-

Posts

1,366 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JacquesCousteau

-

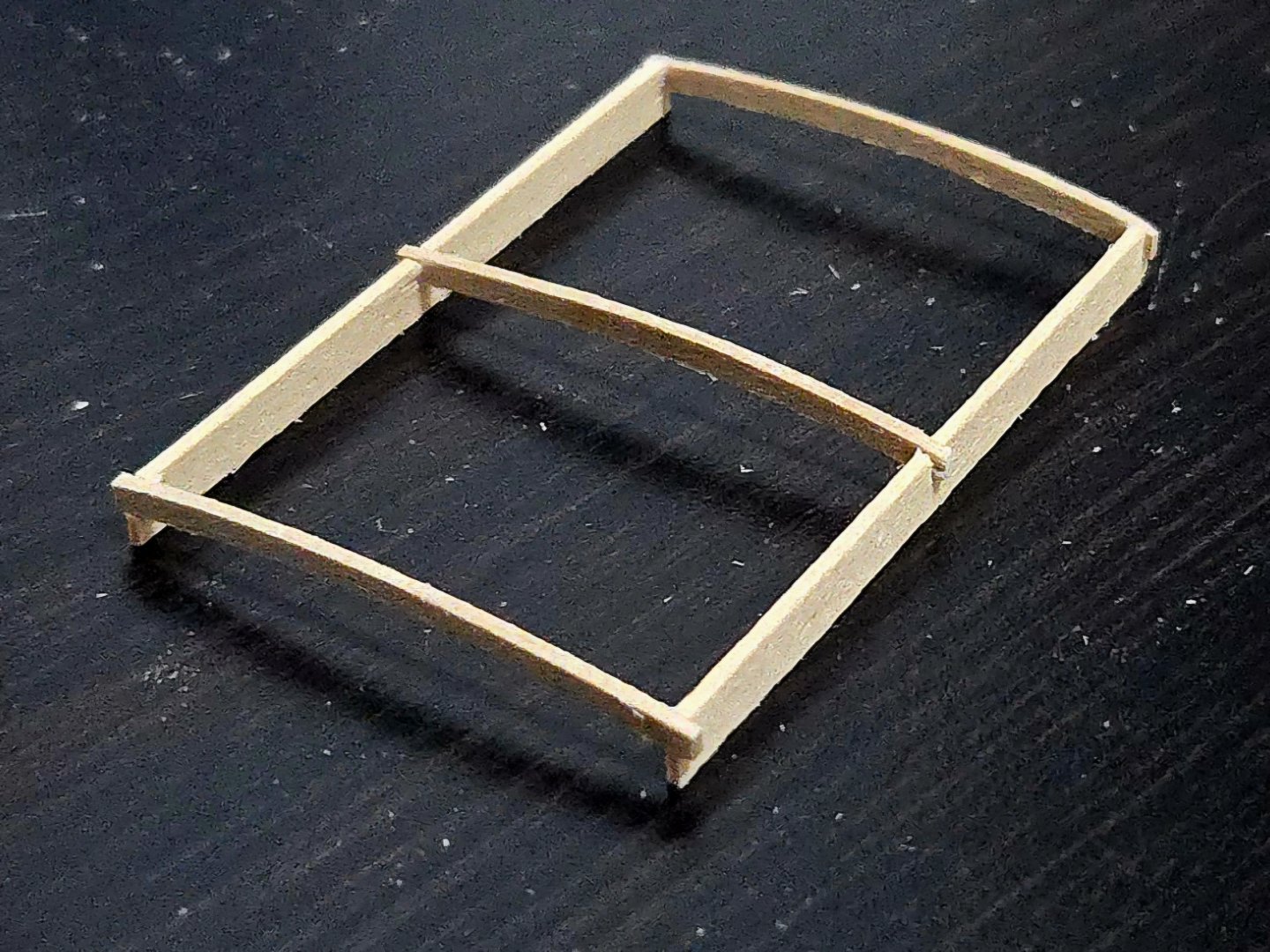

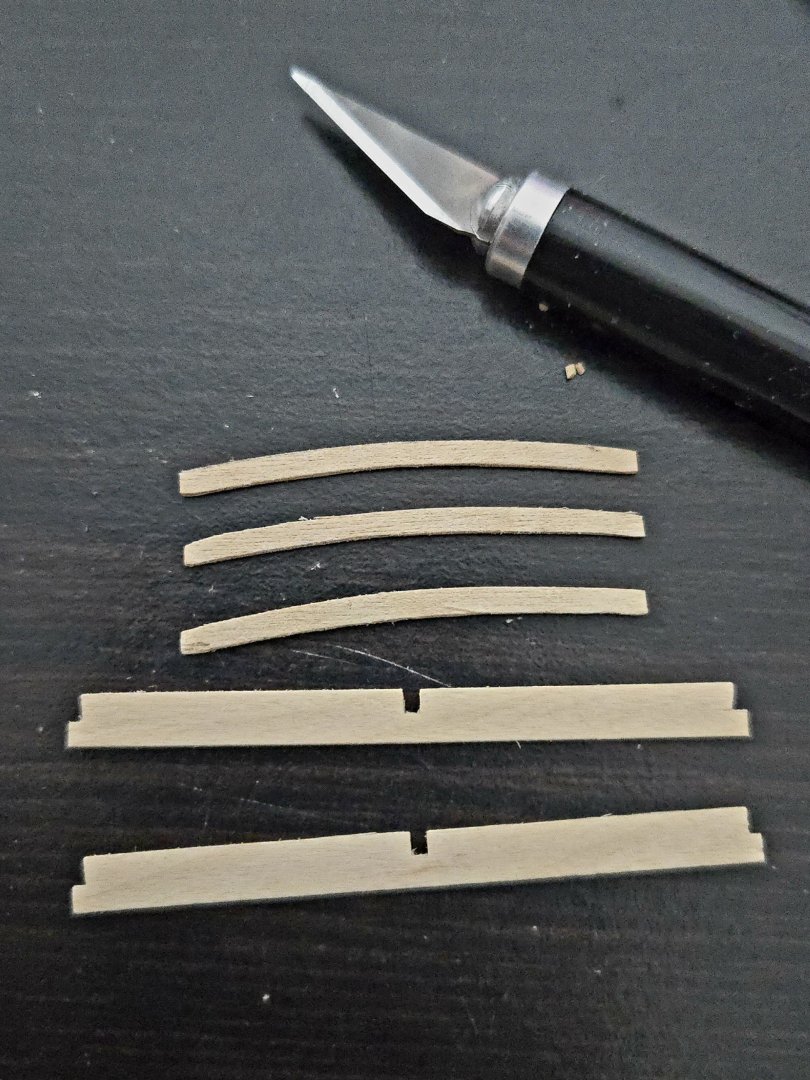

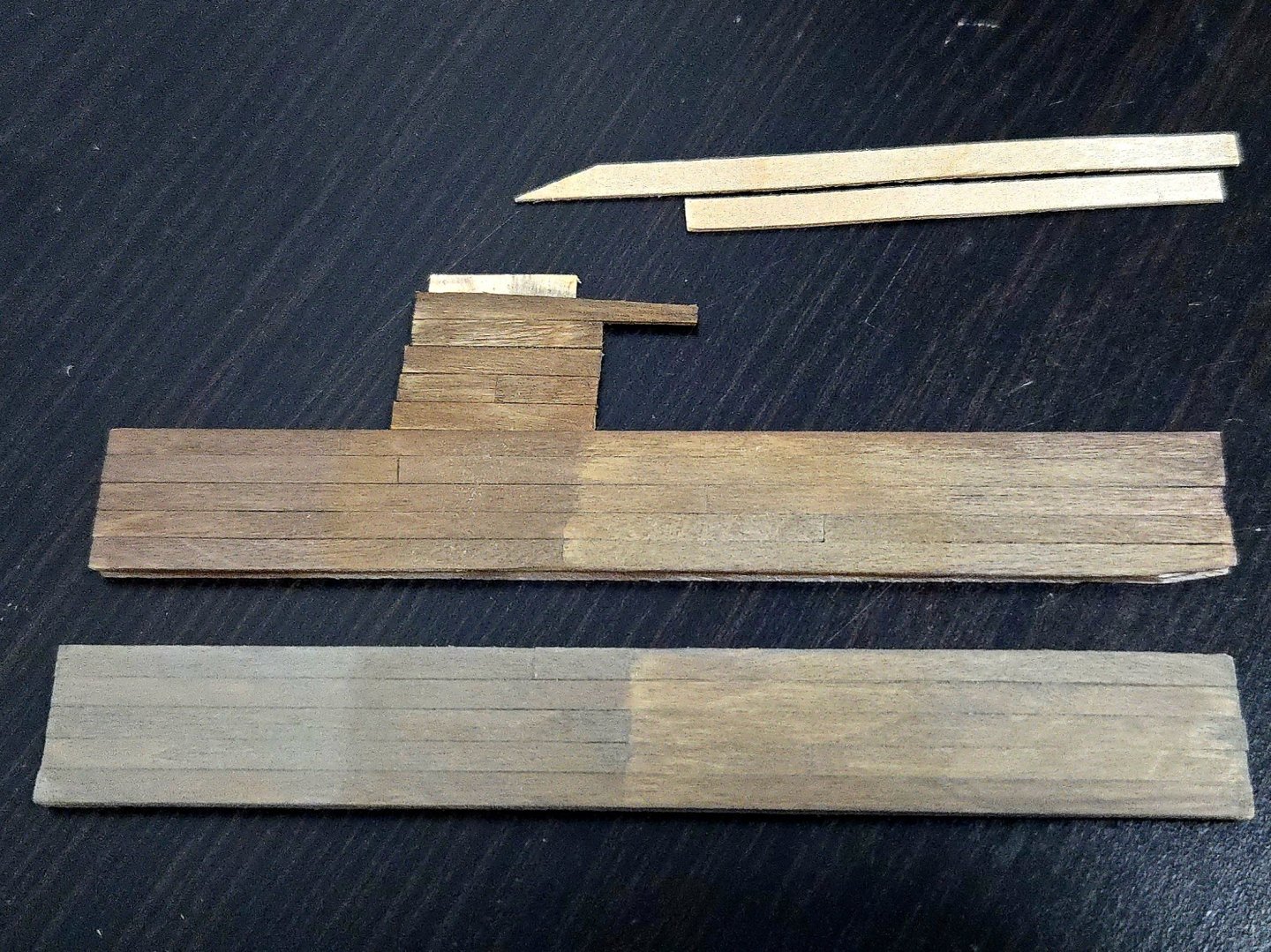

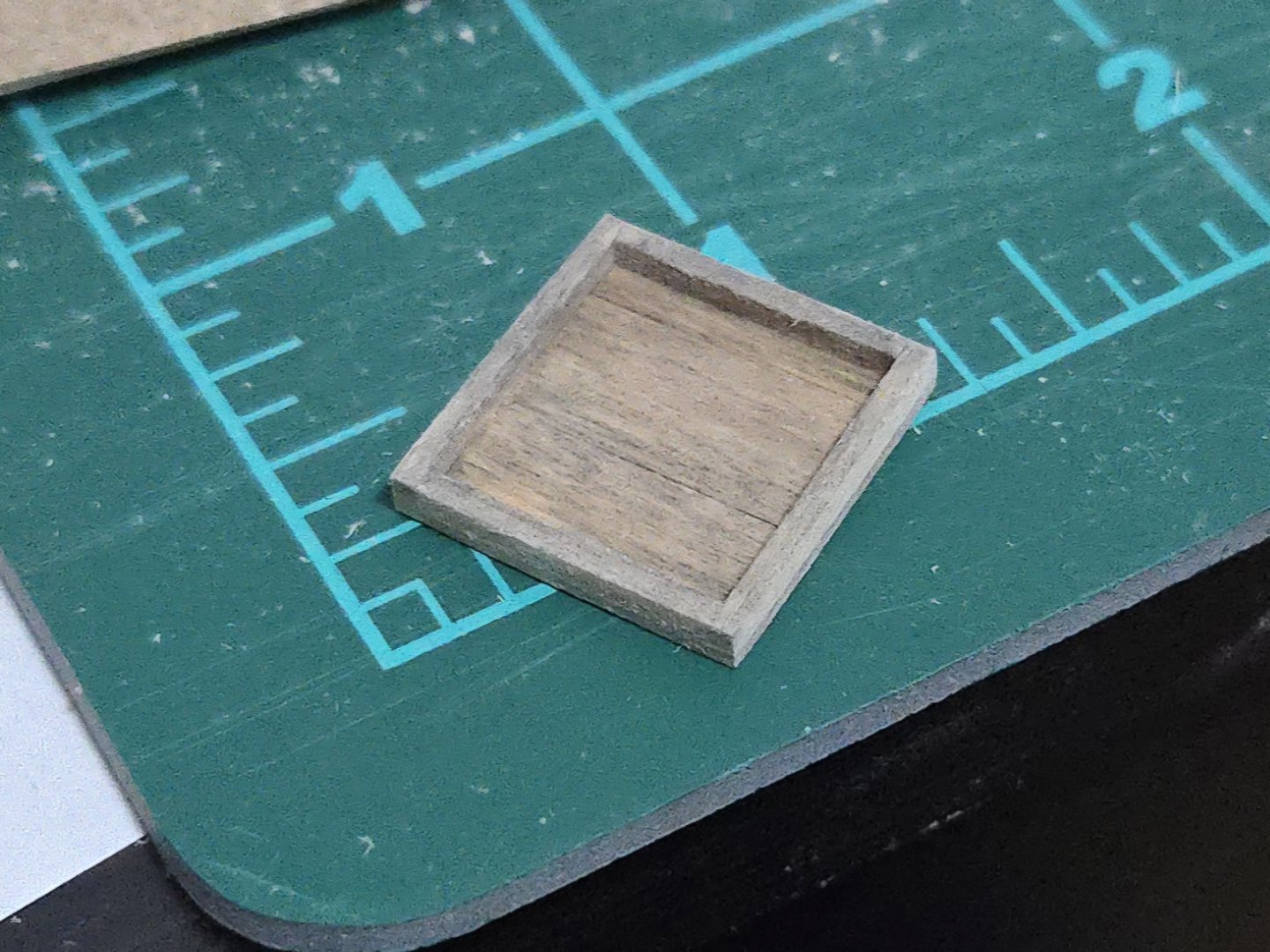

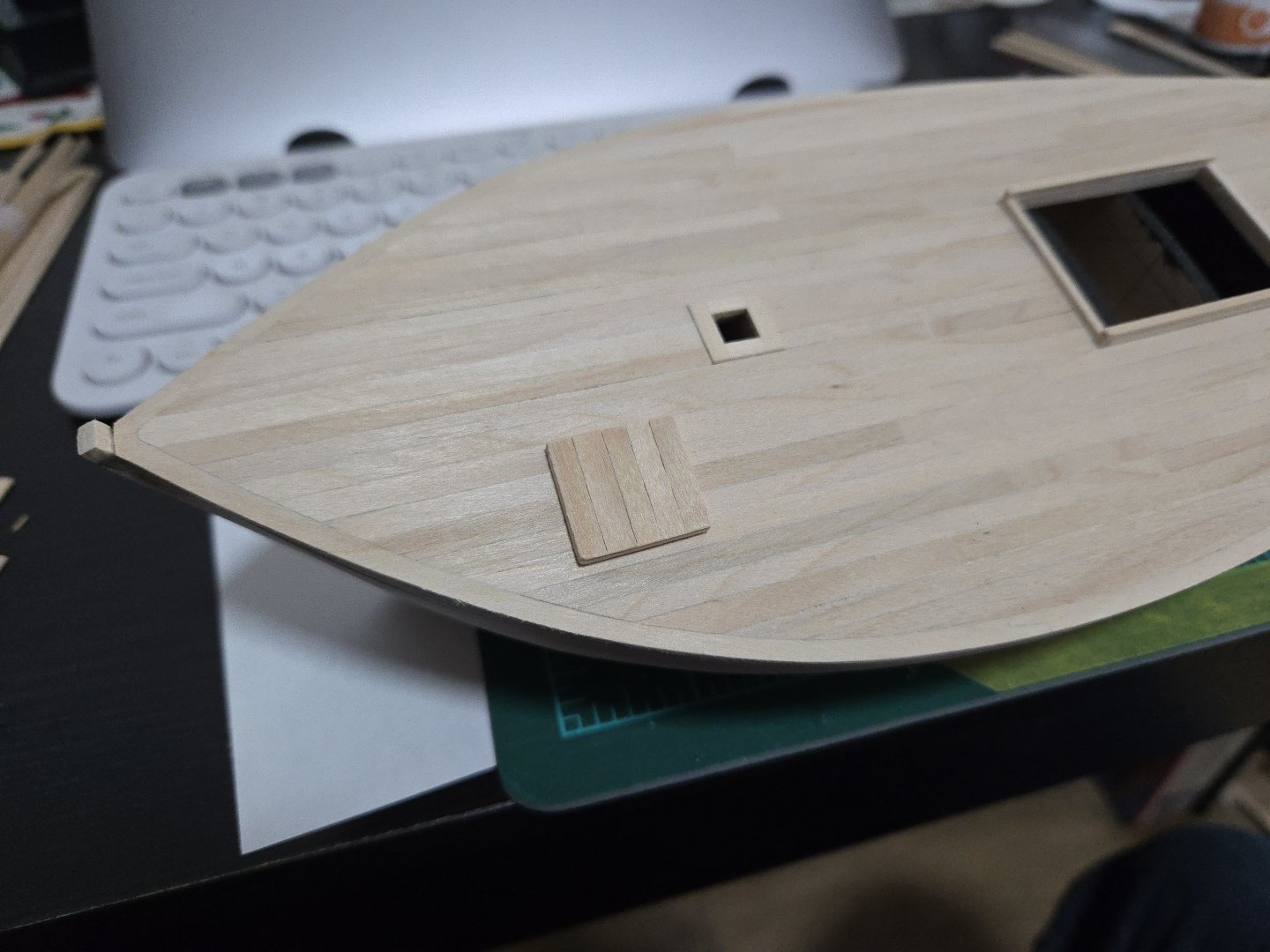

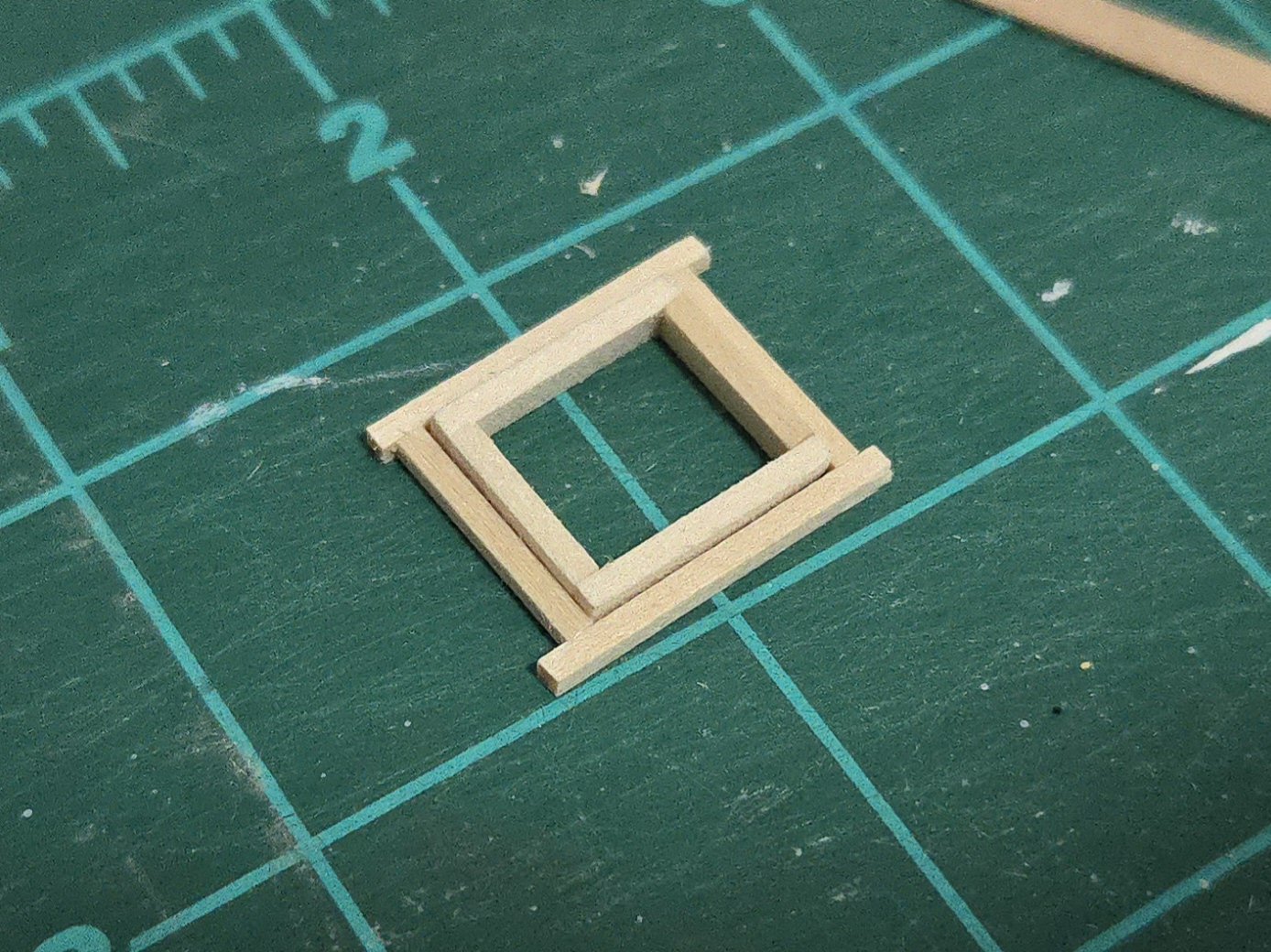

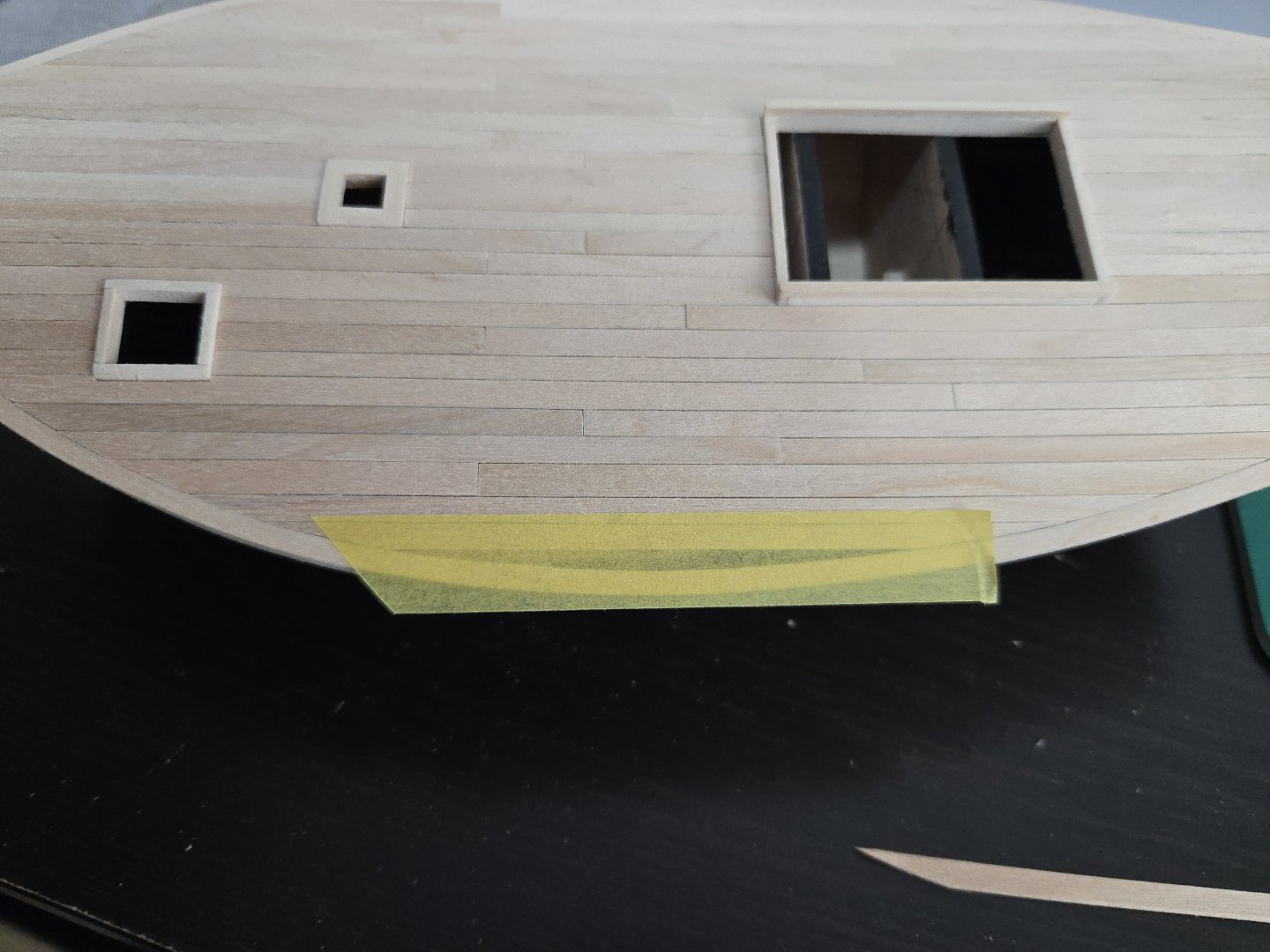

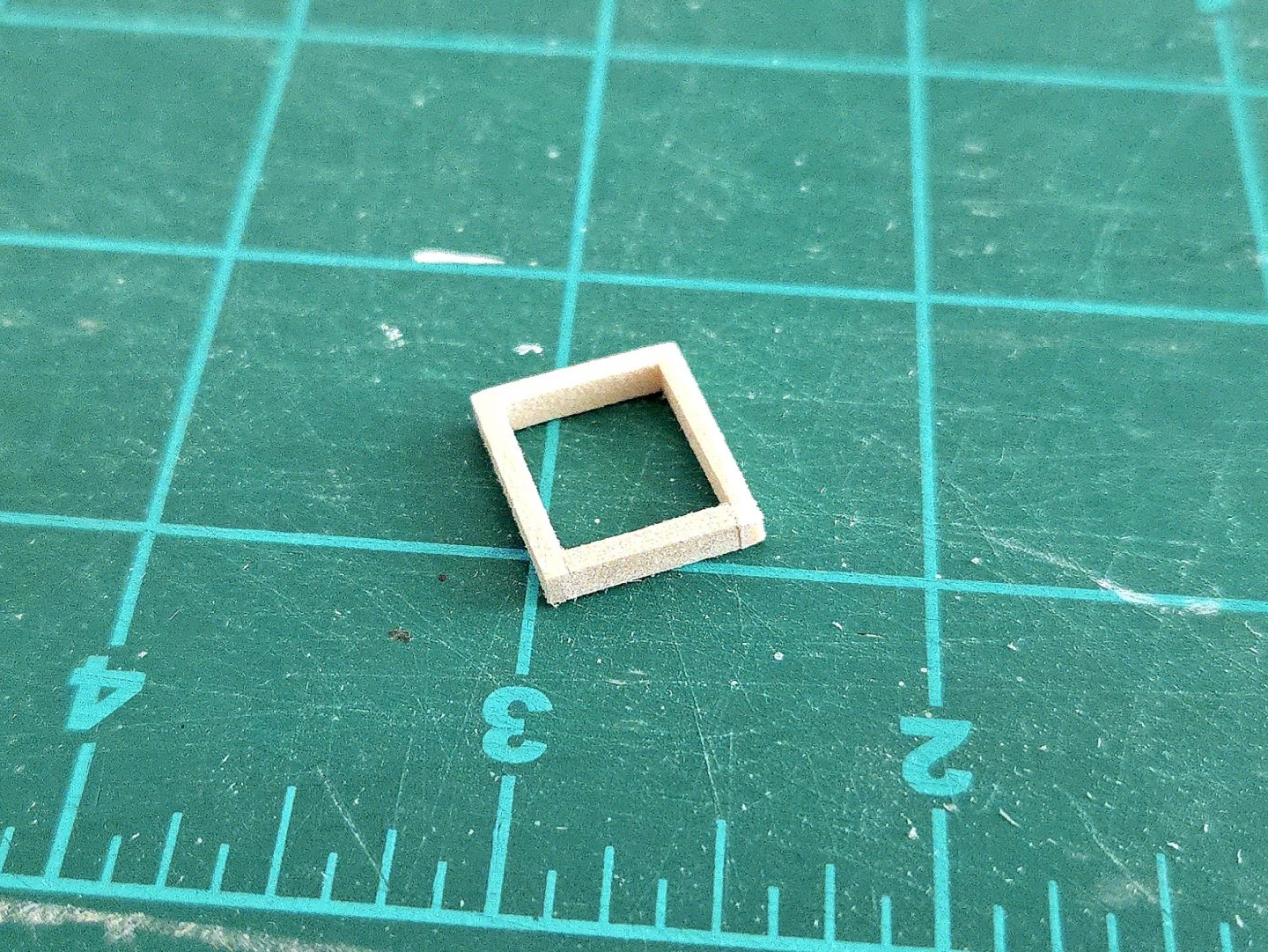

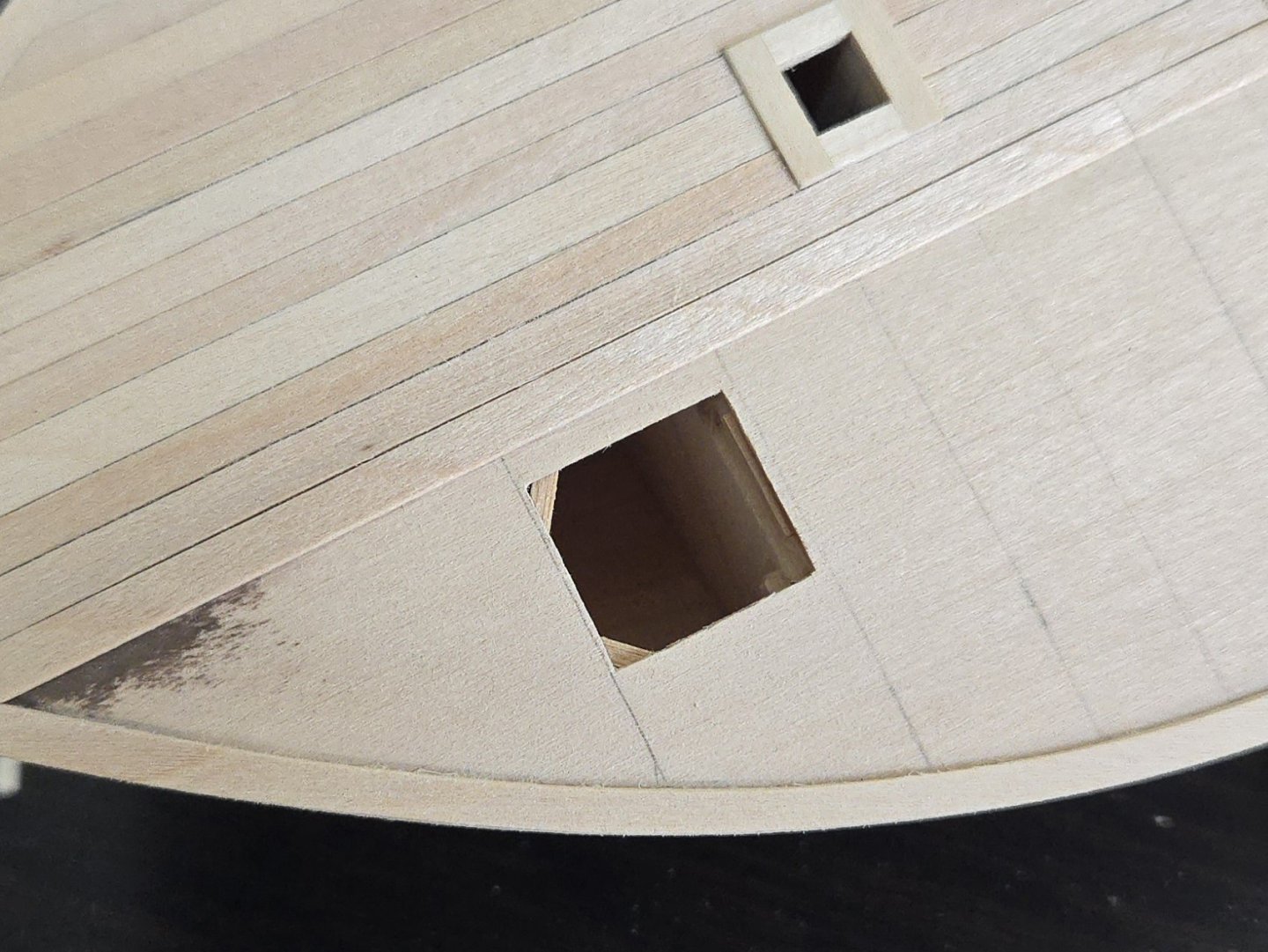

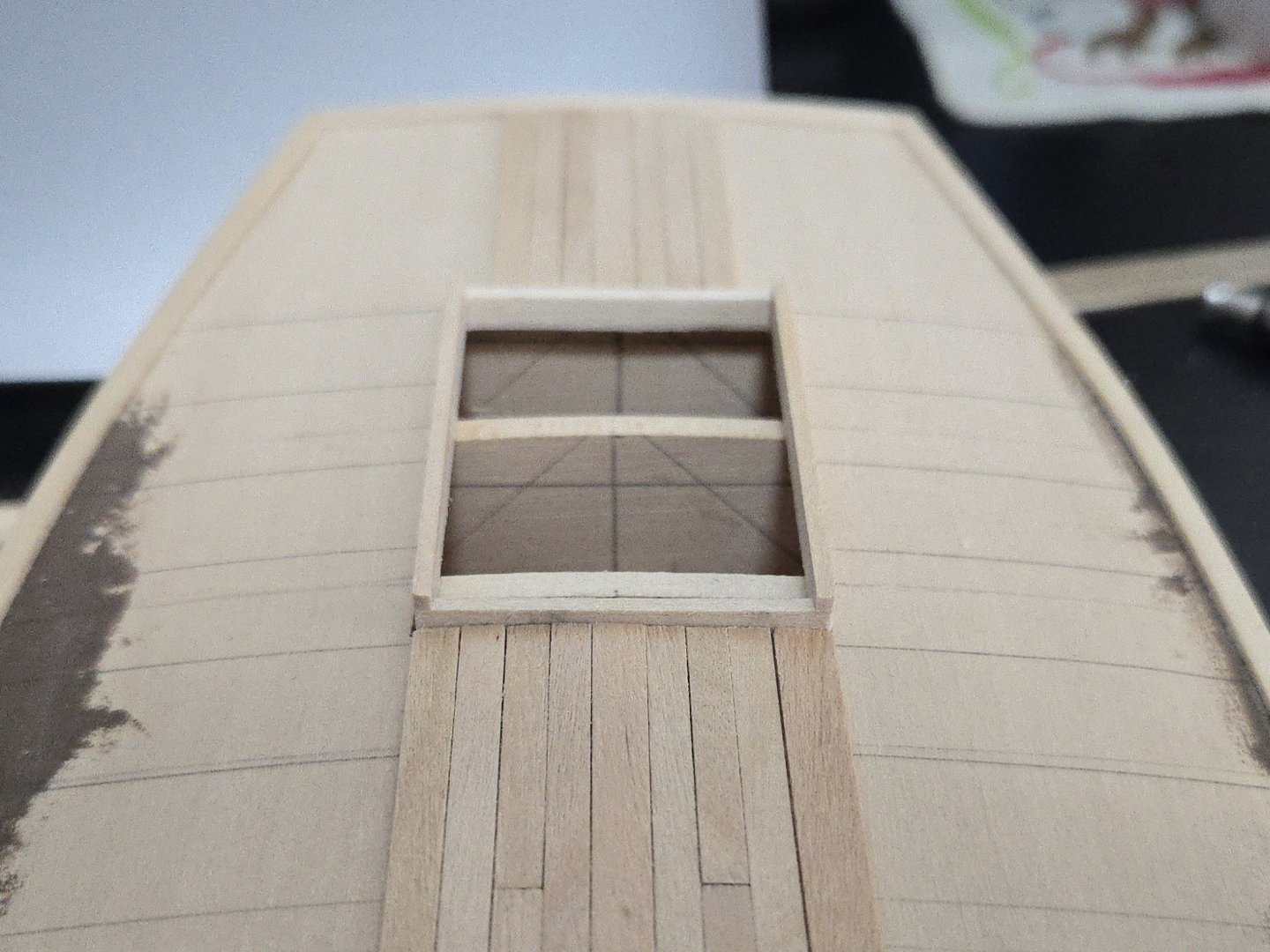

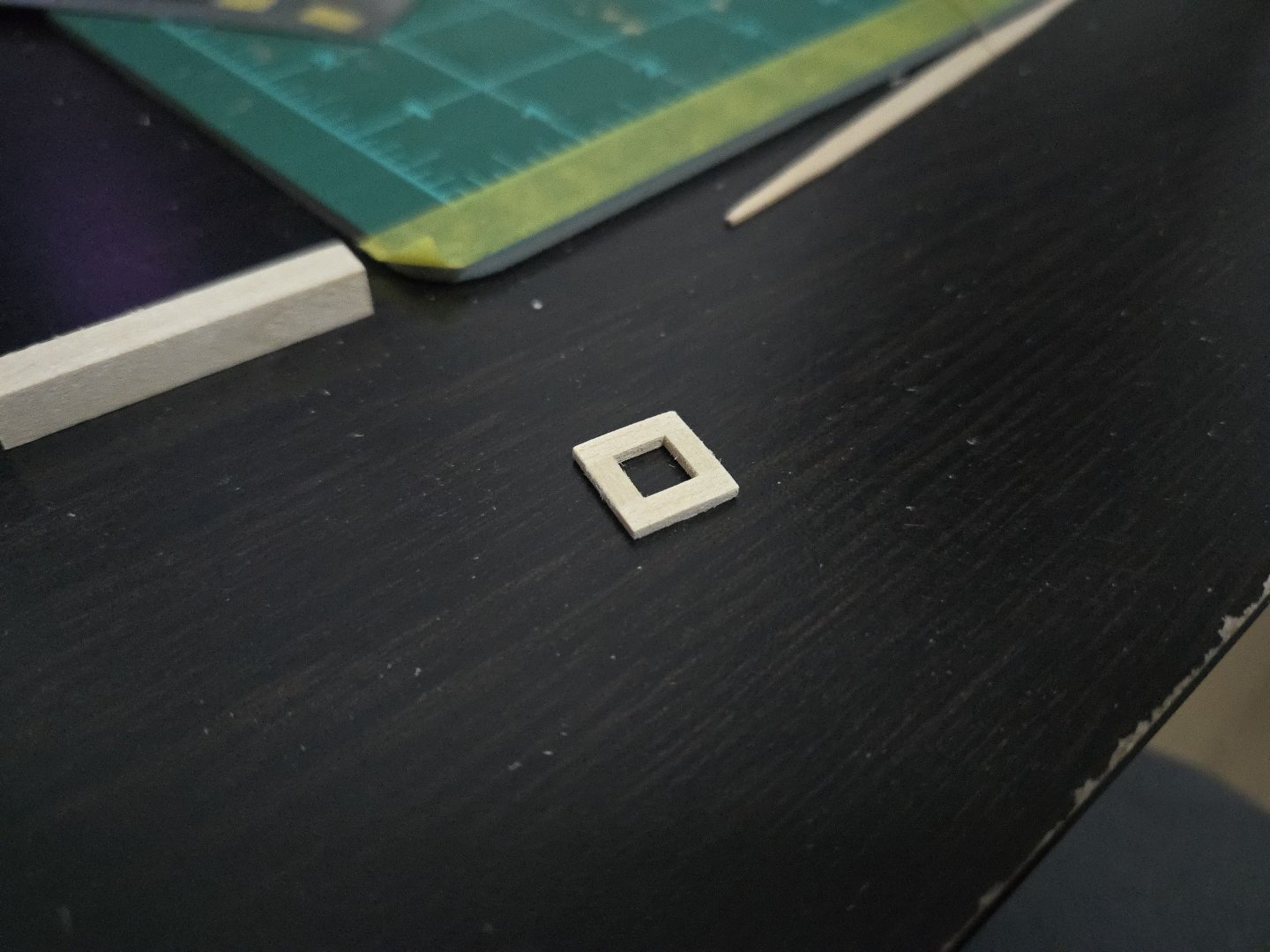

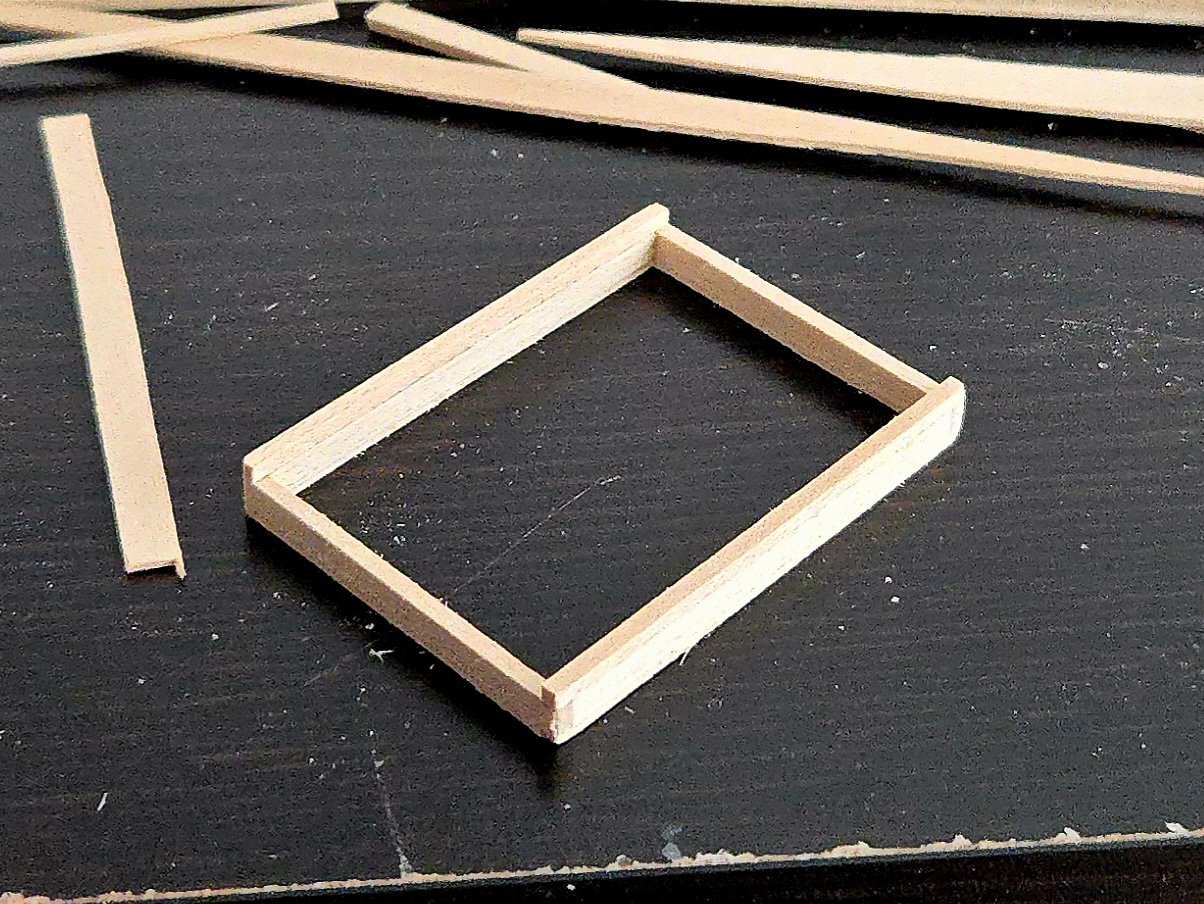

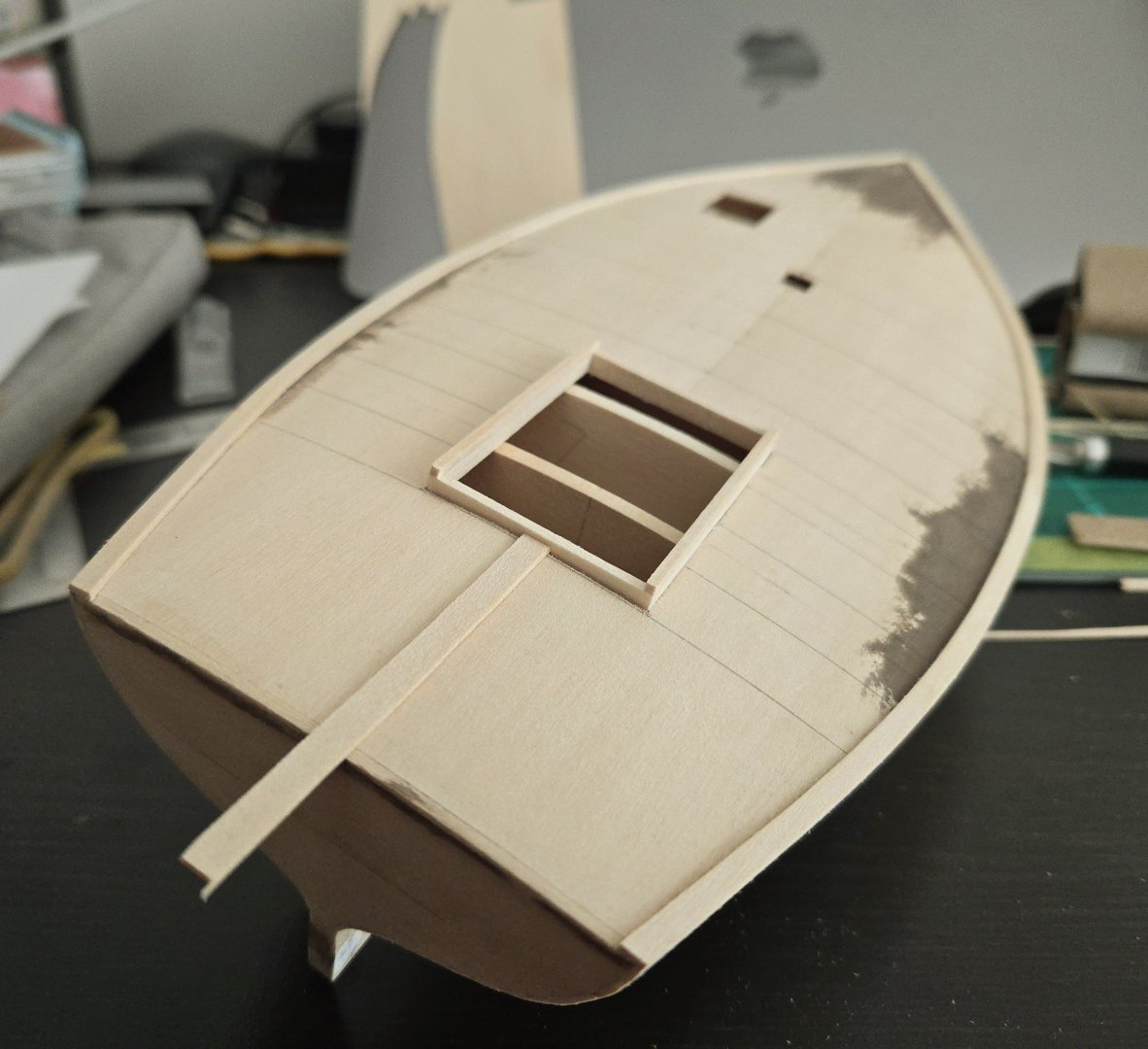

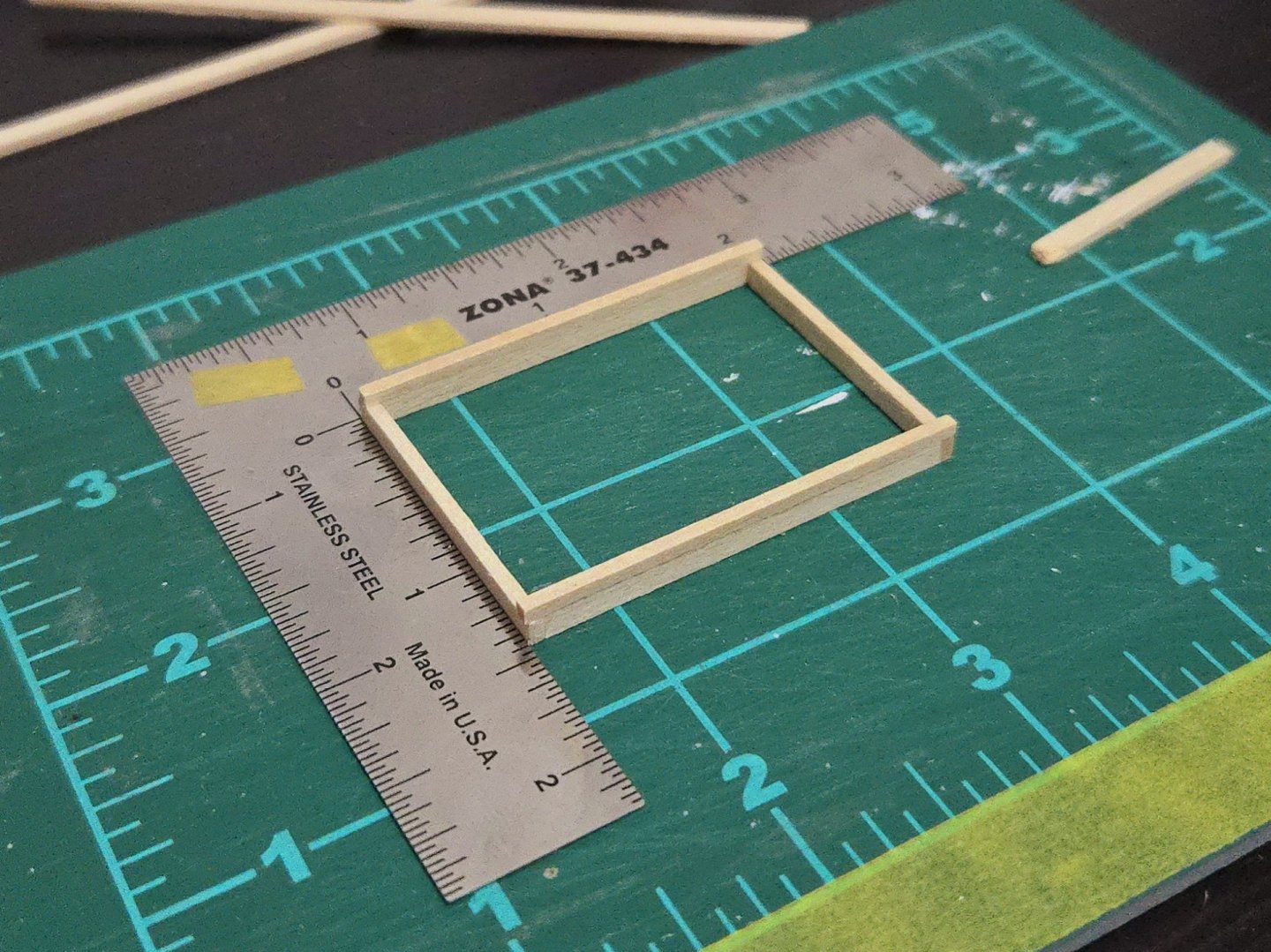

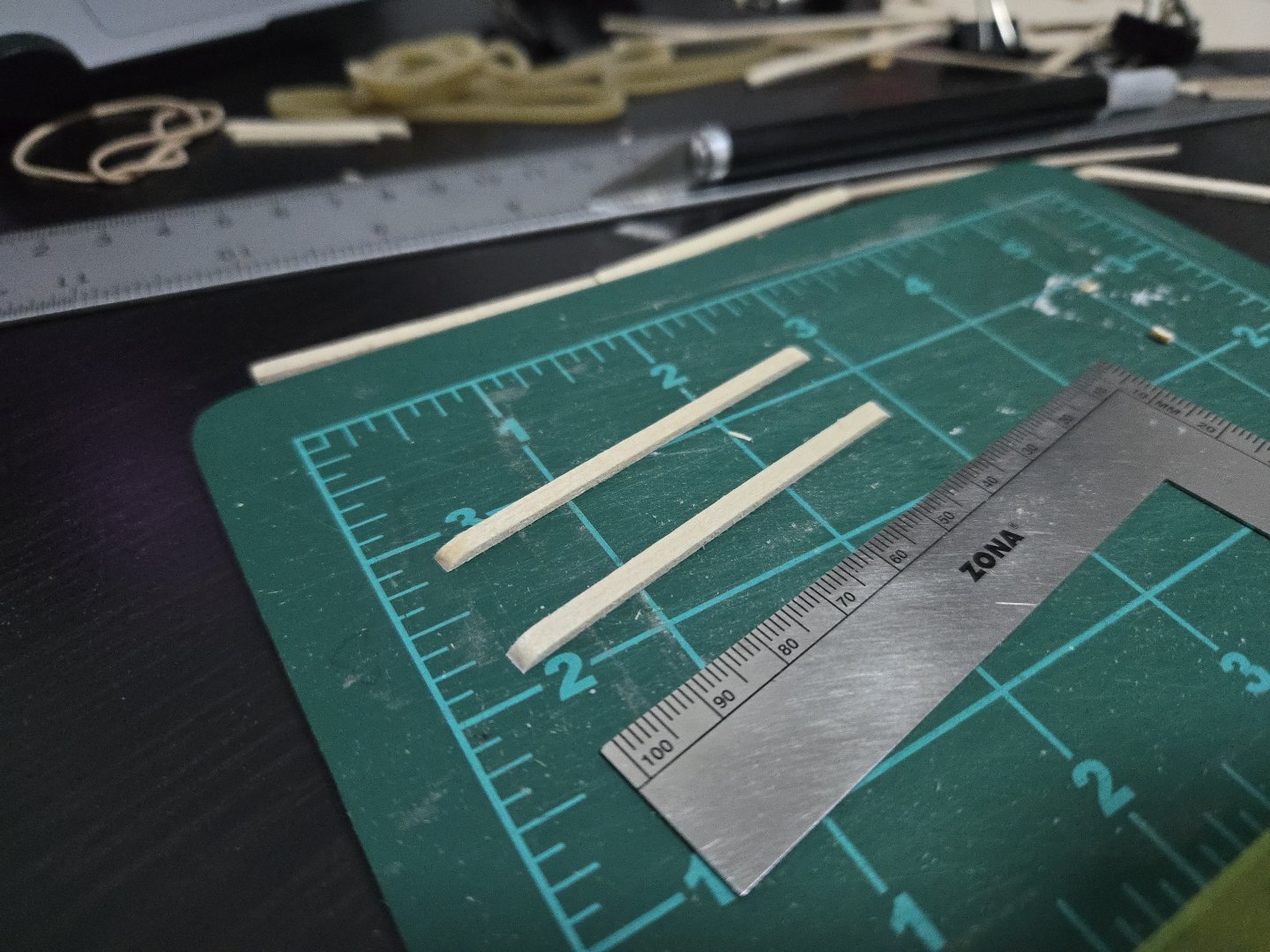

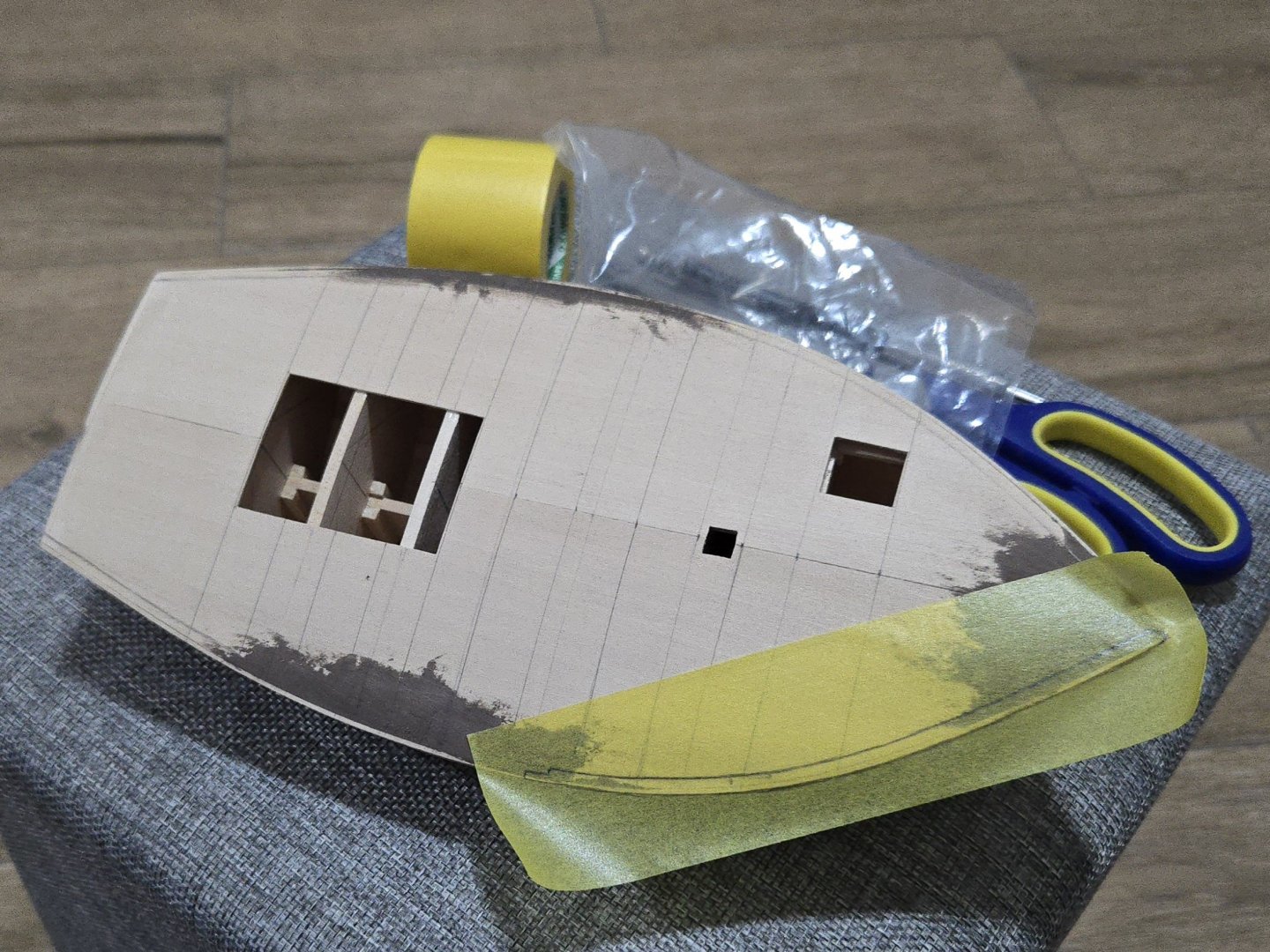

Thanks, all! I've never used sanding sealer under an acrylic wash before, so I decided to test how it looks with some scrap decks. I also was curious as to whether I could achieve an acceptable color with solely acrylics instead of alternating layers of stain and acrylic washes. On both scrap decks, the left half was left untreated before painting, while the right half received a coat of sanding sealer followed by a light fine-grit sanding. The top scrap deck was colored with alternating acrylic washes using colors directly out of the paint jar. For the bottom, I mixed specific colors and made washes out of them. For the top scrap deck, the four combos are, from left to right: 1a) black and dark brown washes on untreated wood, 2a) the same but with an added caramel-brown wash, 3a) the same colors as 2a but on wood treated with sanding sealer, and 4a) black and dark brown washes on sanding sealer. For the bottom scrap deck, the four combos are, from left to right: 1b) mostly a dark gray wash