-

Posts

3,173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Calculating rope thickness (Fictional ship)

Gregory replied to Harry12's topic in Masting, rigging and sails

If you are able to enter data, then you would have entered your scale on the strt page. With this in mind, all measurements you enter would be full size. -

I got the little 8mm blade. Want to see if it helps making molding strips and other details, and because it's hard to resist pretty little tools.

-

@gwish Thanks, you just cost me a hundred bucks.. Couldn't resist..😁

-

Don't want to clutter up your log, but how did you get the elephant and lion shots? Are they telephoto? In any event, they are stunning!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You can use a tumbler like the Block Buster. I have my own little version that works better for me.. I have a pretty good stash of Chuck's blocks so I wouldn't go to the trouble of making the kit blocks work these days. But there was a time when it was all the kit builder had. Of course there are some kits like Vanguard, that come with pretty decent blocks.

-

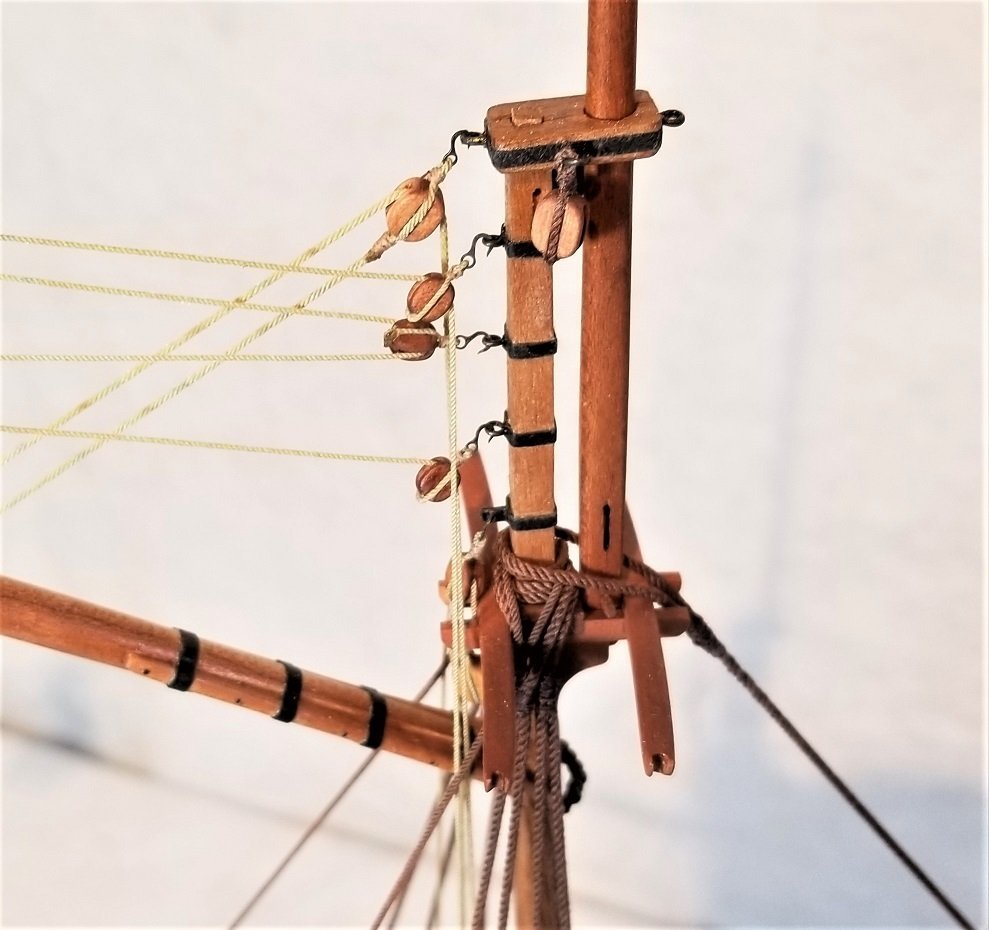

I've stained those 'bargain' blocks with Fiebing's Leather Dye.. I'm satisfied with results.. You can see I ended up with some variation, but i think that image is light overall, because my rope is darker than seen in the image. Just a note, based on another user's experience. If you use shellac on the rope and block after it is in place, the dye can leach out into the rope..

