-

Posts

1,840 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glen McGuire

-

-

- CiscoH, mtaylor, Keith Black and 2 others

-

5

5

-

-

- gjdale, mtaylor, Knocklouder and 5 others

-

8

8

-

First up is the treasure chest. I’ll finish with the ship.

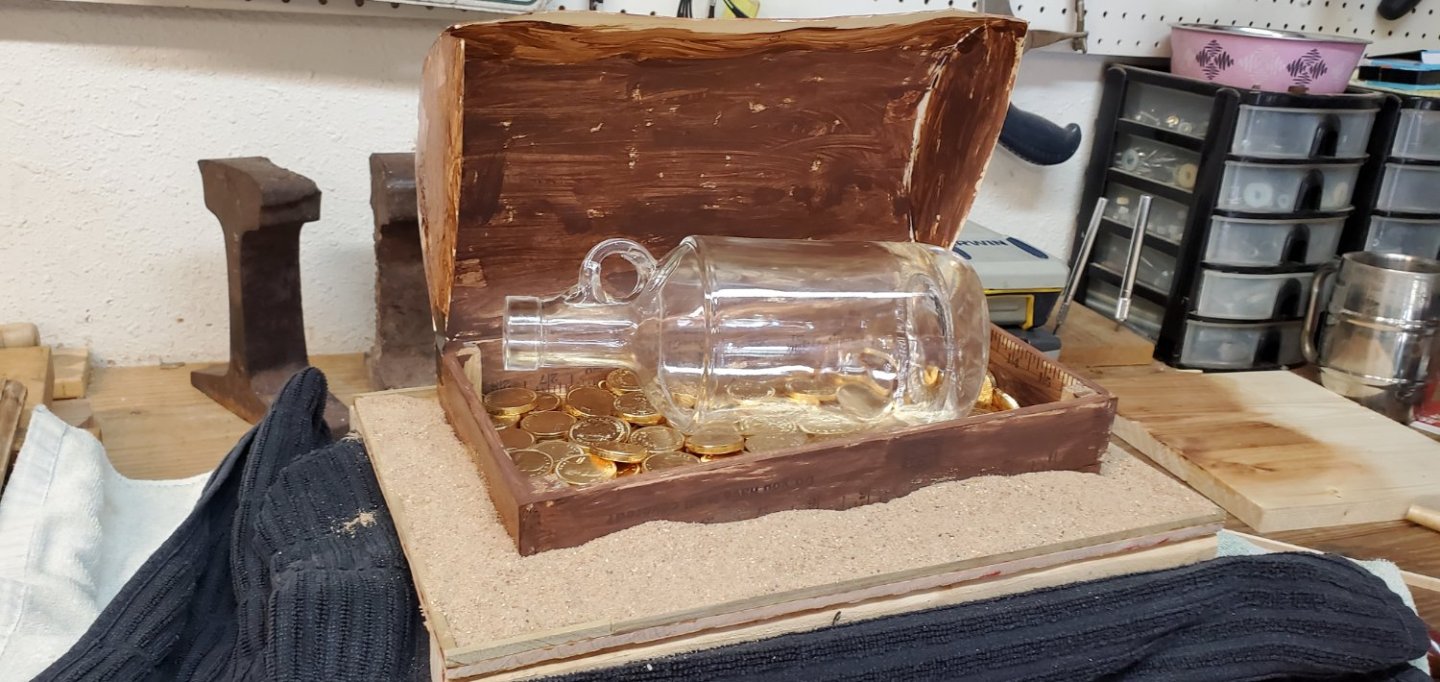

A month ago I was getting rid of a cheap particle board/veneer desk when I noticed the sides of its drawers were actually made of oak. I cut them up into small planks knowing I’d eventually find a use for them. And now they will become the treasure chest for this project!Using the mockup pieces of yardstick as a template for the treasure chest sides, I cut four of the oak planks into their odd shapes to simulate the chest protruding from the sand at an off angle.

