-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

New development! The Lauck Street Ship Yard has announced that they are going to begin to produce the POF Armed Virginia Sloop kit in 1/32 scale once again. The kit will be exactly the same as the kit in this build log, except the parts are laser cut rather than CNC cut. If anyone is interested in a fun but very challenging kit, this is it! http://www.lauckstreetshipyard.com/avskit.htm

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

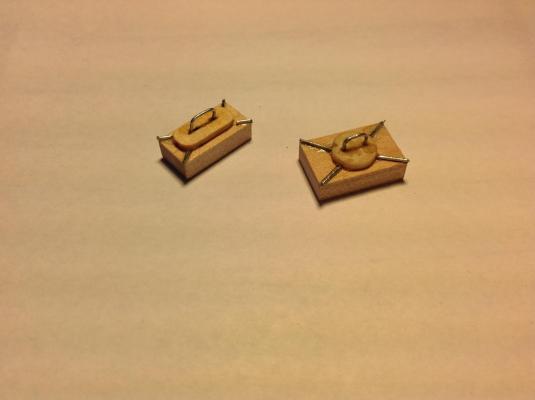

Back from vacation with the family. I started framing the main deck forward. I also built some wooden crates for the hold as cargo. I'm painting the metal bands on the powder kegs copper colored right now. They will go in the magazine. These little details won't be easily seen once the deck s framed in and partially planked, but they are fun to build, and I know they are there!

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Hi, Joe, thanks for the comments. I didn't use the hinges from the AL kit, nor any of the cleats. They are grossly out of scale. For sample, the included cleats would be over 2 scale feet across...way too big. Scale cleats and brass keel supports are available at Model Shipways,

- 21 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Nice job on your Swift! Your nibbling strake turned out beautifully, and considering that the plans don't spell out how they are done, your work is innovative. I used the Lauck Street practicum as a base for my build, and it explained how to handle installing the plywood bulwarks. As to the sprit, the kit is wrong in that the sprit would never be secured to the underside of the fore bit. I lengthen it a bit and secure the heel to the deck with a metal bracket. Historically more correct, and it changed the shear to a more pleasing line! You are doing well...keep it up!

- 21 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Nice work on the beams and carriages, I love the redheart!

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

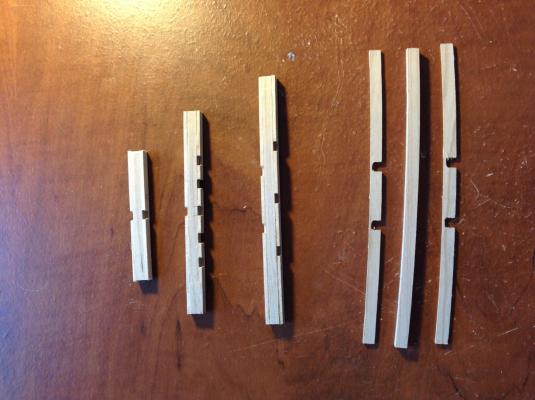

I've started gluing up the main deck beams. There are 12 in all, and each is comprised of three parts: a thicker center part, and two thinner parts, with notches in them that glue to the forward and aft surfaces of the center part. When glued up, the notches form the half-mortises for the carlings and ledges. All in all, a pretty cool system. The photo shows finished beams on the left, and the three components of a beam before glue up on the right.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Thanks, David. The stove was fun to build, and as we've said many times "I know its there!"

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Nice work! I think the cabin roof turned out great.

- 164 replies

-

- model shipways

- armed virginia sloop

-

(and 2 more)

Tagged with:

-

Planking of the lower deck s and hold is completed. Next I'll start work on framing the main deck by installing the deck clamps.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

The lower deck planks are in place. I set the stove in it's approximate position on the lower deck. The space between the fore and aft lower decks is the hold. It's separated from the two decks by bulkheads, and another bulkhead divides the hold into a hold/light room and the magazine. The planking in the hold is applied directly to the frames. There are no beams.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Congratulations on the award, Brian. Well deserved.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

The deck beams for the lower decks installed. The forward lower deck is where the stove sits. The aft lower deck is really just a catwalk that leads from the hold. The hold is subdivided into a hold proper with a light room, and a magazine where I'll add the gunpowder kegs and build the well and shot locker.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Maury: Yep. Every time George needed an alias he chose "Vandelay". When he lied about his employment he claimed to work for "Vandelay Industries".

- 19 replies

-

- VandaLay

- Industries

- (and 6 more)

-

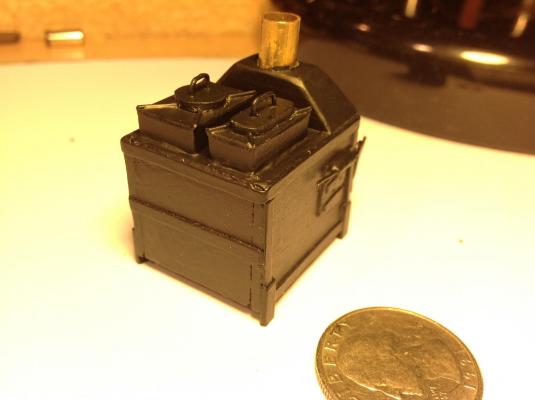

LOL, Don! I was really disappointed in how the stove looked before painting ; wood, paper, bits of metal and contrasting colors looked like a 5 year old's project. But I kept telling myself that the paint will change everything. It brought it together and camouflaged all my errors! Thanks.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Hi Don. I've been consumed by the AVS, but the Snake is sitting near my work area and I may start in again . I took a break because of frustration over the stern of the ship, but I agree, she's a pretty ship and the model deserves to be finished. Hopefully soon. Thanks for the kind words, by the way!

