Paul Le Wol

NRG Member-

Posts

1,044 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paul Le Wol

-

Hi rhephner, in the second and third photos it looks like you tapered the second strake that you installed on each side. Whatever you did with those planks continue doing that. Don’t move on to the next plank until you are happy with the one you are working on. Like everyone has stated, check out all the info and don’t give up. Good luck!

-

Jacques, your hardware fabbing is looking great!

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Good going Keith, I would never have thought of that.👍

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

If you don’t have another tool for squaring the end you can cut the number of pieces that you need a little longer, adjust the stop, flip them around and trim them to the size that you need.

-

Hi alspoll, welcome to MSW. That is correct. You have to keep squaring the end of the piece you are cutting from before making another cut.

-

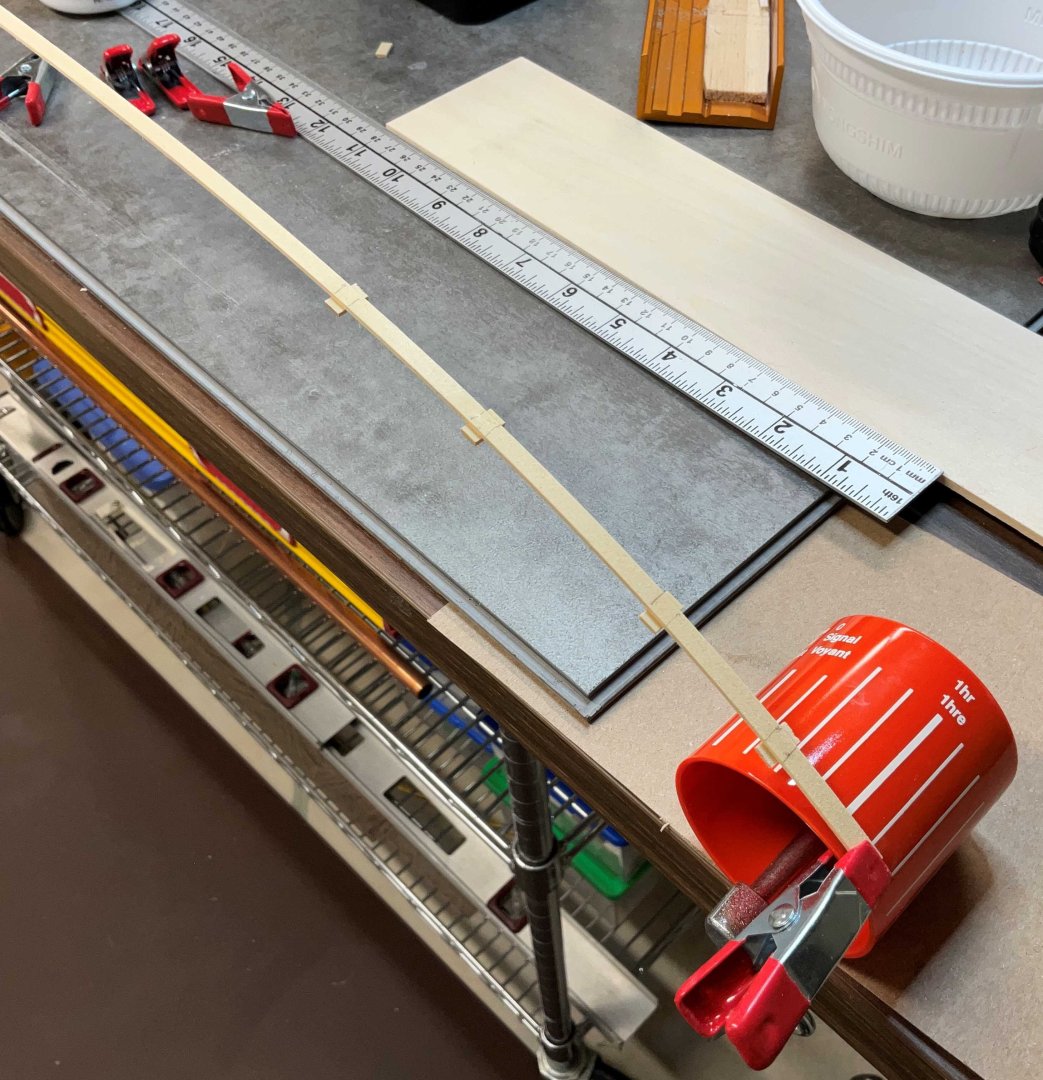

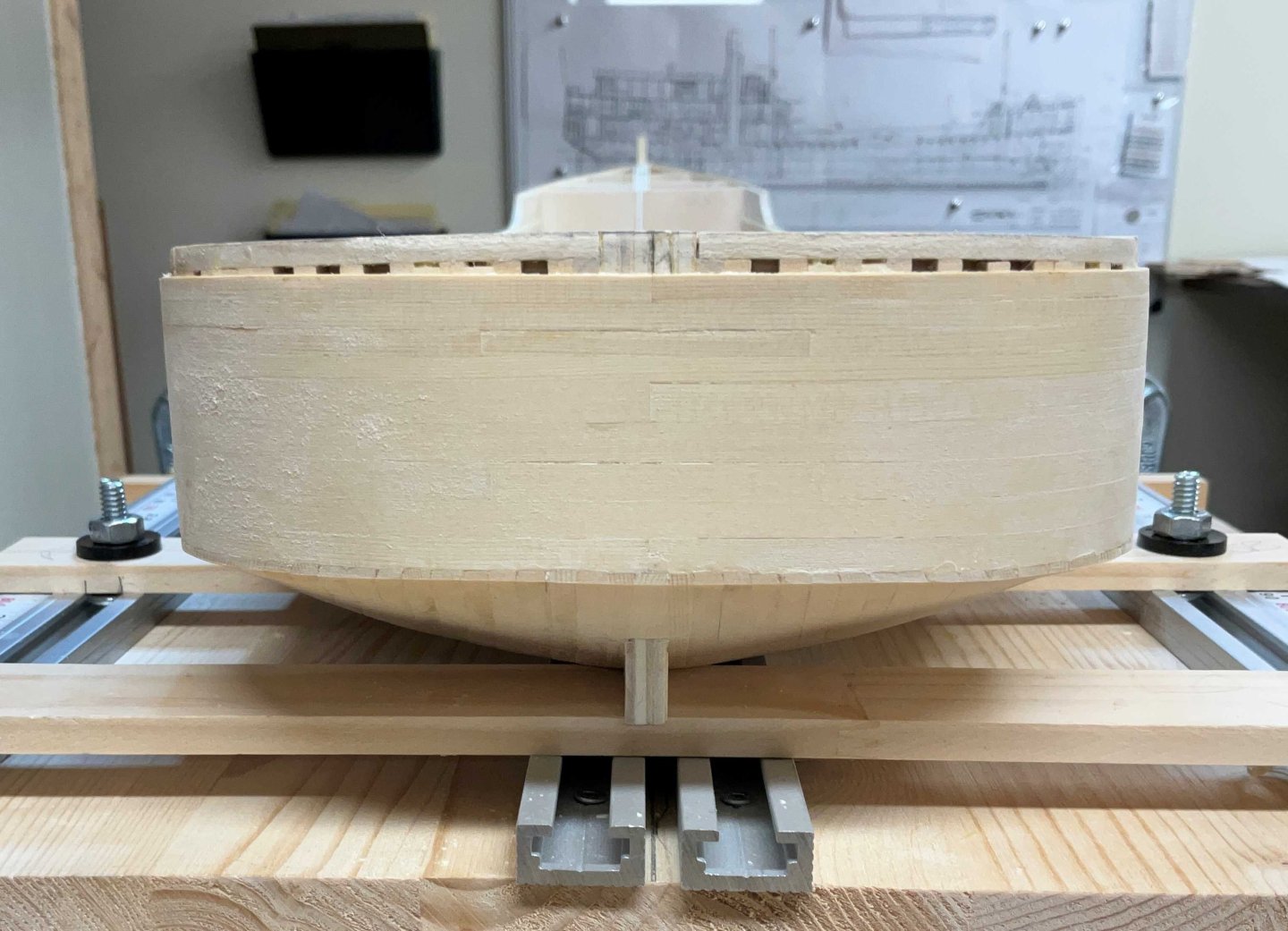

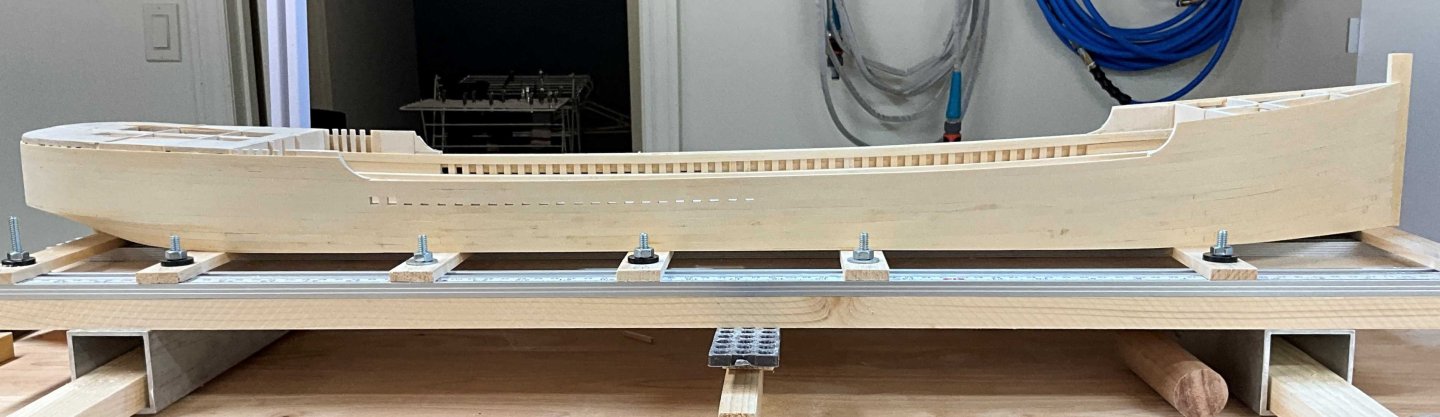