with a bit of dark brown wash on untreated wood, 2b) more dark brown wash on untreated wood, 3b) the same as 2b but on sanding sealer, and 4b) the same as 1b but on sanding sealer. Overall, while I quite liked the gray color, I think the top scrap deck looks closest to the brown decks that appear in photos, and 2a looks pretty similar to my favorite result from earlier tests with stains (which is just above the scrap deck in the photo). As a result, I think that I may not need to use stains after all. As for the sanding sealer, I had thought that it would even out the grain. While it did that for the first few layers, I feel like the unsealed wood ended up pretty consistent. I've also made progress on the hatch covers. For the fore hatch, I found several possible construction methods. One, seen below, just uses a few crossbeams to hold the hatch planks together. Source: https://www.memoriasdelsigloxx.cl/601/w3-article-86081.html However, I decided to go with the slightly more complex construction shown below, where a boxlike frame fits around the coaming. The frame will make it easier to prop open the hatch with a stick, as in the photo. Source: https://www.carlosvairo.com/galeria-puerto-montt-lanchas-chilotas I began by making the frame out of 1/16‐inch square basswood strip, building it around the coaming. I then planked it. Photos show that the fore hatch was planked side-to-side. I think it looks slightly bulky in the closed position, but when I hold it open, the size looks better. Finally, the exterior will be colored to match the deck. But I suspect the interior would be a bit less weathered, so I only applied a bit of wash there. The main hatch is a bit more complicated. As seen below, it's open at front and back, and there are