-

Sorry, Ken I forgot to respond. I'm a woodworker, so I have a full compliment of tools in my shop. Most of them are not applicable to model work because of scale issues. Those I use for modeling include a Byrnes miniature table saw, a Dremel tool drill press and router attachment (both cheap and helpful) and a regular old scroll saw. Of all these, the Byrnes saw (or equivalent) is probably most important. I small benchtop sander is helpful, also.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Thanks, all. David: The stove is flat black - the lighting is giving it a kind of weird color in the photos. The Charly Noble will slip down over the protruding brass chimney. It will be made of brass and blackened.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Gunpowder Kegs

DocBlake replied to DocBlake's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Thanks, all. I'll paint the hoops on the kegs copper colored. The model already has plans for a light room . -

Here's the finished stove. I still have to finish the grease tray. The stove was to have a guard rail surrounding the top cooking surface, but I felt I had to draw the line somewhere. The hinges and firebox door/oven doors are far from perfect...even in this scale every little error shows. Still, I do like working in the larger scales in general because of the detail it allows one to add.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Beautiful job so far, Ken. A very inspiring build.

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

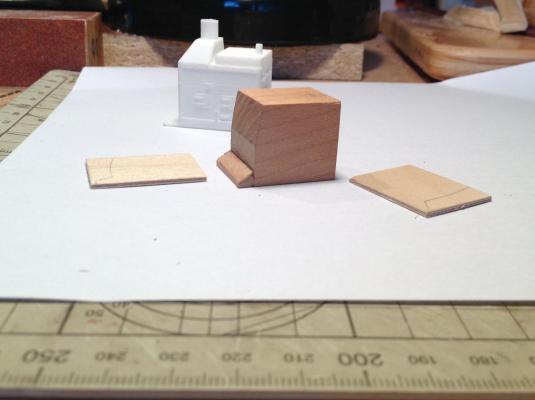

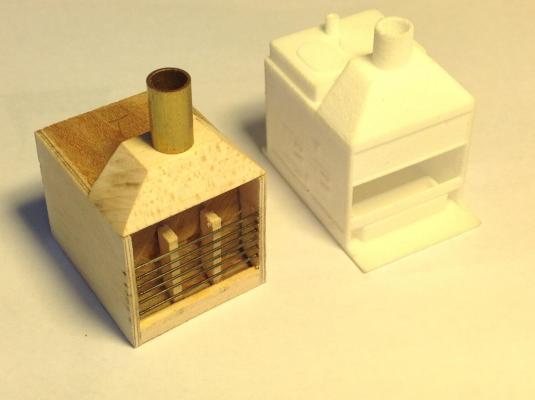

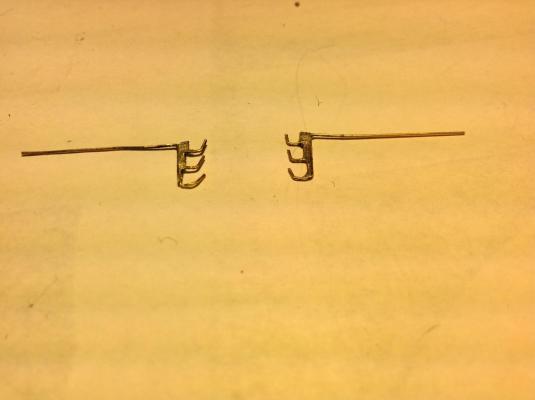

I finished up the third coat of poly on the exterior. Before I did that, I added some trim made of purple heart above and below the great cabin lights. It carries the color scheme of the topsides around to the stern of the ship. I cut out and cleaned up the lower deck beams, I'm planning to change a few things down there, so I started scratch building the ship's stove. The kit provides a very nice 3-D printed stove, but I wanted my own. It's kind of a modified Brodie stove without the chain-driven rotisserie. The first step was to build a "core" out of 2 pieces of wood. I then added the sides out of 1/32" plywood. The grid irons are brass rod passing through holes drilled with a #75 drill. The boiler tops and lids are made of wood, the handles and the diagonal reinforcing rods are steel wire. The oven doors, firebox door and ash tray door are all 1/64" plywood...the hinges are cardstock. I made the spit racks out of brass rod, soldered them together and trimmed them to shape. I need to add the legs, build a grease pan and add some trim to the stove before priming and painting.

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Gunpowder Kegs

DocBlake replied to DocBlake's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Very helpful, guys. I do think I remember reading about copper hoops on powder kegs at some point. It seems reasonable and I'll plan to paint the hoops copper on the powder kegs. Thanks!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.