-

Posts

1,945 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

No need for any flattening. The slight bend is likely temporary due to being in the box. When the hull assembly is built up, all will be straight and true anyway.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Hello Gregory. I do plan to once I have a few sizes done. As the photo etch parts cost quite a lot of money, and I prefer to wait until I have at least three versions to fit on a single production sheet. Ideally, I need another a size below the one shown, and two or three larger, for frigates and line of battle ships. Same applies to hand pumps, but I do currently offer some capstans and other fittings.

-

Yep, InDesign for putting the manual together, along with box art. I also used it to put the plan sheet together, but now use CorelDraw instead, as it's much easier to import my CAD drawings with text into this software.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Now, I hate to disagree with anyone on these forums, but I have built literally dozens of models using MDF for the past 13 years, and have never once experienced what you describe. I too have laid soaking wet limewood first planking to the MDF frames without the slightest issue. I had the first prototype Sphinx MDF skeleton outside by the bins for a couple of weeks, where is suffered rain, sleet and snow. No signs of swelling at all, although the 2mm ply deck did warp. All of my MDF is bought from he same place, and is the highest grade I can buy. You must have been very determined to get your MDF to react like that.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

If you are building her as commissioned by the Royal Navy, Bounty would be coppered for such a voyage. It is an unfortunate fact (for those who hate copper plating), that the vast majority of English vessels (and a little later, French vessels) would have copper bottoms from the 1780's onwards. Blame Charles Middleton...

-

Always a compromise. I could do most in wood, but to keep to scale, they would be way too fragile. The alternative would be to increase widths/thicknesses, and end up with those way out of scale chubby parts like ships wheels. Took a while to decide about the topmast cross trees, as I would have liked them in wood. However, again, the scale widths were too small, and many would have had problems. Nothing worse than having such a part snap/break when you've already started the rigging process, and they were always painted anyway...

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

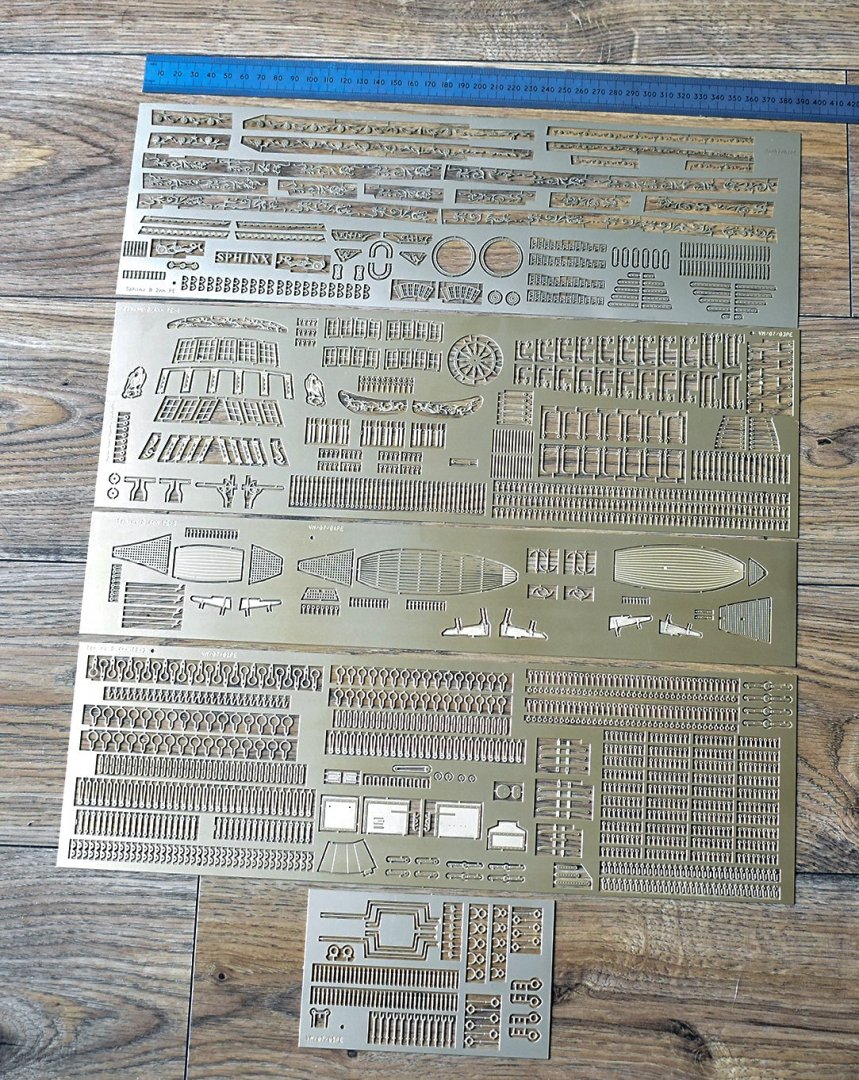

Just had the test sheets arrive for the five sheets of photo etched brass for Sphinx, which I shall get shipped to Jim. these are quite big...