lightly cambered crossbeams notched into tall side walls. Source: https://www.carlosvairo.com/galeria-puerto-montt-lanchas-chilotas There should be around 8 or so crossbeams. These posed a challenge: how could I make so many and all consistent? I also didn't want to make them by bending wood, as if they naturally opened a bit, the hatch sides would be pulled out at an angle. Moreover, that's a lot of notches to carve, and the notches are very fragile. My first attempt at the sides had to be discarded when the wood split around the notches. After some thought, I decided that modeling is in part about tricking viewers by taking advantage of what will be hidden on the finished build--like the underside of the hatch. I then carved just three crossbeams--enough to provide a decent gluing surface for the covering--and will glue on the exposed ends of the rest afterward. From the outside, it will look like a proper hatch, but on the inside, it will be greatly simplified. I then glued together the framework. Next up I'll need to fair the top slightly before adding the covering.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Nice job on the frame! You asked about fairing. Looking at the edges of the frames, I think you need to fair substantially more, especially near the bow and stern. Fairing does two things: first, it allows the planking to take a smooth curve without any lumps or low poinrs, and second, it angles the edge of the frame to match the shape of the planking there, so that the plank isn't just barely glued to a corner but can be properly glued with more surface area. Generally when fairing, you'll leave very little of the laser char on the edge of the frames (although you usually want to leave a little, as otherwise you may