-

Posts

3,172 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

I got those from Crafty Sailor, but he may have stocking issues because I believe they came from Russia.. Won't hurt to check, cause I could be wrong.

-

Archaeological Evidence for the Development of RN Gunnery

Gregory replied to Steve20's topic in Nautical/Naval History

There is gravity, and then there is inertia.... -

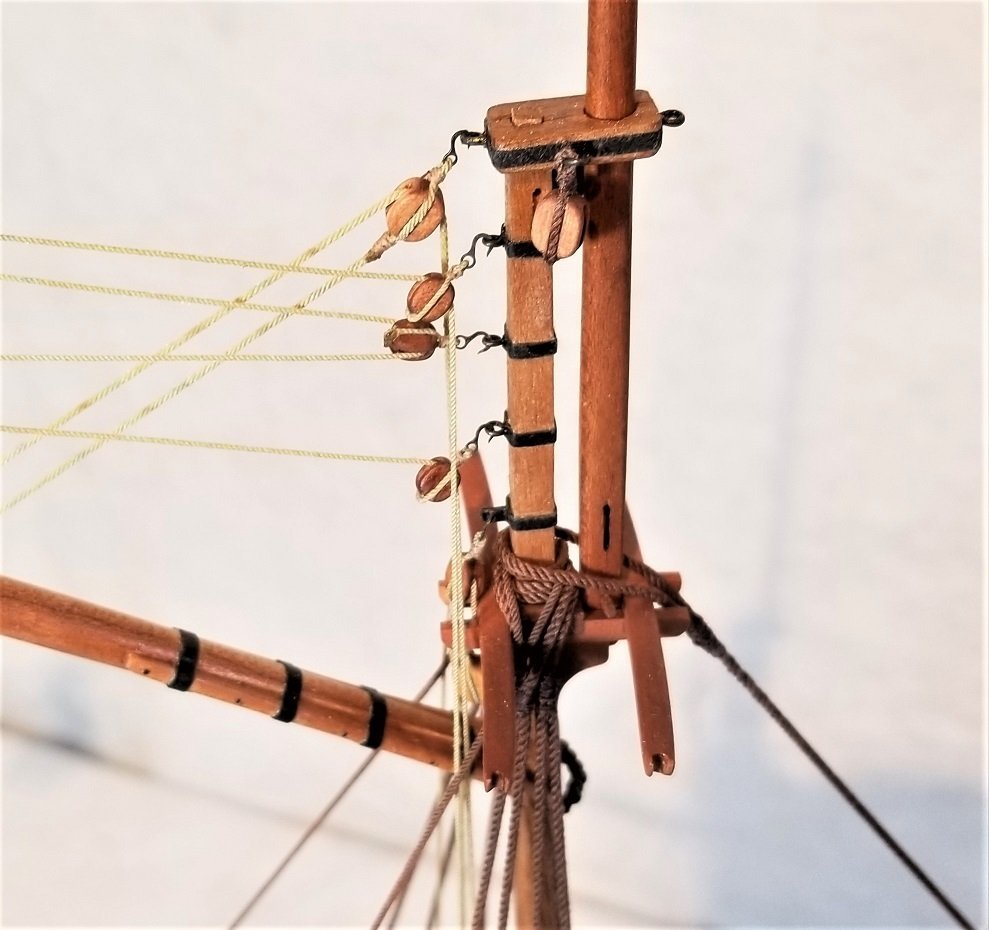

I'm with twokidsnosleep. They take a little getting used to. They have a nice aged look rather than the bright look of untreated blocks. I used Fiebing' for these blocks. There is some variation, because the blocks were from mixed batches I got from Syren. Try rubbing them down with some satin poly thats been thinned 50/50 with mineral spirits.

-

This size chart from Syren is a pretty good way to get you in the ball park. https://syrenshipmodelcompany.com/resources/Suren Ultra Scale Rope Size chart.pdf

