-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by DocBlake

-

-

Thanks, everyone!

Brian: The painting is a .jpg that I reduced to the proper size, then printed out. I glued it to a piece of 1/64" thick plywood, cut out 4 pieces of wood for the frame, then glued them around the painting. Trim the plywood flush and paint with gold paint and you're done. It was kind of fun. There is a portrait of Capt. William Kidd, the "pirate", hanging on the opposite wall of the great cabin.

- mtaylor, dgbot, zoly99sask and 4 others

-

7

7

-

-

Yeah, Brian, that's a problem. It seems that the Sharpie pigment never truly "dries" and the poly is the perfect solvent. My solution to that problem is to use a water-based polyurethane for the first coat to "seal" the black color. It will not dissolve the Sharpie's pigment. MinWax makes a water-based product.

- zoly99sask and GuntherMT

-

2

2

-

- mrshanks, zoly99sask, gjdale and 7 others

-

10

10

-

-

-

Hi Grant!

I have a question. I planked the inner bulwarks on my AVS with redheart, as you have done. After a couple of months the scarlet color has faded to a brown with reddish overtones. I's been protected with 3 coats of poly. Are you noticing a color change in the redheart you used? I know it's supposed to happen, but I didn't think it would be this quick!

-

I installed the bulwark formers (plywood), bending them at the bow with a clothes iron. The scuppers bottoms need to line up with the top of the decking, The shear needs to rise gracefully toward the bow, and the top of the bulwark formers need to line up with the top of the poop deck planking. Lots of fiddly stuff, so I opted for one hour epoxy to glue the parts in place, along with the famous "little yellow nails". I got a nice flow for the shear line. I added the first 3 planks on each side to begin the first hull planking. These were full width. I'll now start tapering the next planks, fore and aft.

-

I'm getting serious about finishing the model now. Although I'm retired, I have a consulting business that's been taking a lot of my time. I'm turning my attention to completing the great cabin. The window seat at the stern is built "admiralty style" also - completely frames, but only some of the planking and raised panel front paneling installed. I've completed the tiller and seized 4 of the 10 blocks required to their eyebolts. Next I install the rudder-to-wheel rigging and start laying the roof beams.

-

-

Duh...It pays to read the posts! Lee Valley Tools! Sorry Brian.

- GuntherMT, Elijah, zoly99sask and 1 other

-

4

4

-

-

-

Thanks, Don,Brian!

Don...I'm getting close. Here's what's left: catheads, swivel guns and supports, channels, transom lights, great cabin roof beams and planking and rigging the steering. Not that much, really.

- Canute, zoly99sask, mtaylor and 2 others

-

5

5

-

- KenW, Ryland Craze, Cap'n Rat Fink and 7 others

-

10

10

-

Thanks, John.

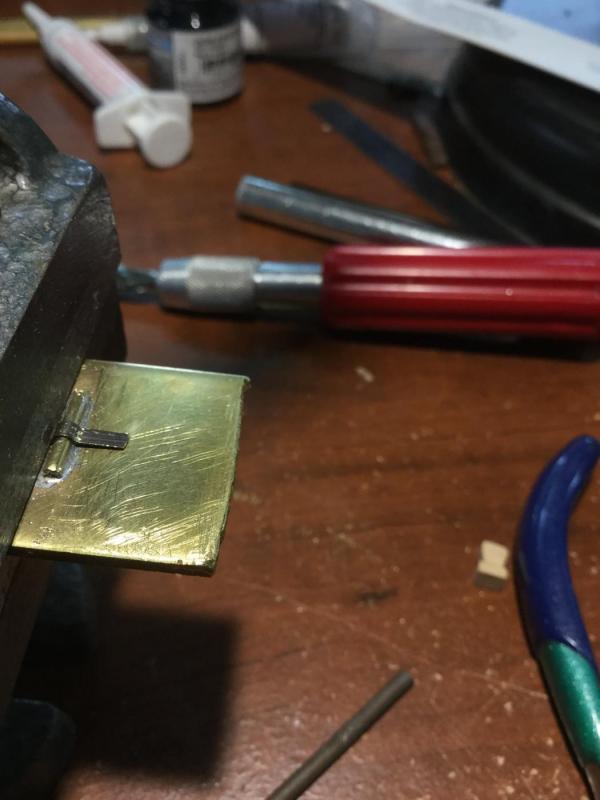

I've been working on fiddly things. I finished the gun carriages, but I had to order 5/64" brass rod to make new trunnions. The supplied ones were too short. next up was the cap squares...an annoying bit of work I have been putting off!. I decided I wanted them made of blackened brass, so here is how I made them (a tip of the hat to John Earl at "modelboatyard.com" for his idea).

I took a length of 5/64" brass rod and filed it flat, creating a half-round. I then soldered this to a piece of brass bar stock 3/32" thick. This was my "mold". I then inserted the brass bar and a strip of blackened brass in the jaws of a machinist's vice and clamped down. Bend the strip over the brass half-round with a needle nosed pliers. Release from the vice and trim to size. The squares need to have holes drilled for the bolts and have the blackening touched up before mounting on the carriages.

- GuntherMT, KenW, zoly99sask and 7 others

-

10

10

-

-

-

-

-

Hi Brian! I got the guns from Cornwall Model Boats. They were the closest to the proper size. Dr. Feldman 's book says a 1/2 pounder swivel was just over 30" in length, including the cascabel. That's about 1-1/32". The guns are 1" long, so pretty close. As for the brackets, I may just epoxy the trunnions in place to avoid the problem of stuff falling apart.

How did you make the cool little red knobs on the end of the yokes?

-

- mtaylor, Ryland Craze, KenW and 7 others

-

10

10

-

-

REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

in - Kit build logs for subjects built from 1501 - 1750

Posted

It looks good, John. I'd leave the photos. I agree they may help others later. Keep up the good work!