-

Posts

1,835 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glen McGuire

-

-

Those are good guesses, but here's what's really going on, Keith.

Husband, wife, and teenage daughter were on a road trip. They got lost, took a wrong turn, and ended up on this floating, wooden contraption because the husband refused to stop and ask for directions. Wife got mad and ran up the stairs looking for help while husband stayed with the car and started talking to a couple of deckhands about how the Lions did in the NFL draft. Daughter yelled at the parents to stop arguing and look her way so she could take a picture and post on her Instagram account.

-

Nice work on the 2-piece metal ring. Looks great and anyone looking at it would think it's a single piece.

- Keith Black, Paul Le Wol, FriedClams and 1 other

-

3

3

-

1

1

-

Exceptional metal work, Gary.

- Keith Black, Paul Le Wol, Jack12477 and 3 others

-

5

5

-

1

1

-

Superb work, Mike! Particularly the finish on the interior planks. great choice on the stains.

- FriedClams, Landlubber Mike and AJohnson

-

2

2

-

1

1

-

Glad to hear your hand is better and you're back in the shipyard, Mark. The planking is looking very nice.

-

23 hours ago, Javelin said:

Having a bit of a Z-cut along the hull in the vertical direction also makes it easier to line up the hull halves. It also prevents the loss of width created by the sawing and loss of saw dust.

Thanks for the comment, Roel. That's an interesting idea to do a vertical Z-cut. I may play around with that before my next split-hull SIB. I've always used tapered locating pins (toothpicks) to help guide things in place when joining the hull inside the bottle. That Yi Soon Shin series looks like it would be worth watching.

On 4/20/2025 at 9:14 AM, Knocklouder said:There is a white out in Manitoba that we are hoping it last to med June

Thanks for reminding me why I live in Texas, Bob!

20 hours ago, Keith Black said:Cutting that hull in half is like jumping out of a perfectly good airplane.

Good analogy, Keith!

And on that note, I'm going to jump out of this Kentoshi-sen airplane for a few weeks. I'm heading up to New London, CT for the Northeast Ship Modelers Show and when I get back, I'm going to dive back into the Constitution and see if I can finish her up.

- John Fox III, JacquesCousteau, tmj and 7 others

-

10

10

-

-

Happy Easter to everyone! An early update from the shipyard here before the day's real activities get going.