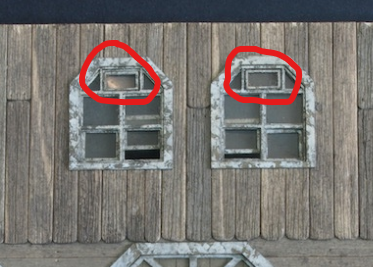

Since the chest is supposedly 300+ years old, I wanted to weather the surface of the wood. For the inside of the chest, I wanted only mild surface aging since it would have been sealed shut and mostly protected from the elements. Borrowing some ideas from @gjdale and his amazing Shipyard at Foss’ Landing diorama, I used a stiff wire brush to give the wood a mildly roughened surface. For the outside surface, however, I wanted significant weathering with deep grooves. I’ve got an old shed on my ranch with wood planks that have the look I want.

So I used my angle grinder with a wire brush attachment. Here’s the setup along with the before and after results.

- Keith Black, gjdale, mtaylor and 2 others

-

5

5

-

12 minutes ago, gjdale said:

the transom window on the door has been left ajar just for Glen...😉

I can breathe now!!! Whew!!!

What an excellent job you did with the SHIPYARD streaking. That looks incredibly hard to do but your end result is very subtle and looks so realistic. Wow.

-

7 hours ago, Landlubber Mike said:

I'm in for another ride Glen!

Glad to have you on board, Mike. I always appreciate your help and insight!

-

Thanks, Ian!!

32 minutes ago, Ian_Grant said:Hana highway on Maui

I've been on that Hana highway a few times. Gotta be one of the most scenic drives in the world, but also pretty nerve wracking when you're forced to play chicken with a semi on one of the countless one-lane bridges! Yikes!!!

And I am also familiar with that hand sign. In fact, I used to have a t-shirt back in the 80s that looked just like this:

-

The SIB Concept:

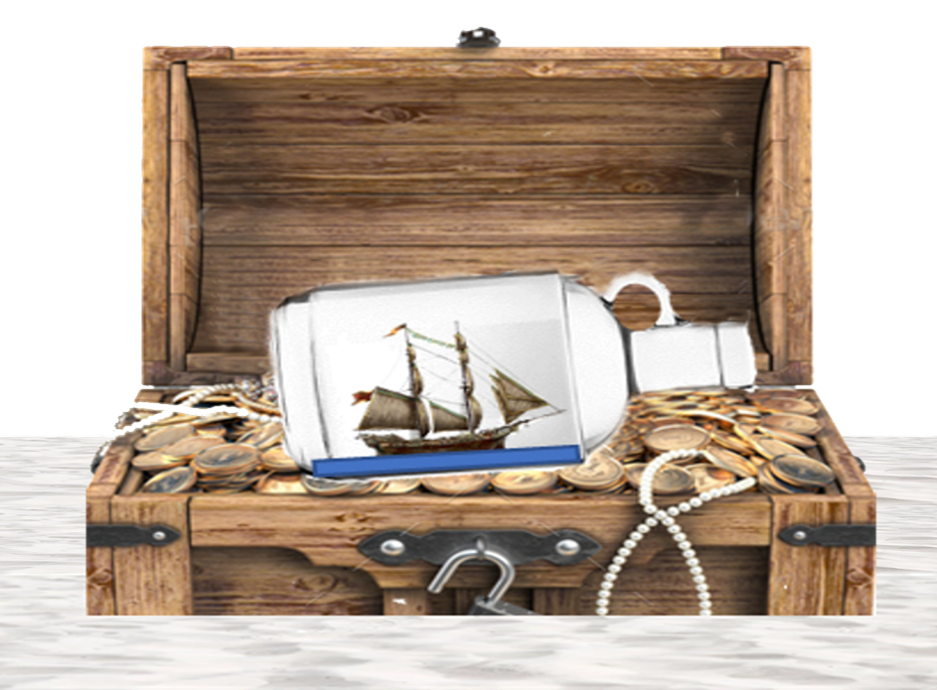

I know it’s more fake news than real history, but I always think of buried treasure when I think of pirates. In the case of Captain Kidd, he is one of the few pirates that actually did hide his treasure (or at least part of it). Some of his loot was found on Gardiner Island outside of New York before his hanging. But rumors that Kidd buried additional treasure at various points along the Jersey shore persist today.So with that as inspiration, I came up with the idea of putting the Adventure Galley in a bottle and the bottle resting inside an open treasure chest that is barely sticking out of the sand. See below for my crude powerpoint rendition of the concept.

