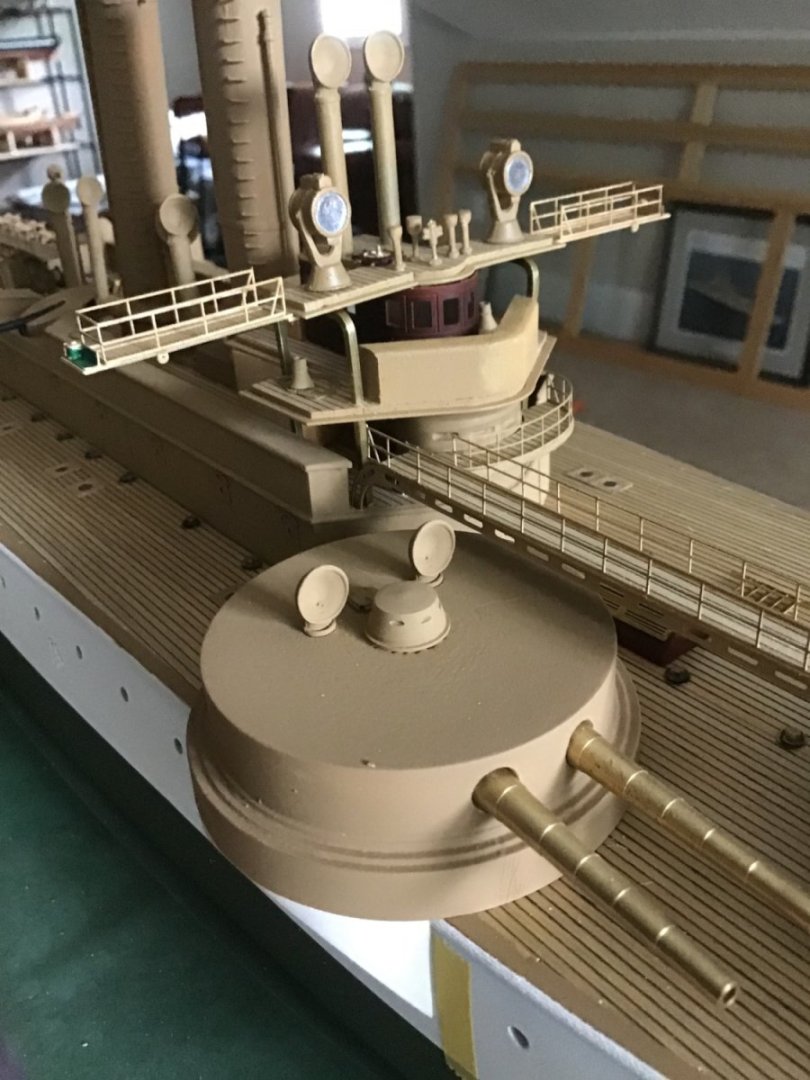

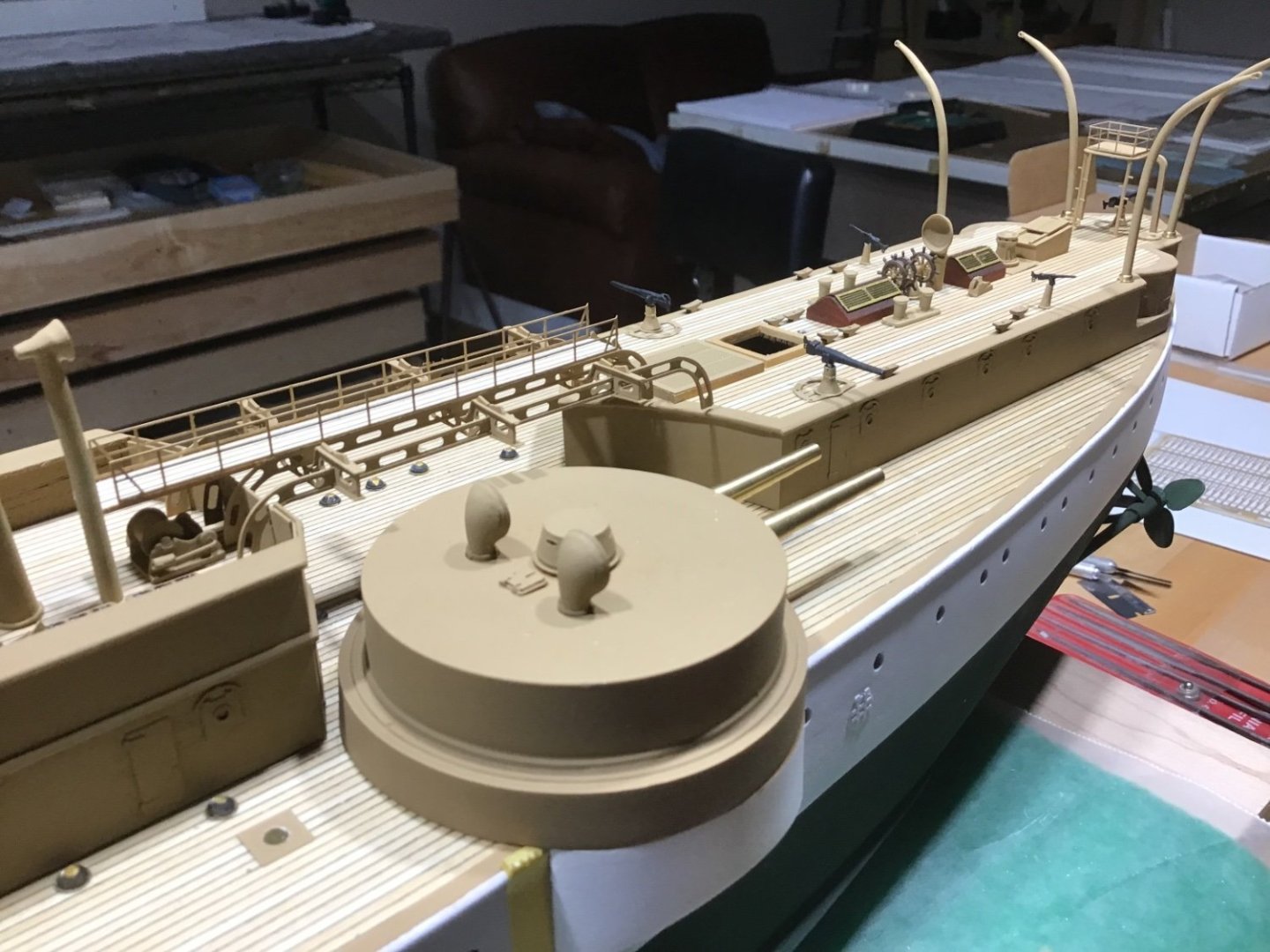

Amidships Superstructure Buildup

Spacer blocks are important construction aids. Building up the amidships superstructure is a good application.

Here we need to find the height of the deck forward of the conning tower and between the amidships 01 level, the deck where the conning sits, and the 02 level, the Navigating bridge, where the pilot house sits. And to correctly position the Pilot House fore and aft.

First Spacer Block

From the plan the conning tower deck is 1/16” below the viewing ports, added this to the thickness of the deck, and subtracted this sub-total from the total height from the man deck to get a block height of 1 1/32”. Cut the block on the Byrnes table saw.This block will be used as a table for attaching the deck to the conning tower. Apply adhesive to the deck edge then slide it on the block to the tower, for a level fit.

Second Block

This block establishes the height between the 01 and 02 levels and will be used as a reference for cutting the 02 deck support stanchions. First dry fit a 1/16” bar on top of the conning tower. Through measuring, and trial and error cutting blocks, found a block height of 47/64” made my 02 deck level and the deck support stanchions will be cut to this length.

Last Block

Next is a block to help with fore/aft positioning the Pilot House on the 02 level. On the plan measured the distance from the aft edge of the pilot house, to the edge of the waterway on the aft end of the 02 deck, and found it to be 9/16”, and cut a block to that size.

Here are several pictures of the ship, with the blocks in position.

First Block

- Keith Black, mtaylor, Canute and 2 others

-

5

5

Face of a Vasa Passenger

in Nautical/Naval History

Posted

Wow, that’s amazing, thanks for posting.