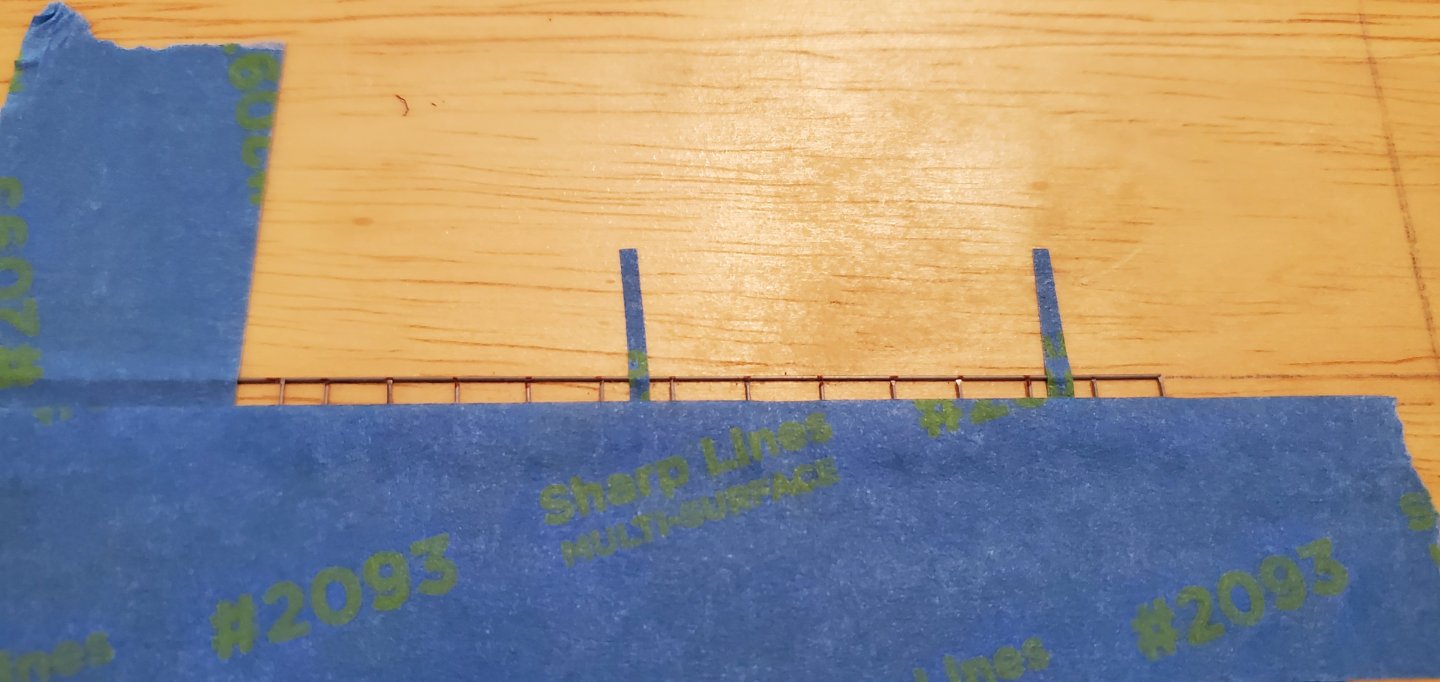

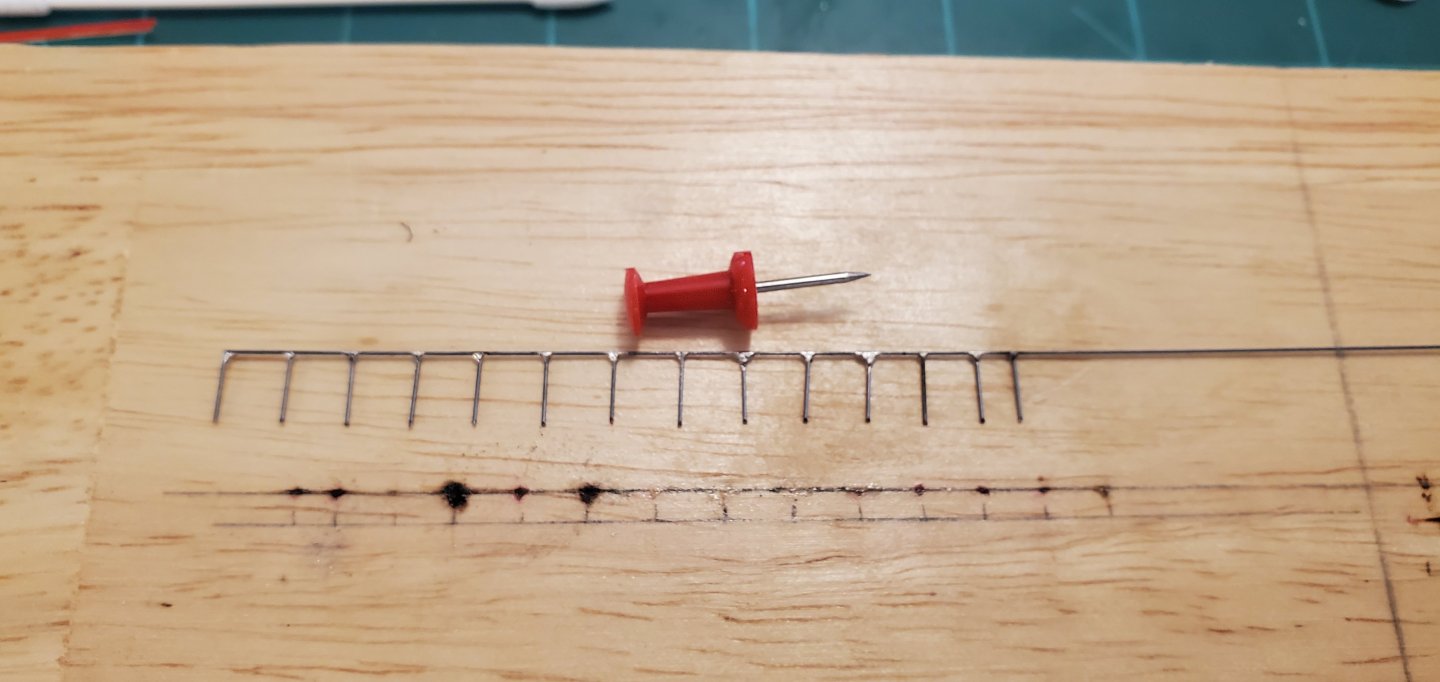

Yesterday's chore was to make the ship's railings. I used 1/64" (.3mm) music wire for scale and also because it needed to be flexible enough to bend with the upward sweep of the bow and stern. The stanchions would be silver soldered in place. The challenge for me with soldering tiny right angle connections like that is holding everything in place because the slightest move will kill the 90 degree angle.

For soldering, I use a technique I found watching an Olga Batcherov video. I cut the silver solder into tiny flecks, use a small paint brush and apply flux to the joint, grab a fleck of solder with the sharp tip of the iron, and then lightly touch it to the joint. I'm not great at the technique, but it's passable work.