deviate from the frame shape). The best way to see if you've faired properly is with a batten--a long, thin, flexible strip of wood. Place the batten along the frames and check if it contacts all the frames, if any are too high and need to be sanded more, and if any are too low and need to be built up. Then repeat at different distances from the keel, covering the whole hull. I think that fairing more at the bow would give you more surface area to affix your plank, too. Also, you mentioned that you're planning on planking first one side, then the other. I'd recommend instead placing a plank on each side in turn. Otherwise, if it's not balanced, the pressure of the planking can warp the underlying structure and twist the hull, which cannot be fixed later. You're off to a good start, and this site has lots of resources and information, some a bit buried in other build logs. Looking forward to following along with your build!

- 51 replies

-

- bounty jolly boat

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Very cool, the parts look great! Another option might be, if you haven't already checked, to see if a public library near you has a makerspace. I was able to use one during my most recent visit to the US to laser-cut parts for an upcoming build. They taught me how to use the software, the only cost was for the materials. They also had a CNC router and a 3D printer, although I didn't use them, and my wife had fun learning how to use their Cricut machine. Depending on what's available near you, it could be another good option, although it sounds like Print A Thing was very fast and reasonably priced.

-

Looks like a tricky hull to plank!

- 90 replies

-

- Friendship Sloop

- bluejacket shipcrafters

-

(and 1 more)

Tagged with:

-

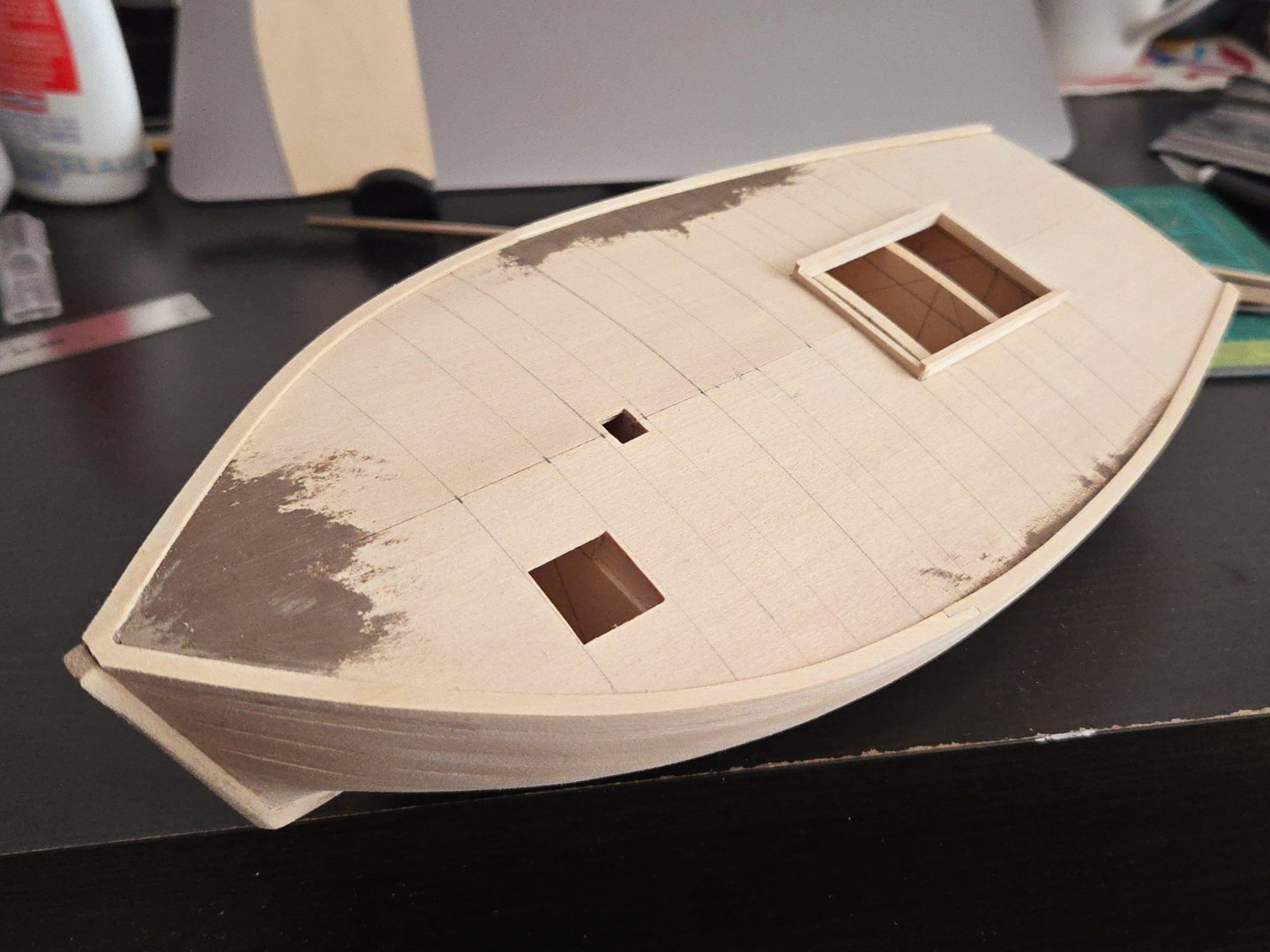

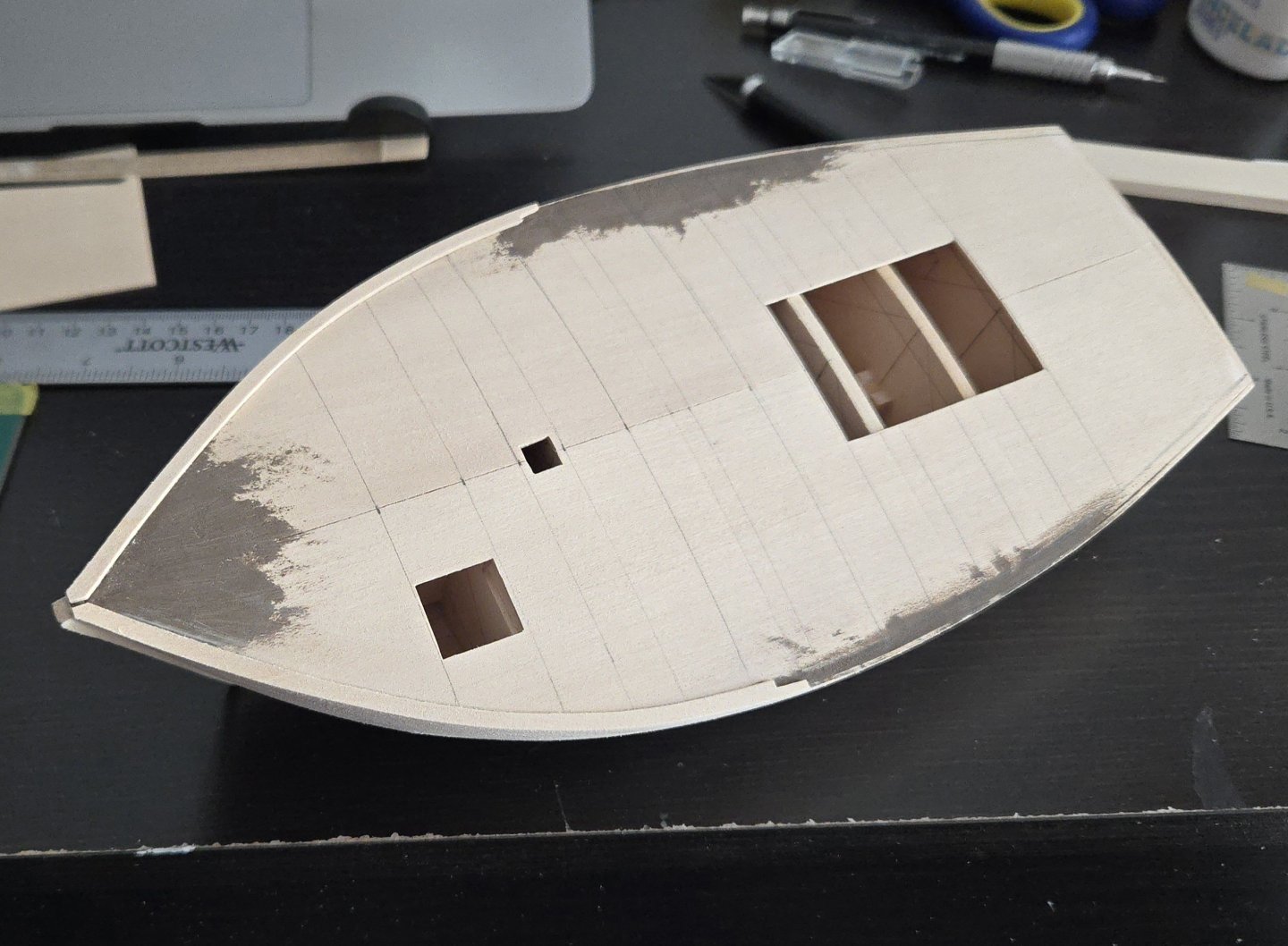

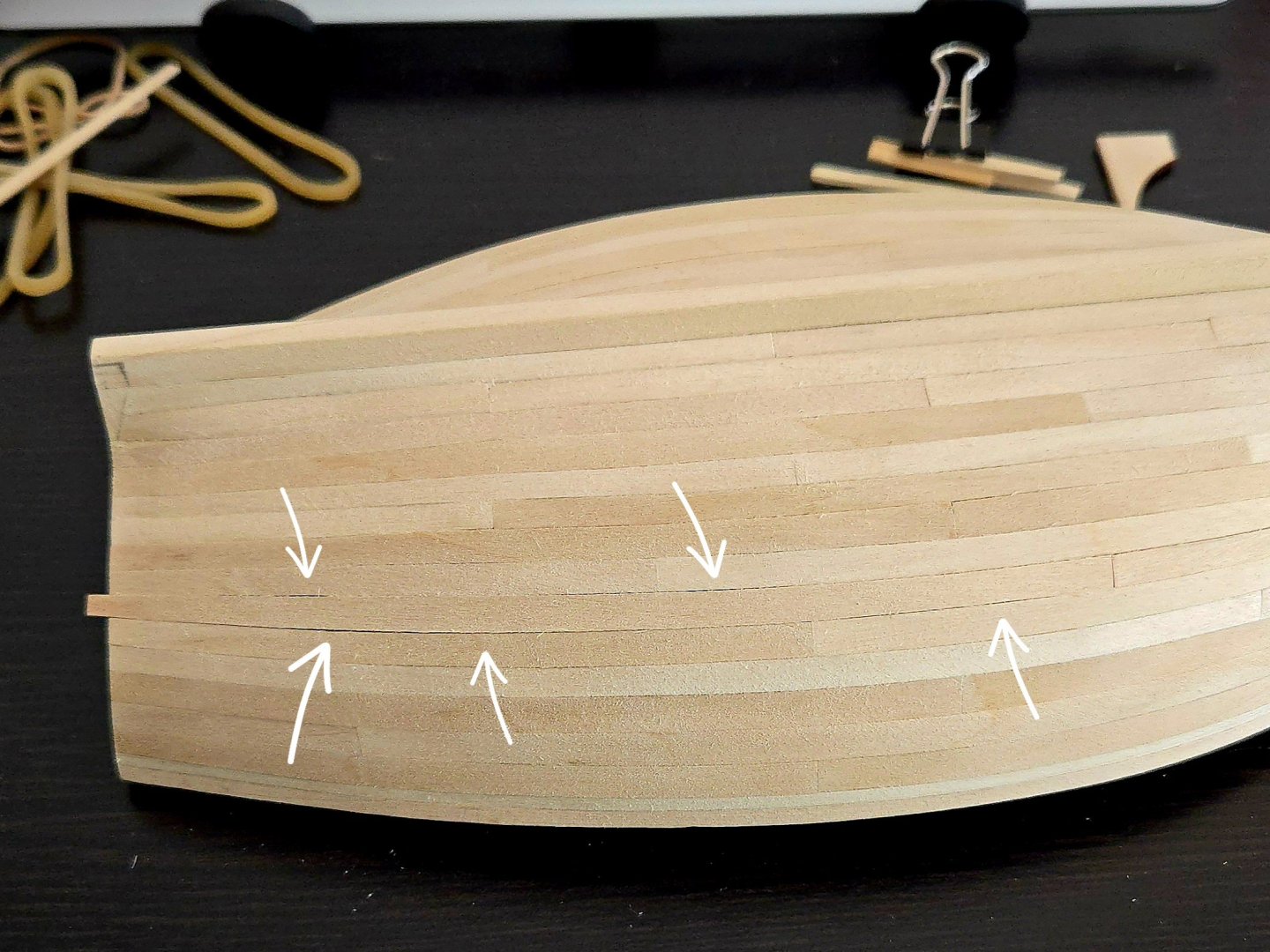

I have yet to visit the Caribbean, although I hope to someday. It's interesting what gets taken up and what doesn't. About a month ago, I visited the small river town of Tlacotalpan, Veracruz. In the 19th century, it was a relatively important port, where goods from Oaxaca were brought by trajinera barges (which interestingly have very little in common with the trajineras of Mexico City) to be transferred to ocean-going ships, but river trade declined after the construction of a railroad across the isthmus of Tehuantepec. Today fishing for local markets is a common activity, and fishermen have totally adopted locally-made fiberglass boats. Interestingly, they favor smaller, narrower vessels than the pangas I've seen elsewhere, while fishermen in the nearby seaport of Alvarado use both types. Below, the smaller vessels are in the foreground, while the tour boat at back left is the type of panga I've seen elsewhere. Boatbuilding in Tlacotalpan: Back to the lancha: while finishing planking the deck, I sanded down the already-complete starboard side. As can be seen below in comparison with the unsanded port side, sanding really made a difference and got rid of most of the unevenness. Continuing on the port side, I finally was down to the last plank, which turned out to be slightly smaller than its starboard counterpart. Rather than the trial-and-error method I had previously used, I decided to follow my hull planking method and use tape to mark out the plank. This helped in getting the rough shape, but there was still a lot of trial-and-error testing, sanding, and testing again. Finally, it was on. I was then able to remove the hatch coamings and mast partners and sand the deck. I still need to use a finer grit of sandpaper on everything. Next, I need to build the hatch covers, which with the coamings will be stained and painted the same as the deck.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Sounds like a good plan to me. This build is coming along well!

- 55 replies

-

- Le Martegaou

- billing boats

-

(and 1 more)

Tagged with:

-

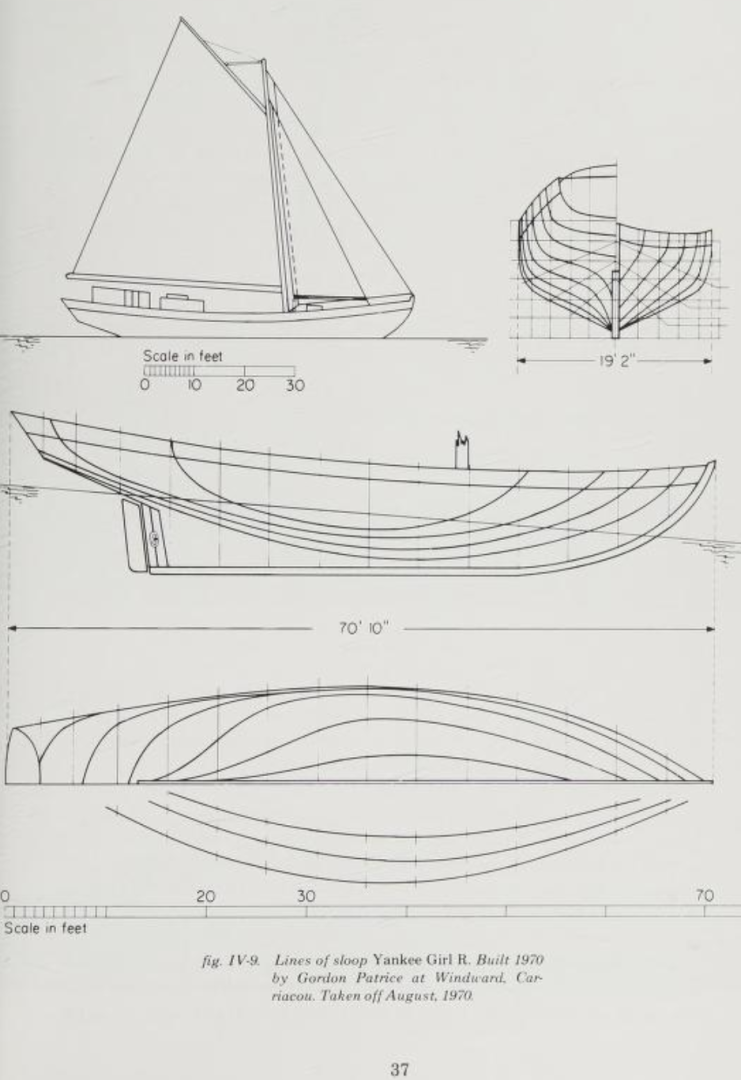

Thanks, I'll definitely add that Doran article to my reading list! I have access to the 1981 edition of Pyle's book. Given that the more recent edition has fewer pages, I'm not sure if they shrunk the images or what. Pyle's lines plans were taken from existing boats, and tend to be relatively simple--deck plans, if included, are very rudimentary. The book also includes a lot of photos. For the smaller, open boats, Pyle's plans plus the photos would probably be sufficient for building over a mold and adding frames later. The larger sloops and schooners would require a lot more reconstruction work for the deck and rigging details. Here's a typical example of the plan drawings for a larger vessel. Actually, it has slightly more detail than usual, showing the deck house in the side view. Plans for some of the smaller boats are shown here and at some of the links in the article text: https://indigenousboats.blogspot.com/2010/11/?m=1

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

The decline of artisan crafts is definitely sad to see. In Mexico, the tourist trade has played a major role in keeping craft traditions alive, at the same time that it has in some cases significantly changed the products themselves. Downtown Mexico City still has a few specialist artisans--I recently wandered across a very interesting old-fashioned leather worker shop, for instance. Interestingly, I’ve come across another useful source on the lancha chilota, something I should have encountered earlier. Finding it was a bit circuitous. While skimming Clean Sweet Wind: Sailing Craft of the Lesser Antilles by Douglas C. Pyle (Preston: Easy Reach Press, 1981), which is itself a fascinating book with many lines plans, I came across a reference to The Tortola Boat: Characteristics, Origin, Demise by Edwin Doran, Jr. (Supplement to The Mariner’s Mirror, Vol. 56 No. 1 [1970]). After checking it out online, and finding it to be a very detailed work—a modeler could use this to make a very accurate build—I realized that I hadn’t fully checked out The Mariner’s Mirror before. It doesn't have all that many articles on vernacular workboats of Latin America (although there are a few), after a bit of searching, I came across “Commercial Sail and Small Fishing Craft of Western South America” by Clinton R. Edwards (The Mariner’s Mirror, Vol. 53 No. 4 [Nov., 1967], pp. 357-370). Although it doesn’t include any plans, it’s a highly useful source on small craft on the Pacific Coast at midcentury, from an author I was familiar with from his Aboriginal Watercraft on the Pacific Coast of South America (Ibero-Americana 47, 1965), which focuses on indigenous designs (e.g., dugouts, reed boats, etc). The Mariner's Mirror article barely discusses the lancha chilota, though, noting that it had already been discussed in a previous article: “The Lancha Velera of Chiloé,” also by Clinton R. Edwards (The American Neptune, Vol. 26 No. 1 [January 1966], pp. 33-36). This whole process made me realize that I hadn’t been making full use of The Mariner’s Mirror and The American Neptune. While The Mariner’s Mirror does have a search function to find articles and keywords, I can’t seem to find anything like that for The American Neptune, probably because it’s no longer published. Does anyone know if there’s an index of some sort for the entire journal? In any case, the Edwards article from The American Neptune is useful, though brief, and much of what it says is similar to information in the Vairo article mentioned several months ago—although Edwards did his research in 1958 and Vairo in the early 1980s—and confirms what I’ve gleaned from photos. A few points are worth noting. First, Edwards does not really comment on the lancha’s origins, although he mentions that larger schooner-rigged vessels were built in the region for the coastal trade before the introduction of motor vessels (suggesting a design affinity if not necessarily a line of development), and his Mariner’s Mirror article includes some general references to the Euro-American origins of many small craft designs from South America’s pacific coast. On the lancha’s form and sailing abilities, Edwards describes is as “a shallow draft, potbellied little sloop, designed more for strength and cargo capacity than for speed. The hull, with its long, straight keel and ample midsection, is well adapted for beaching, but sailing qualities, especially windward capability, are sacrificed in this design. The rounded and rather hard bilges, together with a wide beam, make for stability, a necessary feature for the sometimes stormy waters of