-

Posts

1,321 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glen McGuire

-

-

7 minutes ago, Keith Black said:

Glen, the ship is a little beauty. I love the sails, they turned out great and hang well from the yards.

Thank you, Keith! I went just a shade darker this time and I like it better than my previous efforts.

- Keith Black, mtaylor and Dave_E

-

3

3

-

45 minutes ago, Ian_Grant said:

Would fly-tying thread work for ratlines on a 1/150 ship or is it too thin? Asking for a friend. He knows nothing about fly fishing - is it easily tied into compact knots? What kind of glue to lock them?

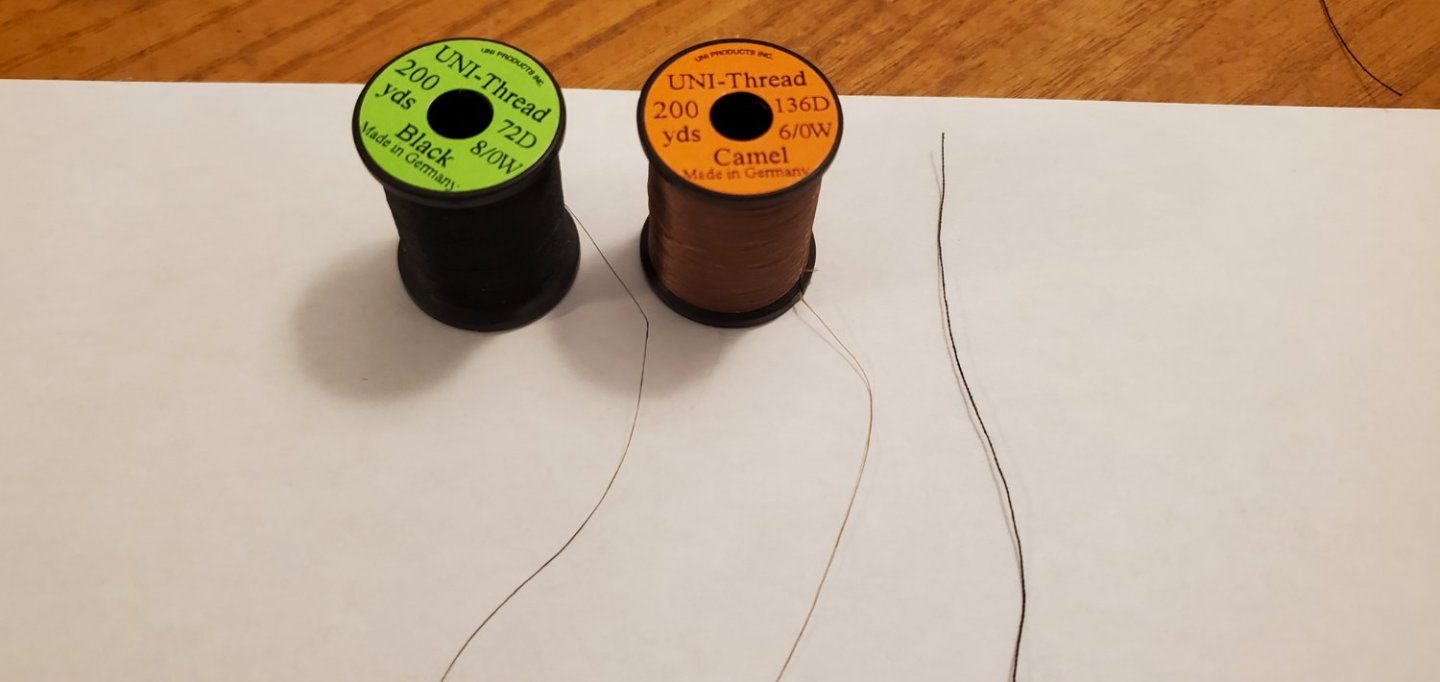

I think it would work well. I used regular thread for my 1/120 CSS Alabama ratlines and in hindsight, it looks a little thick. With the fly-tying thread for these bottle projects, I use 2 thicknesses. The pic below shows the 2 thicknesses I use next to a piece of regular all-purpose thread. The black fly-tying thread (72 denier) is the thinnest and I use it for the ratlines. The camel colored (136 denier) is almost twice as thick (believe it or not) and I use it for the the braces. I believe the 136D would be good for raltines at 1/150 scale.

I get them from Amazon for about $7 per spool. As far as knot tying, it is definitely tedious. It helps to have some very fine point tweezers and super magnifying reading glasses. But they do tie into very nice knots and once I get going, it actually goes pretty smoothly. Afterwards, I put a small drop of CA glue on the knot to lock it in then clip the excess strands with cuticle trimmers (highly recommended tool for thread this small). Very secure knot.

