-

Posts

3,176 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Looking for pre-made sails for Mamoli Britannia

Gregory replied to Bob Lowther's topic in Wood ship model kits

I'm pretty sure Mamoli didn't offer pre-made sails with this kit. Looking at the sails available at Dusek, I do not see any for the Mamoli line. -

Is there a trick to making deadeyes?

Gregory replied to Schooners's topic in Masting, rigging and sails

Looking at the deadeye face on. how should the grain run? -

Very nice work. If I may ask, what is the actual length of the little ship's boat?

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

Is there a trick to making deadeyes?

Gregory replied to Schooners's topic in Masting, rigging and sails

I like this example by dvm27: -

Is there a trick to making deadeyes?

Gregory replied to Schooners's topic in Masting, rigging and sails

Your method I have seen before.. You might consider drilling the holes before shaping the deadeyes.. -

It might be worth the saved effort to use the etched decking on the lower decks, where little if any will be visible on the finished model.. Also, you might consider doing a some fairing of the bulkheads before gluing the framework all together. You will have a much better angle of attack with the bulkheads off the ship..

-

ModelExpo sells the Rattlesnake plans for $35.. They should have more information than the older version, since it sounds like your rigging guide is incomplete. The also have the Master Korabel Long Boat kits

-

The banding certainly doesn't show up in you photos.. I cant imagine anyone calling you on it as a point of contention...

- 97 replies

-

- macedonian

- frigate

-

(and 2 more)

Tagged with:

-

The cannon look really good. No layering sometimes seen with 3D printing..

- 97 replies

-

- macedonian

- frigate

-

(and 2 more)

Tagged with:

-

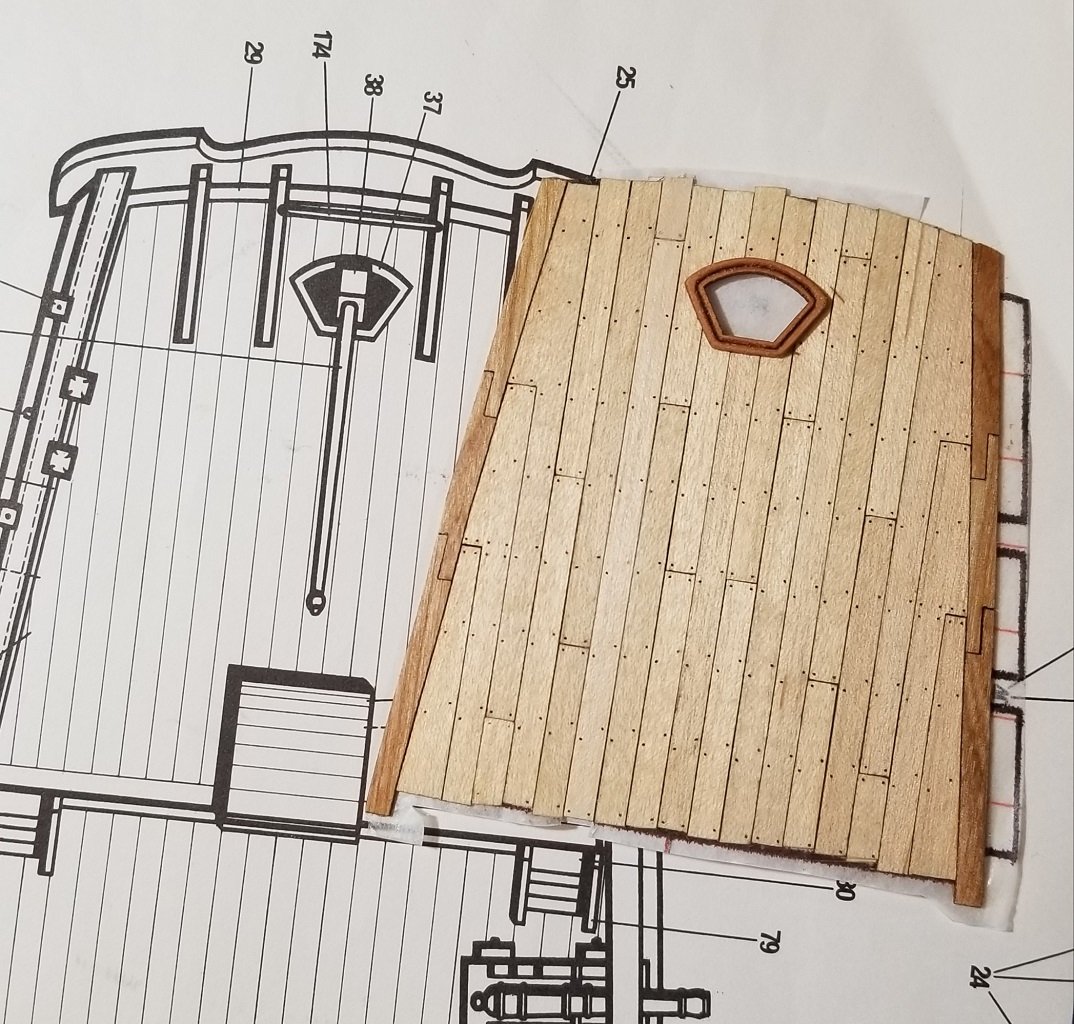

P.S. I have picked up so many tips from the other members here, I may not always remember to give credit where credit is due. With that in mind, I want to say that I got the idea for the scarfed planks near the margin from Chuck's instructions for the USF Confederacy. The instructions for most, if not all of Chucks designs are available for free at Model Expo, and they are an incredible resource for detail work. However, they are a mixed blessing in that they really set the bar high, and make it a little difficult for me to reach a point where I can say " O.K., That's good enough; time to move on.

-

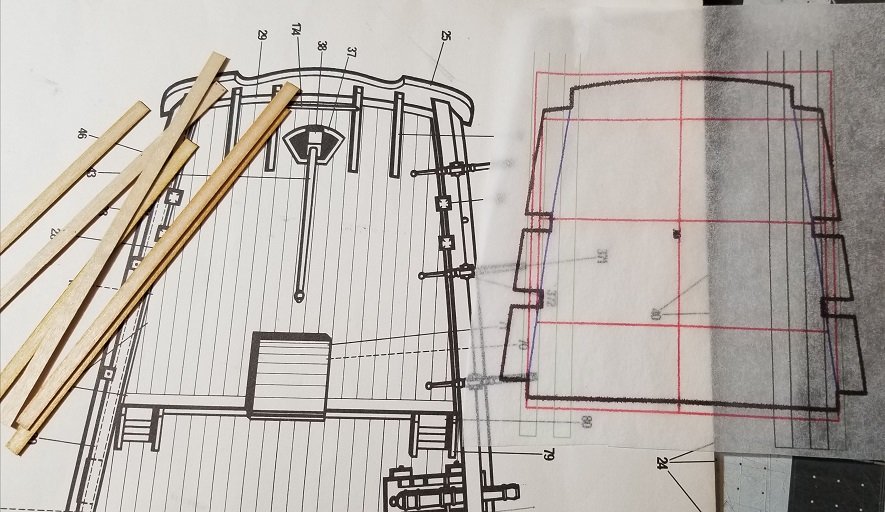

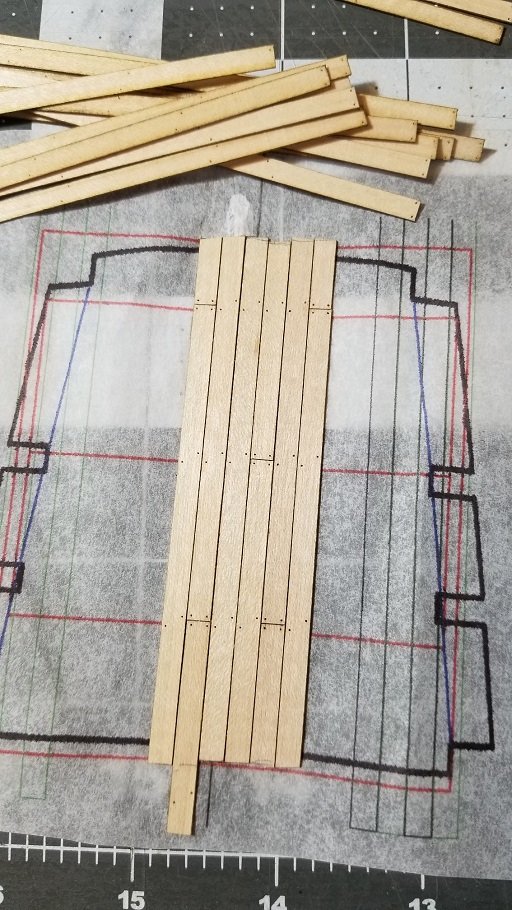

Finished up the quarterdeck planking. If you compare my finished work to the last post, I decided to increase the number of imaginary beams under the quarterdeck. Three would have been unlikely and it made it difficult make the scarfed planks look nailed realistically. It is my understanding that ' nibbing ' wasn't done in the period ( 1711 ) this ship represents, so I shaped the outer planks with hook scarfs to avoid points butting into the margin. As I was finishing this up, I was reminded of why I like to do this off the ship.. I had completed, or thought I had, the work you see above and was applying some poly when I realized I had left out a plank on the left side of the deck. It was obvious after the fact, but I had spent so much time staring at the tree nail pattern, I guess I saw what I wanted to see. Anyway I was able to splice in the missing plank/s with very little effort compared to the problem it would have been if all the planks had been glued onto the false deck. Instead of just splicing in a plank, all of the planks to the left of the missing one, would have to have been ripped out.