the gulf” (33). Taken together with Vairo’s comments about lanchas being slow to turn, it’s pretty clear that these were far from speedy, but why would they be? Unlike, say, a fishing boat that needed to be fast and weatherly to quickly get a fresh catch to market, the lancha was designed for wholly different purposes. The article includes a few details that, taken with photo evidence, may impact the final appearance of my build. On painting, Edwards describes the lancha as generally black on the exterior, occasionally with white bulwarks, and with the deck, hatches, and coamings left unpainted (33-34). The different-colored bulwarks that I’ve seen in some color photos may have been a later development. On the rigging, Edwards notes that steel wire has practically totally replaced rope in the standing rigging. “The rigging is set up with rope lanyards rove through rigging eyes and chain plates. Manufactured fittings such as turnbuckles and rigging shackles are rare. Many of the metal fittings are fashioned from miscellaneous scraps of iron which are bent crudely and adapted to use as marine hardware. Often, lengths of wire or iron chain are made up in rather ragtag assemblies to repair broken shrouds or stays” (34). This helps explain the reasoning behind the often bedraggled-looking stays that I’ve noted in photos. One interesting tidbit is that caulking was usually made out of the inner bark of the larch tree, rather than cotton, which seems to me to be a continuation of similar techniques used for making sewn-plank dalcas prior to the development of the lancha. Indeed, Edwards notes that the use of traditional techniques “such as hand-hewn lock joints, socketed frames, and use of treenails, which have all but disappeared in modern boatbuilding, are preserved in the trade here” (35). On lancha construction, Edwards notes that lancha building was concentrated in Chonchi and Quellón on Chiloé island itself, and in the mainland port of Calbuco, with Chonchi having a reputation for especially durable boats. Notably, Edwards states that boatbuilding itself was done by professionals, as specialization was required given the complex nature of the work, but “one or two boatwrights capable of making extensive repairs may be found in almost any town among the islands, and the farmers themselves are generally adept at maintenance and minor repairs” (35). As he makes it clear, lanchas were typically owned by farmers and used for carrying produce and other small cargos, such as lumber. One further question that I have, then, has to do with how farmers ended up purchasing their lanchas. Was it a cash transaction, or was there an element of barter or even of the communal mutual work obligations that Daughters noted as continuing into the 20th century? How expensive was a lancha, and what proportion of farmers actually had one? How did this compare with the dalcas used previously? And how did all of this change over time? Answering these questions, which would likely require work in notarial records, would help to better piece together the relationship between the rise of the lancha chilota and the spread of the market economy on Chiloé, an issue I pointed to in an early post here. Another interesting point raised by Edwards, echoing other sources I’ve referenced, is that most lancha bows were “usually plumb or only slightly overhanging” (33). This is definitely not the case for this model, but though it may be a bit unusual it’s not necessarily inaccurate. See, for instance, this vessel, the Marisol del Carmen. Source: https://www.latercera.com/paula/aprendices-de-chilote/ (As a side note, the Marisol del Carmen was unfortunately wrecked by a storm in 2018, thankfully without loss of life.) Source: https://www.soychile.cl/Puerto-Montt/Sociedad/2018/06/01/536776/Lancha-chilota-naufrago-en-la-costanera-de-Puerto-Montt.aspx As for the build itself, I’ve been busy this week so I’m still making very slow progress on planking the deck. The most interesting other thing that I’ve done has been to paint the interior of the fore hatch and the parts of the main hatch that would be visible with the cover cracked open. These are hardly great paint jobs, but are intended just to leave the interior dark and shadowy. I’ve decided that the fore hatch will definitely be left open, but the main hatch will depend on whether I can convincingly hide the central spine of the model, which otherwise is very visible even with a coat of black paint. Options include just adding a black panel to cover it, or adding some cargo—either a representation of a load of lumber, or a sack or two to represent produce, like those I added to the cargo canoa build.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thank you, all, for your input. I hadn't really been thinking of displaying the model resting on the guarda playa, but I may need to reconsider. Going for a full diorama could be interesting, but I think I'll stick with a simple wooden base this time around, as I've been looking forward to using the cherry board and I think the wood tones will contrast nicely with the black painted hull. Wefalck, it's interesting how starting modeling has changed how I look at materials encountered in everyday life. Suddenly, so many items seem full of possibility. Just the other day I was walking past a hat shop and noticed that they sell some kind of long, straight, narrow straw material. It would have been extremely useful for the thatching on the Canoa de Rancho build, and would likely be ideal if I ever decide to model a reed boat. Anyway, I've finished planking the starboard side. Fitting the last plank was quite the challenge. I should note that I've seen no evidence of the planks being nibbed into the covering board. I also didn't end up following a set butt shift pattern, instead just trying to avoid placing any too close together. I've also been making a little more progress on the port side. I've discovered that the model isn't perfectly symmetrical, so I'll be carefully measuring at every step to ensure a relatively even planking job. This first plank alongside the main hatch, for instance, needs to be slightly narrower on the port side than on the starboard side. I think slight differences in plank width will be less noticeable than having a different number of planks per side. I think that sanding the decking will smooth out some of the dark lines between planks.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thanks Paul! I have considered it, I think it could be a very interesting option. It would definitely be unique and also true to life. That said, I think it would also somewhat obscure the curves of the hull, and it would also preclude displaying set sails. I'm still deciding whether I want the sails set or furled.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