After looking at that picture, however, I wasn’t convinced the whole treasure chest scene was all that great of an idea. So I decided to do a mockup to see if it would look any better. I cut up a yardstick and made treasure chest sides.

Then I made a base with a hole in it so I could adjust the angle of the chest. I figured it would look better if it was off kilter sticking out of the sand.

Then I took a manila folder, shaped it into a lid, sloshed some brown paint on it, and taped to the chest in an open position.

Next, I spread some sand around the base and I set my chosen bottle on a top of a bunch of chocolate gold coins.

After looking at the completed mockup, I changed my mind and decided this could actually be a cool project - assuming of course that I can fashion a decent looking treasure chest peeking out from the sand. That remains to be seen.

OK. That’s probably way more back story than anyone wanted to know. So without further ado, here we go!

- Ian_Grant, Baker, Keith Black and 6 others

-

9

9

-

My original plan was to build a pirate ship after I finished the Independence, but then my son intervened with his junk ship request. So now it’s time to circle back and take on a pirate ship. I wanted a pirate with an interesting story as well as an interesting ship. After considerable research, I decided on Captain Kidd’s Adventure Galley. I was intrigued by his personal story of pirate hunter turned pirate. Plus, the Adventure Galley was quite a unique ship. Here’s some background on the pirate, his ship, and the SIB concept I have in mind.

The Pirate:

Captain Kidd’s story is fascinating, although the particular details differ depending on the source. Basically, he was a pirate hunter turned pirate. He began as privateer commissioned by several noble lords of England (including King William III) to hunt pirates. He weighed anchor in the fall of 1696 and over the course of the next couple of years, captured several ships. In 1698, he took his greatest prize, the 400-ton Quedah Merchant, which was an Indian ship hired by Armenian merchants and carried a large treasure of gold, silver, silks and other valuables.

Shortly afterwards, Kidd was declared a pirate by the same English Government that had given him his commission. By some accounts, it was because the Government’s view of privateering had changed. Others blamed it on his poor treatment of captured crewmen. Still others insisted that the East India Company, which had ties to the Quedah Merchant, pressured the crown as retaliation for Kidd’s capture of their prized ship. Regardless, he was lured to Boston with a false promise of clemency, but not before he supposedly stashed much of his treasure near Long Island, NY. After surrender, Kidd was extradited to London in 1701 and hung for piracy and murder.The Ship:

Captain Kidd’s main ship was called the Adventure Galley. It was launched in 1696 and purchased by Kidd a year later. It was a 284 ton, 3-masted frigate equipped with 34 cannons and designed for a crew of 150 men. After capturing the Quedah Merchant, Kidd scuttled the Adventure Galley and took over the Indian ship, renaming it the Adventure Prize. I found the Adventure Galley unique because it was a hybrid, similar in a way to the steam/sail ships of the mid and late 1800s. Kidd’s ship featured square sails AND two banks of oars. The oars gave it maneuverability in calm seas – theoretically a significant advantage in combat.There are a number of fully assembled Adventure Galley models for sale by various makers. I find it interesting that most do not show the oars or even have ports for them. However, a company in Madagascar called Le Village displays a model on their website that does include the bank of oars. See below for a picture of the Le Village version. I will base my Adventure Galley loosely on their version but likely add some elements from other models and illustrations.

-

-

-

-

- Edwardkenway, Egilman, Jack12477 and 10 others

-

13

13

-

This is really fascinating work, Grant!

- Keith Black, gjdale, Canute and 7 others

-

10

10

-

@Ian_Grant, @Alva004 Thank you for the kind words and thanks even more for following along. I fell like everyone here is a contributor to the project!

- mtaylor, Keith Black and gjdale

-

3

3

-

1 hour ago, Keith Black said:

Glen, are you diving right into your next project or is a small break in order?

