-

Posts

1,390 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JacquesCousteau

-

Thanks! I've enjoyed following your pile driver and Lula builds.

- 286 replies

-

Thanks for following, looking forward to watching your Perseus build come together! Thanks! More to come soon, hopefully.

- 286 replies

-

Thanks, Glen! It was a lot of fun, and it was definitely inspiring to see how you find creative uses for materials in your SIB builds!

- 286 replies

-

Thanks, Paul, your encouragement and responses to questions throughout the build has been incredibly helpful!

- 286 replies

-

And a few more photos of the finished build, continuing my previous post (which is more of a reflection on the build):

- 286 replies

-

Finished! I started making this model (or at least drafting my first attempts at plans) on 22 July 2023, and began this build log a few days later. It was my third build overall and my second scratch build. At the time, I thought it would be simple and quick, not much more complicated than the dory I had recently finished, and I thought that I could knock it out in a few months or so while waiting for a kit to arrive. As it turned out, it ended up taking 515 days in total, just under a year and a half, to finish (and 270 posts!). Along the way, this simple build turned into multiple models (including a digression into making some entirely unrelated models as Christmas gifts) and a much deeper dive than I had anticipated into research, opening up a series of questions about, among other things, processes of technological change and intellectual exchange. I also developed substantially in my model-making skills, such that I can see clear differences between the Cargo Canoa (finished about a year ago) and the Canoa de Rancho. This build, and the many helpful comments from so many people, has taught me a lot. Even though it's a simple vessel overall, I tried my best to make it with care and to not shy away from difficulty, even if this meant, for example, tediously re-making the thatched roof. While there are still things that I can see could be improved, I'm happy with how it turned out. This has been an incredibly rewarding build, well worth the time and occasional frustrations, and I'm glad I did it. Below: The Canoa de Rancho, at left, and the Cargo Canoa, at right. I feel like my improvement over time is apparent, although I also wouldn't have been as happy with my results on the Canoa de Rancho without making a lot of mistakes on the Cargo Canoa. (Figure at right for scale.) There were a number of frustrating aspects of this build. To name three specific parts, the thatched rancho took a lot of time and experimentation, the sail was tricky to get right, and the metalwork for the rudder hinges was challenging. More generally, it was difficult at the outset to proceed given that I only had photos to go off and no plans--in this respect, the model is perhaps one of the "models that shouldn't be built" according to Howard Chapelle. That said, I think I was able to produce a reasonable model based as much as possible on existing evidence, especially photos. (And it certainly helps that this vessel has a flat-bottomed, wall-sided hull--a curved hull would be significantly more challenging). Moreover, I've tried to be clear about the choices I've made in interpreting that (sometimes confusing or contradictory) evidence. Some parts of this build are quite conjectural. A lot of the details of the rigging (like the parrel or the robands) were not very clear in photos, but I hope that I've at least provided a reasonable explanation for why I went with the rigging details I went with. Similarly, while I have yet to find a clear photo of the floorboards, other evidence made it clear that they existed, and I hope that I have at least proposed a coherent and plausible explanation of how they might have been. Finally, with better photo evidence coming out over time, I have gradually come to believe that the locker under the helmsman's platform is inaccurate. This is an error on my part, and all that I can say in my defense is that at the time it seemed a reasonable interpretation based on literary sources. Nonetheless, I don't think that we should let the possibility of making such a mistake hold us back. This is especially the case with branching out from modeling vessels that are well-represented in plans and in existing models, including most Latin American workboats--subject that I'm particularly interested in and that I think are well worth building. Ultimately, all that we can do is explain our reasoning and evidence as clearly and compellingly as possible and make a case for why we've made the choices we made. I think the two main takeaways I've had from this build are: 1) This is an excellent, supportive community with a ton of resources. When I had questions about how to do something, I was often able to find existing posts that answered my questions, or I was able to ask and receive a lot of helpful advice about everything from judging hull colors in black and white photos to sail-making. I would not have been able to finish without such a helpful community, and I offer a heartfelt thanks to everyone who followed along, answered or asked questions, offered comments, or just gave the occasional like. It's easy to feel isolated in this hobby, but having so much support and so many examples of excellent builds through this site was really crucial in helping me push forward and strive to improve. Thank you all. 2) Being careful rather than trying to speed through things really pays off. This model took a lot longer than expected, but the end result is worth it. When I was building my NRG Half-Hull kit, I reflected on the advice to treat each plank as a model in its own right. The same can really apply to pretty much any part of any model. For any new modelers out there (as I was when I started this), I can't emphasize enough that taking the time to get everything satisfactory, and even practicing with test pieces, is the key to getting a result that you're happy with. This has been a fun, challenging, and rewarding experience, and I can't wait to continue working on more Latin American (and other) workboats. I'm glad that I was able to capture, in model form, an often under-studied aspect of maritime history, one which was nonetheless important in shaping people's lives and can tell us something about the past. I hope that anyone reading this considers modeling an overlooked subject that speaks to them. This site has an impressive and growing collection of build logs for such vessels, and I can confirm that modeling one is a very worthwhile endeavor, challenges and all. Once again, thank you to everyone for your help and support. I'll include a few more photos in the next post.

- 286 replies

-

After a bit of work, I was able to re-wet, re-shape, and salvage the sail, and the model is now nearly complete. Upon reflection after my frustrating and rather chaotic first attempt, a few things stood out. First, on the positive side, I was happy with how the aft half of the sail (over the rancho) turned out, which spurred me to try to salvage things. Second, while the white glue holding the boltrope in place had stood up to some tests on the sail and seemed like it would hold, the tests didn't involve nearly as tight folds as on the final assembly, and the glue came loose in many places. Fortunately, I was able to use the Aleene's Fabric Fusion to re-glue it in place, and it held up much better (thanks for the suggestion, Glenn!). Third, a big part of the problem was that I needed to furl the sail in contact with the rancho roof to get the shape right, but none of my clamps were suitable to hold things in place, meaning that I needed to press down on the aft part of the sail while trying to shape it elsewhere. This was a recipe for disaster. After thinking a bit more, I realized that I could use thread to tie the sail/yard down over the rancho, and could cut it away later. This worked out--although I could probably have tied it tighter, and I ended up placing a clamp at the aft end solely to weigh it down a little, the thread at least held the piece roughly in place and allowed me to focus on the fore half. Finally, I was using the sheets to wrap up the sail, but I wasn't able to get them very tight, which contributed to some of the loose and awkward folds/draping in the fore half. Upon rewatching Tom Lauria's video about making furled silkspan sails, I noticed that he was able to use a lot of separate ties, using the knots to get things tight. In his case, these were part of the model, but I realized that I could do the same thing with thread, then wrap the sheets over those locations and carefully cut off the thread. This worked much, much better. So, here's the assembly while drying. In hindsight, I would not recommend using wood shims to clamp the sail material, as the wood stuck a little to the sail's glue, but it turned out ok. There were a few places that I wasn't happy with, such as the odd bolt rope shown below--after being reattached, it had come loose again after being folded in a way that made it very difficult to re-attach it precisely to the sail edge. Unless you're looking right at it, though, it's hard to notice and just looks like a fold in the sail, so I decided that I could live with it. In any case, here's the full sail assembly. Overall I'm happy with how it turned out. Next, there were a few loose ends of the rigging to deal with. First, I finished off the parrel (the end of which still needs trimming below). Then the end of the backstay. The looped excess line could be a bit tighter, but I may need to remove the mast and rigging for a possible move in about a year and a half or so, so I've only glued the end of the loop so far. I may try to glue a tighter loop with shellac if I can find any, so it can be easily dissolved in alcohol for removal. Finally, the halyard. I was originally going to run this to the port belaying pin aft, but then I realized that this would only really be done when the yard/sail was hoisted. In most photos, when the yard has been dropped, the halyard just hangs relatively loosely. I've noticed quite a few photos that seem to show the rancho itself (or presumably its framework) being used to belay lines, so I decided to run the halyard through a few loops around the rancho framework near the mast, as though the crew has loosely tied it off to keep it from interfering too much with the fishing gear. At the moment, part of the line has been soaked in a glue-water mix and is being held down with a pair of forceps in order to look like it's hanging naturally. Once this dries, I'll be able to remount the rudder, and the model will be complete!