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Hi Alex, Your model is certainly inspirational. However, the vast majority of detail that isn't shown on the original Admiralty plans for Sphinx Class was gleaned from the AOTS Pandora, as this seems to be the closest match for the slightly smaller Sphinx.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Very nice, and very well executed. I will always have a fond affection for this kit, as it was my very first wooden boat kit I bought and made.

- 83 replies

-

- finished

- billing boats

-

(and 1 more)

Tagged with:

-

Hi Tim, No, I buy enough materials for a certain amount of complete kits. If I started messing around with different options, it would get messy. I still have a full time day job, so I would rather use what time I have developing complete kits. I can sell certain items individually like cannon or boats, but not the actual kit laser cut parts. The only extra for Sphinx will be the pearwood blocks and deadeyes. Other than that, it will be a 'full fat' package with everything to make the model and three ships boats included. Thank you! I think for the even larger kits, I will revert back to 'standard' designs, due to costs. But I don't mean other manufacturers 'standard', I mean something like my Victory designs 'standard'. This means I will probably have planking strips for deck planking and most of the hull will be conventionally planked, rather than pre-cut/engraved. The designs for Sphinx have been an evolution from the fishing boats to Duchess to Sphinx. I fear the costs for a 64th scale heavy frigate and larger models still would be too prohibitive, and Sphinx is the absolute limit I dare push to. Even then, I will probably lose some sales due to the cost, as people will still ask why the high price, but I believe the right people will buy, those who enjoy making the models and like adding even more, stamping their own mark on the kit. Cheers I will be developing an 18 gun brig after Sphinx, before starting on a much larger development (that I cannot wait to get my teeth into) And yes, James will build the prototype, once I have cut all of the parts...

-

Don't know about cornering the market, I just want to develop stuff I like, and see how far I can go without the restraints of developing for other manufactures. I do know that having a kit like this so pre-cut (for the hull, only the lime and pearwood planking is used, and only at below main wale level, everything above this is fully pre-cut parts), is time consuming to develop, and material heavy. This will have around 35 individual laser cut sheets, and 5 large PE sheets in 0.2, 0.4 and 0.6mm. However, having so many parts doesn't necessarily mean complex, it just means there's a lot less for the modeller to make themselves. I hope...

