-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

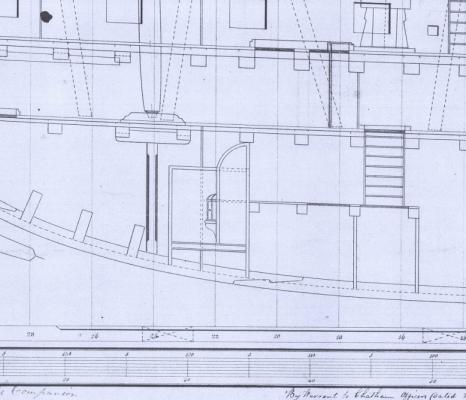

Daniel, It appears that Rob is following the drawings closely. Attached are sections from the original plans for Blanche, Euryalus, et al. the aft magazine is indeed quite a small space. Allan

-

Edge bending planks

allanyed replied to ortho85's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Augie, If you bend the wood first, as with your jig, is it difficult to mark and taper each piece? The taper is not a constant from widest portion to narrowest, and each plank ends at a different point along the length of the hull so each piece has to be shaped slightly differently. The jig would have to be modified quite a few times as the curve changes for every strake, especially at the bow. I would think it is much more difficult and time consuming to mark and shape the taper on a prebent plank even if you do not modify the shape of the jig more than a few times as the planking goes on. In the end, whatever works well is a good thing! Allan -

Alan, The frames were beveled inboard and outboard so there was a fair line running from stem to stern and to give a flat surface on which to fay the strakes of planking. Your picture on the right is the what you need to achieve. As you get nearer the bow and stern, the beveling was extreme before cant frames became the norm early in the 18th century. The green line on the stern looks odd to me. What does this represent? Thanks for sharing your work with us. Allan

-

Edge bending planks

allanyed replied to ortho85's topic in Building, Framing, Planking and plating a ships hull and deck

If the wood is soft and wet you can slightly bend (edge set) and it will stay in that shape when dry. Harder woods cannot be easily edge set and will lift. There are several write ups on this site on planking, including spiling. Why fight the wood when you can cut it to the shape that will allow it to lay without trying to fight the wood? Allan -

HMS Euryalus by egen -

allanyed replied to egen's topic in - Build logs for subjects built 1801 - 1850

Egen, In the Arming and Fitting by Brian Lavery he goes into these pumps in some detail. Between several designs by Coles and Noble, there are at least two designs that could have been on Euryalus. The last design by Coles was in 1803, but it was not successful and they were removed. Look at the contract in Volume I and you will see confirmation of what Ed T mentions above. It specifically forbade inclusion of masts, pumps, and stove so without a bill of sale, bill of materials or some such paper work there is no telling what was installed. Allan -

Ciao Mauro, Your Lettie Howard is looking very nice. Do not forget to scrape a little of the paint on the bulkheads when you glue on the bulkhead stanchions so the glue gets into the wood. . Are you going to include the foretop mast or leave it off as she is rigged today? Thank you for posting the photos.

- 111 replies

-

Drake, Before using lip balm, take a look at the ingredient list and then make sure they are compatible with the rigging line material you are using. There a number of oils and fragrances. and other chemicals, some of which may be harmful to the rigging line over time. Bees wax by itself has no payoff on the lips, it is much too hard so softeners are added. Allan

-

My oh my what a great mini project! Of course now I have to try this, and once again explain to the boss when she asks why I have patience to try these kinds of things, but little else. I will be blaming you of course, so you are forewarned. Allan

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Ed Your attention to the smallest detail is what puts you on a different level. Most builders are not even aware of the details to which you have paid attention, let alone incorporate them into the build. Allan

- 3,612 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

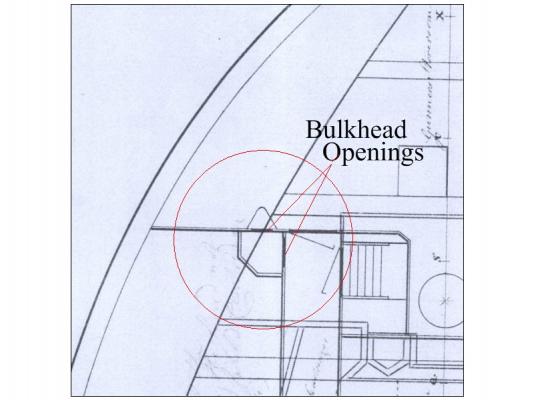

Druxey, I thought the same thing about the lanterns being opened in the room if it was not the magazine. The drawing I posted earlier, and especially the one below gave me pause. Why are there bulkheads forming a little room to the back of the lantern rather than just opening the lantern inside the gunner's room. Would there be loose powder normally present in the gunner's room? Thanx Allan