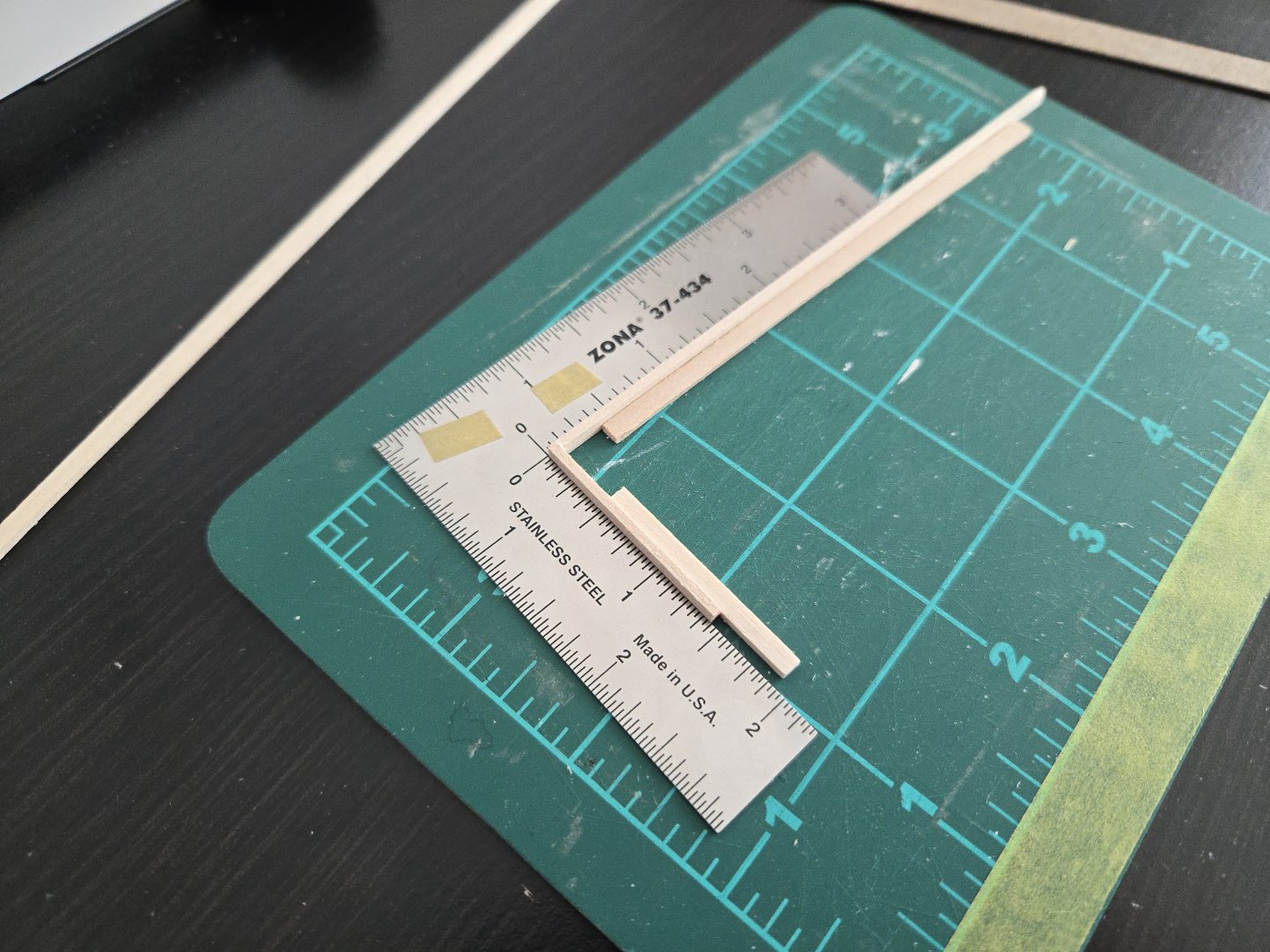

No worries! I do when I'm in the US, but I'm usually limited to what I can pack in a carry-on and I generally buy sheets rather than strips as they're more useful for my hull planking method. In the future I may try to get more strips though. Unfortunately, so far all I've found in Mexico City is 1/16‐inch basswood sheets, and a wide variety of balsa wood (which is not very useful for modeling). On another topic, I'm trying to figure out the base for this model, so that I can do any required drilling on the bottom before anything fragile has been permanently added to the topside. I liked the sort of "scaffolding" I did for the Canoa de Rancho, but I want to do something different on this build. On my last trip to the US, I placed an order with Joe at Modeler's Sawmill for, among other things, a 4x16x3/16-inch cherry sheet. (I'm quite pleased with the order, and highly recommend the shop.) The wood will make a nice base. 3/16 is a bit on the thin side for a base, but I'm planning on thickening it a little with a cheaper wood on the bottom, and then adding a thicker trim around the edges, either in cherry or in a contrasting lighter wood. I plan on finishing it with linseed oil, as I did with the basswood of the NRG Half-Hull. Aa can be seen, it's a bit oversized, so I can get some extra usable material by trimming it down to an appropriate size. I'm thinking of two options for how to mount the model. One would be to make a simple wooden cradle, based on a pair of bulkhead shapes from the plans. This option would require the least amount of work on the bottom of the hull--at most, just a small hole in the keel for a pin. That said, I'm not crazy about how cradles can interrupt the smooth lines of a hull. So, the second option would be to support the model on two lengths of brass tubing running into holes in the keel. It would have an effect kind of like what I did on the Juana y José cross-section, below (although there the posts are wood, and they actually fit around the keel, which is very thin). This option would much better show off the hull. The challenge is with drilling into the keel. The keel is 3/16-inch thick basswood, so I don't want to choose tubing that's too thick. Moreover, ideally I'd like to drill the mounting hole into the false keel, as well, which would make for a much stronger mounting, but the false keel is only 1/8-inch thick and thus would require even thinner tubing to create a reasonably secure mount--I think 1/16-inch tubing is about the thickest I can reasonably use, although I'm not sure if that's so thin that it will bend too easily. My best bet may be to position the holes where the bulkheads are located, so that there's a bit more wood to support everything. However, this brings me to the other challenge: the difficulty of drilling straight and perfectly centered, especially as the sheer makes it impossible to position the boat upside down such that the waterline is perfectly flat and even. Thankfully, at least there's no drag on this hull, and the waterline is parallel to the keel. To deal with this challenge, I think my best bet would be to make a drilling jig with scrap 3/16‐inch basswood. By measuring carefully and drilling a pilot hole from both sides, I can theoretically get centered perpendicular holes the proper distance apart, and I can place the jig on the keel to hold the pin vise properly squared and centered to drill into the keel and false keel. It would be a relatively simple matter to mark the depth on the drill bit with a bit of tape or something so that it sits evenly on the base. At least, that's the plan. If it doesn't work, I can always go with the cradle option.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thanks, all! @Keith Black, I agree that they're not the best quality lumber, but Midwest strips aren't available here. @Jim Lad, not all coffee stir sticks are the same, but some are surprisingly decent quality. In the photo below, the ones on the right are pretty atrocious. I only grabbed them for paint mixing, although I'm now thinking they could be cut up to represent a cargo load of rough-milled lumber. The sticks in the center/center-left are the two types that I'm using. Although some are inconsistent and unusable (see the two on the far left), in general they have a relatively even grain and can just be lightly sanded on the edges to even up the sides before use. Widths aren't perfectly consistent, which would be a problem if I were making, say, a ship of the line, but this is acceptable for a small workboat that in real life at times had deck planks of inconsistent width. @Glen McGuire, that could have worked, but then the center plank would have been off-center unless I removed all the planking and started from scratch. I ended up slightly widening the two replacement planks. Although the plank that goes to the edge of the hatch is still wider than its counterpart on the other side, it's less noticeable now. In any case, before I continued on the port side, I needed to frame the fore hatch. This was surprisingly tricky for two reasons. First, due to the deck camber, the pieces needed to be joined at an angle. This took some work to get right, and I had to redo a couple of the parts. Second, there was nothing inside the hatch hole with which to hold the coaming in place. After trying and discarding a friction fit--too much risk of the coaming falling in and being lost forever--I carefully super-glued in a few supports, two in the fore corners and a long thin one along the aft edge. With this, the fore hatch coaming is ready and I can continue planking the port side. I've also made progress on the starboard side.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

After some consideration, I decided to remove the two planks from the port side. I can replace them with slightly thicker planks and end up with a more even planking job. They came off pretty easily after being soaked in rubbing alcohol--while there's a lot of surface area glued, the glue joint isn't all that strong as I'm not able to clamp any of these planks. I'll just make sure to secure any cleats that may have a bit of pressure on them not only with glue, but also with a pin. In any case, I've continued planking the starboard side. I'll just need to take care that the port side planking matches.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thanks! Planking the deck seemed to be going well. However, I then ran into a problem. The coffee stir sticks I'm using for planking are not wholly even. I thought that I was doing a good job of evening them with a bit of sanding, and they seemed close enough. However, as I reached the edge of the main hatch (which is centered), I found that the port plank needs to be a full 1/16-inch wider than its starboard equivalent. The three previous port planks were all slightly narrower than their starboard equivalents. Individually it's not really noticeable, but the cumulative effect of three in a row like that really added up. Below, you can see how the rightmost plsnk is notably wider. So, I'm now trying to figure out how best to deal with this. The simplest option would be to just leave it as it is--as discussed in earlier posts, the real vessels certainly had some irregular-width planks on their decks. I'm concerned that this will look a bit off, though. Below, you can see how that would look, roughly, with further planks loosely held in place with rubber bands. My sense from this is that the wide plank running into the hatch is still quite noticeable. The other option would be to remove one or two of the port side strakes and replace them with slightly wider ones, so that the plank running into the edge of the hatch could be a bit narrower. I could remove all three to fully redo it, but I think I could disguise the irregularity just fine with just one or two new ones. In any case, this is a definite issue with using coffee stir sticks as modeling material. They seem fine overall, but I would recommend checking carefully with a gauge to make sure they're even.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thanks, all! Keith, I agree that workboats are fascinating subjects (and very nice job on your steamboat, by the way). I've finally gotten started on the deck planking. First, I had noticed that some photos show a thicker square or rectangular mast partner, as can be seen below: Source: https://www.memoriasdelsigloxx.cl/601/w3-article-2204.html I made one out of basswood, building it around a small length of 1/4-inch square stripwood that will serve as a stub mast during building. I then added a covering board along the stern (which will be covered by the aft rail), and also a bit of wood at the bow to extend the stem (the joint of which still needs to be filled and sanded). It was now time to begin the deck planking. The main hatch coaming and the mast partners are just friction-fit into place for now so I can get a tight joint, but can remove them to sand the deck. I started with the king plank, which had to be made of multiple stir sticks--hopefully the color differences are evened out a bit once I apply stain and washes. I then added the next two strakes, one on each side, using the thinner of the two sizes of stir sticks. I'll be using a mix of the two widths in a semi-random pattern throughout. In this case, the thinner sticks were the perfect size to match the edge of the mast partner, so that subsequent strakes don't need to be cut to shape around them. Going forward, I'll need to add the fore hatch coaming, and work out some sort of plank butt shift pattern.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