-

-

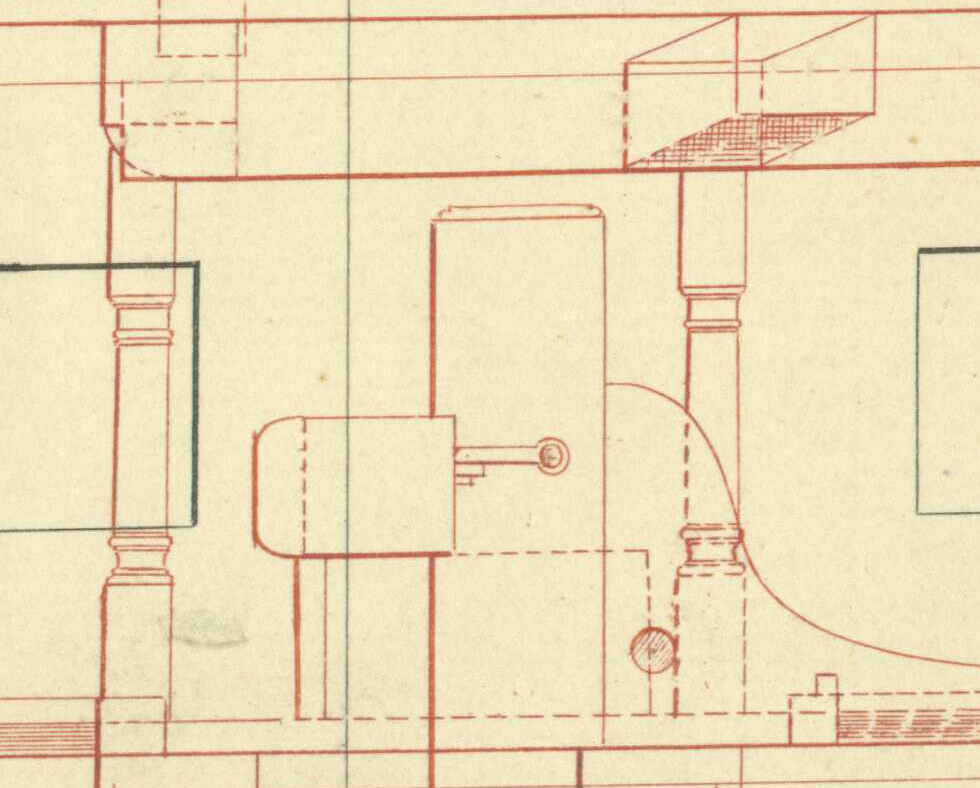

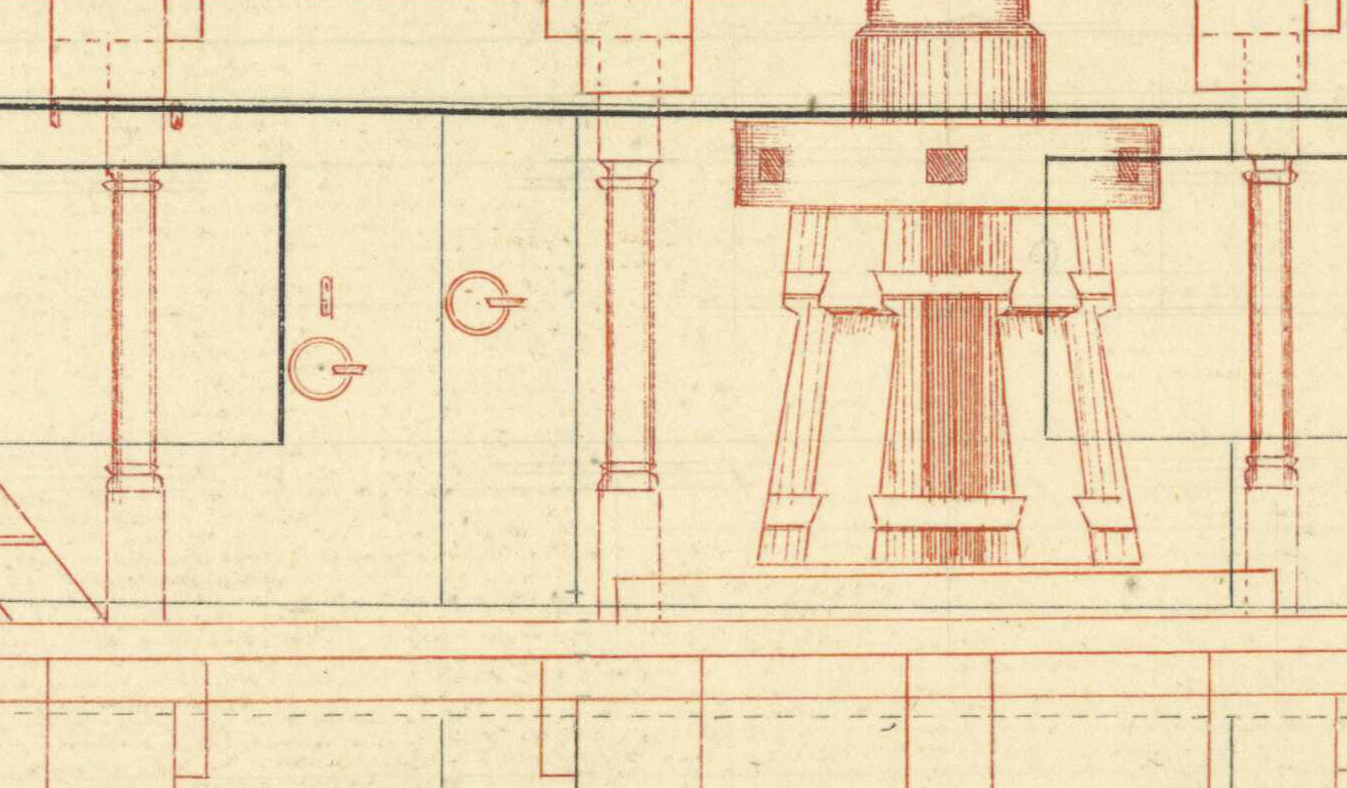

Just to keep the discussion going. Here is a draught of " 'Dorsetshire' (1757) Scale: 1:48. Plan showing the capstans, lanterns, turned columns, A snip from that drawing. Did someone not follow the 1750 establishments? 😁 Medea 1778 One More: Prudent 1768 . The shading would seem to indicate the centers are turned. P.S. I realize, without further evidence, we cannot assume the ship was built as drawn.