-

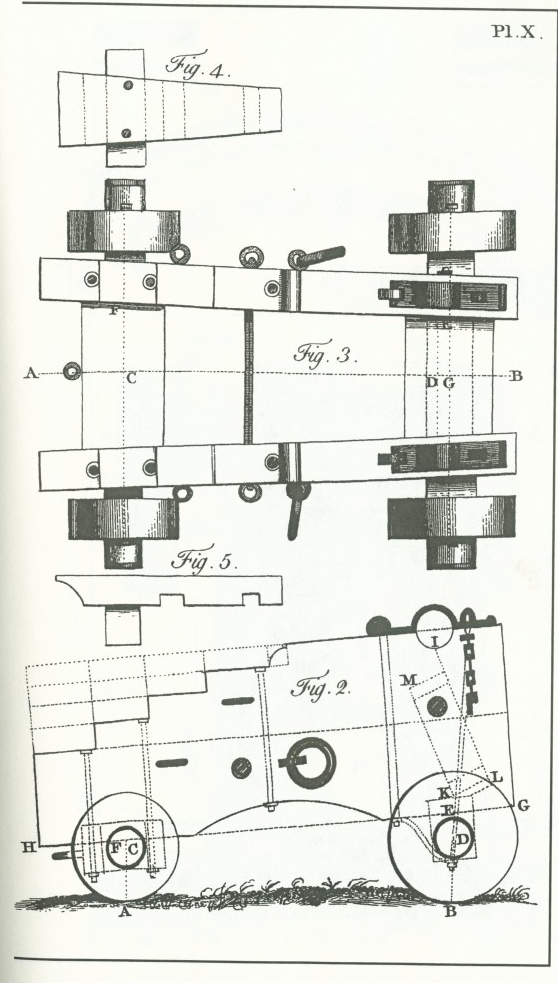

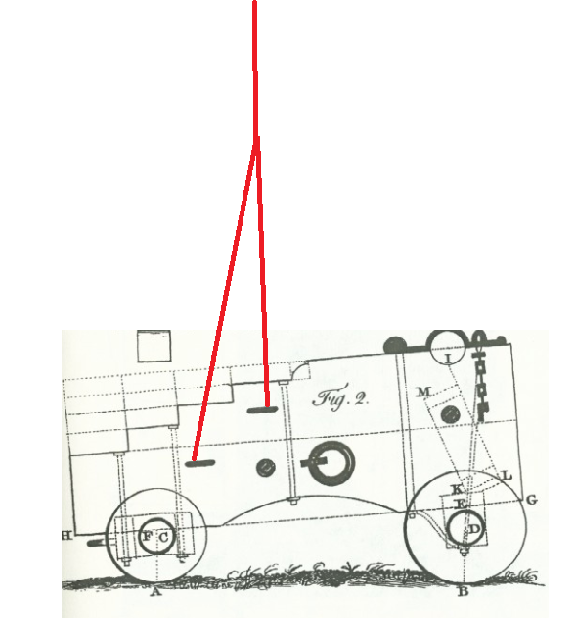

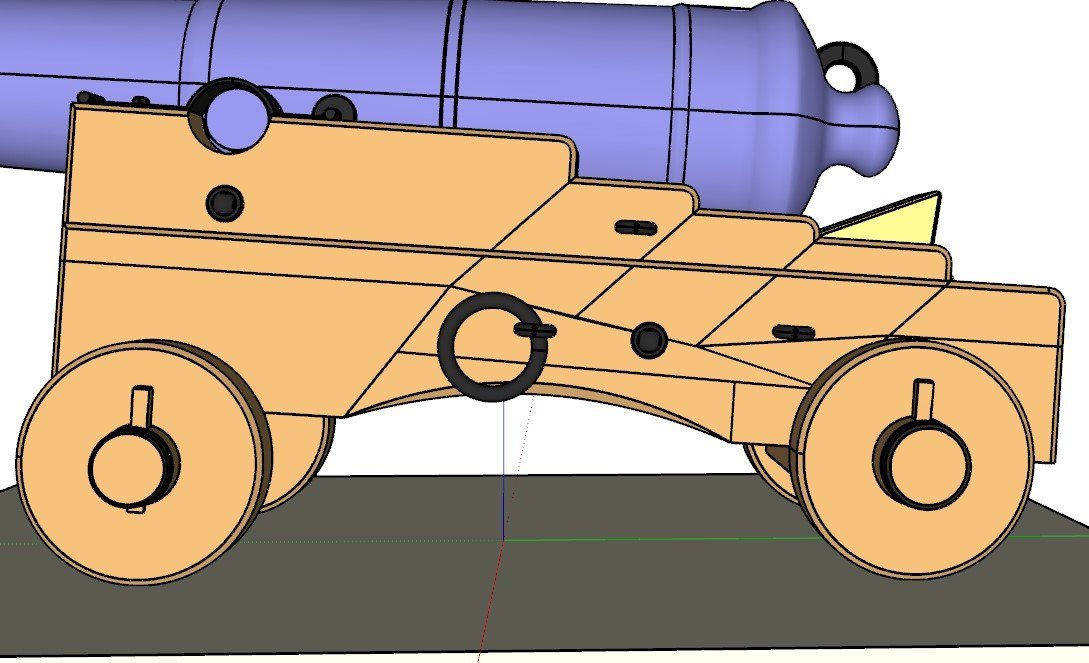

Allan, the replica is clearly not rigged for action , but the question still remains about the circled eyebolt. It is shown on contemporary drawings and is present on the artifact shown above, but we can't seem to find any reference for it's purpose. My best guess is that it may have been used for moving off of, and onto the ship. The two points of connection would have provided more stability. Of course there would be any number of ways to rig a harness for moving, but the two eyebolts would offer a quick solution using hooks. Can anyone find a picture of a carriage being loaded onto a ship? The only pictures I can find are just the barrel.