- 286 replies

-

Thanks! I think I can be my own worst enemy at times trying to match what I see in my mind's eye. In any case, I was able to find the Aleene's fabric glue, so I'm hopeful that the bolt ropes won't fall off if I add them if I make the new sail.

- 286 replies

-

Re-furling the fore half has proven by far the most difficult part of this build. The bolt rope has come off at multiple points from the sail being dampened and re-dampened so often, and it still doesn't seem to be hanging quite how I'd like it. At this point, I'm going to let it dry overnight. Tomorrow I'll see if I can re-glue the bolt ropes. If I'm still unhappy with it, I may re-do the sail, this time with a single layer of filter, less material, and possibly without the boltropes.

- 286 replies

-

Plastic wrap removed for the final drying. At this point, I've decided that the hanging part of the sail forward doesn't look right--without any real weight, it doesn't hang very naturally. I'm going to try to place the plastic wrap over the fore half of the hull and re-furl that part.

- 286 replies

-

Furling the sail has been nerve-wracking, both because I don't want to danage any of the fragile pieces, and because it's a bit of a tricky shape to furl as part of it rests on top of the inclined rancho roof. This necessitates furling the sail on the model itself. So, I first took a bit of plastic wrap to cover everything so the rest of the model wouldn't get wet, and then placed the halyard through the mast sheave. Rather than a really tight furl, I decided to try for a relatively looser one, especially toward the fore end. After a lot of careful folding, wrapping, adjusting, clamping (clamps will be removed before it fully dries), and placing weights, here's how it's looking so far. And after removing some clamps: I'm not sure if I'm 100% convinced by it so far. The fore end looks a little oddly-folded to me. I suppose that I can re-try, though, by rewetting it. Also, as a quick note: on my test version, a single sheet of filter seemed too transparent and flimsy, even after painting and gluing, so I doubled it up then and on this version. I now think that it may have been better to simply go with a single layer, though, as the transparency issue wouldn't matter much on a furled sail, and the fragility can be handled by being cautious. Something to consider for the next build.

- 286 replies

-

The yard and sail are now ready to be attached to the model, furled, and shaped. Tying off the robands was a bit tedious but not difficult. Here it is nearly done, with just a few more left and some ends to trim. And here, after finishing and trimming. I'm not sure quite how accurate my robands are, but I think they're a decent enough representation (see, for instance, the small knots visible in one of the photos in post #260), and they especially will be once the sail is furled. Next, I added the fore and aft sheets, using .5mm rope from Ropes of Scale. I then returned to the parrel, which I had inconclusively tried to figure out earlier. After considering the evidence, three things are clear. First, the parrel forms a pretty big loop around the mast--rather than the small loop I did for the Cargo Canoa, the two ends of the loop should join near the yard itself. Second, there's no photographic evidence of anything like the parrel system used on many Mediterranean lateeners, in which a separate line allows the parrel to be tightened and loosened from the deck. Third, upon close inspection, while the halyard knot itself seems pretty bulky, I'm not really seeing evidence of separate ropes like a parrel running around the yard. All of this makes me think that the parrel was tied off at the end of the halyard around where it was itself tied to the yard. Perhaps this isn't completely accurate, but it's more accurate than what I did on the Cargo Canoa and comports fairly well with the photographic evidence. With that in mind, I tied one end of the parrel around the halyard. The other end will be tied off once the yard is in place on the model. The yard/sail assembly is now ready to go! Here's hoping that moistening and shaping it doesn't make it come apart.

- 286 replies

-

Nice start! On the wood issue: Cherry is a nice wood that's cheaper some of the others that have been mentioned, if you'd like the model to look a bit darker. Rather than buying a bunch of samples and testing them out, you could look at models on this site that you like the look of and see what wood you like. If you search, you'll also find several posts about which types of wood to use. Some say that Beech does a decent job of representing oak in scale, for instance, and others like Alaskan Yellow Cedar, Holly, or other woods. Based on a quick look, Teak seems to have large visible grain which could be a problem for modeling. As for planking dimensions, 1/8-inch thick wood is much too thick for the curves of the hull. People generally use 1/16, 3/64, or 1/32-inch thick wood for planking--something that will easily bend. 1/32-inch curves very well but doesn't leave you with much room for sanding, 1/16-inch may be better for a model of this size. I'd recommend checking what thickness other people have used for planking similar models (such as the Winchelsea, another frigate which has a lot of build logs on this site). The width will depend on whatever was appropriate for the time and place--without doing a lot of research, you could probably just see what other people have used for similar models in this scale.

-

Thanks! Very good eye, I hadn't noticed the wider plank, and excellent question. Looking at other photos of the sane vessel, it seems like it has wider deck planking on the side of the main hatch and where a cleat is located, so it may be structural. Source: https://www.carlosvairo.com/galeria-puerto-montt-lanchas-chilotas That said, photos of other vessels like the Quenita, below, seem to show pretty consistent deck planking, and sketches by José Garnham don't mention anything about wider structural deck planks. Source: https://lanchaschilotas.com/dscn7150-2/ The details of the deck planking are hard to make out in older black-and-white photos. So, the wider planks may well be structural on the vessel that Vairo sailed aboard and photographed, but from other evidence, it doesn't seem like it was a widespread practice. Maybe it was a characteristic of a particular boatbuilder? Thanks for asking, it's definitely an interesting issue.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Unfortunately, I just realized that I made a mistake. Checking photos of the lancha Quenita, it's clear that the deck runs over the top of the transom. Source: https://lavoladorachiloe.blogspot.com/2008_06_08_archive.html?m=0 Unfortunately, I already trimmed the top of my transom planking, so the subdeck will also run over the top. Given that this will all be painted, I may see if I can make the exoosed end of the subdeck invisible with the judicious use of filler and sanding.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