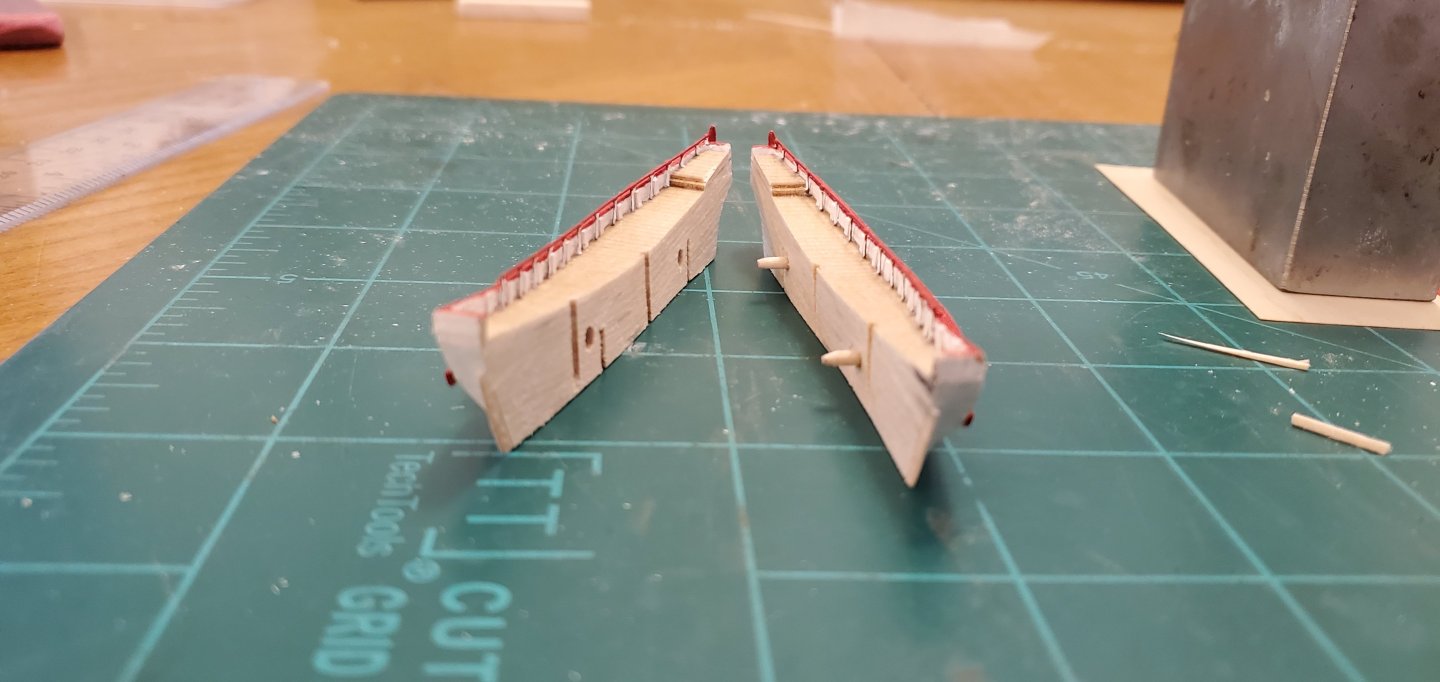

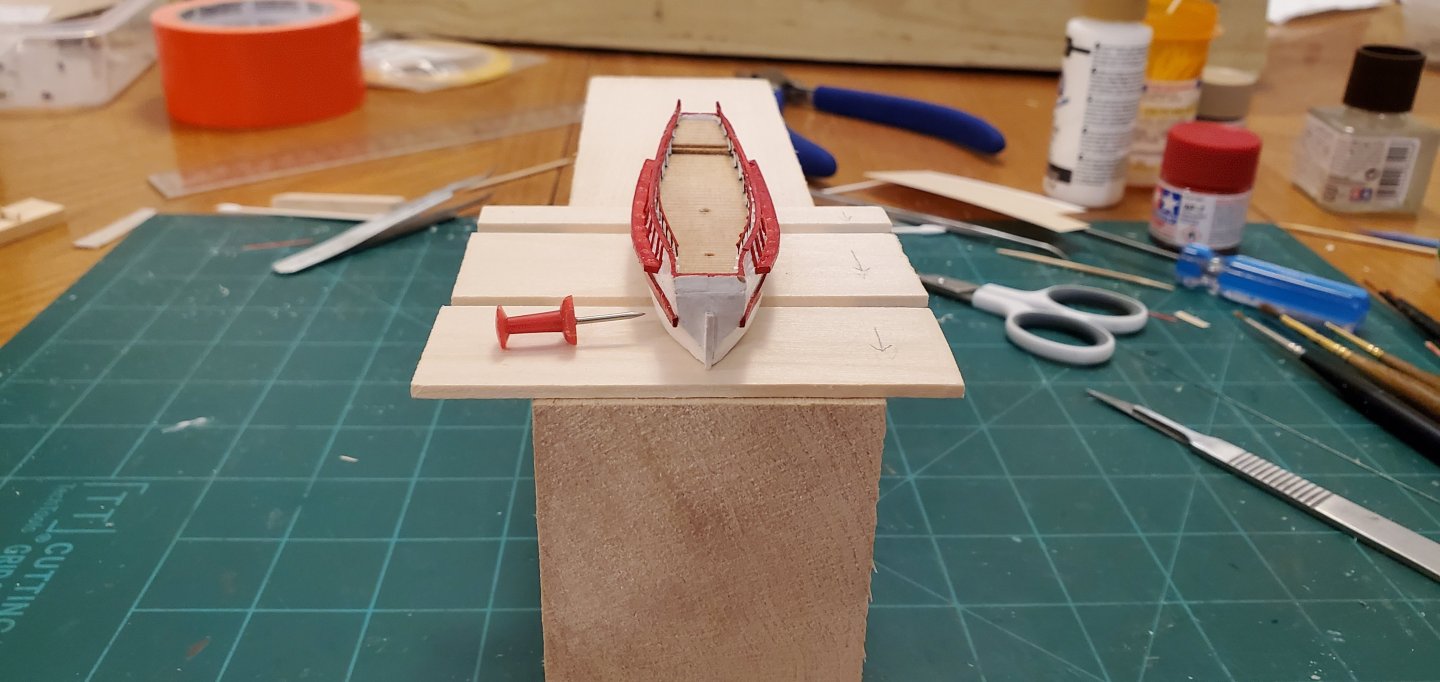

After installing the railing, it was time to split the hull. Ugh. I really don't like the idea of taking a saw and hacking on this thing I've invested so many hours in! It makes me nervous. I've done a few split hulls before and always struggled with making a clean cut right down the centerline. Kind of like the soldering above, the challenge is holding the hull stable while making the cut.

I came up with a new idea that I thought might work. I drilled holes halfway thru the bottom on the ship and inserted 4 toothpick dowels, 2 on each side of the centerline.

I drilled matching holes in the block of wood, inserted glue, and dropped the ship in place. I didn't drop it all the way down though. I inserted 3 planks of 2mm thick wood between the bottom of the ship and the block of wood but did not glue the small planks in place. The idea was to remove the planks after cutting the hull. The gap from the removed planks would allow me to use the saw to cut the hull from the block.