-

Eagle Emblem

Gregory replied to _SalD_'s topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I wonder about the source of Sal's image in the OP. Chances are it is a mirror image. I noticed the orientation of the arrows and the olive branch are reversed from what is commonly seen. That said, I think the orientation of the wings is Sal's primary concern. -

Because it would up the cost of production in a kit, just to include useful information or detail that is going to be ignored by the builder. Most kit builders are not as detail conscious as the members at MSW, and kit manufacturers are not going to go to extra expense to include those details. The guys who really care are the members here, and they can count on guys like you for information to take their build to the next level.😁

-

Eagle Emblem

Gregory replied to _SalD_'s topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Henry, the 'presidential eagle' was my example of a Google search. I think Sal is needing the eagle from the Great Seal, but with the wings oriented downward. I just did a search for 'federal eagle' and did come up with this: I'm just not seeing the Great Seal with the shield on the chest and the banner in the beak with the wings oriented downward. Mabey a graphics wiz could combine two or more images to get Sal what he is looking for. -

Decorative trim/rail

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

No kit was getting those features ( headrails ,etc. ) right until Chuck came along.. Vanguard is making some very respectable stuff. I'm hoping to get up to speed in Fusion360 and create some respectable parts on my own with CNC.. I'm spending more time on method, than I am on ship building. Maybe I will get to a point where I can help someone out with their kits, but I'm not really interested in doing any full-time production stuff. -

Eagle Emblem

Gregory replied to _SalD_'s topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

https://www.google.com/search?q=presidential+eagle&tbm=isch&sa=X&ved=2ahUKEwjRquHD9_L-AhVclGoFHeXgAxAQ0pQJegQICxAB&biw=1920&bih=1097&dpr=1 -

Decorative trim/rail

Gregory replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Dave, the scrolls in the image you provided are part of the hair brackets, extensions of the cheeks, which are quite different than the typical moldings running the length of the ship, which are similar to the brass pieces you show. Here is a reference from Chuck's Winchelsea which shows how they are built up from lase cut parts. It might not be too difficult to make similar parts from scratch. The rail caps may end in a scroll, but the molding pattern is still somewhat diffierent than your brass pieces. I apologize if I am not understanding what you wish to accomplish. -

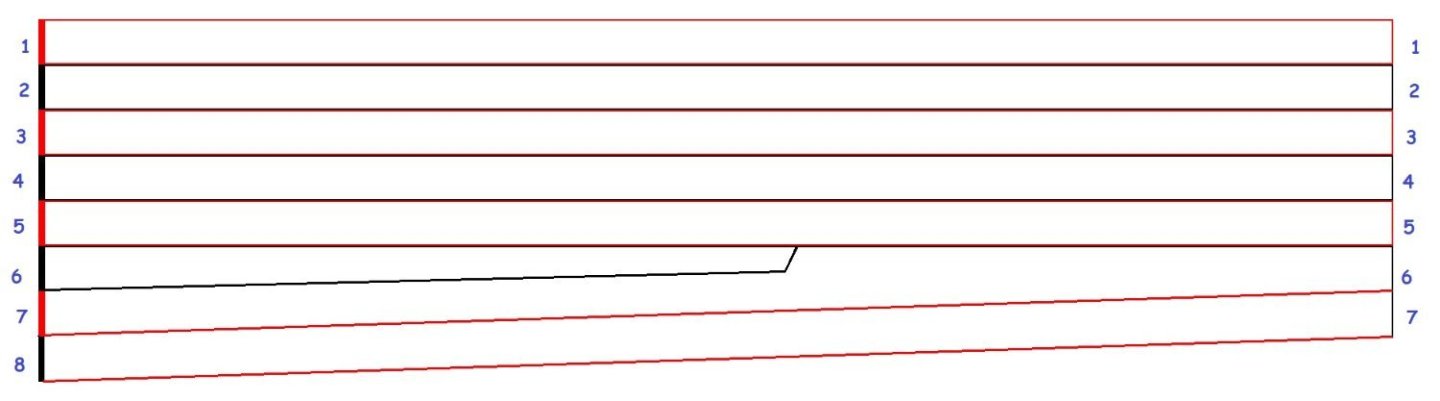

It would be hard for me to comment on the drop plank at the bow. The drop plank helps to keep the taper from being too profound. You want to avoid getting the width less than 1/2 the original width. It looks to me that your tapering looks consistent with a good appearance. For the stern, I agree consistent width looks better, but at this point, no drop plank would give you a plank tapered to 4.375 mm, which i think would look OK I think it is up to you. Once it is all finished smooth and oiled, or whatever finish you choose, I think it will look good either way.