Hey Keith - Literally minutes after posting the finished pics of Zheng He to the gallery I took off to southern California for a quick dirt bike riding trip. Just got back last night. So I guess that was a small break, right?

Actually, I've got an idea for the next SIB project but need to play around with some things to see if I think it will really work or if it's just a dumb idea.

- Keith Black and mtaylor

-

2

2

-

On 9/8/2022 at 9:59 PM, Louie da fly said:

Wonderful work, mate!

19 hours ago, BANYAN said:I have really enjoyed following this build mate.

Thank you Steven and Pat. It's great to have both of y'all from down under following along and providing your insight!!

- Keith Black and mtaylor

-

2

2

-

Thank you, Mike and Phil. I really appreciate y'all following along.

-

Thank you Grant, Keith, and Mark for the kind words. It's been an interesting journey going from my son's innocuous comment last May of, "Hey dad, you should do a junk ship in a bottle" to this!

Much appreciation to all the talented MSW people that followed along the way and offered likes, encouragement, comments, and suggestions - @Landlubber Mike, @John Fox III, @Ian_Grant, @BANYAN, @GrandpaPhil, @ccoyle, @Roger Pellett, @Snug Harbor Johnny, @Louie da fly, @Charter33, @Alva004, @Prowler901, @Knocklouder, @French Mr Bean, @Aoi, @shadowcaster, @Siggi52, @Baker, @Paul Le Wol, @Harvey Golden, @robdurant, @modeller_masa.

Not only do you make the final product better, you also add to the enjoyment of the work.

-

-

Here’s my idea for the final presentation. My thinking might be a little far out, but hang in there with me on this!