Right after I took the picture below, I thought, "why did you put that keel on the bow when you knew you were going to cut the hull down the middle??" So much for my improved thinking things thru and planning things in advance. And yes, Keith, It has stopped snowing now.

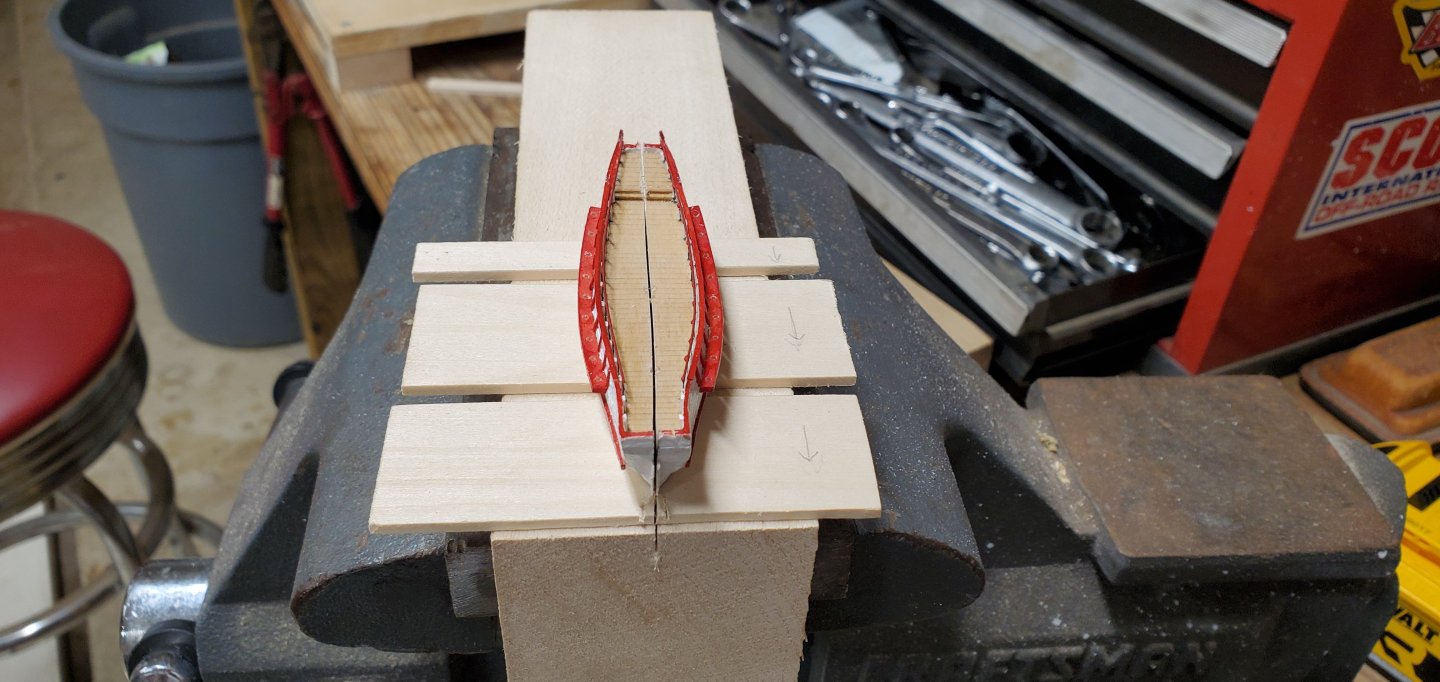

But actually, having the keel in place helped line things up visually and also gave me a challenge. My fine-kerf saw is just barely thinner than the 1mm wide keel. If I was good enough with the saw, I should be able to split the keel with the saw, right? Challenge accepted!