-

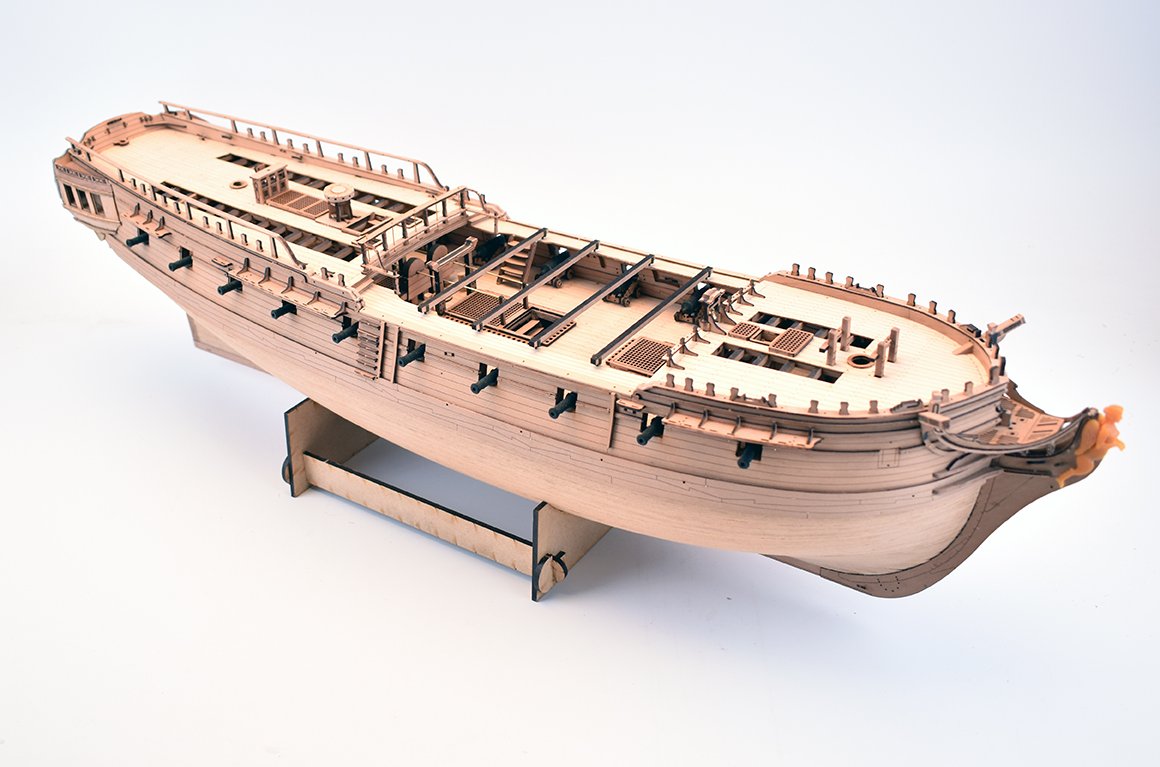

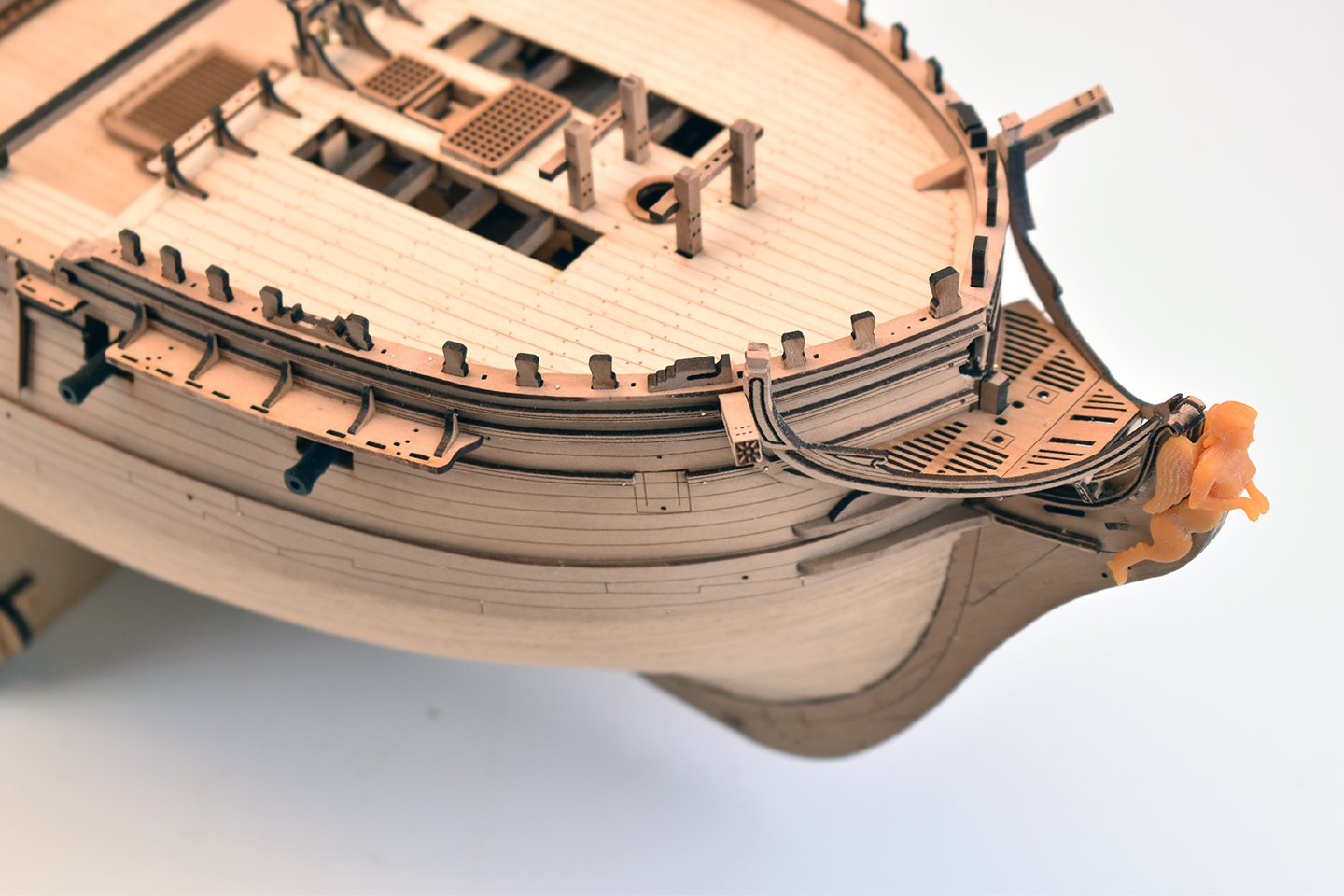

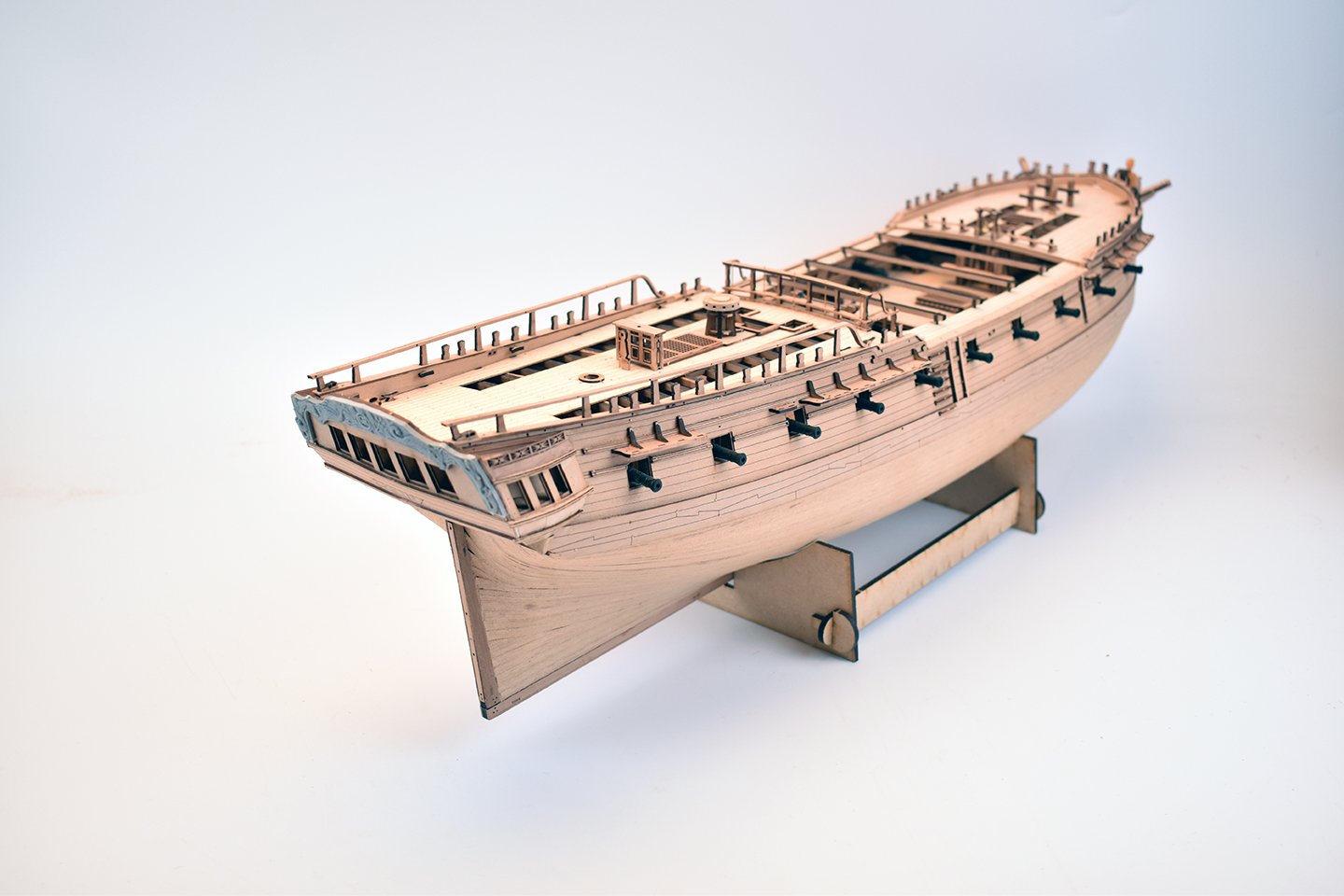

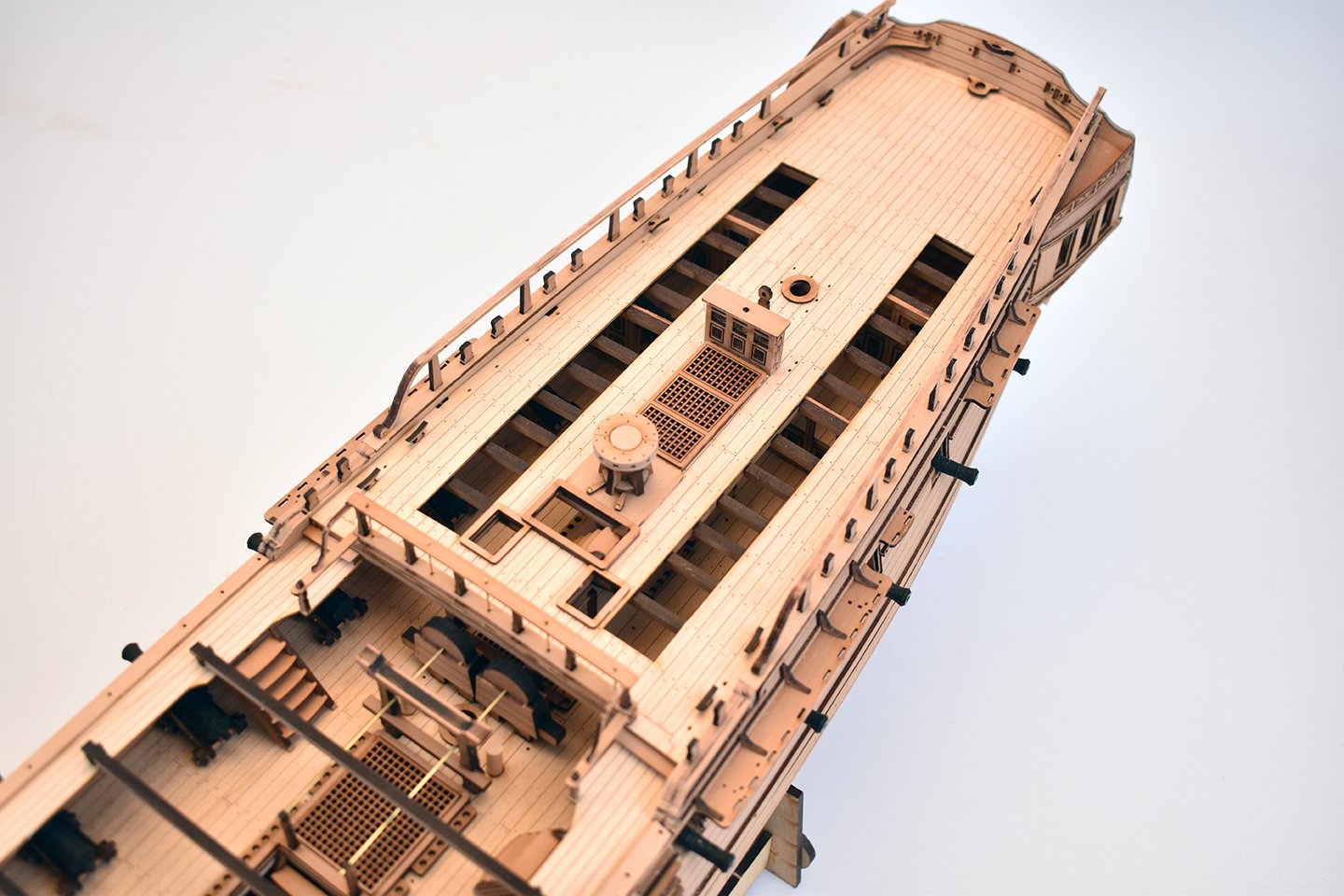

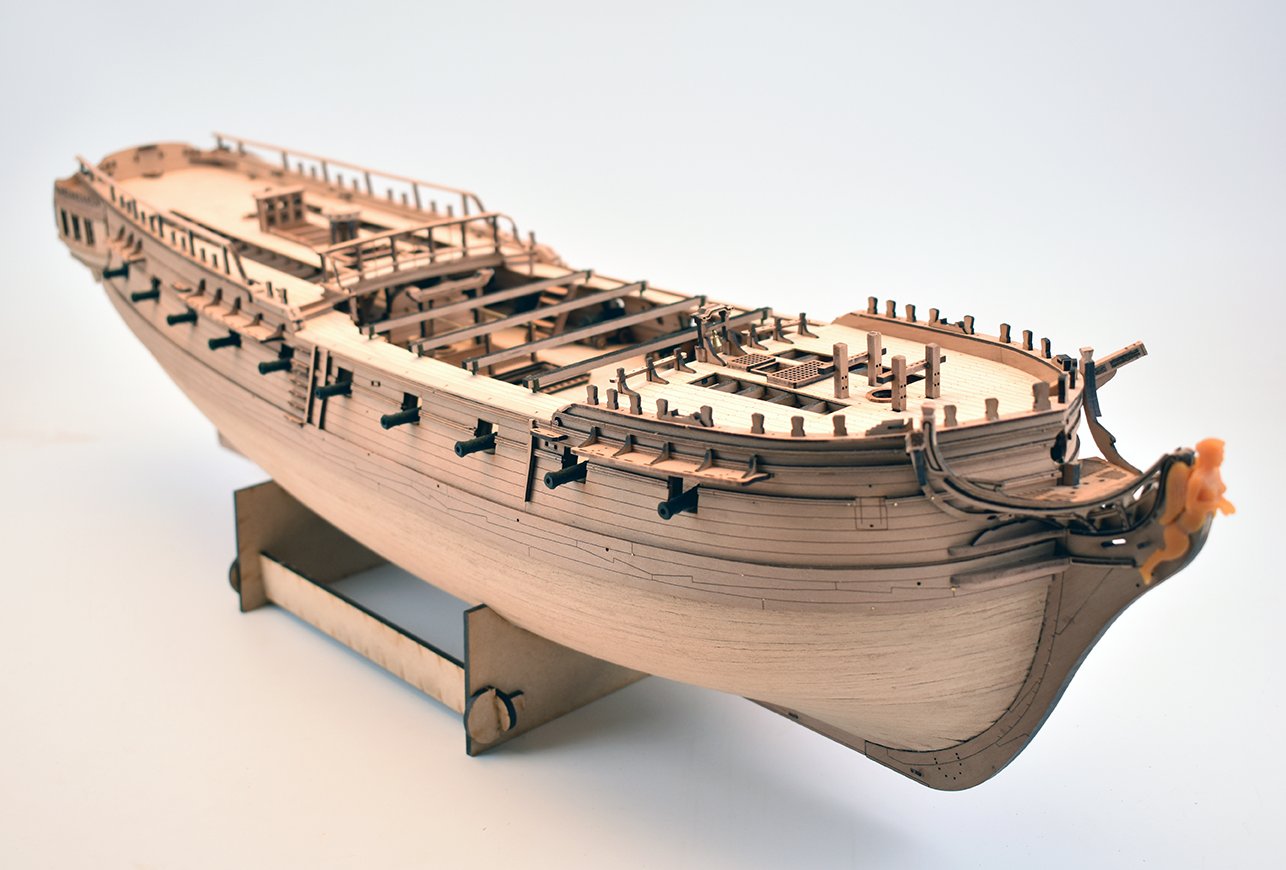

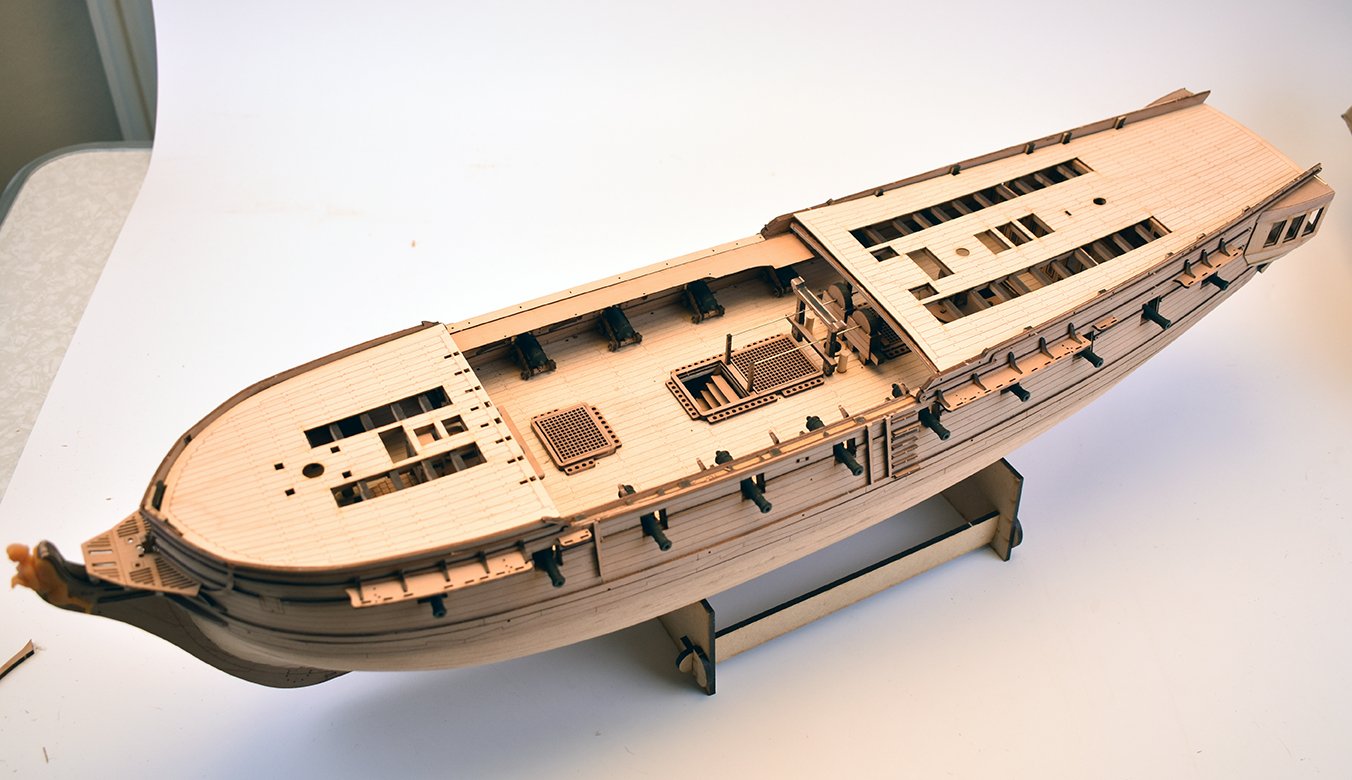

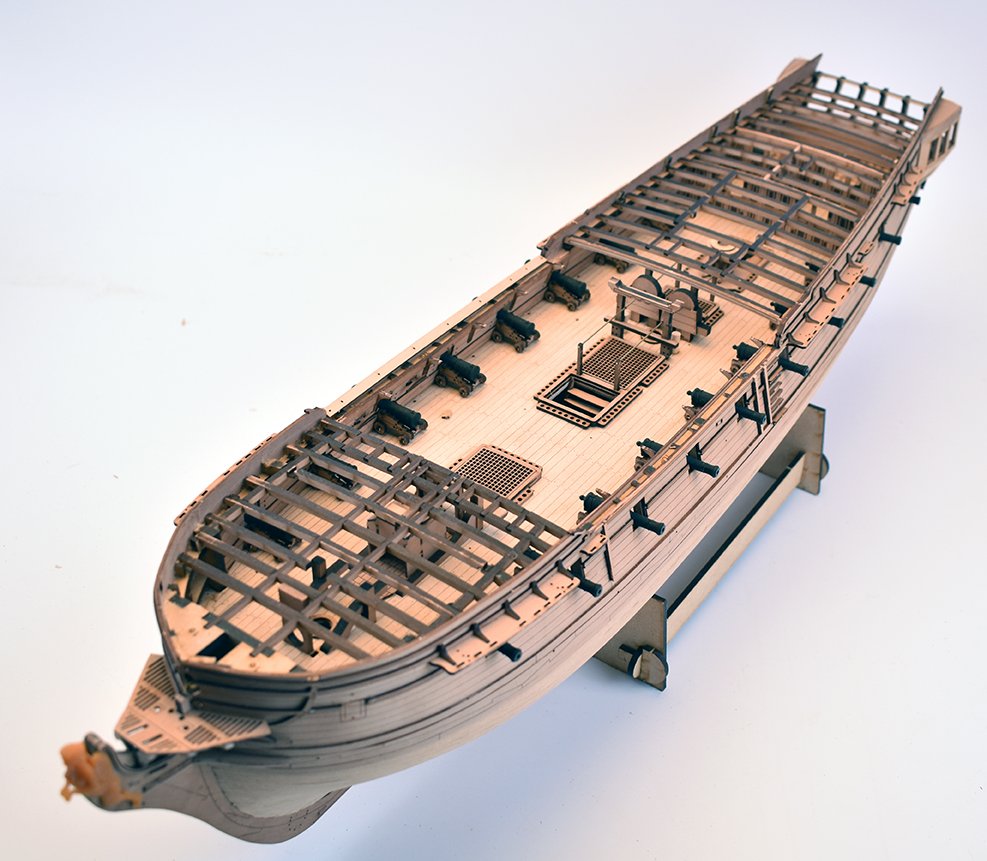

OK, I have now finished with the 'pre-prototype' model, and have all the info I need. A lot of small changes have been made, so this model shows (many) mistakes that the prototype model will not have. What is shown is around 95% of the hull laser cut parts and the castings. For the boat beams, the U shaped brackets presented a problem. I was going to do them in PE, but wasn't happy with them, as they protrude above the gangway by around 1.5mm. So, these are now perfectly scaled 3-d printed parts, using a very tough resin, and are the kit versions. A very small detail, but happy with the result. The gangway has changed since these pics, with the widest part nearest the quarterdeck moved