-

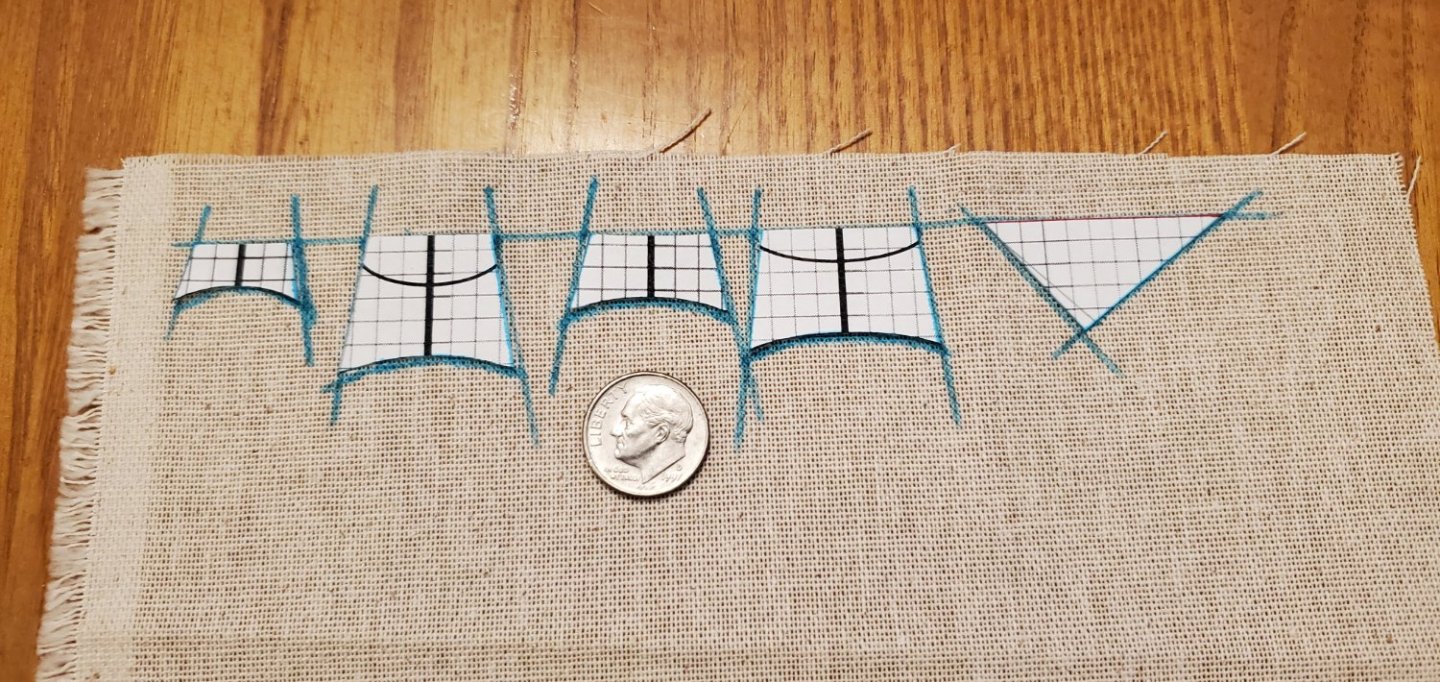

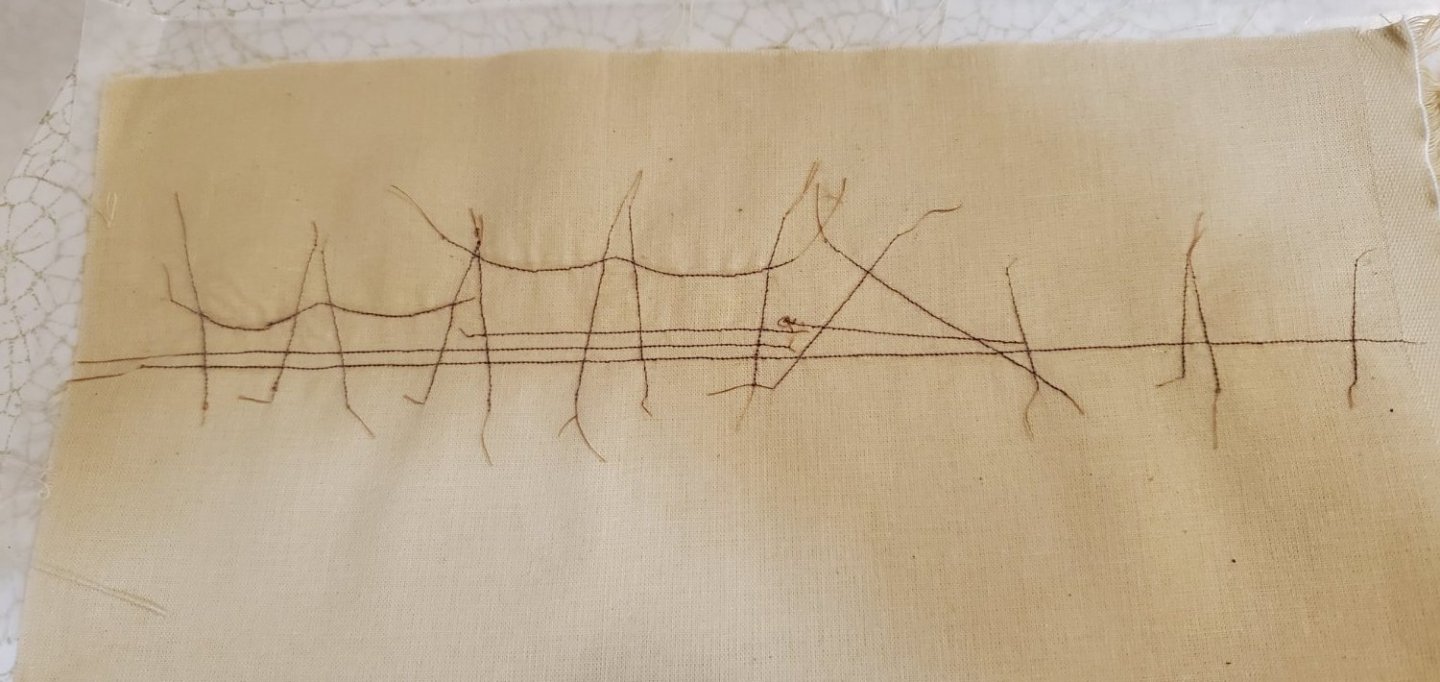

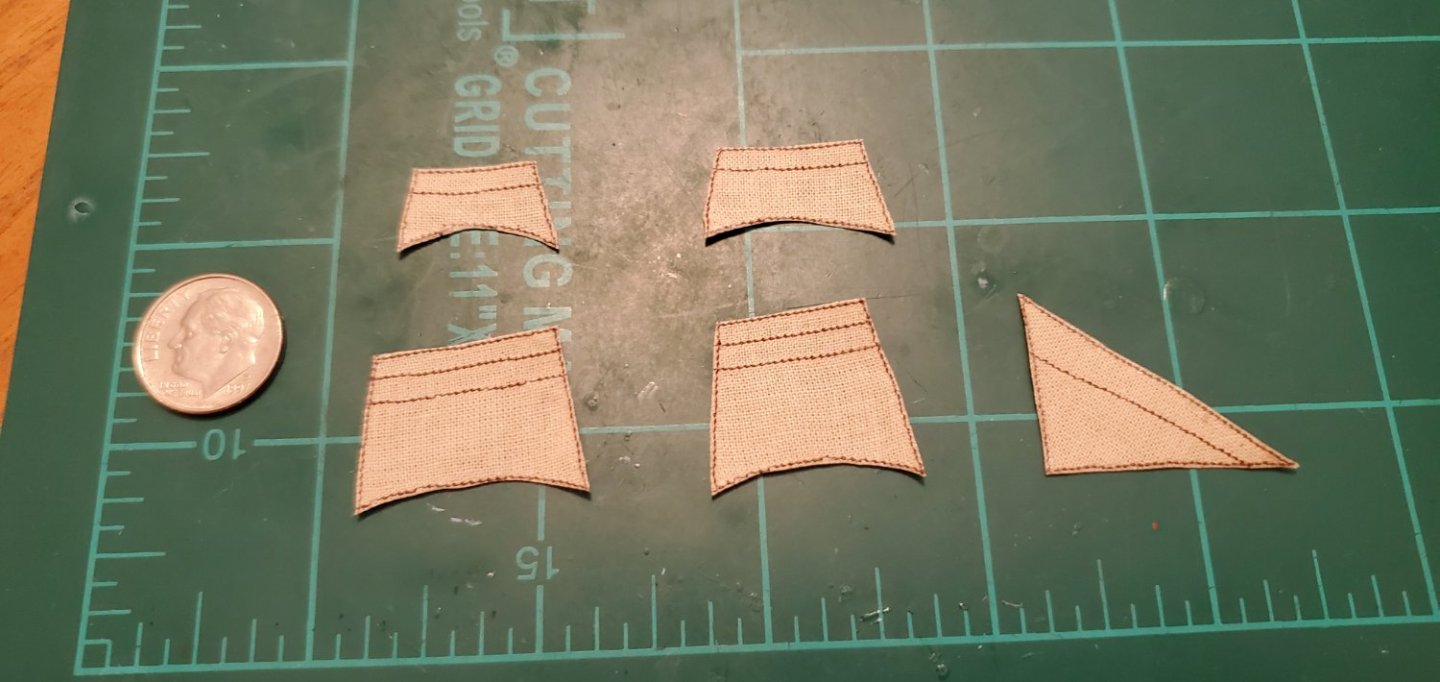

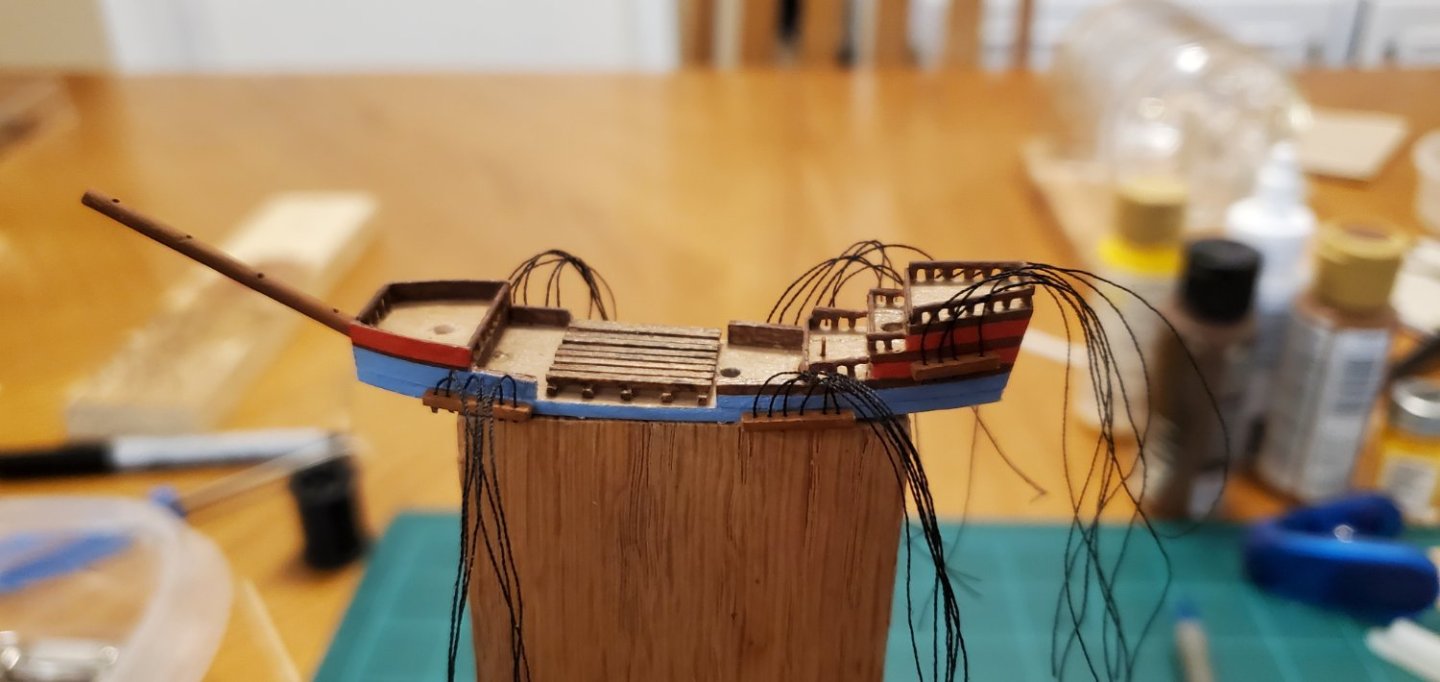

Today I worked on the sails. The pics show the basic process steps. They are made from muslin and the thread for the bolt ropes and reef bands is fly-tying thread again.

I've still got to make some anchors, add the ship's boats and maybe some misc deck fittings. Getting very close! I know the bottom halves of the hull will fit inside the bottle easily. Not sure about the top with all the sails, yards, and crow's nests. I have a feeling it's going to be another tight squeeze!