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

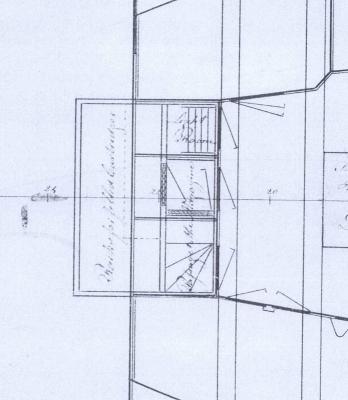

Remco, Your build is exceptional and a pleasure to follow. I do have a bit of confusion in my own mind on the bulkhead lanterns. This is not a criticism as the lanterns are VERY nice. They are showing exactly opposite each other. I always thought, (and very possibly incorrectly) that the access to the bulkhead lanterns was from the opposite side of the bulkhead much like the lanterns in the light room. The attached drawing seems to indicate access through the bulkhead, thus my comments. Of course they could have hinged doors inside the room and hang them as shown on Kingfisher, but it was a new one for me, or at least the first time I remember seeing this configuration. Thanks again for sharing your build. Allan

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Help with king plank

allanyed replied to captainbob's topic in Building, Framing, Planking and plating a ships hull and deck

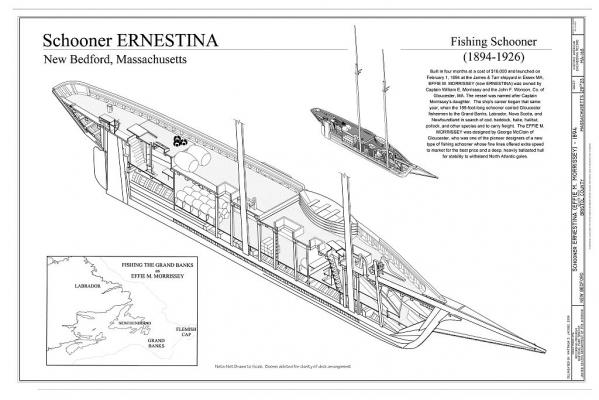

Bob, The drawing of the Ernestina shows what appears to be a king plank on the raised portion, but none forward. Different vessel, different designer, so maybe one of those "either/or" situations. Photos of her deck indicate a king plank aft, as well. Allan -

Robert, The breech rope does appear that it will cause the rings to flip and jam the rope. It is also highly unlikely that the running tackle on cannon on a cutter, would have a double and single block on each side. Two singles on each side were the norm except on 32 pounders according to the History of British Sea Ordinance 1523 to 1875 Volume II, by Adriana Caruana. Allan

-

Further to Gary's post, these were called half bucklers and blind bucklers, the latter of which fully closed off the hawse hole inboard on British ships, at least in the 18th century and into the 19th century. There may have been other methods, but this seems to have been at least one common method of keeping out the water. The manger was present as well to help contain water (and mud, when the hawsers were brought in when raising the anchor) There were relatively large scuppers in this area of the manger as well to let the water run off. Allan

-

Danny It will be a sad day when the work is finished, for those of us following your build. I may have missed in an earlier post, but is rigging in the future for the Vulture? Allan

-

Rob, When you get to that transom, fire away with the questions. I am sure Wayne or I will be able to help, at least I hope so. Another book??? I swore never again, but........ Allan

-

Ed, I would be delighted to display the hull in a prominent place just as it is! Allan

- 3,612 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

So noted Ed, and I rely on your experience that it is a better way to go,,,,,,, but it sure looks like a tempting thing to try. Allan

- 3,612 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed, Presetting the half frames with the cross spall is so simple yet effective. I will remember one for sure. Now, how about something cleaver for setting pairs rather than individual cant frames? Allan

- 3,612 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Rob, Thanks for the latest posts, it is really nice for me personally to see her coming along so nicely. Allan

-

Sherry, You can try to contact Polytek (www.polytek.com) and/or look at some of their Youtube videos. We use several of their RTVs for making molds for our automated lipstick molding machines, and I also have purchased RTV's and casting resins from them in their Easy Flo line of products. Great stuff. Allan

-

Ed, I don't which I like more, the home made clamps or the stern framing. Great work all around! Allan

- 3,612 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Good bye, loosening knots!

allanyed replied to Ulises Victoria's topic in Masting, rigging and sails

Thanks for the idea. Is there any potential negative long term effect from a chemical incompatibility with the rosin and various rigging line materials such as cottton, linen, &tc? Thanks Allan -

Hello Baris, Properly spiled planks can be soaked and pre-bent and dried before gluing to the model. If this is done, they can be held with the fingers for a minute or less while the glues starts to set.(aliphatic glue). There is no need for pinning. That said, making perfectly spiled planks is not always possible if only using strips of wood such as come in kits rather than cutting from sheet stock as mentioned by Chuck. A number of planking clamp designs have been shown on this site including many by Ed Tosti in his Naiad build log (and books.) They eliminate the need for using pins. Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.