Hi Everyone, hope you are all doing well. Thank you very much for the Comments and Likes! The hull planking is finished. As the planks ran off the bulkheads and below the waterline, 1/8" blocks of basswood were added to define the waterline and add to the structural integrity of the hull. They were glued into place after the planking was installed to make it easier for clamping. Once the blocks had been installed the planks were planed down so that they were 1/16" proud of the blocks. The process started at the stern and moved forward. I had some Cleco type side grip clamps that had been used for metal work. They have a strong grip but didn't mark the AYC. They were good for the straight lengths. I got them from Aircraft Spruce. They are about 6.00 CAD each plus you need the pliers to put them on and take them off. I started making the tabs that are glued to the back of the planks longer so that they extended from both sides. This made them interlock with the previous plank's tabs. After the planking was completed they were sanded back to the waterline and the hull was mounted back onto the build board. I went over it with 120 grit paper but it still needs more sanding. Once the sanding is finished the rub rails can be attached. Hope to see you when the dust settles.

-

Ross, congratulations on completing Diana! She is beautiful. Good luck with your Essex build

-

Looking good Glen! Glad you could fly the original flag.

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Best White Wood Glue For Ship Building

Paul Le Wol replied to OldeManToad's topic in Modeling tools and Workshop Equipment

Hi OldeManToad, welcome to MSW. I’ve been using LePage Multi Purpose White glue with good results. I like using white glue solely because it dries opaque. Even if the model is being painted I don’t like looking at yellow glue stains while it is being built. Have never tried Titebond. Good luck with your Albatros build. I should have said that it dries translucent. -

Ryland, congratulations on receiving the Jim Roberts Award and thanks for posting the great photo!

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Glen, the deck houses are exceptional, especially the rails!