- Landlubber Mike, GrandpaPhil, mtaylor and 6 others

-

4

4

-

5

5

-

On 12/6/2022 at 6:34 PM, Keith Black said:

you always get stage fright at about this point in you SIB builds

So true, Keith! I'm hoping to avoid another horse pucky moment!

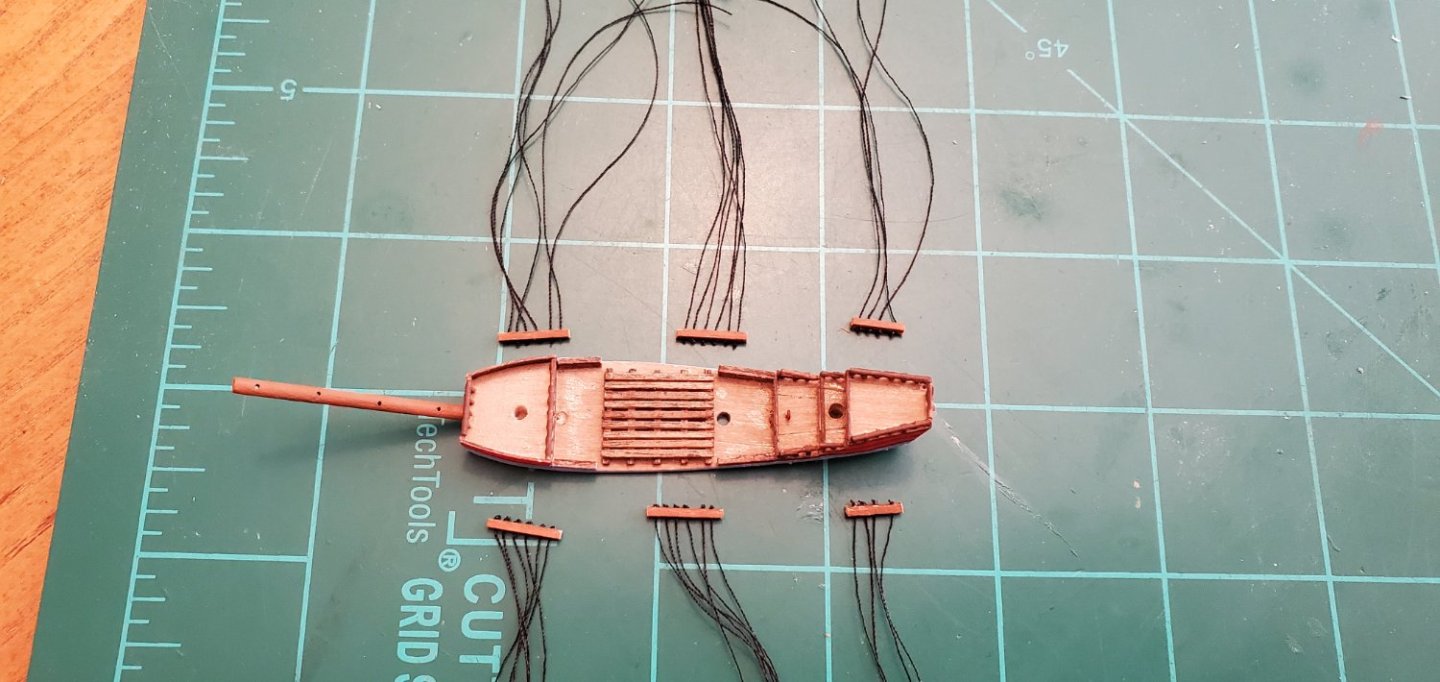

Got the braces strung and threaded yesterday. They are tied to the yard ends then strung thru tiny eye bolts along the sides of the deck, over the bow, and thru the bowsprit. The brace threads are long and extend thru the neck of the bottle so I can adjust the yards angles after insertion.

- mtaylor, Keith Black, GrandpaPhil and 6 others

-

9

9

-

-

6 hours ago, Benjamin sullivan said:

Wow, looks great put together

Thanks, Benjamin! Fingers crossed it still looks like that after being stuffed into the bottle and reassembled! I'm getting nervous just thinking about it. 😳

- Keith Black, Dave_E, Ian_Grant and 1 other

-

4

4

-

4 hours ago, gjdale said:

Applying shingles is a little bit like tying ratlines – it seems to take forever, but eventually we’ll get there….

Also reminds me of putting copper plates on a hull. Row after row after row after row...

