Thunder

Members-

Posts

582 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Thunder

-

Hi, I did mean Ronald's but think you have the same issue. Unfortunately not at home to check plans but that angle looks very severe. Be worth checking against other builds on here. On Eugenio's i was wondering where the stern board should go with the chase gun ports. There also seems to be no run aft over the rudder. Take a look at the below (lifted from Kevin's build) Sorry Kevin, hope you do not mind.

-

I like the drawing holder idea. I have been looking into getting one of the below but not located in the UK yet. You may want to check out HMS Cruiser builds as well. The hull structure is almost identical.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

There used to be a loop hole where if you got a company to post to someone in the US and they forwarded to you marking the item as a present you didn't pay the duty. I believe they have closed that now. My wife brought me the Lauck Street 'Fair American' and really got stung. To be honest, if she had known about the extra cost, it would not have got purchased. I have never brought anything direct from the US since.

-

If this is the quality of your work then I think I will have a lot to learn by following this build. Inspiring.

- 370 replies

-

- Model Shipways

- Confederacy

-

(and 1 more)

Tagged with:

-

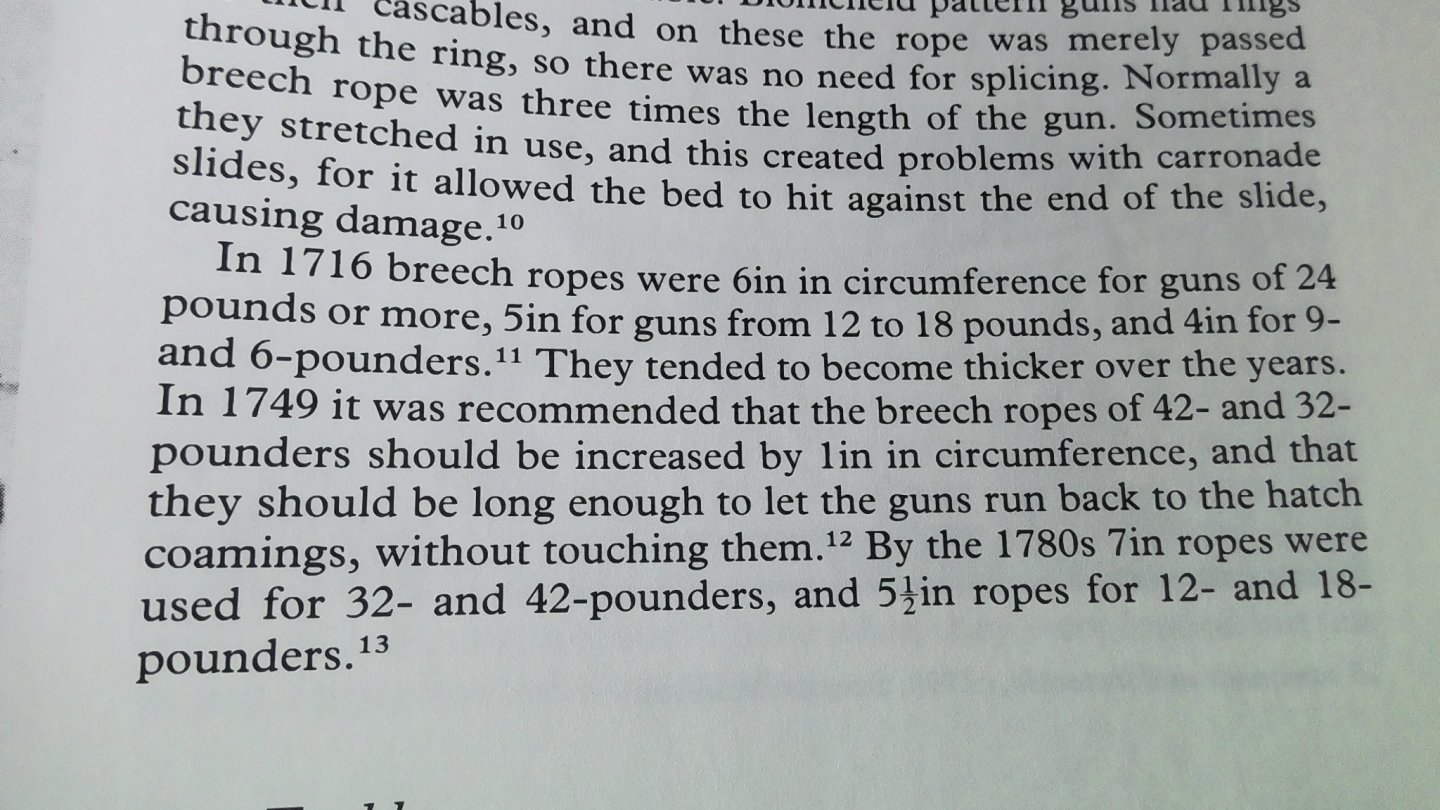

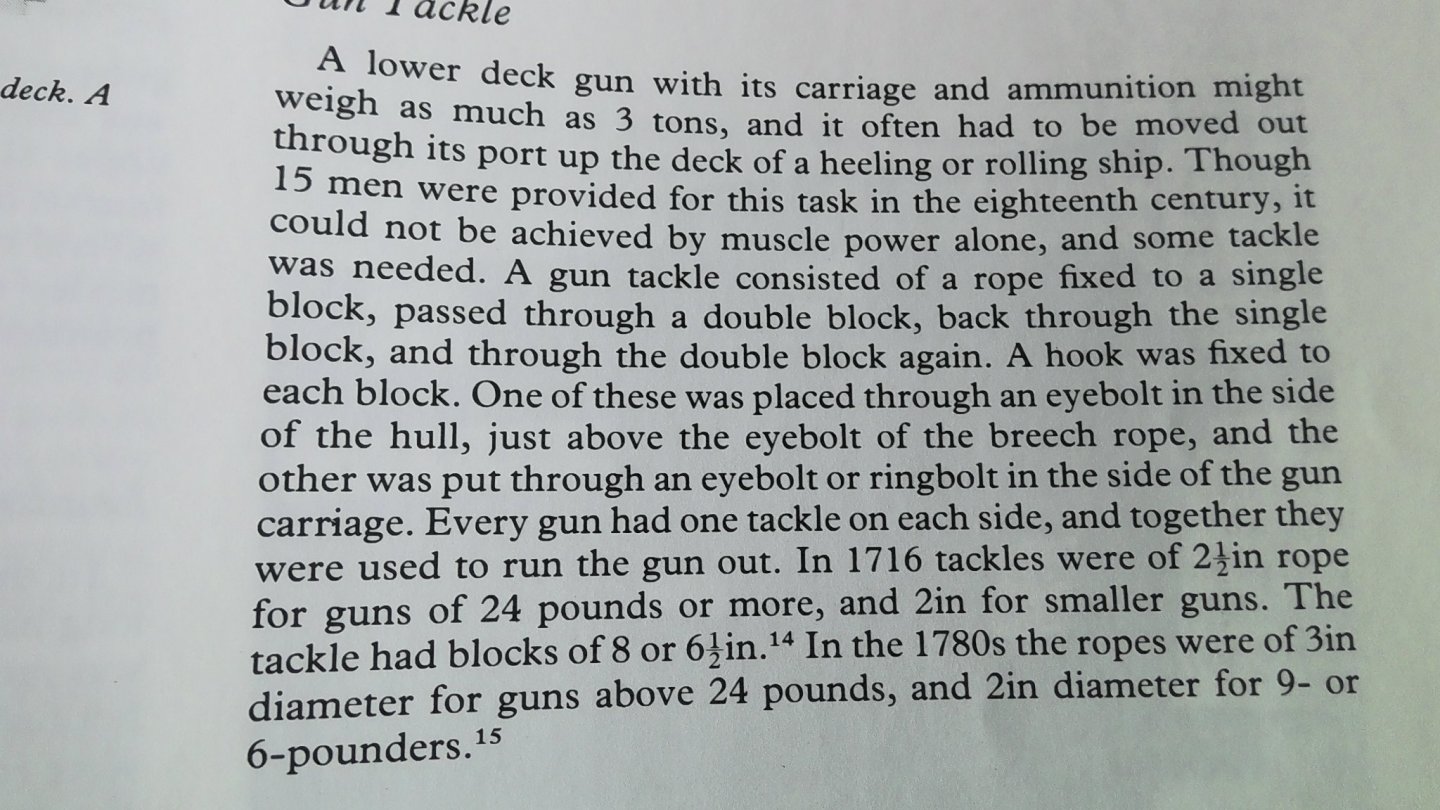