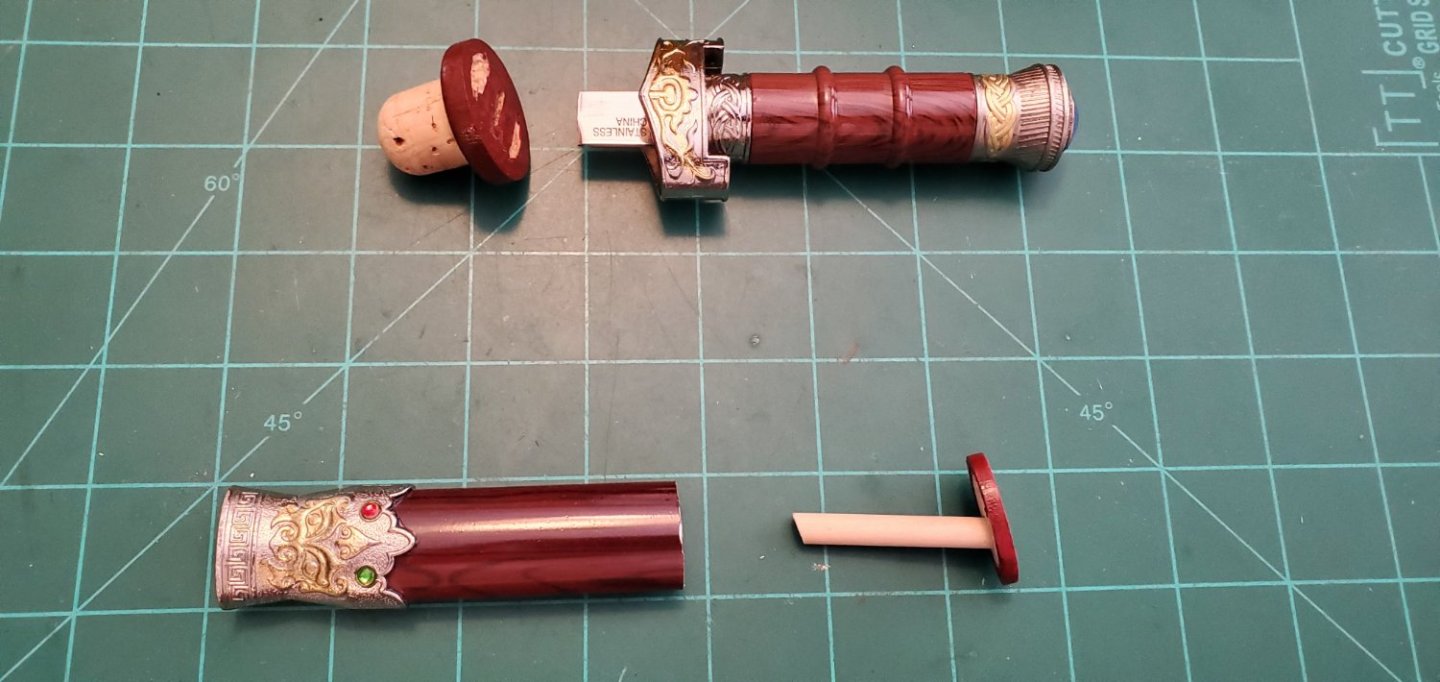

Since the base is a sword holder and the bottle sits on the sword holder, the bottle should serve as the sword or at least bear some resemblance to a sword, right? So my thought was to have a sword handle protruding from the bottle opening and the end of a scabbard protruding from the bottle’s base. I was not sure how that would turn out but was determined to try.

I found a smallish Chinese-style sword on Amazon and ordered it. The sword is actually a letter opener that fits inside a scabbard. To secure the sword handle to the bottle opening, I cut the sword's blade off about ¾” from the hilt. Then I found a cork stopper that fit the bottle opening (the bottle originally had a screw-on cap), sanded it down, and slotted it so the cut-off blade would fit snugly inside. Then I color matched the stopper to the sword handle’s color.

For attaching the scabbard end, I could think of no option other than using epoxy to affix it to the bottle’s base. The scabbard is actually thin metal painted to look like wood. I cut it off at the length I needed to balance it with the handle. Then I carved out a little wood grommet with a small, angled support and epoxied the scabbard to the grommet. Then I epoxied the whole thing to the bottle’s end and set the bottle inside the boot holder to cure. Believe me, I was more then a little nervous turning the bottle on its end like that to fit inside the boot, but everything inside held tight!

While waiting for the epoxy to fully cure, I added a few touches that a friend with an eye for details suggested. I took 2 of the small red and green “jewels” from parts of the scabbard that I was not using and added them to the hilt to match the scabbard end cap. I also highlighted the Chinese lettering on the base (“A Great Treasure in Your House”) with a paint color that matched the sword handle.

- mtaylor, Paul Le Wol and GrandpaPhil

-

3

3

-

On 8/30/2022 at 8:00 PM, Keith Black said:

I guess this means no penguins, lions, tigers, and polar bears.

While waiting on an Amazon delivery so I can complete the treasure fleet base, I decided to see if I could actually make something resembling a tiny penguin. Since the longhorn herd turned out pretty well, a penguin shouldn't be too hard, right? So here he is.

He's 1/16" tall. That scales to about 1/750 based on a 4' tall emperor penguin, so it's definitely a reasonable size for one of my SIBs. I may open up the Aurora bottle and try to mount him on one of the broken ice floes. If that doesn't work, I'll save him and maybe do an Endurance down the road.

Oh, and I named him Keith.

- BANYAN, Keith Black, hollowneck and 4 others

-

1

1

-

4

4

-

1

1

-

1

1

-

Welcome aboard, Steve! Looks like you've got a flair for western art as well based on other things in your work area!

- Dave_E, Edwardkenway, Keith Black and 1 other

-

4

4

-

Fascinating! Thanks for showing the detailed steps in your wood weathering process. I've got an idea floating around in my head for the next SIB project and this technique might be just what I need to pull it off.

How's that for a teaser right back at ya!! 😁

Adventure Galley by Glen McGuire – FINISHED – 1/400 - BOTTLE

in - Build logs for subjects built 1501 - 1750

Posted · Edited by Glen McGuire

I cut the rusty gutter into strips and pieces using a dremel cutoff wheel. The first pic shows all the cut pieces; the 2nd is a closeup of a few; and the third is a dry-fit sneak peak at the lid.

I think mother nature aged the metal to perfection for what I was looking for. I just painted the cut edges with a matching rust color and then sprayed everything with 2 layers of clear coat. I will probably use rusty nail heads to simulate the rivets since I've got an endless supply of them.