-

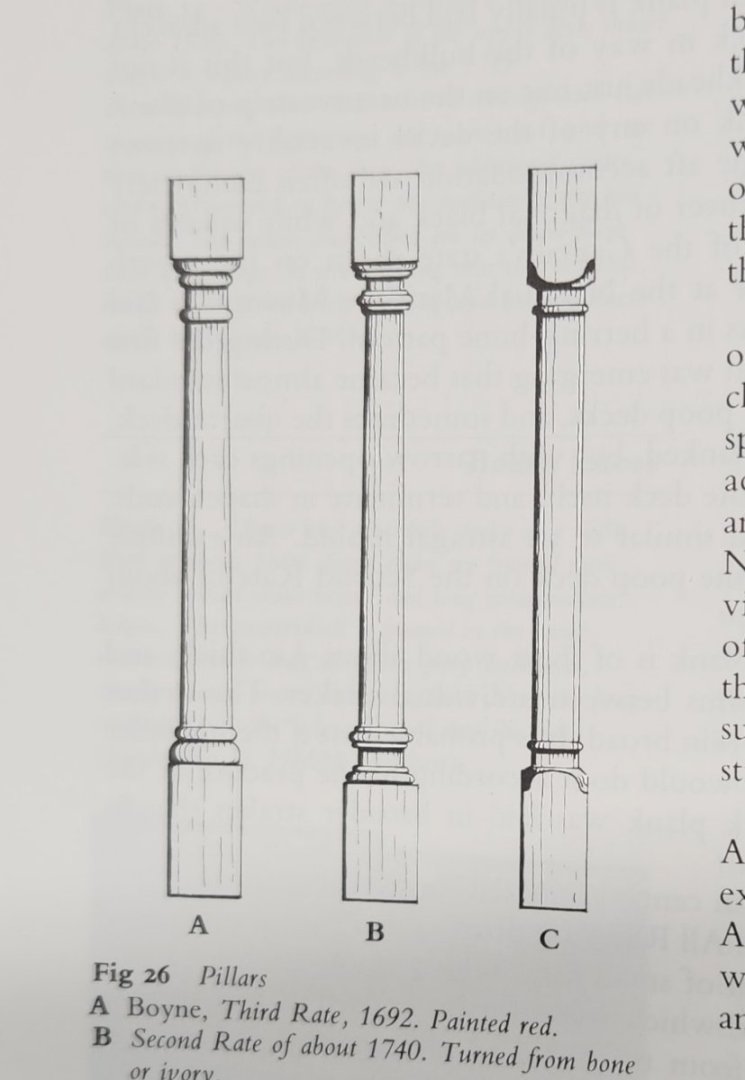

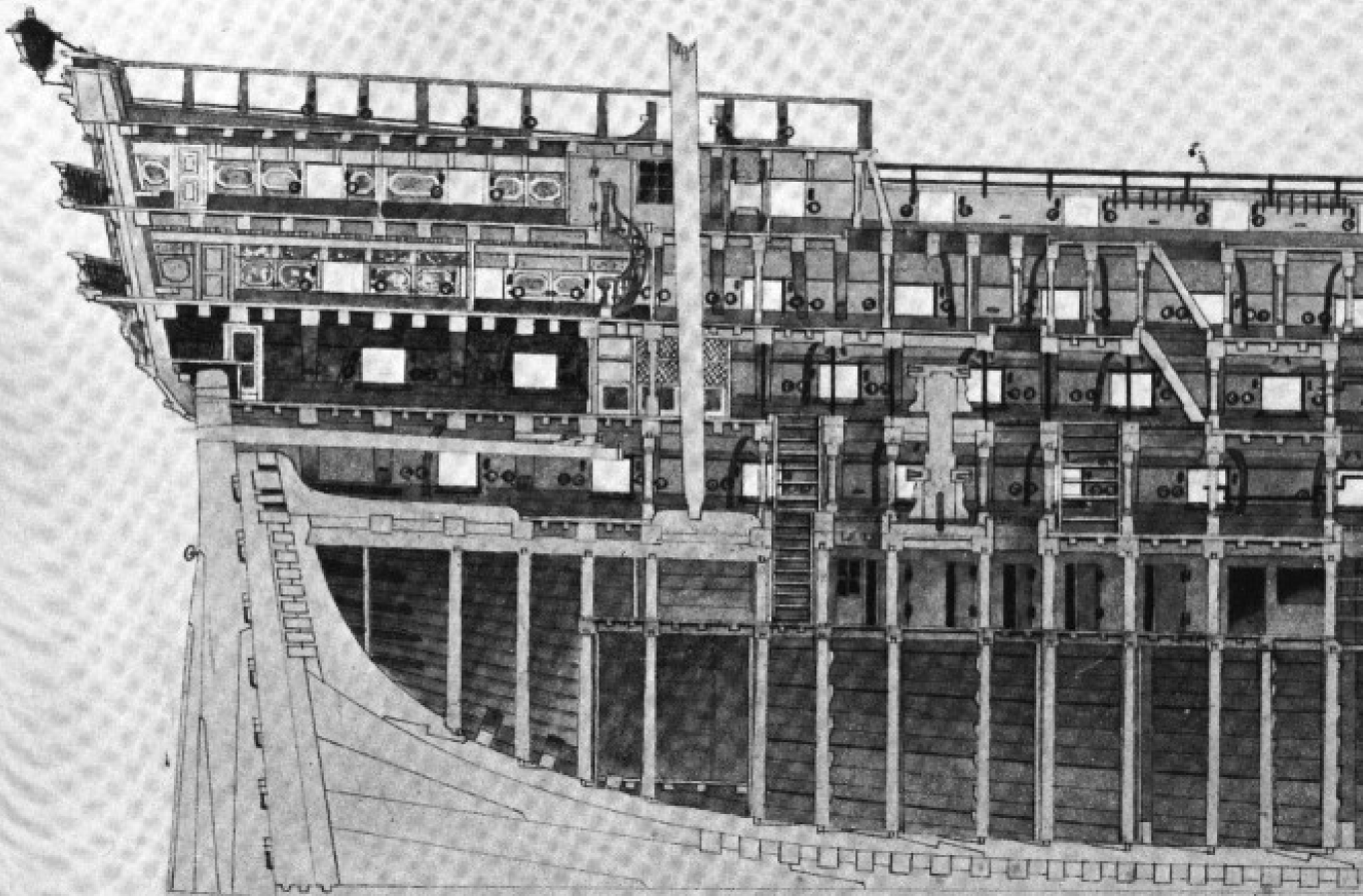

Chamfering the corners would not reduce the square diameter from 16" to 13". Besides, you would now have an octagon and not a square. Are octagonal pillars described anywhere for these ships? Are "square" pillars found in any contemporary drawings? This is an illustration from " Navy Board Ship models". Of course it doesn't prove anything about Victory during the time in question, however in the absence of contemporary drawings to the contrary, I think McKay's opinion is as good as any. P.S. Here is an illustration from Lavery of " Early 19th Century First Rate " .. I guess those pillars could be square, but they don't give that impression.