-

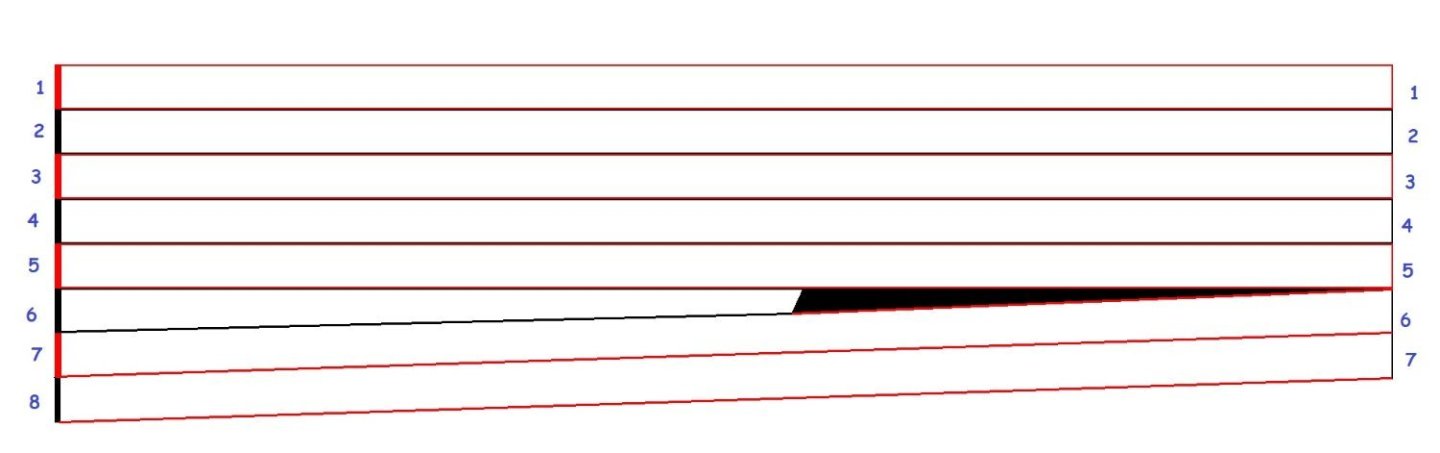

Here are some ideas. I was messed up on my math for the stern problem. 3.5cm Means you need 7 x 5mm planks to fill the space. You can do this with a drop plank. The possible issue with this design, is you need stock that is wider than 5mm. There are a couple ( or more ) ways you can approach this. Here are two possibilities. A filler piece like this that you blend in as well as you can. ...or like this. Again, matching up the wood as best you can. I hope this helps. Gregory