The flashing looks so realistic.

-

- gjdale, Landlubber Mike, Keith Black and 6 others

-

2

2

-

7

7

-

-

2 hours ago, BANYAN said:

When you trailblaze you have to expect such dilemmas Glen; it is how you overcome that matters and you have done a great job.

Thanks, Pat. I really appreciate that!

- Dave_E, Keith Black, BANYAN and 1 other

-

4

4

-

38 minutes ago, Keith Black said:

You recovered better than TCU.

LOL! Maybe that's part of the problem. I'm usually working on the ship with one eye and watching a football game with the other!

10 minutes ago, Dave_E said:Sweet! 👍😀

Thank you, Dave!

- Knocklouder, Keith Black, Dave_E and 1 other

-

4

4

-

I was hoping I was done wearing the dunce cap, but no, it stayed firmly on my head as I attached the backstays. While attaching one of the starboard backstays on the foremast, I pulled it snug and promptly pulled off the channel on the port side. Note to self - glue the channels to the hull BEFORE painting the hull. Duh.

I recovered from that blunder and moved to the main mast where I pulled the dunce cap on even tighter. I grabbed a backstay with tweezers and secured it to the mast. I leaned back to admire my magnificent work and realized that I had attached a shroud instead of a backstay. With the channel ends of the shrouds already tied and glued firmly in the channels, this was yet another dodo move.

After much cursing and gnashing of teeth, I actually got lucky. After clipping the shroud away from the mast, there was just enough length left to tie it off to its eye bolt. Whew!

After that, things settled down and I got all the backstays and shrouds in place as well as the pull threads. Everything tightened up nicely with the masts at a reasonable upright angle and no sagging lines.

-

On 11/26/2022 at 9:45 PM, RobTBay said:

What's the forum etiquette, or typically people's opinions, on starting a build log on a half-finished model?

Hey Rob, I discovered MSW right as I was finishing my first ship model (see link below for CSS Alabama). I had taken a bunch of pictures along the way so I decided to post a build log even though I had just finished the model. I was hoping I would get some constructive comments from some of the master builders out here. And let me tell you, I was not disappointed!! I learned sooooo much from all the comments.

So even though you are halfway done, I would highly recommend starting a build log ASAP.

- Keith Black, mtaylor and Knocklouder

-

3

3

-

Welcome aboard, Lyle! We are all glad you found us!