Hi, Had a look in Brian Lavery's 'The Arming and Fitting of English ships of war 1600-1815. He does not include a lot of text other than that below: Does not state for our period with 6 pounders for the breechings but does state circumference. If we say 5.5" circumference that gives 0.7mm for our scale. I have added the text for the tackles but this gives more confusion as it seems he has worked on sizes in Diameters for these. This does not make sense as it makes the tackles 0.79mm which is bigger than his breech rope. I would think he meant circumference for this which gives 0.25mm and blocks of 2.5mm. Unfortunately it is often the case that the more you research the more confused you get. I have an extensive library but often find these great authors contradictory or, in most cases, do not have the information you need. Perhaps they could not find it either.

-

Hi, Yes very useful chart, even my books on arming and fitting do not give this detail. Works out at 1.59mm. I have just put some 1.5mm on one of my cannon and compared with photo of victory I posted and think you may be right. You will have to step up the eyebolt sizes as well in order to rig. At first I thought the chart might be giving circumference instead of diameter but this brings it out at 0.5mm which seems too small.

-

Hi, 1.5mm seems huge to me, have you worked that out from a good source? I used 0.75mm, I would only go as high as 1mm. If unsure i tend to go smaller rather than larger as larger, in my opinion, tends to look clumsy. However, it will be worth getting a stock of 1mm and 1.5mm as I used these sizes for the standing rigging. 2mm and 2.5mm is also worth having mainly for anchor ropes. The Amati is what I have. I used the natural and dyed black. I have answered on my log. Sorry for delay, only just got back from holiday and had to look at model to confirm what I used.