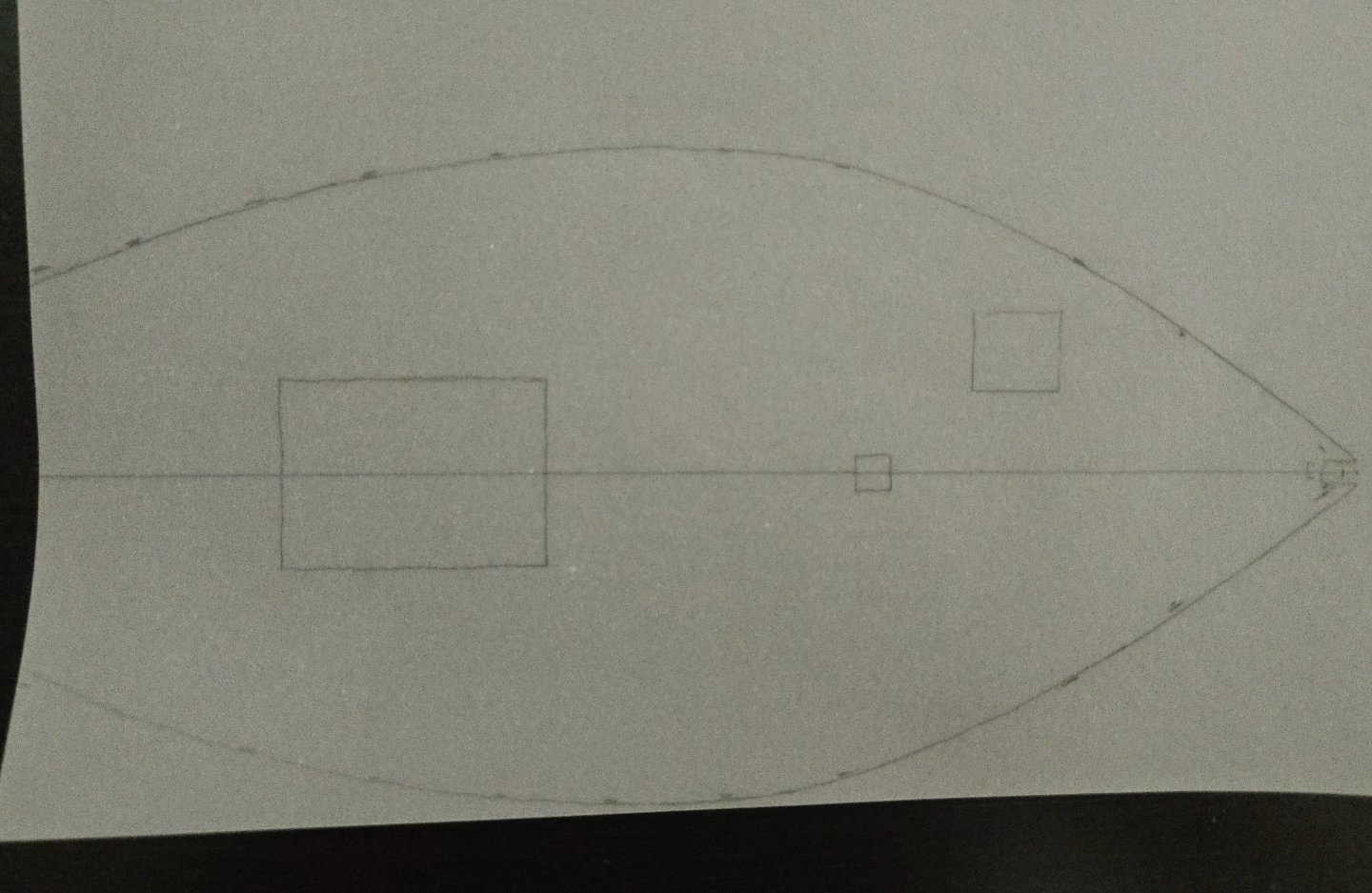

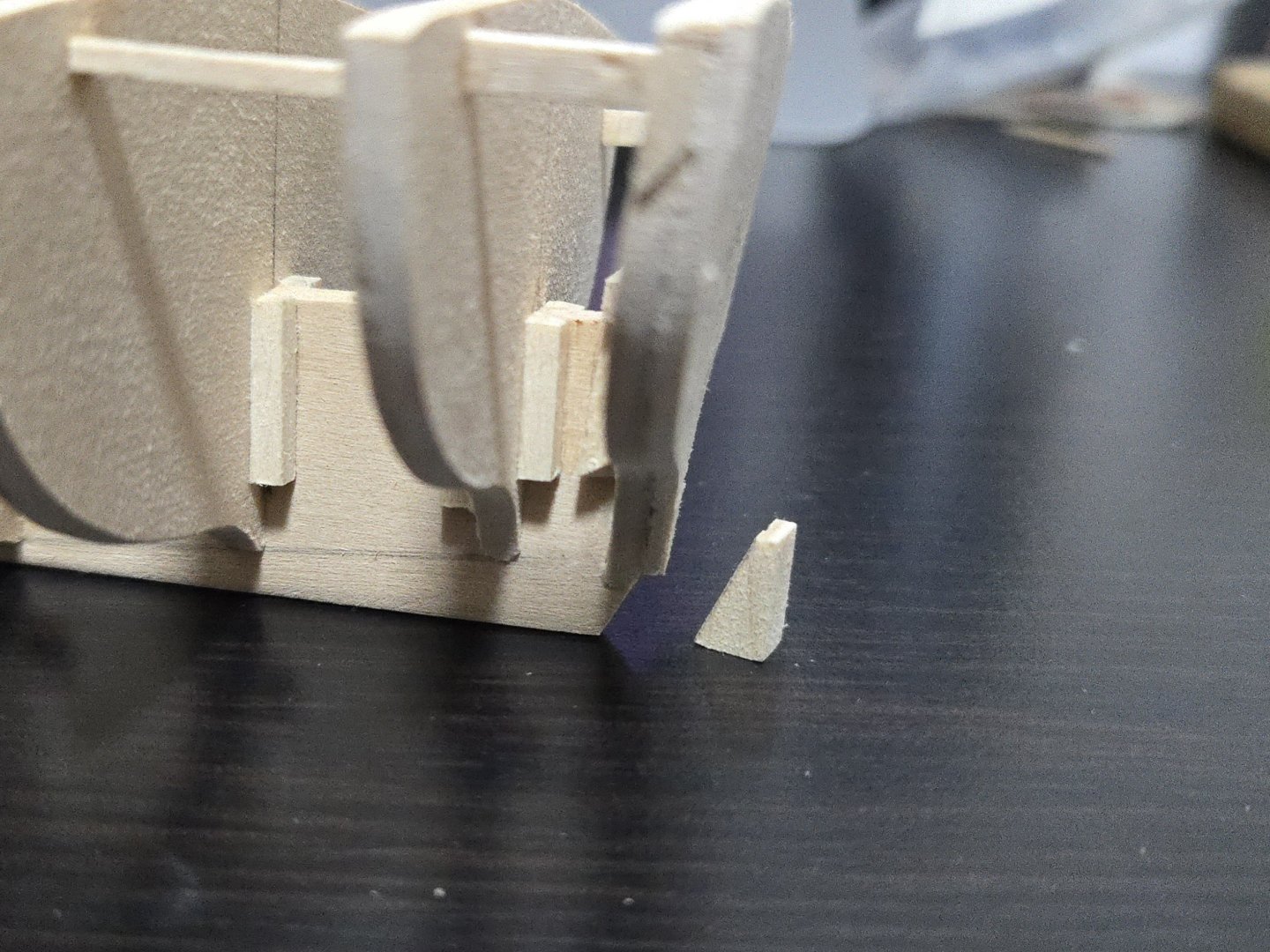

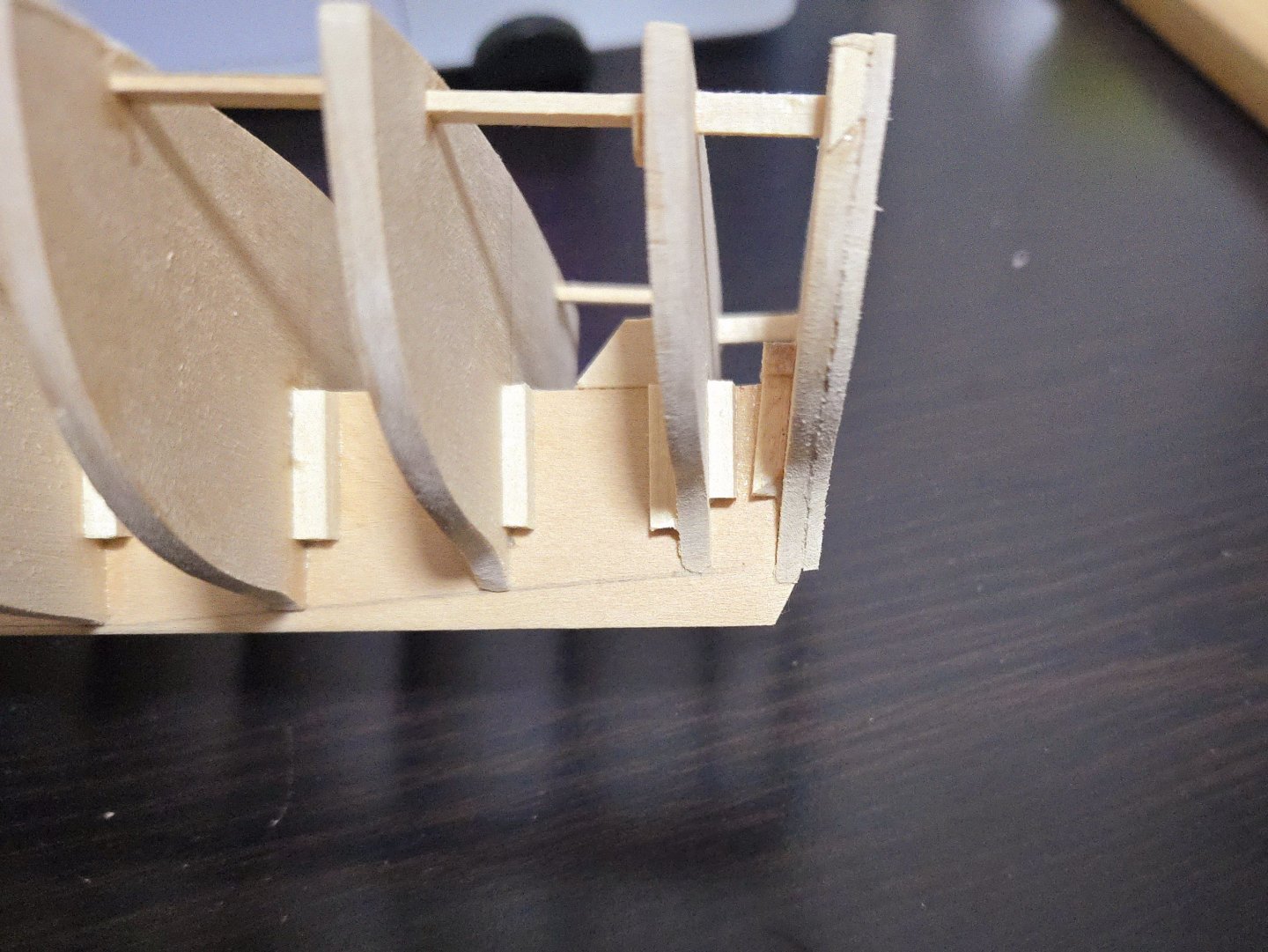

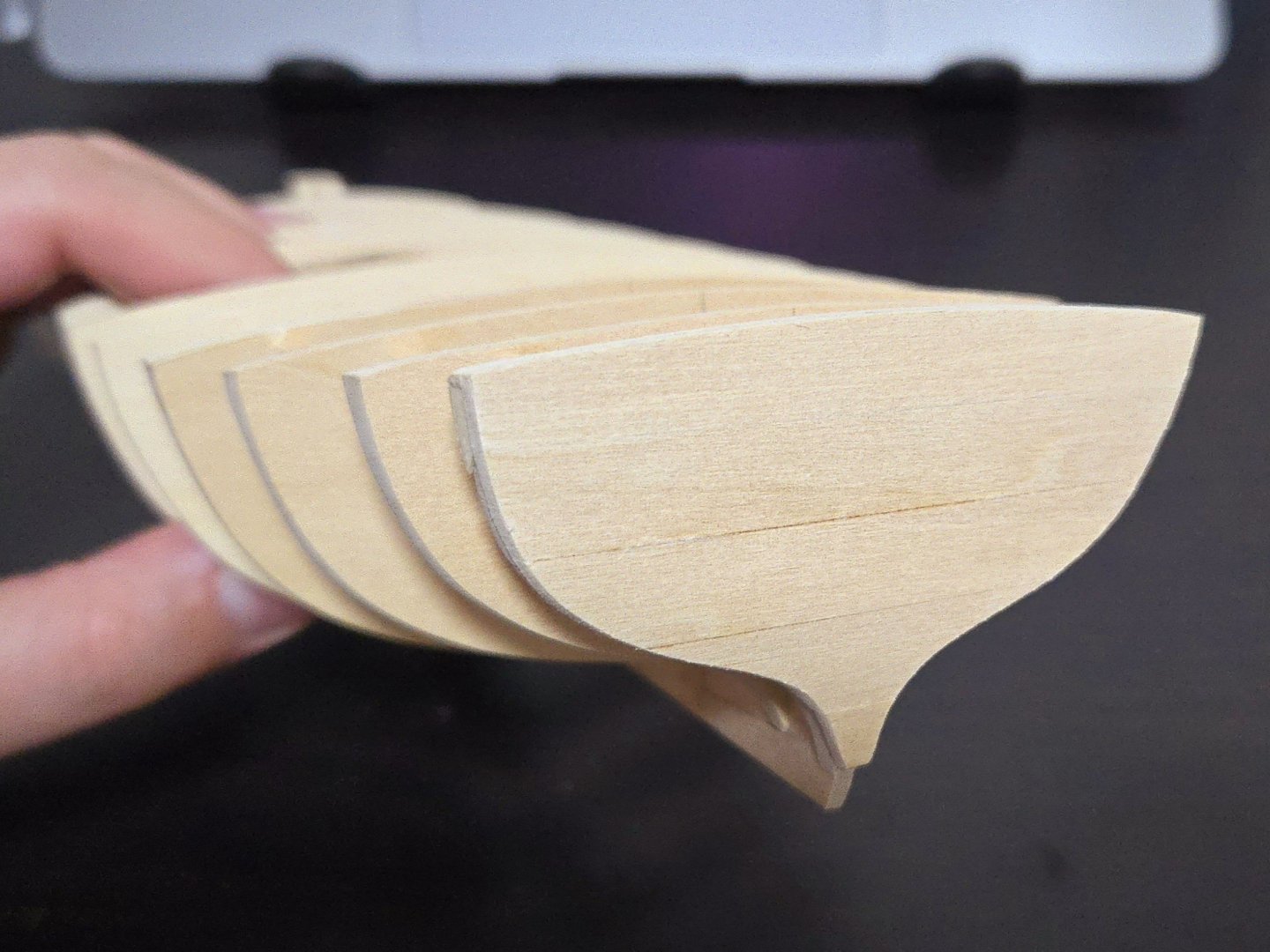

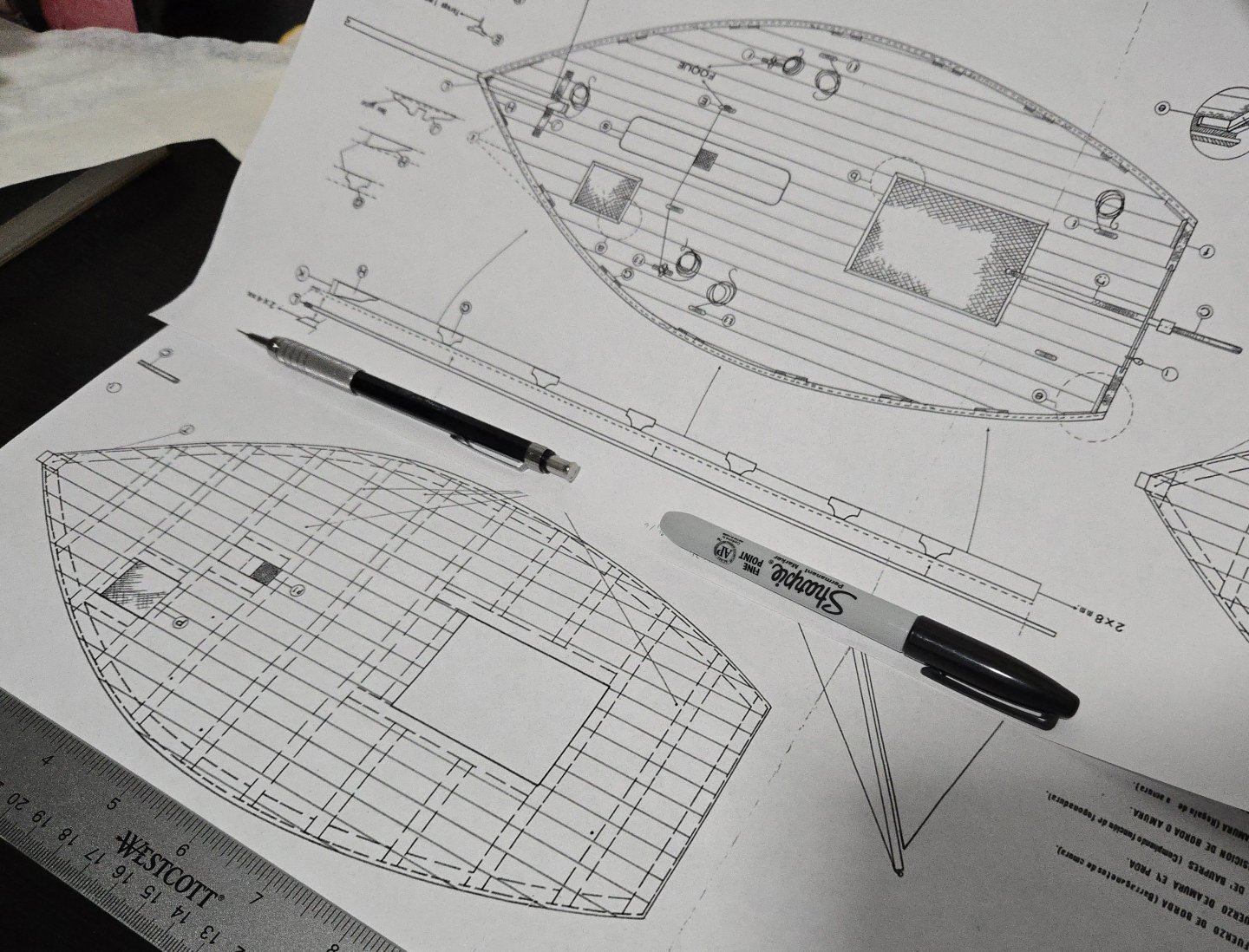

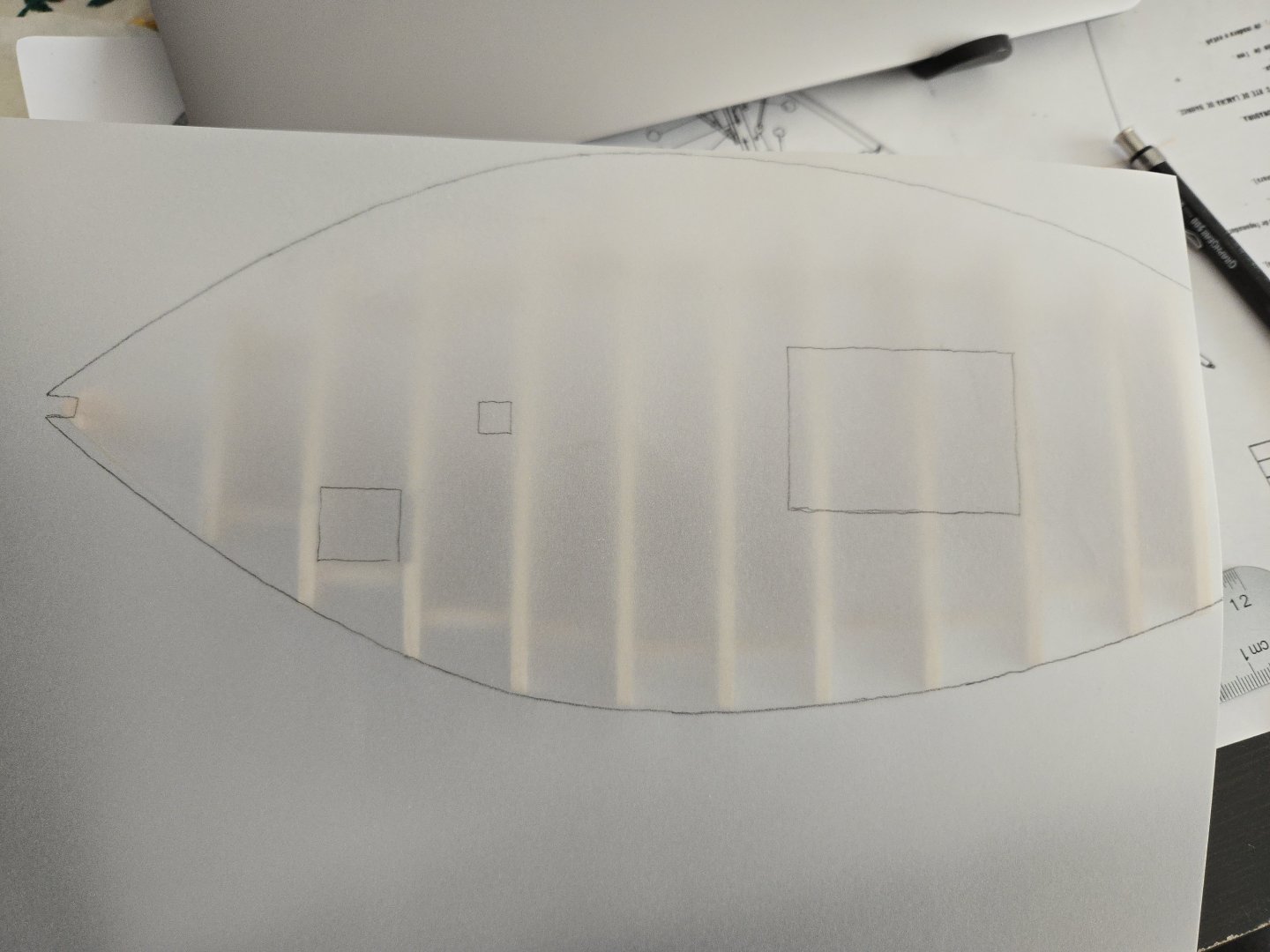

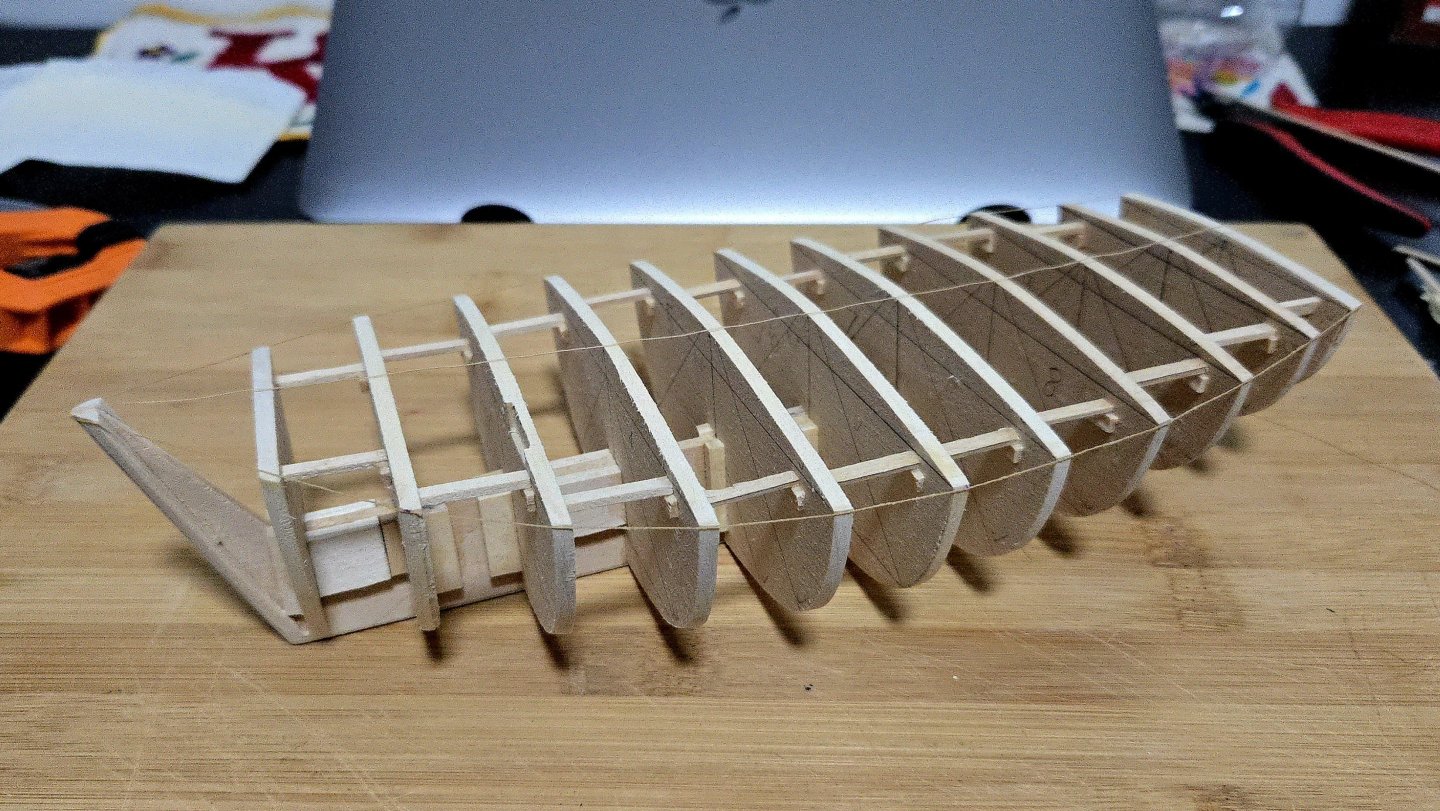

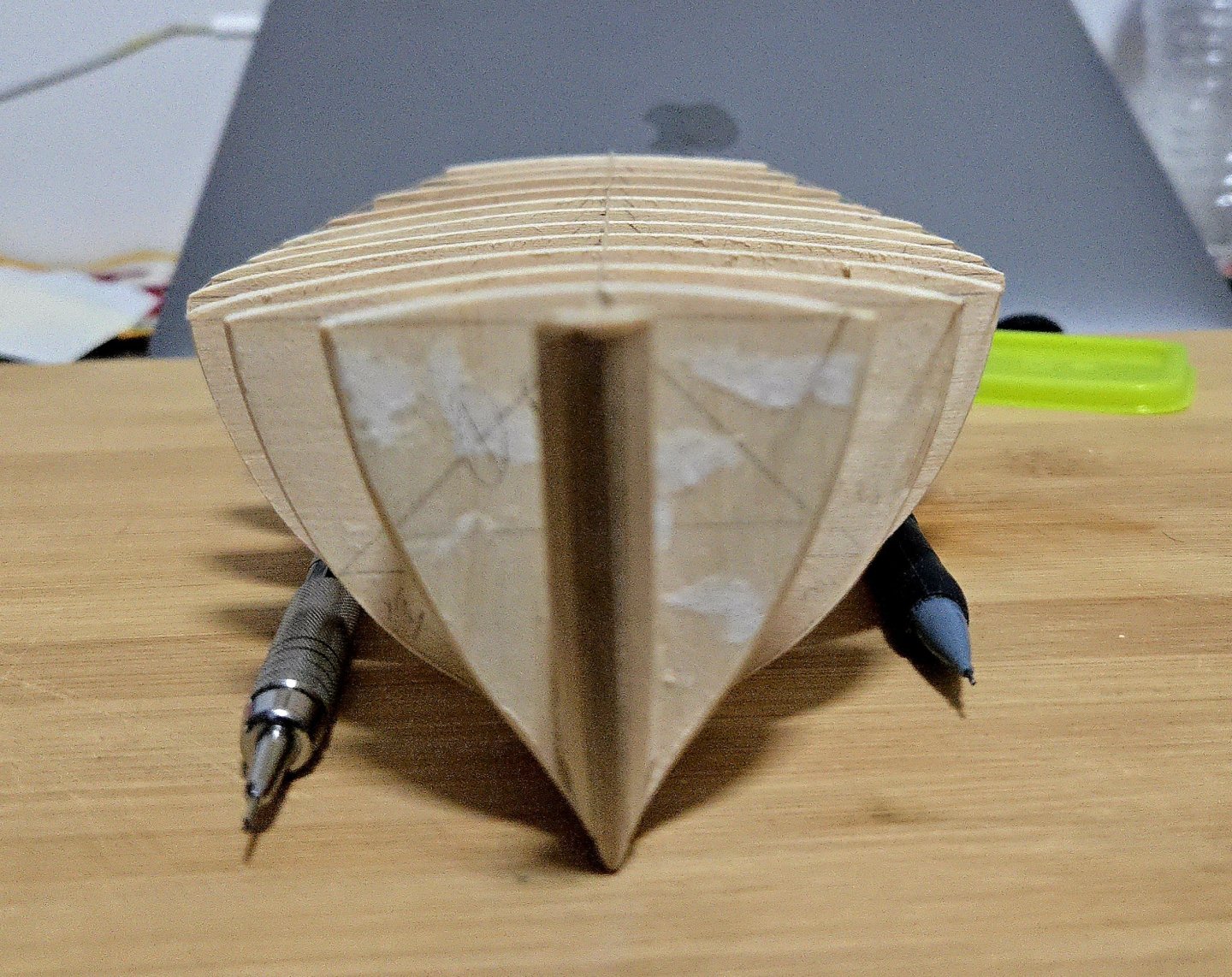

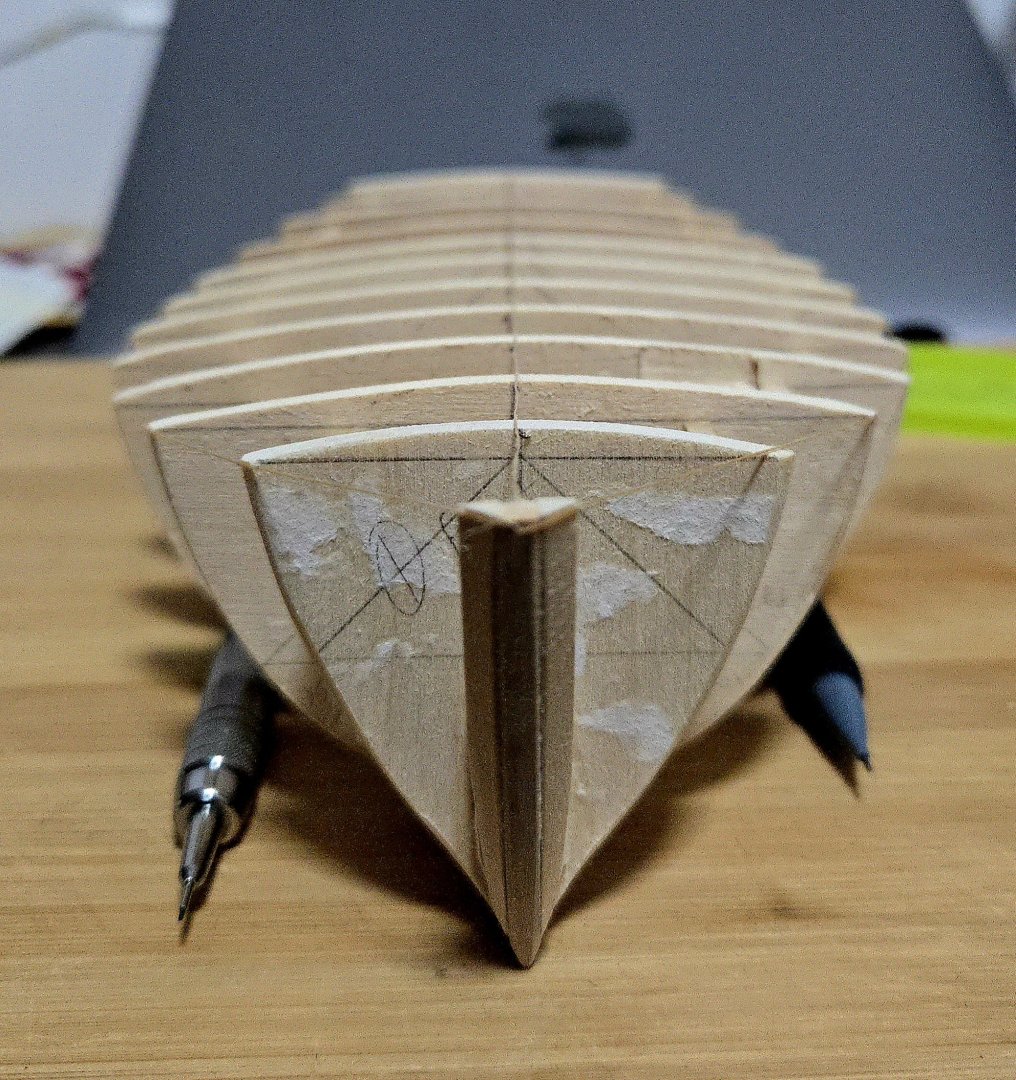

A bit more progress. First, on the stern, I planked the transom. Some photos seemed to suggest somewhat wider planks on the transom than on the sides of the hull, so I went with relatively wide planks. (If further evidence suggests that's not accurate, I can just scribe extra plank lines, and this will all be painted anyway). I also used relatively thick, 1/16 inch thick basswood, so as to provide a better gluing surface at the transom. As can be seen, I also started work on the sternpost. On