- Dave_E, mtaylor, Keith Black and 1 other

-

4

4

-

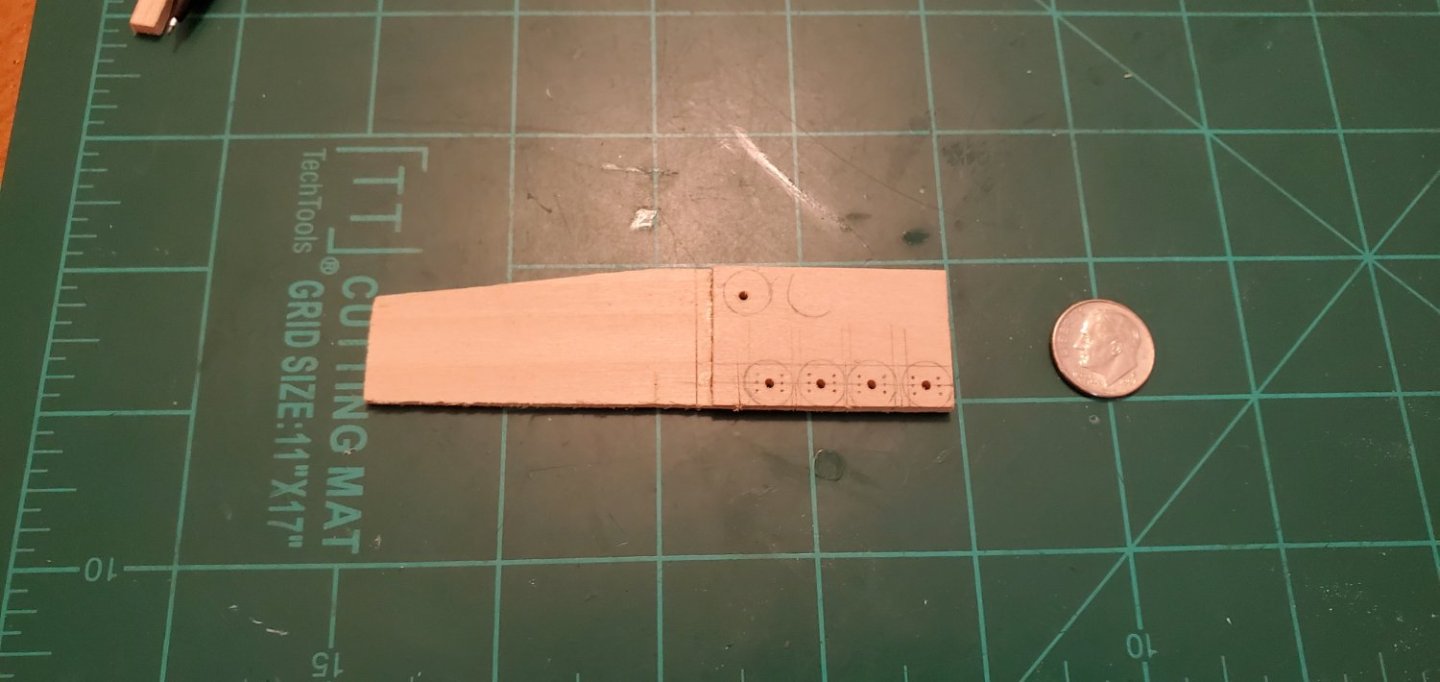

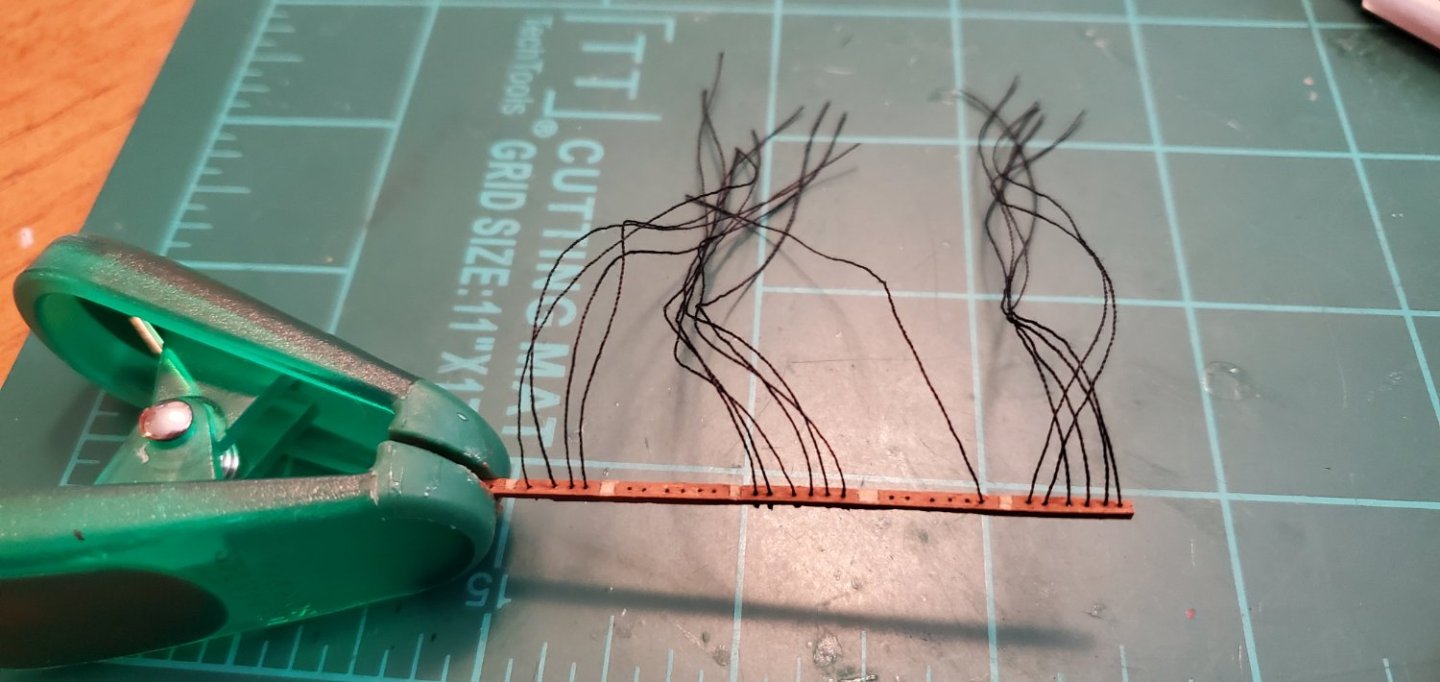

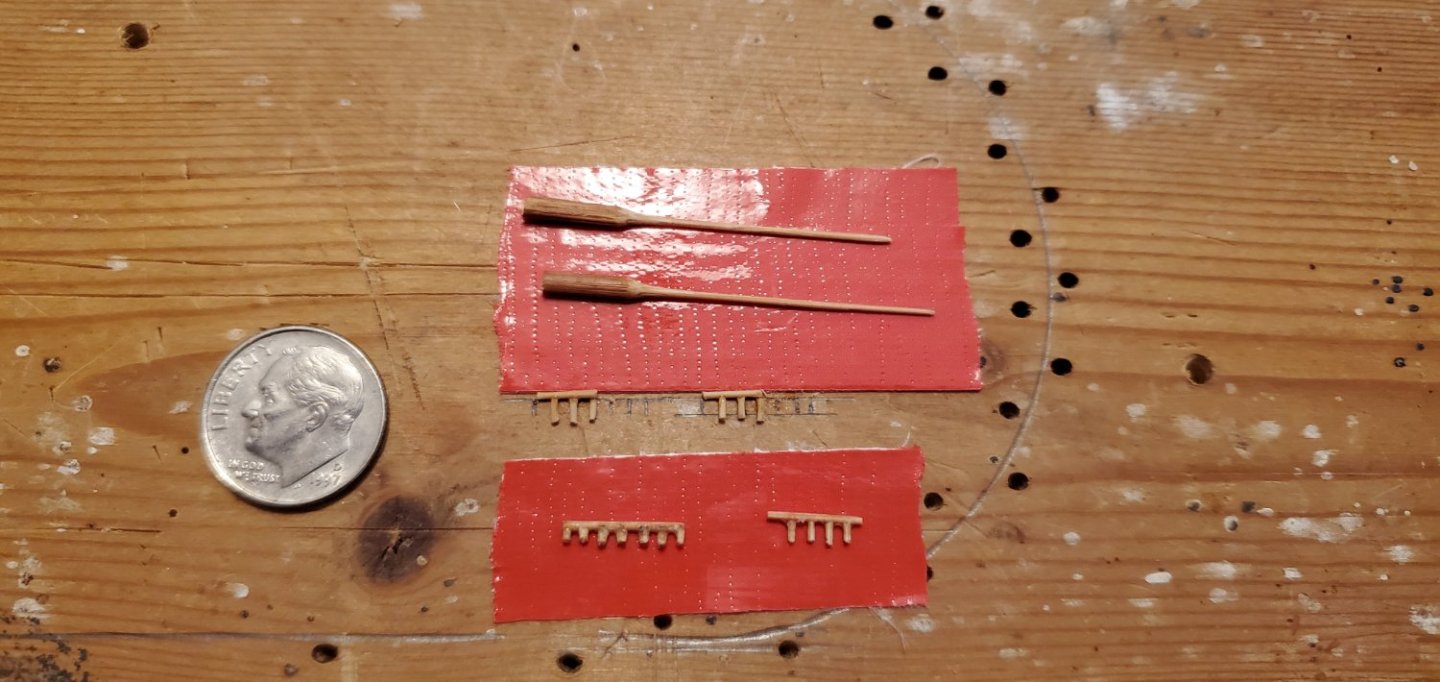

I decided to try an assembly line type process for the channels/shrouds/backstays and do them off-ship before attachment. I started out with a single strip of wood for all the channels, drilled the necessary holes, threaded the shrouds/backstays, and tied them off. Then I separated the channels and attached to the ship. At the end it looks like a scraggly, bad hair day, but the process worked pretty well.

- Dave_E, Keith Black, GrandpaPhil and 7 others

-

7

7

-

3

3

-

8 hours ago, Keith Black said:

Glen, have you considered rice paper? I'm considering using it for the sails for Amelia.

Never heard of rice paper before. I will look into that. Thanks, Keith.

-

Well done under that extra pressure!!!

- mbp521, John Ruy and bobandlucy

-

2

2

-

1

1

-

1 hour ago, GrandpaPhil said:

However, let me see how it works for making my set of sails for Solferino.

OK. I'll stay tuned. Thanks!

- GrandpaPhil and Keith Black

-

2

2

-

45 minutes ago, GrandpaPhil said:

I also bought everything for a complete set of silk span sails.

Where do you get your silk span, Phil?

- GrandpaPhil and Edwardkenway

-

2

2

-

I hope everyone had a wonderful Thanksgiving and got to spend lots of time with family and friends.

Work continues on the masts with installation of the upper shrouds and ratlines (I'll do the lower shrouds after I step the masts into the deck). The first step was drilling tiny holes and fitting .75mm x 6mm eye bolts to the crow's nests. Those are the smallest ones I can find on Model Expo's website and I find them very useful. Here, I tie the lower the lower ends of the shrouds to them. I also put one thru the mast just below the crow's nest to tie off all the upper ends of the shrouds (see first pic).

Once the upper shrouds are in place, the ratlines are next. I snip thin fly fishing line into small pieces about 10mm in length. Then I drag them thru Aleene's fabric glue and lay them across the shrouds.

The last step is to trim the edges with cuticle trimmers and try real hard not to cut the shrouds which causes immediate loud cursing and thrown tools.

And the port side is done (with no loud cursing yet).

-

-

Thanks for the positive comments and the likes.