-

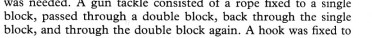

The AOTS Blandford also shows double + single for 6 pounders. I guess Goodwin didn't read Caruana.😁 Lavery in " The Arming and Fitting, etc... " .. without regard to caliber. Takakjian in AOTS 'Essex' shows double + single for 12 pounder. Was Caruana's data part of the establishments? Did armorers always follow this practice? Double + single has become a modeling convention, particularly with kits, and most builders will never be shown anything to the contrary until after they have done all the work. ( ....hours of fiddly work. ) I agree with Thukydides that the aesthetics come into play with ship models, in many areas that are contrary to contemporary full size practice. With that said, Thukydides, your Alert sets a high standard in ship modeling. I apologize if I have cluttered up your log with this distraction.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Construction of Masts for 18th Century 'Ships of the Line'

Gregory replied to tmj's topic in Nautical/Naval History

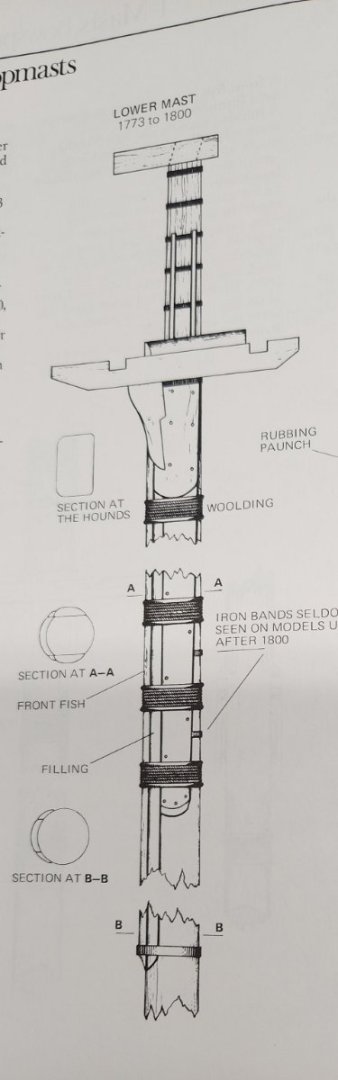

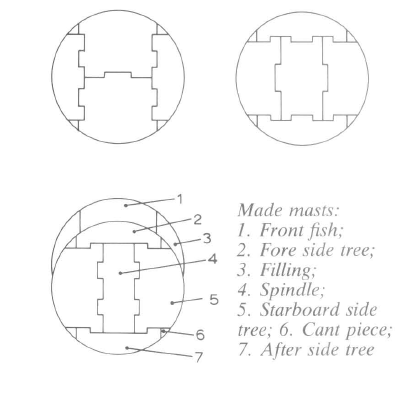

When you say " how", do you mean tools and methods, or just design? Lees shows a lower mast from 1773 to 1800. Note the sections. Mondfeld shows the cross section of a made mast, but there would be little point and somewhat challenging, in trying trying to model this type of construction, unless you wanted to score some lines along the mast to to represent the pieces used. For more details you could get a copy of James Lees The Masting and Rigging of English Ships of War, 1625-1860 or Historic Ship Models by Wolfram zu Mondfeld. The Anatomy of Nelson's Ships by Longridge is also a good modeling reference for Victory. -

Timber-framed outdoor kitchen - Cathead - 1:1 scale

Gregory replied to Cathead's topic in Non-ship/categorised builds

How long does that cedar stay aromatic? One of my favorite scents... -

Books to learn Fusion 360

Gregory replied to allanyed's topic in CAD and 3D Modelling/Drafting Plans with Software

Do you have any links for the YouTube tutorials for Fusion360 based on the drawings in this book. I could not find any. All the videos I see are for AutoCAD The book says: In fact, it provides no instructions at all for using the interface of Fusion360 It is just a collection of CAD drawings with the dimensions. It really does not look very useful for learning Fusion 360. -

Interesting knot tying gizmo.

Gregory replied to Bob Cleek's topic in Modeling tools and Workshop Equipment

Good find.. looks interesting. Here is a three pack at Amazon for $8.99 I saw one for as little as $2.99 , but delivery takes a bit longer.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.