-

Hi sorry for slow reply, I have been away and could not say till I came home and had a look at the model. I used 0.75 Amati. I do prefer Amati for the larger sized threads for both colour and quality. The natural colour only. The larger standing rigging is dyed Amati Natural.

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi, I am away so cannot measure what size i used at the moment. I know I probably gauged by eye as finding accurate sizes is near impossible. They are smaller than most people think if taking those on HMS Victory and HMS Trincomalee as a guide. You can see on the attached that all but the breechings are a single loop so depends what detail you want to go to. Mine are all single loop. The kit sized eyelets on the etched sheet were a good size but think mine made from enamelled wire. If you have a set of miniature drill bits you can use the shaft to twist wire round and make any size you want. Another source i am just investigating are eyed fishing hooks. You can buy down to size 26 which are tiny. Cut the eyelet off and use or use complete as hooks for rigging. Buy barbless. They come in different shapes of shaft as well as sizes. Cutting the eyes off two and gluing to a third with an eye also makes a nice little grapnel.

-

Hi. yes should be closed. To be honest it has annoyed me that I didn't make new ones ever since I fitted them as should not be hard to do. Also if you solder them there is less chance of them pulling open. If going to solder will be worth doing the bottom of the loop with the deadeye in as these are a bad design and will pull open the split being at the point of most importance.

-

I tend to put the three sections of mast together off the ship, i.e. main mast, topmast and t'gallant. That way they can be glued and dry with a straight line drawn under them so you can see they are all in alignment. I then install on the ship. Make sure the ship is level, fore and aft, to its waterline and from side to side. You can install a plumb line to the rear of the mast (rear so rake of mast makes it swing freely, and as long as this is in alignment with the mast you should have it set accurately. Of course if you get the rigging incorrect you will pull the mast out of position but gives you a good starting point.

-

THE ORDER OF DRESSING THE MASTS AND YARDS - HMB Cruiser 1796.docx attached the order I rigged but remember I rigged the lower yard on the main mast as a cross jack, as you are depicting a later date you may want to rig as a sail carrying yard arm. The kit depicts a half way house calling it a cross jack but rigging Jeers.

-

Trouble is, if your in the UK, is getting good quality timber to scratch build. You can buy the same as the kit but it is a costly job. Truith is I don't really even like the kit wood either and do not have room or facilities to mill my own. This and accuracy is why I will be watching the Vanguard models so closely. For my kits purchased I really hope he starts selling timber or, even better, starts selling replacement timber packs for other manufacturers kits.

-

I would definitely complete the rig of the cannons before starting the rigging to the masts. It would be far to fiddly afterwards. I think the kit only expects you to show the breech rope, which is the thicker rope that goes around the Cascable. There are plenty of eyebolts in the kit to complete correctly, just not enough blocks. One thing I did end up doing is removing the pumps from the base of the mast, they were in the way for completing the rigging. I have used different thread sizes to the kit instructions but other than that have not ordered any extra parts. I expect to add rigging blocks as include more rigging than the kit suggests and modify depending on my research. I am away for two weeks now so do not have my sizes i can tell you that the main and fore mast stay sizes were increased, off top of head worked out at 1.27mm 'but don't quote me,' and I ran out of 0.25mm. I seem to have an abundance of other size threads in the kit which has always been the case with their kits in the past. I would use your time waiting for your order to plan your rigging. I always used to do this in depth and thought I would get away with it this time. Unfortunately I have paid the price. First thing to do is to check your order of the rigging, I then used to make notes of how to complete each step and do a more accurate belaying diagram. It is worth the effort. The kit drawings do not describe what each item is for so it is worth labelling. By checking James Lees most is correct but i didn't agree with all of it.

-

Sorry missed a comment, I did not use hooks, just rigged direct to eyebolts. Incidently you can see i used CA here and you can see the discolouration i mentioned and the kinks put into the threads due to them going brittle.

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Wahka, I made additional rigging blocks as the ones in the kit will be too large. If you have the same amount of blocks in the kit as i had then there will not be enough. I am just finishing my rigging and have dipped into my own stock. I have rigged additional items such as reef tackles and bowlines. The thread is the finest you can get which is used in angling for fly tying. Blocks that small I have made from white styrene and painted. I think the doubles were 2mm by 2.6mm and the singles 1.5mm by 2mm. Get the length of styrene and cut the grooves along each length, paint brown, drill first block holes and cut from length. Once all cut thread onto some wire to paint the ends. If you experiment with different electrical side cutters the action of cutting produces a curved end to the block. You just have alittle bit of waste cutting the first curve of the second block. Don't close ups really show off all the faults!

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

I do tend to use CA but it has two disadvantages. Yes it makes the thread and know brittle, You need to make sure the block is angled correctly for its application or you can get a unnatural kink, especially if block is on a pendant. Second is that if it spreads onto the wood of the belaying point or yard arm it will stain it making it look permanently wet. However, it thread you are using has too much nylon content PVA doesn't work as well.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.