my model, this will just be a small triangular piece, as that's allthat would be visible. On an actual lancha, much of the sternpost is internal, running upwards along the interior of the transom (as seen in the image below of the more recently constructed lancha La Voladora), and rabbeted below it to provide a solid ending point for the plank. Source: https://lavoladorachiloe.blogspot.com/2008_06_08_archive.html?m=0 I cut out the space for the sternpost, then cut it from the same material as the keel: It will be more fully shaped later and then joined with the keel. I also did some more work on fairing the hull and the deck, adding a few shims here and there and sanding down a few high points. This hull is proving very challenging to fair. Partly this is because it's quite a rounded, bulky vessel, but I also have to wonder how accurate the plans are for producing a fair hull or if I screwed up on something. I also started work on the subdeck. The plans include two top-down views of the hull, so I simply traced one on tracing paper. As it turned out, the tracing was a bit off from the model, being overlength (and slightly too wide or too narrow at many bulkheads): I've begun marking up the tracing to get a better fitting subdeck. I plan to make one that's slightly oversized and then sand it down.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thanks for the suggestions! I may have to get some fabric glue, but for now, I'm trying a bit of undiluted white glue. I added the bolt rope and marked and cut out the holes in the sail to attach it to the yard. I've been wondering how best to lash the sail to the yard. A wide range of methods have been used historically, from a simple loop around the yard to complex robands. I know