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

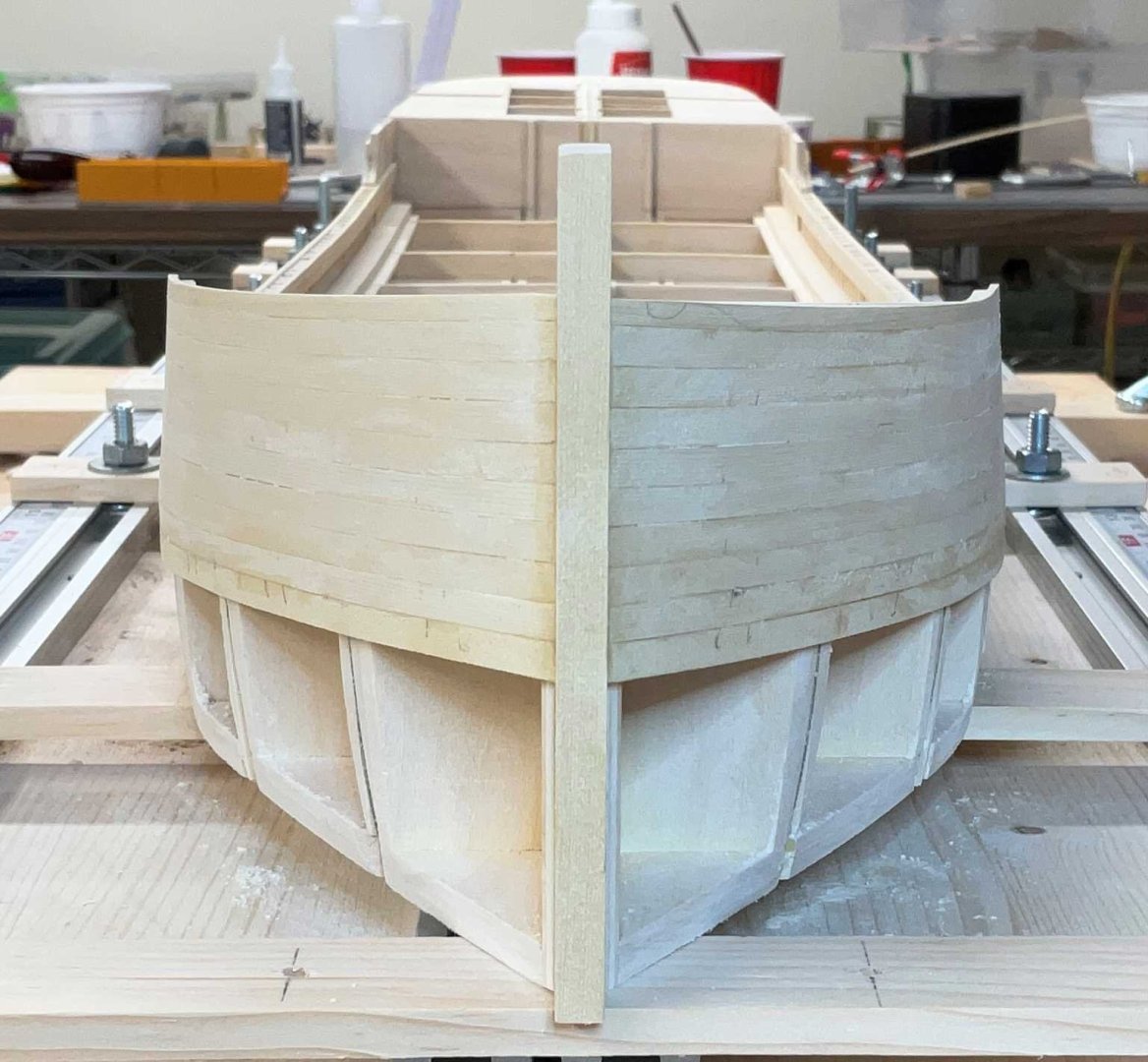

Hi Everyone, I hope all is good. Thank you for the great Comments and Likes. Just have a bit of a planking update today. I worked my way up to the rails and added support for the forecastle subdeck which will be 1/32" plywood. The model had to be removed from the build board and turned over to finish the fairing and planking down to the water line. Once that was done I started to focus on the counter. The first two strakes on Port and Starboard needed tapering, bending and twisting. A combination of CA and white PVA was used to keep them in place. My 2 year old Starbond CA was not up for the job so I picked up some Bob Smith CA. Read a lot of good reviews about Bob Smith and I completely agree with them. Support made from 1/8" basswood sheet has been added at the water line. The rest of the counter planks have a slight taper and run off the stern so back to using just white PVA. Next post I hope to be finished the hull planking. See you soon.

-

This is my take on the people in the photo. If the woman was the captain, she would be standing in the doorway of the pilot house wearing a big smile. She may be the captain’s wife/ daughter who had just brought him lunch. The captain is eating lunch in the pilot house because she wants to take the dishes home before they get underway again The man driving the car is a travelling salesman so the captain has to keep his eye on him during lunch. Those guys in the background are a whole other story.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.