back a few mm, so the ladders are in between the cannon. The slots in the quarterdeck were moved back a lot further, in order to show the chequered deck pattern in the aft cabin. Ladders are cut in 0.6mm pear, and look much better, scale-wise. The catheads are made from 5 laser cut and engraved parts each, otherwise they would have looked pretty basic.. Al PE is done and sent off to Italy to be produced for the prototype model, and I now have the task of part numbering everything and doing a full parts list, followed by starting on the CAD drawings for plans...

-

'The Terror' - BBC series Mar 2021

chris watton replied to Rik Thistle's topic in Nautical/Naval History

It was strange seeing reviews for this series, and giving the impression it is new. I have had this via my Amazon Prime account for almost two years! It is very good, though, if a little strange...- 8 replies

-

- John franklin

- 1845

-

(and 2 more)

Tagged with:

-

That's the idea! And yes, the upper deck beams are in their correct positions with correct spacing, according to the Sphinx Admiralty plans. These beams locate into slots on a pattern each side of the inner bulwarks, which in turn are slotted into the sides of the bulkheads, so there's zero chance of misalignment. No need to check every station with a rule... ETA - The gun deck bulkheads near the stern will have panelling detail on both sides, as they will be visible on the finished model. For the upper decks, my idea is to just use the laser engraved maple veneer, as this will give scale deck plank thickness. However, I may also include a 0.8mm ply version for those who wish to have a more substantial underlay for the maple veneer deck, or simply want to plank it with their own choice of wood.

-

OK, just took a few pics of the pre-prototype model of Sphinx, so you can see where I am up to. Please bear in mind that this model is disposable, no paint, no varnish, it has been dropped a couple of times, as the