that many small vessels with similar rigs use a single line to do it (although often not with a simple loop). However, in looking at the photos I've found of canoas, it seems more like they used separate, relatively simple robands--I have not seen any photos showing evidence of a rope running the length of the sail (besides the boltrope). See below: Source: https://www.mexicoenfotos.com/antiguas/jalisco/chapala/un-velero-panorama-MX14561525002424 Or here: Source: https://www.mexicoenfotos.com/antiguas/jalisco/chapala/cargamento-de-entre-MX14652247742300/5 So, I've decided to just do separate, simple knots (secured with super glue) at each tie-off point. I've started with the central pair around the halyard, which will keep the yard from slipping away. I still need to trim the ends.

- 286 replies

-

Thanks! I had noticed that the botter looked pretty different from the lancha in hull shape and use of leeboards, but I didn't realize that the construction details were so different as well. That's also fascinating about the dhows and Inuit vessels. It's worth noting that Chiloé wasn't alone in Chile in shifting away from traditional vessels to more European-style boats. Maino Prado also briefly discusses the replacement of traditional seal-skin and reed rafts in the fishing industry with wooden chalupas and similar vessels in the 19th century. As for who built (and owned) lanchas, this is a topic I need to research more, but it seems likely that there was some degree of specialization involved--less "everyone built boats in their backyard" and more "most carpenters, of which there were many, had at least some boatbuilding knowledge"--but this is a subject for further work.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