-

Great build. Will be one of my go-to's for mentorship.

- 335 replies

-

- alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Don't forget the build log index..

-

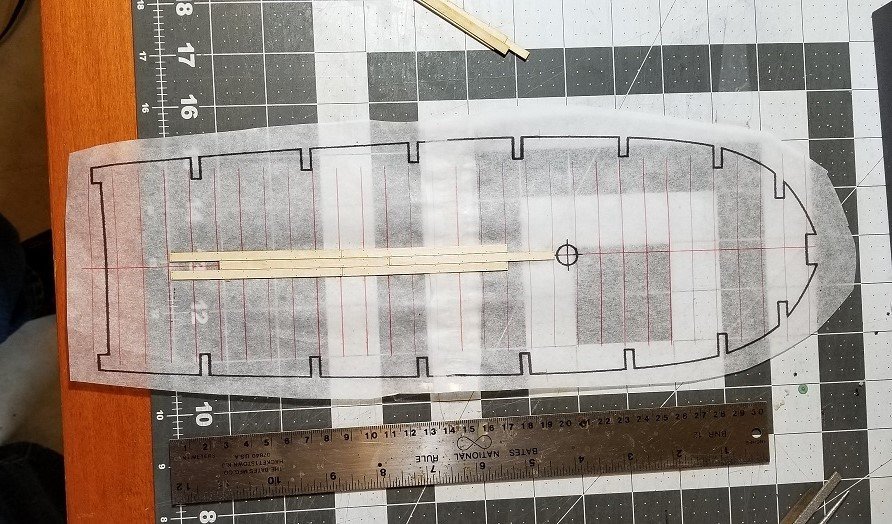

No update for a while but I haven't been entirely idle. I have almost completed the first planking, but it is uglier than I would care to share at the moment.. I have continued work on my gun carriages. Fine tuning the design, and experimenting with different wood, in an effort to come up with a final plan. Meanwhile, I'm still exploring the use of my laser cutter to refine what can be done with this kit. When it comes to planking the deck, I like to do it off of the ship. I print the deck plan on tracing paper, then glue the planks onto the paper. This is a first effort with planks made from maple veneer with my laser cutter. I feel the laser char takes care of the simulated caulking. (.. to be honest, not the first effort, but the first time I'm happy enough to show what I've come up with ) I hope to be showing more progress in the near future. Anyone who has experimented with fabricating their own parts, can probably attest to the amount of time you can spend trying to get it perfect, which never really happens.

-

Miniature Desk-Top Laser-Cutter

Gregory replied to wefalck's topic in Modeling tools and Workshop Equipment

Do you have a lower end 2D photo editing program with layers, such as Photoshop Elements or Corel Paint shop? -

Miniature Desk-Top Laser-Cutter

Gregory replied to wefalck's topic in Modeling tools and Workshop Equipment

Sorry for the confusion.. I was replying to VTHokiEE regarding the laser he linked to on Amazon.. -

Miniature Desk-Top Laser-Cutter

Gregory replied to wefalck's topic in Modeling tools and Workshop Equipment

I have had one of those for a while. They do some serious cutting. ( not metal ) You need to be ready to do a little modification to make it versatile, but you can google " K40 " laser modifications, and see a lot of useful information. I have heard some people having a bad experience with out of the box alignment problems, or not working at all. I was fortunate not to have any problems other than the learning curve. -

Planking diagram

Gregory replied to wefalck's topic in CAD and 3D Modelling/Drafting Plans with Software

Does it actually give you a " flat " rendering on the screen? You could do a screen capture , and do some size tweaking in a drawing program where you have print capabilities.. -

If I recall, all my ModelExpo orders have come by USPS Priority mail. It looks like an 8oz package from Miami to Rhode Island is $8.45 When you figure shipping materials and time spent, $9.95 doesn't seem to be out of line. It sounds like John is being a real nice guy if he's giving you shipping credit..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.