-

Posts

3,175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Is there an easy wooden tall ship out there to build?

Gregory replied to thegrindre's topic in Wood ship model kits

Any wood ship model kit is going to be complex.. But the way to keep it as simple as possible, is to reduce the armament, and reduce the rigging.. Just to get a feel for the wood kit building process, you might start with something like one of these kits from Model Expo: LOWELL GRAND BANKS DORY WITH TOOLS 1:24 SCALE It's currently bundled with a nice little tool set. Only $49 MODEL SHIPWAYS MS1457 18TH CENTURY LONGBOAT You would get a feel for how fast the building process is, then come back for ideas about a bigger, more complex project. There should be a build log or two for the kits mentioned, and you can see how others did. -

You're off to a great start.. How much experience do you have with wood ship models?

- 29 replies

-

- constructo

- prince

-

(and 1 more)

Tagged with:

-

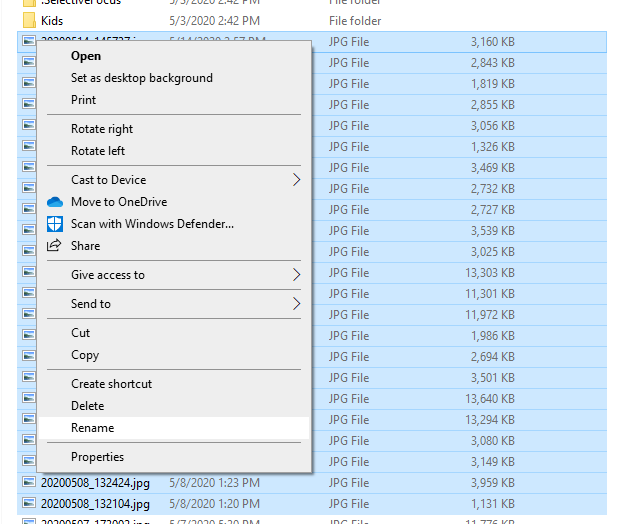

Just another little nit pick: It would be nice if modelers would consider renaming their pics before uploading them. Seeing a lot of " 20200504_152930.jpg " & etc. is distracting. In Windows, you can rename a batch of pictures by highlighting all of them, right-click to rename- and give them something short and sweet like " Schooner ", And they will all be named " Schooner(1) , Schooner(2) etc.. Just a thought..

-

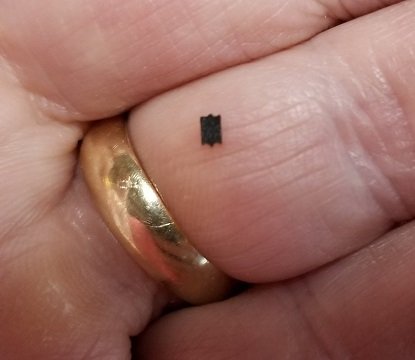

Finished up my quarterdeck bulkhead project. The scrap pile grew considerably while refining this.. The cupola, also inspired by Greg Herbert and David Antscherl's Speedwell, was more challenging for me than I expected. Still trying to avoid paint, I settled on a wood mold that I covered with copper leaf.. The patina was created by enclosing the part in a sandwich bag with a chopped boiled egg.. Go figure... What to do next.. Capping rail? Tiller ? Cannon? I have already fiddled a bit with all of those.. Now to get it done...