starboard forecastle bulkhead can testify, and no PE as yet, which is why I have just use brass rod for the chain pump handles, just to make sure all holes for this align correctly. This is just to make sure designed parts fit, and if not, changed and replaced. Today I glued the forecastle and quarterdeck beams in place, and finished the final deck engraving designs for the forecastle. I think once upper decks are fixed, my only real design job is for the inner upper bulwarks.

-

Cheap and effective tools

chris watton replied to Ron B's topic in Modeling tools and Workshop Equipment

Stanley Knife, small rusty old plyers, pin vice and steel rule - set up for life! -

Cheers My broadband problems have zero effect on my work speed. What does have an effect is my full time day job. In the week, on work days, I work on the CAD designs before work, and on my days off, I work on the (pre) prototype model. A little slow, exacerbated by the sheer number and complexity of some parts compared to previous designs, but it's coming along. Oh, one more thing, I forgot to mention, I asked my wood supplier if I could have 0.8 x 4mm pear for Sphinx, plus some sheets in the same thickness, as I feel the 1mm is a little too thick, and the 0.8 would be easier to manipulate. So for Sphinx, the wood thickness for laser cut will be 0.6, 0.8, 1, 1.5, 2, 3 and 4mm. Planking will be 1x5mm limewood first planking and then 0.8x4mm pear for second planking, but the planking does not start until just below the main wale.

-

I am here, but I have no internet or phone line until at least next Tuesday. We bought a pay as you go wi-fi dongle thingy, so I could at least reply to emails and book all orders to be posted. I am still working long and hard on Sphinx. All photo etch designs will be complete within two weeks, and I am hoping the laser cut designs will be complete very soon. This is a lot more complex than the other kits, and requires a lot more development time.

-

3D drawings 18pdr at 1/64 scale

chris watton replied to Barbossa's topic in CAD and 3D Modelling/Drafting Plans with Software

In that case, this website may be of help: Frédéric LA HOCHE qui propose des éléments pour la construction de modèles réduits de bateaux en bois They do offer a full suite of Venus cannon, but I note they are in 72nd scale, unfortunately. -

3D drawings 18pdr at 1/64 scale

chris watton replied to Barbossa's topic in CAD and 3D Modelling/Drafting Plans with Software

Are they long or short 18 pounders? I ask because many 38 gun frigates had the short barrels (8 foot, 41.8mm in 64th), yet 36 gun frigates were usually equipped with the longer type (9 foot, 46.6mm). Also, what is the launch date of the model you are making? If is it around 1795 or later, you probably will need the Blomefield pattern (with the ring located on the cascabel), which is something that isn't done on commercial turned brass cannon.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.