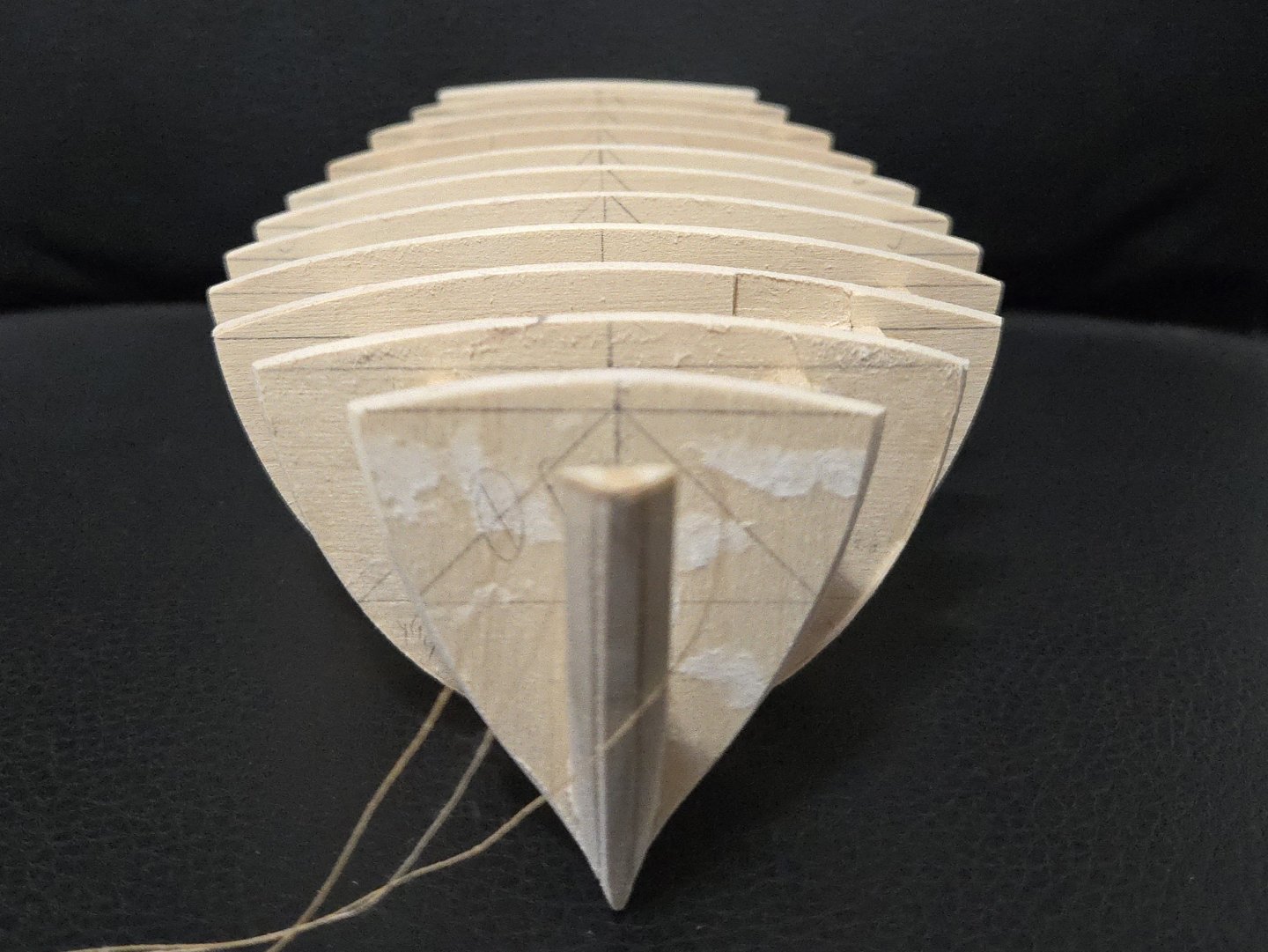

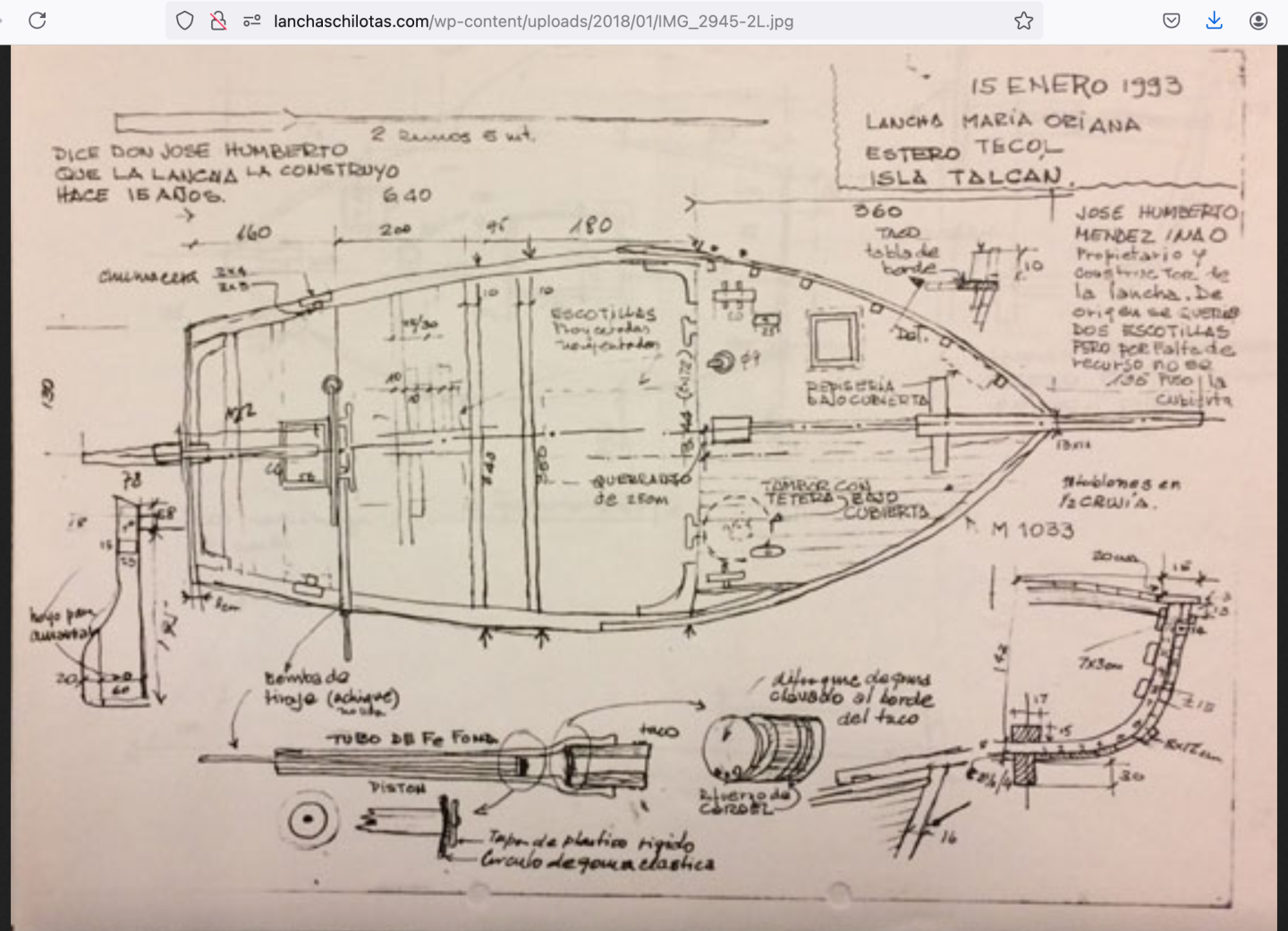

While I slowly add the bolt rope to the sail for my Canoa de Rancho build (which should be finished shortly!), I've gotten back into the Lancha Chilota. When I left off, I was trying to figure out the deck camber, as it was apparent from photos that the camber given in the plans was excessive, but I couldn't find anything about what the actual camber should be. Fortunately, I was poking around José A. Garnham's website and found that it includes a number of his sketches from research giving various dimensions from several lanchas and other vessels in the early 1990s. (Oddly, the sketches don't seem to be linked to from any of his posts, but are findable if you view a photo and use the buttons below it to scroll, one photo at a time, through all photos). Among them was one drawing of the Maria Oriana, an admittedly unusual lancha--it was only decked on the foreward half, as the owner ran out of resources at the end to completely deck it--that specified a camber of 20 cm, or just under 8 inches. (I wonder if this vessel's camber was recorded, unlike that of other vessels sketched, because the odd deck arrangement made it much easier to measure without having to go below deck). Source: http://lanchaschilotas.com/wp-content/uploads/2018/01/IMG_2945-2L.jpg This was a big relief. Based on some other vessel types, I had been considering going as low as 3-4 inches of camber, but knew this would throw off the lines of the top of the hull, given that the plans specify about 12 inches of camber. 8 inches of maximum camber seemed much more doable. So, I marked out the new deck height on the bulkheads, based on the proportions (2/3 of existing camber). I then used my mini-plane and sanded. As I got close, I began checking with a batten for fairness. Ultimately, I only reached the fully reduced camber on a few frames, but the others are within 1/32-inch (or 1 inch at scale) in order to keep the deck properly faired. I can live with a maximum deck camber of about 9 inches instead of 8, as it's much closer to accurate than 12 was. The lines of the deck now look much flatter, and the model should look much closer to the photos I've seen. Before: After: I also added some thread along the sheer line on both sides to check alignment, finding a few edges that needed to be raised or lowered. Of course, it's only upon taking the photo below that I realized the thread had popped off the first bulkhead, which was easy enough to fix. I've also been using a batten along the top of the bulkheads to fair the deck besides just at the center line and sheer lines. Once the top is fair, I'll be adding a 1/32‐inch false deck--this will be my first planked deck so I'd like a firm backing--and then will be adding a sternpost and then planking the hull.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Thanks! I'll have to check if it's available here, sounds very useful.

- 286 replies

-

Thanks! It's good to know it's not just me. Slight hiccup in my plans. After cutting out the sail, I began gluing on the boltrope (0.35mm from Ropes of Scale) with white glue. I glued along the foot first. As usual, I had trouble getting the rope to stick right close to the edge of the sail. Before I went farther, I decided to test whether the boltrope would hold when the sail was moistened and furled up--after all, the sail is covered in a mix of the same white glue, which becomes quite flexible when dampened. In general, the glue held, but there were a few points where the boltrope came off, especially while wrapping up the sail. As a result, I'm debating whether to include a boltrope or not. It would certainly be more accurate to include it, but I'm a bit worried about it coming partly off midway through furling and ruining the sail, especially as the furled sail will be much more rolled-up than I did in my brief test. I'm also debating how visible the bolt rope will really be. My sense from the test sails, like below, is that the edges of the sail really aren't very visible among all the folds. The presence of ropes used to wrap up the sail also may "trick the eye" into not really noticing if the boltropes are missing. While the boltropes seem like they would only maybe be visible in a few parts on a sail furled up like in the photo below. Source: https://memoricamexico.gob.mx/swb/memorica/Cedula?oId=vvts2osBVs6S4R6nk8il In any case, it's something for me to consider.

- 286 replies

-

It's been a while since the last update, but I've finally been able to make progress again, and I'm in the home stretch. First, as mentioned earlier, the grapnel anchor I had used turned out to be inaccurate, so while visiting family for Thanksgiving, I ordered a different anchor. Unfortunately, given shipping times and prices, I was only able to get one with a wooden stock, while photos make it clear that they used metal stocks. That said, everything I've read says that Britannia metal is pretty soft, and that's been my experience with filing off flash, so I decided to see if I could modify it to fit a metal stock. The anchor kit with the wooden stock. Like the grapnel, it's 20mm long. Unlike the grapnel, it came pre-blackened, although I painted everything in the end anyway. Drilling a new hole in the shaft by hand was a very slow process. It doesn't help that most of my cheap drill bits have a totally flat rather than a pointed tip, which is fine if you're drilling into basswood but seems to slow things and makes the drill bit slip easily when drilling into metal. I had to use a larger, sharp-tipped drill bit to mark the initial hole. It was also tricky finding the right pressure to place, as you do need some to make the bit cut into the metal. I learned how fragile drill bits can be: my thinnest one abruptly bent under the pressure. Alas, poor drill bit. Nonetheless, after what seemed like a very long time, I finally got a hole through the shaft. I was then able to superglue a length of brass rod in place to make the new stock. The whole anchor was then painted. Finally, I removed the grapnel and affixed the new anchor to the end of the chain. I'm sure I can find a use for the grapnel on another build. I'm pleased with how the anchor turned out, it looks much more accurate. Compare with the anchor in this photo: Source: https://memoricamexico.gob.mx/swb/memorica/Cedula?oId=g_ts2osBVs6S4R6nsc0d Besides the anchor, I was also finally able to find some large coffee filters, and have begun work on the sail. The end of the build is in sight!

- 286 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.