-

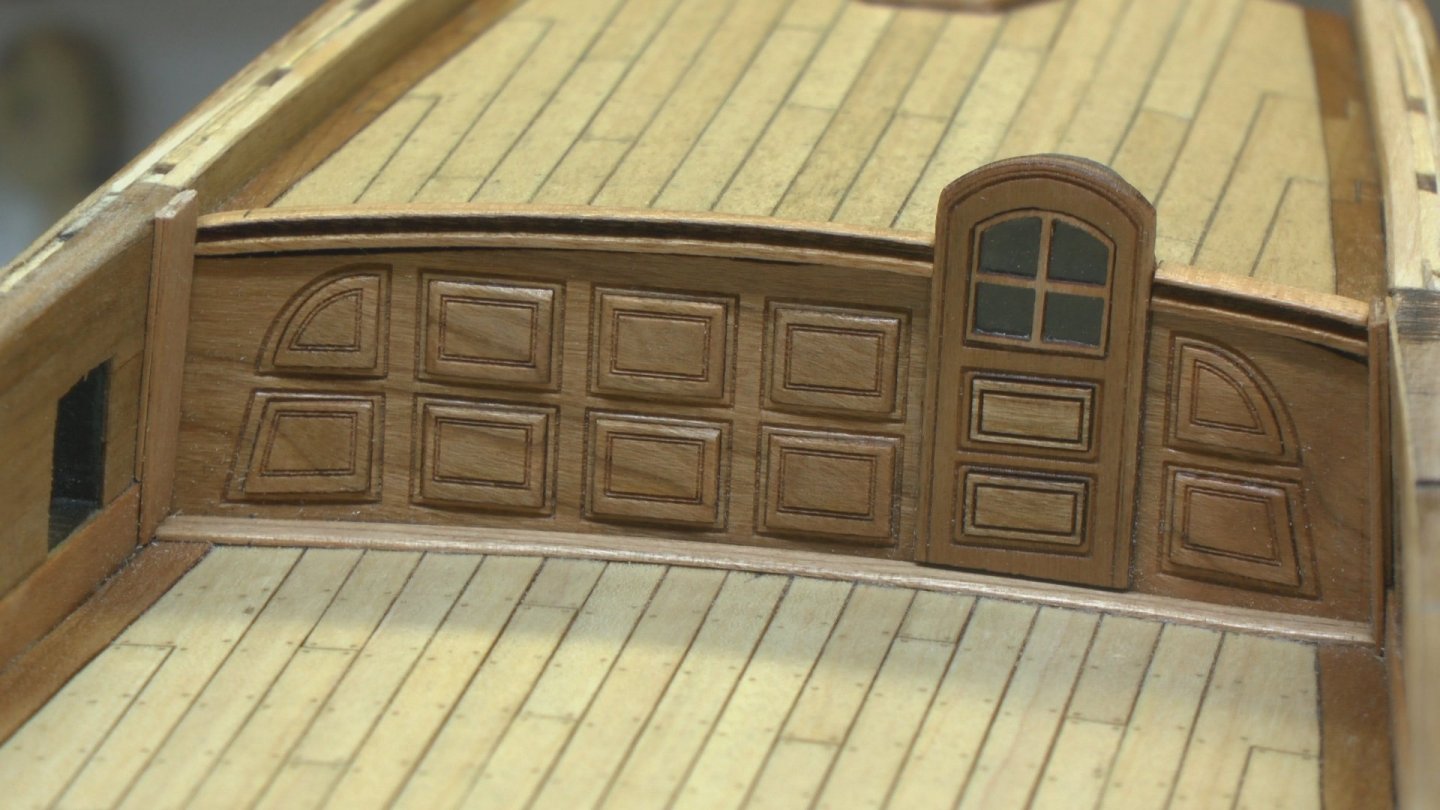

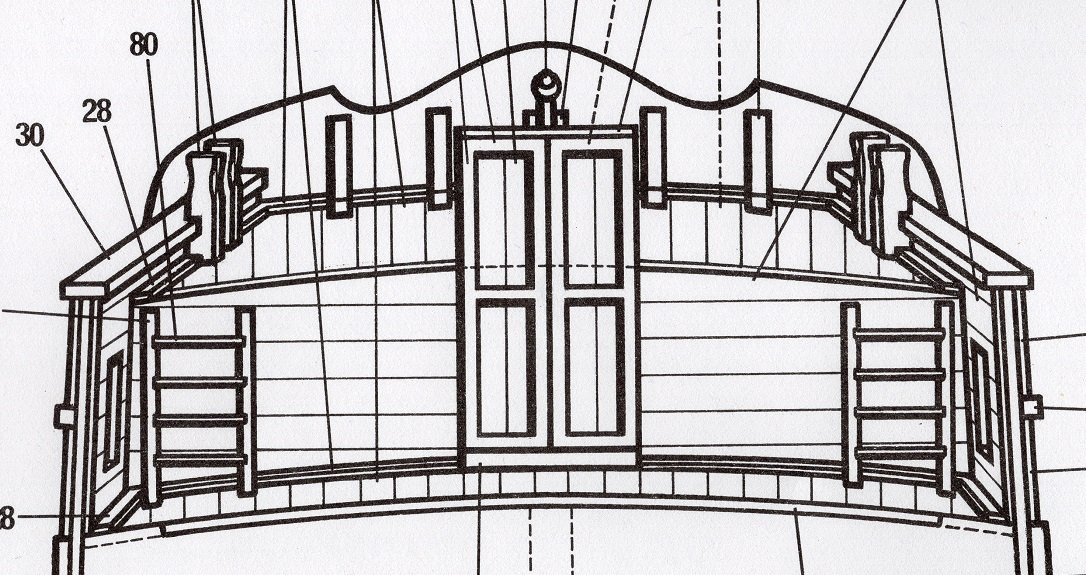

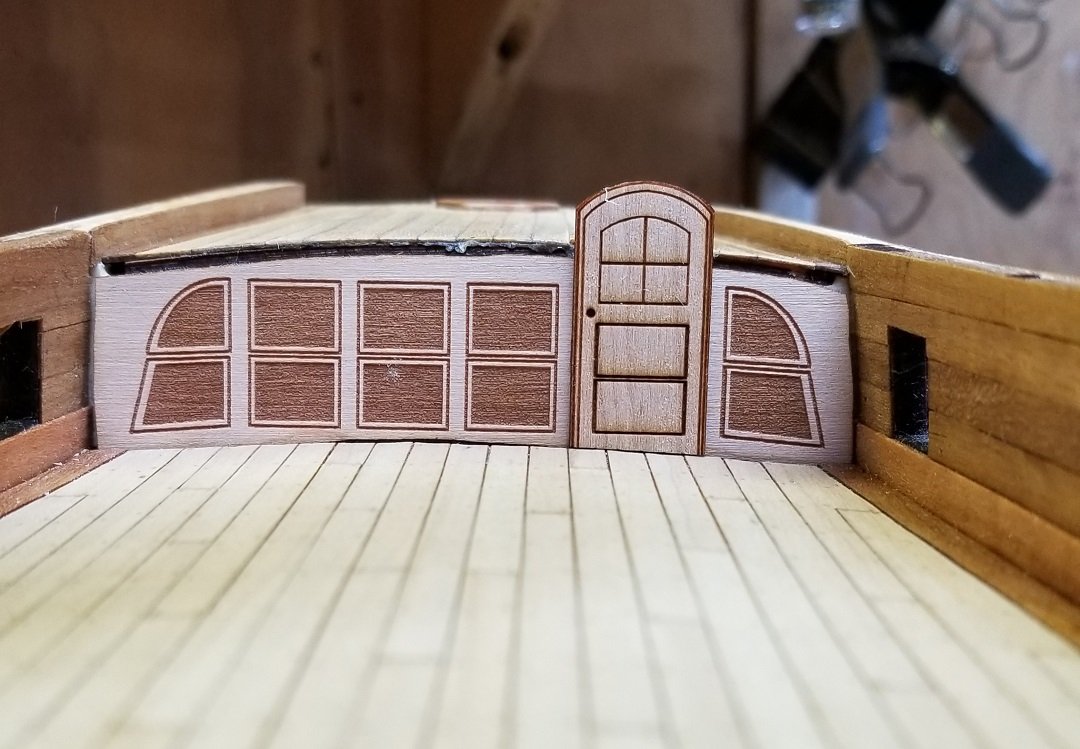

One of the detail projects.. The kit plans show an unlikely door to the great cabin. Scaled from over 7 feet, it seems there was some misunderstanding about the average height back then, or even now. Here is my prototype for the bulkhead and door. I borrowed some dimension ideas from Greg Herbert and David Antscherl's Speedwell , where I calculated the door height to be about 4'7". Stooping a bit as you step down, would seem to be the order of the day. I plan on refining this a bit more and will present the final design later.

-

I think you will find most of the CNC work in the scratch build topics. I think the biggest challenge for kit builders, for me anyway, regarding CNC, is getting the design of the part from the kit plans to a cutting file to drive the machine. This has been true for me with my laser cutter. I have spent more hours than I want, learning to use the software to get the kind of precision and results I want. I have one of those little CNC machines that I haven't got out of the box yet. Instead I went ahead and focused on my laser work, and it has kept me busy enough, that I haven't been in the mood to tackle a new learning project. While most members here are always happy to help, they also want to spend their time building, and not teaching CNC or laser cutting techniques. They may not get past the point where they talk about their $2,000 machine and software that is $100 monthly subscription. A great example of the high end of CNC work is from a member here, HJX, is doing the CNC work for the Winchelsea kit, group project. Your best resources may be another online group that is focused on CNC work. Just because they may not be building model ships, the technique would be the same. Welcome to MSW!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d4295e1ab1b18f537e3435a34ce1151e.jpg)

.jpg.54bd85dbe9945a405707180fc596a2dd.jpg)

.jpg.c3e74fbaf77f77d9324b889fa8910239.jpg)