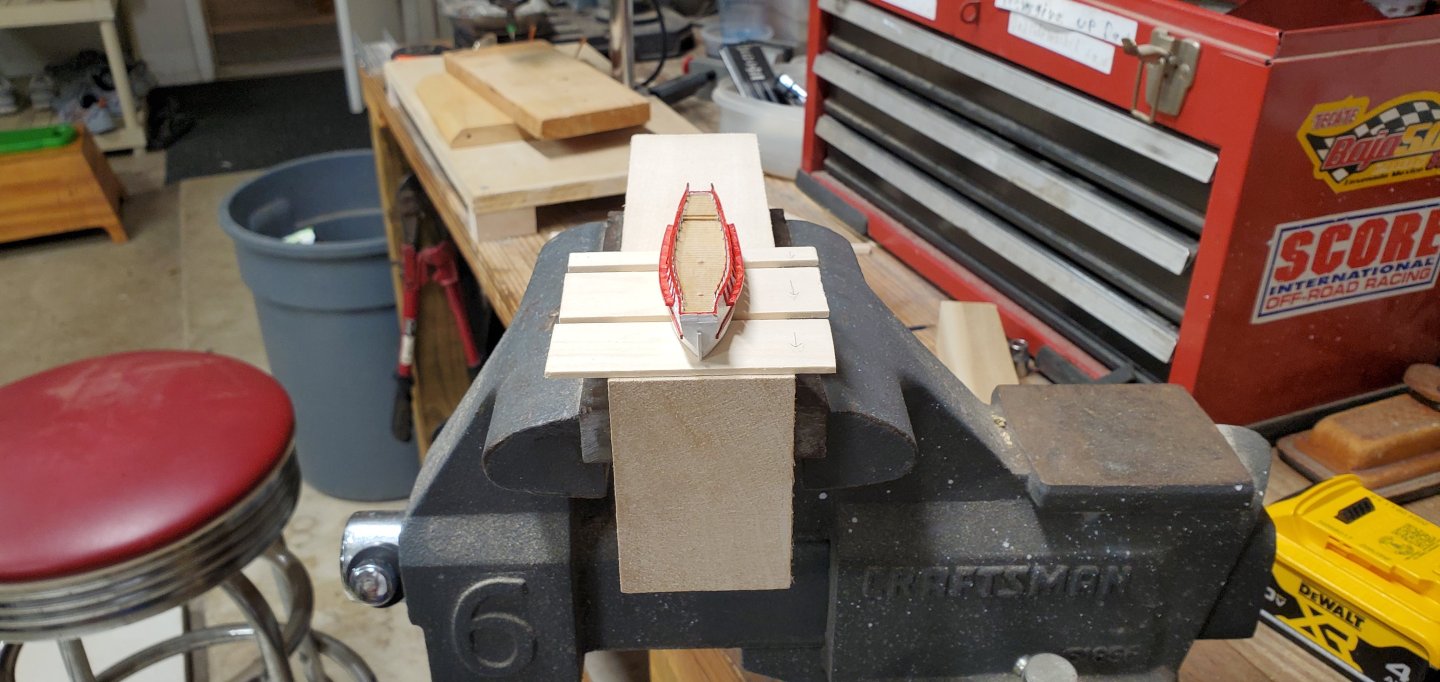

I put the block of wood in my workbench vise and hit it with the fine-kerf saw.

Here's how she came out.

-

6 hours ago, Keith Black said:

Lula and the pile driver, a tender love story.

You are quite the matchmaker, Keith! I'm sure it was love at first sight!

A masterful job on both Lula and the pile driver. I will miss your updates, but I pray that the scan results are favorable and you are back to finish up Lula and the Tennessee very soon.

- Keith Black, Canute and FriedClams

-

2

2

-

1

1

-

17 hours ago, catopower said:

Here are the pics, for what they're worth.

Thanks for posting these, Clare. That ship is remarkably similar to my Kentoshi-sen. The upsweeps on the bow and stern are more pronounced than mine, but your ship looks like it's got the same footprint and it certainly has the same deck for oarsmen. The 3 deck houses are almost identical and even oriented the same way. There are some differences, like the onboard windlass vs mine where it's suspended beyond the bow. Very intriguing! Thanks again for sharing.

- Canute, catopower, Keith Black and 1 other

-

4

4

-

41 minutes ago, FriedClams said:

Oh, and I'm having pangs of clamp envy.

I'm right there with you, Gary!