@Paul Le Wol, I'm not sure why they removed the full aft rail, but it seems to have been a general change not limited to just the Quenita. Perhaps it did make cleaning easier. A bit more progress on the build. First up, the guarda playas have been added. I still need to add a bit of filler where they didn't conform perfectly to the hull. As can be seen, the model now properly rests on the guarda playa. I also finished the main hatch coaming. I built this out of several layers, as this allowed me to use strip materials I had at hand. Given that the hatch cover will be either completely or almost completely closed, the layering shouldn't be visible. First, I simply butted together some 1/16x1/8-inch strips, taking care to get them square. After finishing that layer, I placed a 1/16‐inch square strip over the top running fore and aft. The overlap considerably strengthens the joints. It also properly represents how the aft edge of the coaming could be lower than the sides, as shown by some photos--although some lanchas also simply had an even-height coaming. (Meanwhile, the fore edge will be completely covered by the hatch cover). I tested this out by placing it in the hatch opening. I found that it was a little low considering that the deck planking needs to be added. So, I added a 1/32-inch thick strip along the bottom to raise the coaming slightly. As can be seen, the aft edge will now protrude an appropriate amount above the deck. Next up, the fore hatch coaming and the support around the mast.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thank you! I've now finished up the covering boards and added the filler piece at the bow. (The seeming irregularity aft at the line of the transom is actually just a blotch of dark filler.) There are a few steps before I get to planking the deck. First, I've decided that the hatch coamings will be set into the holes in the subdeck, with the decking butting up against them, rather than being placed over the decking itself. So, I need to make the coamings off the model, making sure that they're square, and then will put them in place without gluing while adding the deck (so that they can be removed while I sand and stain the deck). I won't be leaving the hatches totally open, as the interior of the vessel is nowhere near accurate, but I have been considering whether to have them cracked open so as to add visual interest without exposing the framework to sight. This may be easier with the fore hatch, which can be propped slightly open on one side, than with the main hatch which slides open. In any case, I'll need to make a decision on this so I can paint any potentially visible interior black. Second, I need to decide how I'm handling the stern. Later lanchas--such as the Quenita, below, or those photographed in the 1980s by Carlos Vairo--had no full stern bulwark or rail. In the Quenita's case, the deck planking simply ran to the end of the deck. Source: http://lanchaschilotas.com/wp-content/uploads/2011/03/DSCN71501.jpg However, pretty much all the photos that I've seen of earlier lanchas show a built-up bulwark (or is the correct term rail?) across the stern. See, for instance, the photo below: Source: https://www.bibliotecanacionaldigital.gob.cl/bnd/629/w3-article-613545.html I'm tempted to go for the earlier style, but it does pose a bit of a challenge in terms of figuring out how the stern bulwark was constructed. I need to figure this out before planking the deck, as it seems like the deck planks would end against this construction. Finally, with the addition of the covering boards, it's clear that I'll need to slightly extend the stempost and smooth the resulting joint with filler.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

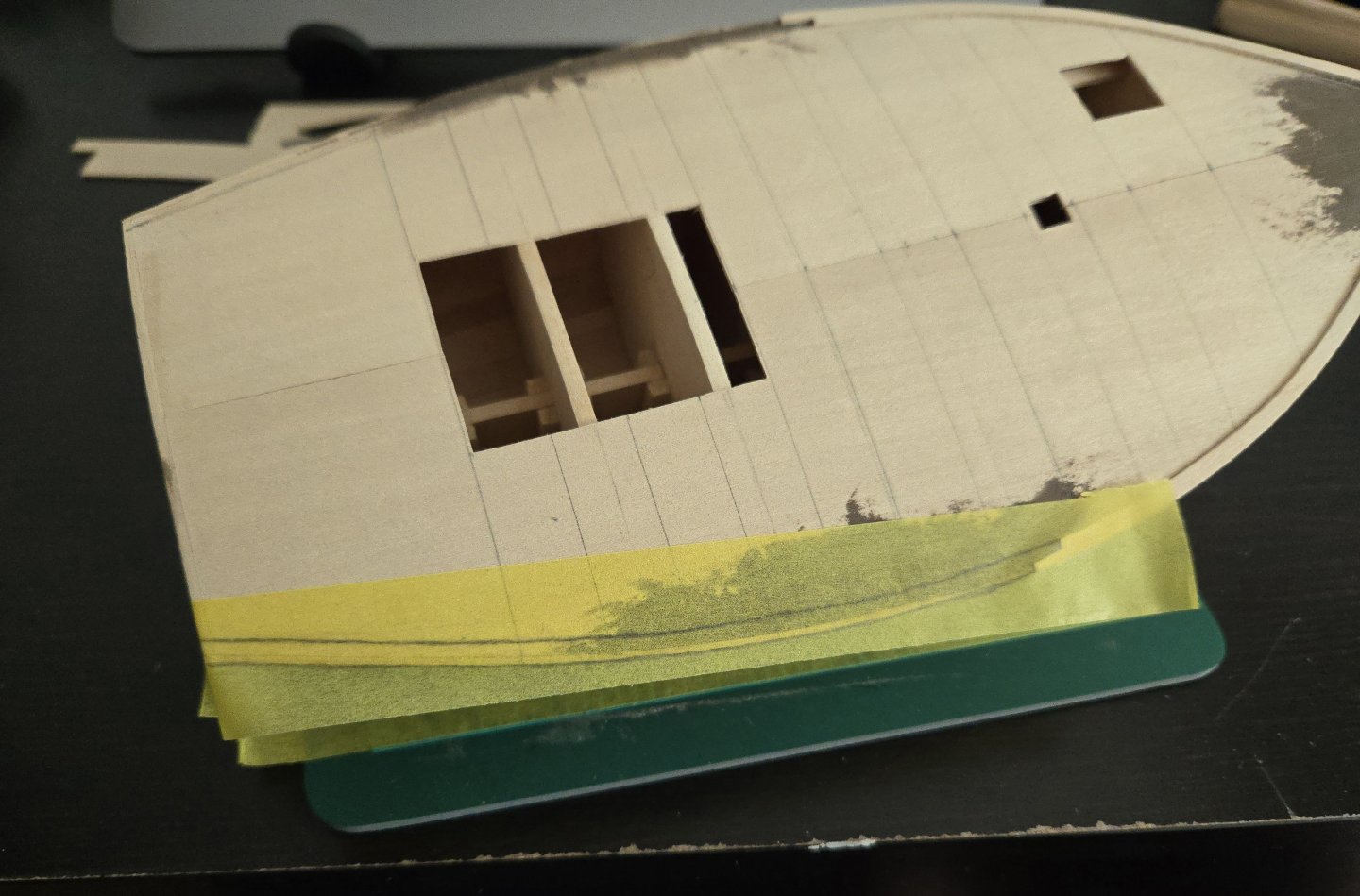

Thank you, @Paul Le Wol, @Jim Lad, @Keith Black, @Thukydides, @Knocklouder, @Glen McGuire, for the kind comments! As much as I enjoyed planking the hull, it's fun to now move on to other tasks. First up, I applied a bit of filler to cover the joints between the transom and the subdeck, and between the keel and sternpost (so as to later scribe a more accurate false joint, for the latter). I then began work on the covering boards. First, I marked a line 1/8-inch inboard from the edge of the hull. I did this by holding a short length of mechanical pencil lead against a bit of 1/8-inch wide scrap and running the scrap along the edge. I then used tape to take down templates for the covering boards, as seen below. I focused on getting the covering boards properly shaped inboard, as the edge would be sanded flush with the hull. The photo below shows the two fore covering boards in place and shaped, although I need to fine-tune the scarf joint at the aft end and add a filler piece at the bow (which will be covered by the bowsprit in any case). I also began work on the guarda playa--the "bumper" plank around the turn of the bilge. This was used to protect the hull while the lancha was beached for loading/unloading by low tide. Although not all lanchas had one (based on photos), enough did, and the guarda playa is an interesting enough detail that I wanted to include it in my build. Below: The guarda playa is visible around the turn of the bilge on the closest vessel to the camera. Source: http://ceph-puerto-montt.blogspot.com/2009/02/album-del-recuerdo-imagenes-de-nuestra_22.html José A. Garnham's drawings of lanchas suggest that the guarda playa was either made with a special extra-thick plank, or by simply adding a separate plank outside the rest of the hull planking. I chose the second option and will be using a bit of 1/16x1/8-inch strip to make them. First I used a ruler to check where on the hull the guarda playa should be located. This detail isn't included in the plans, so I just went with what looked reasonable in terms of length, making sure each end was in line with the frame lines signaled by the hull plank butts. I then cut the strip to length, curving each tip a bit. Next up: to finish the covering boards, glue on the guarda playas, and start work on the hatches before planking the deck.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

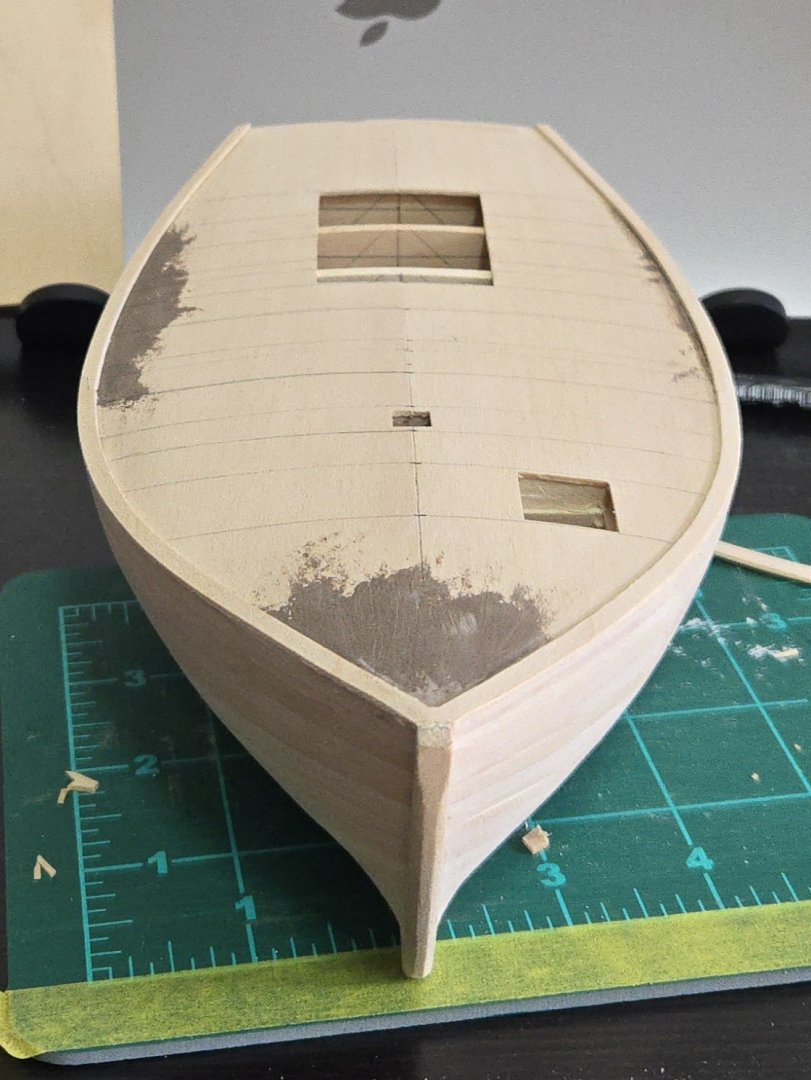

Thank you! The hull is now fully planked. The final planks were the trickiest. If any of the other planks were a hair too thin on one side, it wasn't really a problem because they only had to run alongside the previous plank. But these final planks needed to fit properly on both sides. Moreover, it's not possible to place them alongside the previous plank to get a sense of where there are high and low spots while shaping them, making it much harder to fit. As a result, I needed to redo half of them. The bow plank, ready to be glued: The very final plank needed to be redone. Below, I've indicated a number of spots where there was too much of a gap--maybe I could have just filled it, but I wanted to get it right: After redoing it, there was just one spot with a slight gap, much smaller than on the first attempt and eminently repairable with filler. This I could live with: To glue it in place, I used rubber bands and shims, except at the transom where I had to just hold it for a little while: I've seen the final plank referred to as the "whiskey plank," although maybe pisco would be more appropriate for a Chilean vessel. I'll have to celebrate tonight. In any case, after trimming the ends and giving the hull a preliminary sanding, here's where it stands: Overall, I'm pleased with my decision to use a single layer of planking in 1/32‐inch basswood, which I hadn't been sure about at the beginning. 1/16‐inch wood would have been much more difficult to bend at twist, especially at the lower bow, and if I had planned on double-planking, I would have felt like it was pointless once I reached this stage (but then I would have had to deal with the gap in the rabbet). That said, I can see a couple areas for improvement in the future. First, while I think I did a good job of keeping the planking symmetrical at the stem, I wasn't checking past that. So, one plank on the port bow ended up having a bit of a bulge just past the stem, as seen below, which (if you look at the bow-on photo above) did slightly throw off the strakes above it relative to the starboard side. It's not like I'm going to redo that plank now, but it's a reminder to keep an eye on symmetricality beyond just the stem. Second, I noticed that there are a few low points on the hull on each side of plank butt joints, especially near the bow. This seems to be because, when bending the plank into place, it tends to run straighter/flatter between the adjacent bulkhead and the butt location than it would if it continued, as the wood would take more of a curve between the bulkheads in the latter case. (If that makes any sense). I think the only way to deal with this would be to cut planks one bulkhead overlength and then cut to size after bending, but this is complicated to do. In the future, I may give it a try for planks at the bow, at least, as that's where the wood is most curved and the issue is most visible.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.