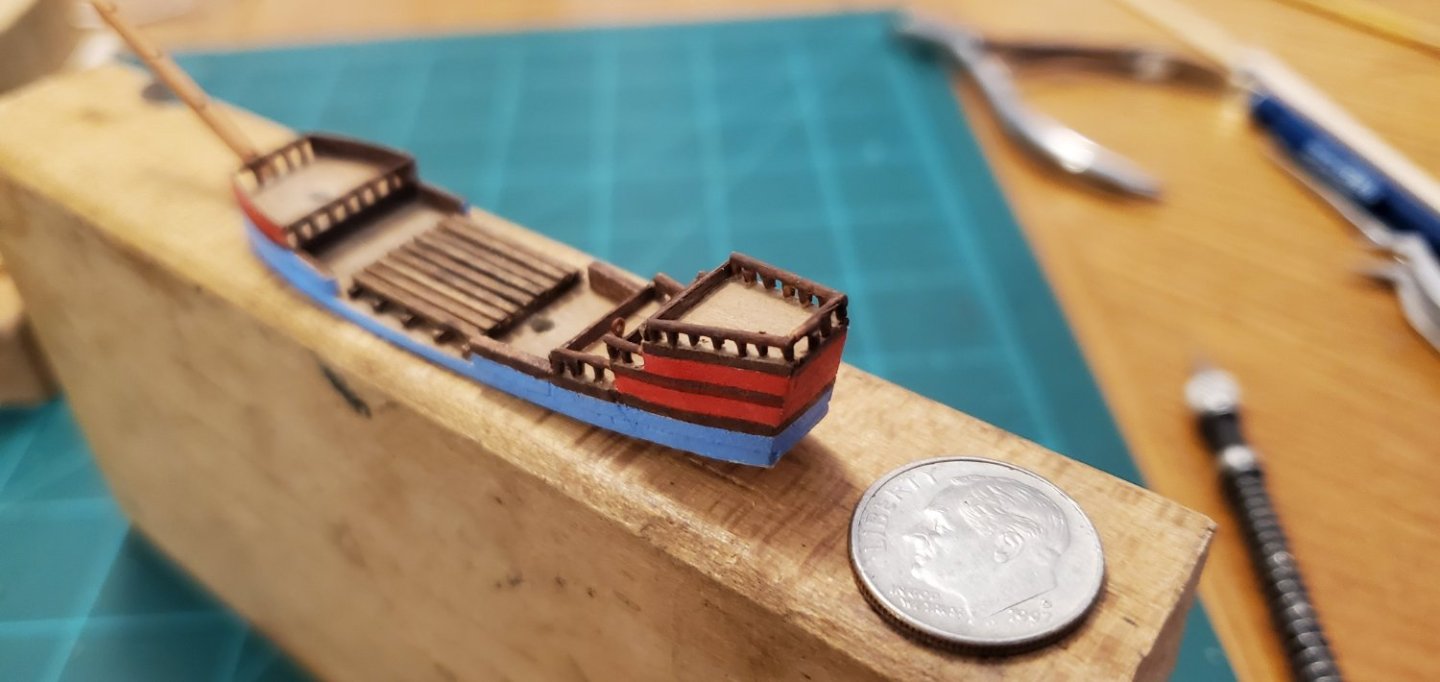

More cold and rainy weather here yesterday and today, so the cows get neglected but the ship gets lots of attention. Continuing with the theme for this project, I had to totally rebuild the main mast. The hinge was too high and would not fit thru the bottle opening. Then I started making mast tops which is the usual next step. I got about halfway thru and it suddenly dawned on me that this ship has crow's nests instead of the flat mast tops I'd built for every other ship.

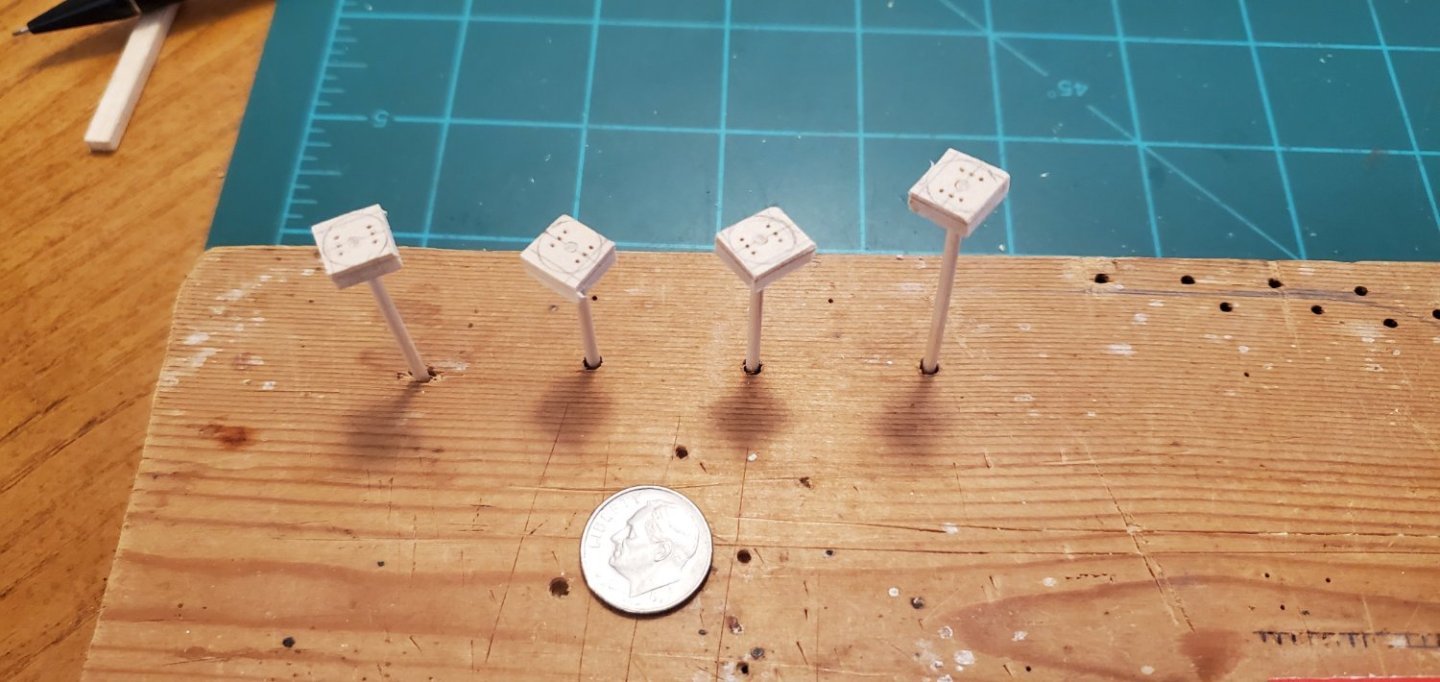

So once again it's 2 steps forward and 1 back. But I thought this would be cool because I've never tried to make crow's nests before. The pics below show the steps from drawing them out to placing them in position on the fore and main masts. The mizzen mast has a large lateen sail which will be another new thing for me to deal with later.

The last pic shows a test fit. Lots of room to spare for yards and sails. Or so it seems right now!

!

!

- BANYAN, Knocklouder, Keith Black and 7 others

-

7

7

-

3

3

-

-

It was cold and rainy all day yesterday in Austin, which made for a good day to watch football with one eye and work on the ship with the other. And I needed all day to tackle the rails. In an earlier post, I showed the little bamboo sticks I'd sanded down to < 1/32" in preparation. Time to see if I could turn them into decent looking rails. The first pic shows the evolution from bamboo stick to rail ready for attachment to the ship.

The results were not perfect, but I think they came out ok. As usual, the farther away you get, the better they look.

Adventure Galley by Glen McGuire – FINISHED – 1/400 - BOTTLE

in - Build logs for subjects built 1501 - 1750

Posted

Hey Grant, I looked into silkspan after the success you had with your Amati Hannah sails. I was going to order some from Sig but they were out of stock on the light and medium. I tried a couple of local hobby stores here in Austin and they didn't even know what I was talking about. I just checked the Sig site again and they are still out. So if I could find some I would definitely give it a try.