-

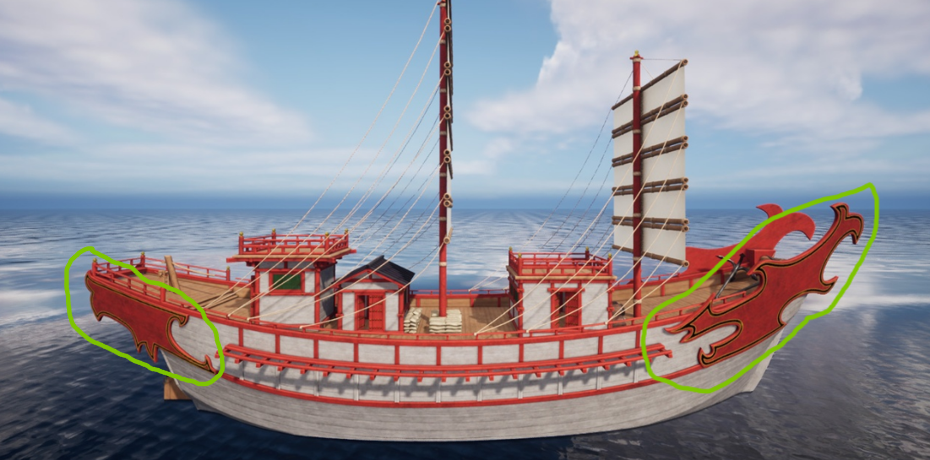

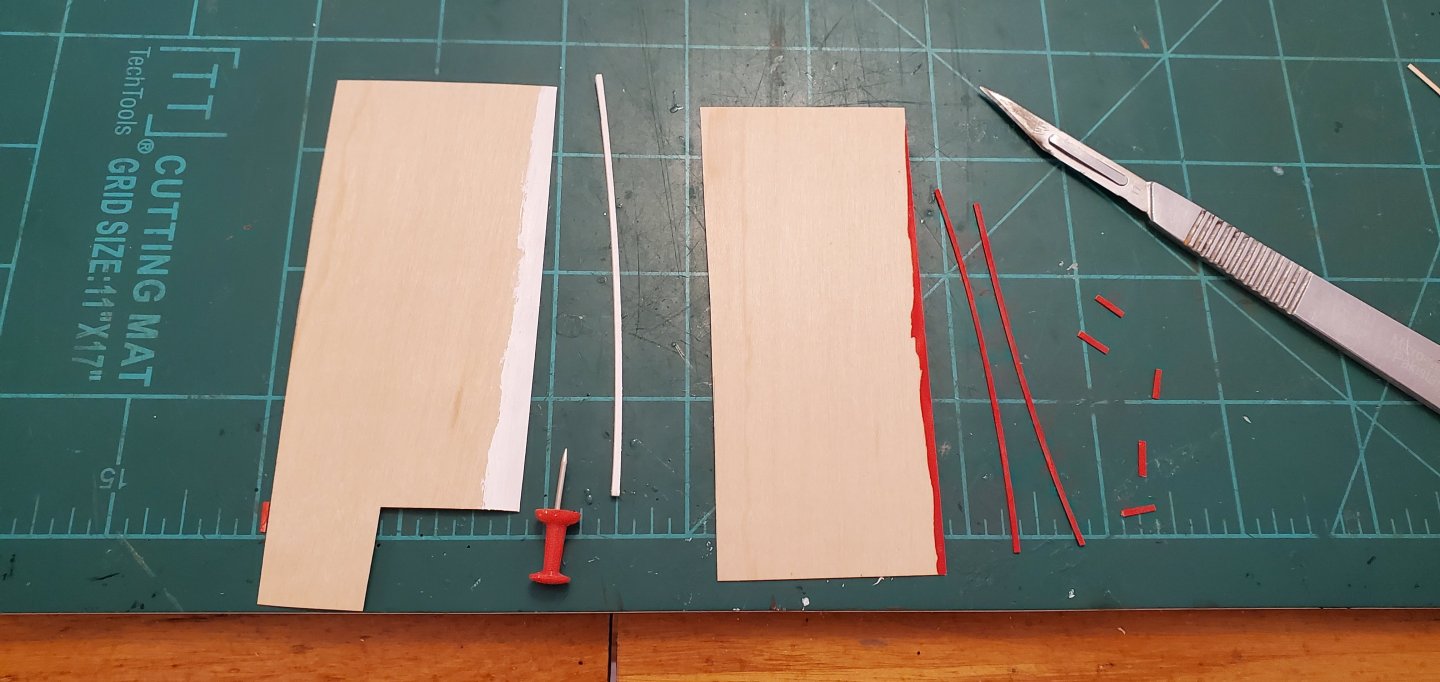

Time to put some lipstick and perfume on this pig! There's a lot of narrow, red trim on the outside of the hull as well as some thin, perpendicular slats that support the inside of the bulwarks (I'm making those white). For the long piece of trim that travels underneath the oarsmen plank, I used the 1/64" birch plywood and cut a 1mm wide sliver. For the red trim above the oarsmen plank, I cut < 1mm slivers of super thin maple veneer that's measure 1/128" in thickness.

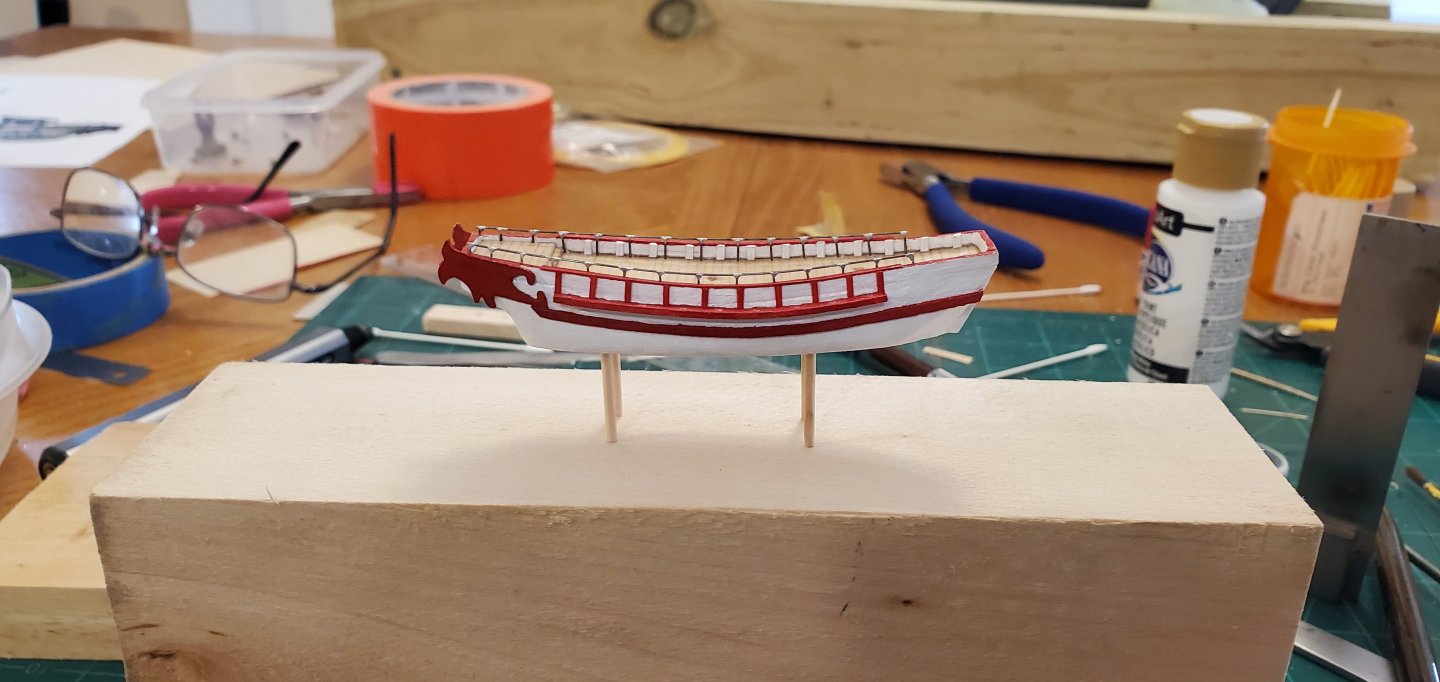

Here's an in process pic with the stern carving painted and in place as well as the trim beneath the oarsmen plank. The vertical trim pieces above the plank are glued in place but not yet cut down to size. You can see the keel in place on the square bow. It looks a bit strange to me, but that's what the picture shows (at least one of them anyway)! I also added a two-step poop deck.

Here she is with all the trim in place. The large, ornamental carving at the bow is only taped on for the photo shoot.