-

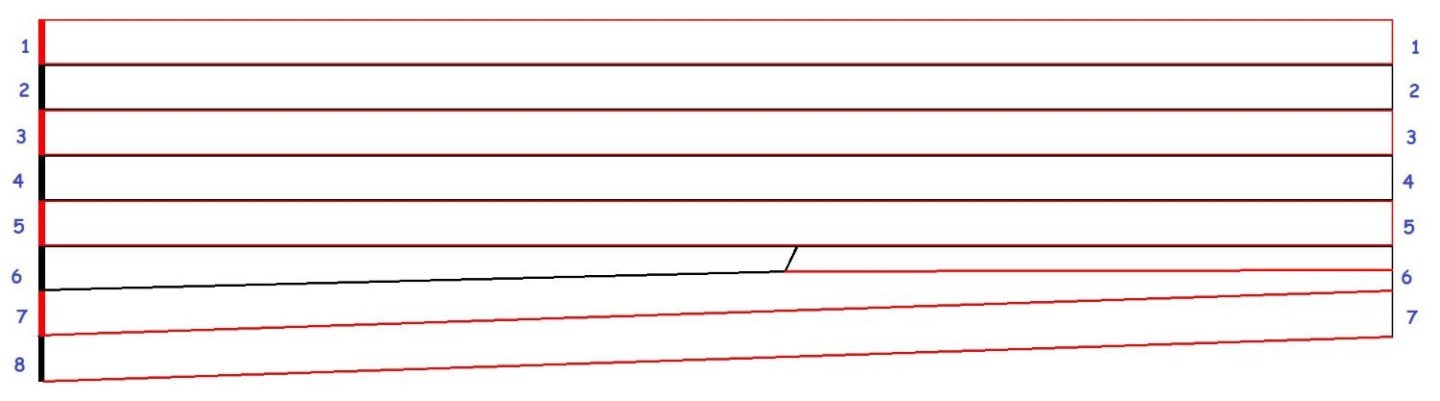

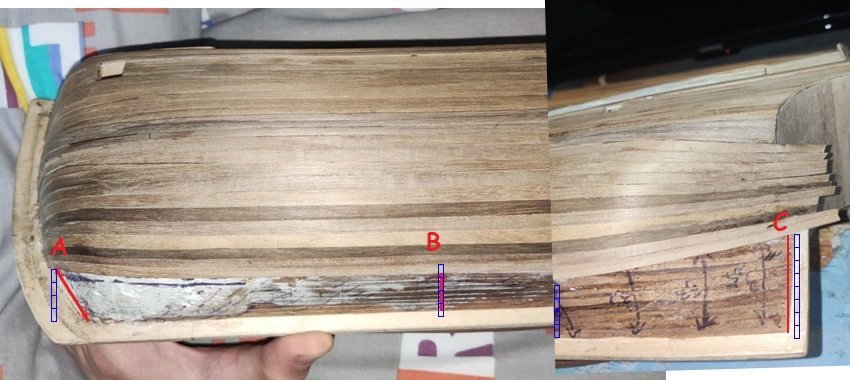

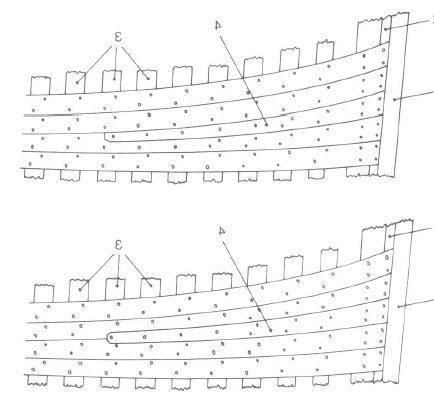

Here is what I have for you so far. Without knowing the measurements at A, B & C I cannot say what kind of stealers and or drop planks you may need. How many full width planks can you place at B, or will the space divide evenly by 5? You may need a stealer at A rather than a drop plank, or you may not need any. If C is twice the distance at B you would need 8 stealers to fill the space, as a stealer replaces 1 plank with 2. A drop plank reduces 2 planks to one. From Mondfeld. Your stern would look like this if you had to turn 4 strakes into 8 to fill the gap. ( It would be done without the sharp points ) It may be difficult at this stage of the planking to make these corrections without removing some of the planks

-

HMS Victory Renovation - Outer Planking Removed

Gregory replied to Steve20's topic in Nautical/Naval History

I heard from somewhere that the forests of Britain were wiped out during the Golden age of sail. -

Stern stealers do not seem to be very common on contemporary or scratch models. The builders just widen the planks as necessary. With kits this is not possible because there is no material for wider planks. Therefore one or more stealers will be necessary approaching the steepest. To approximate a planking expansion for this model, I would need the following information: The width of your planking stock The distance from the keel to the top of the sternpost The distance from the keel to the bottom of the Wales at a midship bulkhead. This is an actual measurement, not just the vertical distance. Also, the measurement from the keel at the turn of the stem, up to the bottom of the Wales. If this is not clear, I will try to provide a diagram later.

-

The documents and many examples on this forum ( Look at the Cheerful and Winchelsea build logs ) are the best references we have. They are as clear and detailed as it gets. The primary concern is measuring the space available for the number of strakes, and yes, stealer or drop planks might be of help. I know you said you have read everything, but you might take another look at this: https://modelshipworldforum.com/resources/Framing_and_Planking/Lining Off your hull for planking.pdf

-

I particularly like the way the actual carriage shows how countersunk the eyebolts are and the washers under the through-bolts. The eyebolt for the breach rope ring also has an interesting shape, in that it is squared off to some extent and the ring fits fairly tight in the bolt. Those are some details to consider when modeling gun carriages. FWIW Your picture sparked some interest, and Googling for that image led me to: https://maritimearchaeologyprogramdenmark.wordpress.com/2010/01/06/guns-in-3d/ They have a 3D model for Rhino and Sketchup. I have neither program, so I downloaded the trial for Sketchup just to look at the model and have some details for future reference.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.