-

4 hours ago, Knocklouder said:

I knew I had seen that bow before, sorry buddy but it is hockey season now lol.

I thought it was always hockey season up there in Canada! Who knew that the ancient Japanese had an influence on Canadian hockey?

- Canute and Keith Black

-

2

2

-

-

On 4/15/2025 at 12:50 PM, catopower said:

I have a couple photos I took of it, if you're interested.

Thanks for the comment, Clare. I agree that there is not a lot of info about Japanese ocean going vessels for the earlier periods. When I started this project, I had a difficult time finding a historical Japanese sailing ship that was of interest. I just went thru your Kitamaebune build log. Very impressive work on an equally interesting ship!

Yes, please attach the pics of the model from the Sea Folk museum. I would love to see them.

-

-

Hey Mark! I'm late to the party, but got here just in time to read about your injury. You have made very nice progress so far on this build and I look forward to seeing you back in action! Get well soon!

-

Creative way to bend the stern planks to shape. Nice, clean work with the whole planking, Paul. She is looking good!

- FriedClams, Keith Black, Paul Le Wol and 1 other

-

3

3

-

1

1

-

-

On 4/13/2025 at 10:35 AM, Knocklouder said:

The lion in the middle is the kit supplied figurehead.

If that's a lion, I'm a Tom Cruise look-a-like!

- Coyote_6, Ryland Craze, Keith Black and 1 other

-

4

4

-

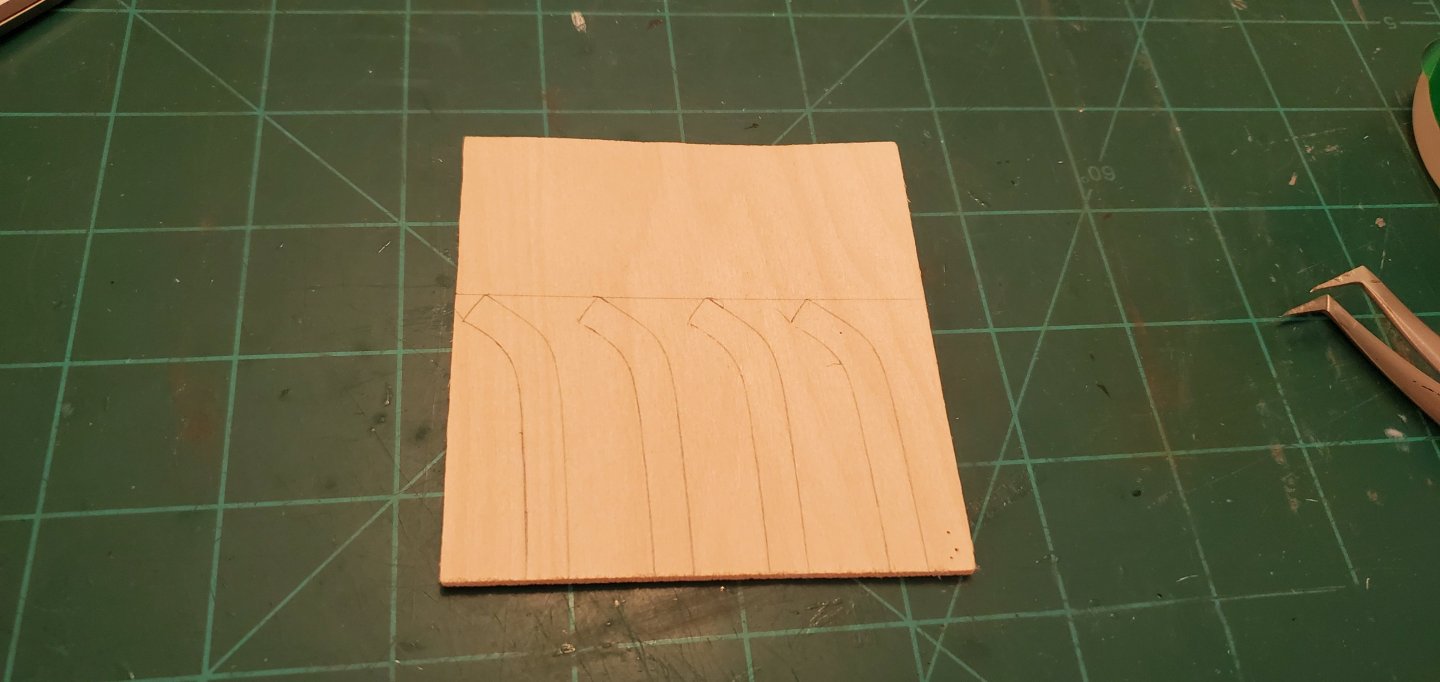

It's probably fixing to start snowing here in central Texas because I actually thought a couple of steps in advance on this project. When I was bending layers for the hull, I realized I would need a matching bend for the bulwark and the oarsmen platform on each side of the ship. So I bent some extra layers along with all the ones I needed for the hull. Snow and me thinking in advance don't happen very often around here.

Here's the bulwark in work. I took one of my bent extra hull layers, drew the outline for the bulwark, sanded the outside to shape, cut out the inside, and smoothed everything out. You may also notice the odd deck planks that run perpendicular to the centerline of the ship.

Next was the oarsmen platforms.

Trying to decide what to do next, I figured I'd take on a real challenge (for me anyway) - making the ornamental bow and stern shapes. I'm not sure what you would call them. The one on the bow is not exactly a figurehead. So if anyone knows the proper terms, please educate us.

For the bow and stern ornamental things, I needed some very thin wood. On @Keith Black's Lula log, he used some 1/64" birch plywood from Midwest Products for some of his tiny furniture. I thought that might be just what I needed so I ordered a sheet. It got here yesterday and I found it to be a really good product.

I decided to start with the harder of the 2 shapes - the bow. I drew out the shape on the plywood and used scissors to cut off a squarish piece around the outline. Then I used a cordless handheld Dremel-like tool to carve the intricacies. It was very delicate work because the plywood is so thin, but it did not splinter or delaminate. The only downside I found was it created a lot of fuzz on the edges. But I can deal with that. I'm happy with the plywood product and how the bow pieces turned out.

These pieces make the hull structure way too tall to fit into the bottle's opening, so they will have to be affixed to the ship inside the bottle. There is also a windlass of sorts that fits between the 2 pieces. So I'll probably use it to connect the 2 pieces first, then install as a single sub-assembly. Uh oh. I think it's starting to snow again outside.

-

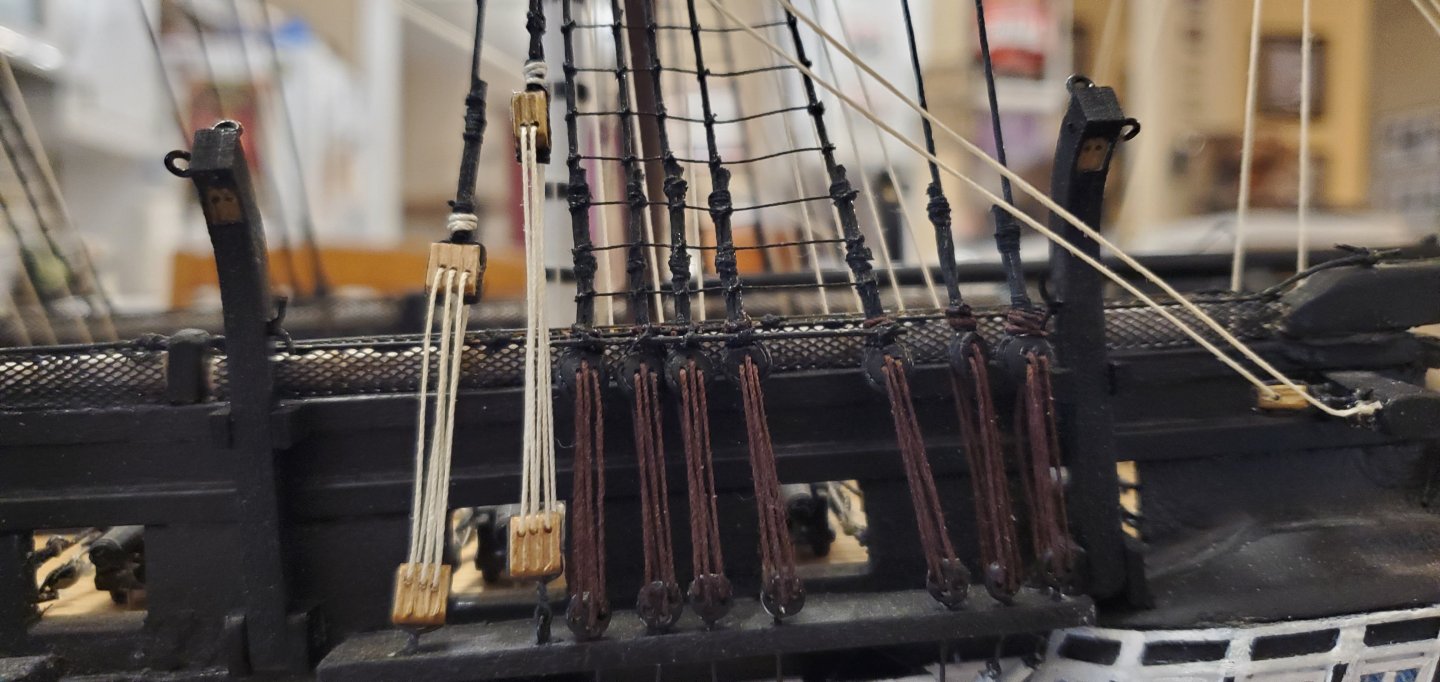

I snuck back over here and got a little more work done on the Constitution. The next thing on my list was the quarter davits - a fairly simple process. I drew them out on 1/4" thick basswood and cut them to shape.

The instructions called for mortising a double block into the davit near the top end.

Next was adding a hinge at the base and an eyebolt on top. Then painting.

I also needed to add a cleat to the side of each davit. The original builder had already made and installed some cleats on other parts of the ship. It looked like he made them out of 2 bent pieces of wire. I liked the way they looked so I decided to do try the same thing. I took some .02" diameter music wire, bent the ends to shape, and soldered together.

And here are the quarter davits completed and installed.

- gsdpic, tmj, JacquesCousteau and 10 others

-

13

13

-

That rigging is looking really good!

- Keith Black and Knocklouder

-

1

1

-

1

1

-

Nice, Ian! I found a video of what I'm pretty sure is a Texas penguin. He walks on ice and snow about as well as we drive on ice and snow down here!

https://youtube.com/shorts/n9Fw2xrlszA?si=AXD9M3g5MM3Y-KTg

- Keith Black, Kenchington, Knocklouder and 3 others

-

2

2

-

4

4

Golden Hind 1578 by Knocklouder - FINISHED - Airfix - 1:72 - PLASTIC

in - Kit build logs for subjects built from 1501 - 1750

Posted

Dang, Bob! I show up less than 2 weeks late and you're almost done with the thing! Warp speed.

Looks great. Your paint job is fantastic.