-

Posts

3,607 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yvesvidal

-

Beautiful job overall. Lots of good idea in your thread. I will have to follow your Build Log when I decide to build that kit, sitting in my stash. Yves

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

It is hard to believe that this is 1/200 scale. It looks so realistic and perfect. Yves

- 202 replies

-

- Russo-Japanese War

- Mikasa

-

(and 2 more)

Tagged with:

-

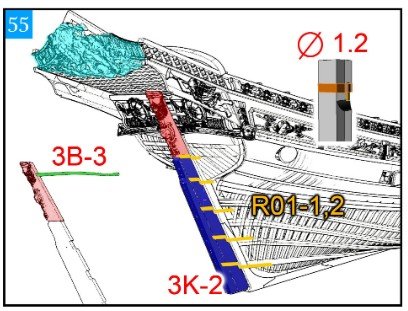

I just completed a very delicate phase of the build: the rudder and tiller. I wanted these to be movable while keeping the capability to take them apart, as this assembly is very fragile. The hinges are photo-etched parts which is not the easiest for making something sturdy and working. The kit of the HMS Bellona offered brass cast parts which are a lot more solid and well designed than what the Chebec kit offers. This is how I approached the conundrum: A small piece of brass ( diameter 1.2 mm) is soldered against the photo etched parts provided in the kit. This is then chemically blackened (and later on painted...) and placed in shape around the rudder: Using electronic components pins, I insert the pins into the wood (diameter 0.7 mm), solder the pins to the PE part in about 4 locations. A little bit of sanding and painting on top, make it look decent. I could not find nails small enough to fit into the PE parts. Of course, while soldering, you want to make sure the wood is not burnt or overheated. It is all very delicate. The female parts going along the stern keel are the most delicate to adjust. Again flat PE not easy to put in form. Here I am using small pieces of tube (material similar to teflon) and I glue them in place along the stern. The rudder pivots very smoothly and there is no jerking. Then the same approach (pins, soldering) is done on the stern, making sure the PE parts are hugging tight the small piece of tubing. Additional CA glue is used to keep everything in line and happy. Verification of the rudder motion: The Boxwood carving is then glued to the rudder and painted black and then dry-brushed with Tamiya gold leaf. CAF Model did a great job at 3D machining this little carving: Once installed, the tiller is inserted into the rudder: The hole is tight enough and holds the tiller without any glue. Motion is possible: Et voila. Needless to say, this assembly is going to be removed, stored and will be back on the model, when is it completed. Yves

-

Excellent decision !!! Too many projects to justify loosing sleep with a single one. Yves

-

Chris, You may know more than I do about this specific kit manufacturer, but I can give two clear examples of the kits I have and am building and no build log of them can be found online: CAF Model HMS Bellona and CAF Model Le Chebec. The Kits made by CAF Model are excellent (in my opinion) but rather difficult and poorly documented. Definitely not something I would recommend to a beginner. What happens quite often, is that potential builders will get excited about a kit and later on realize that they cannot complete it or loose interest in it. We all have had to deal with this kind of problems. Yves

-

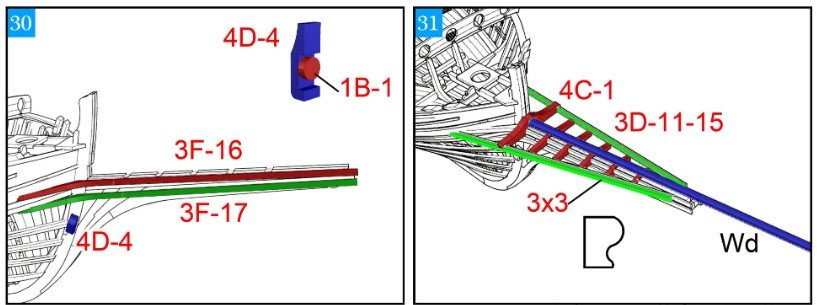

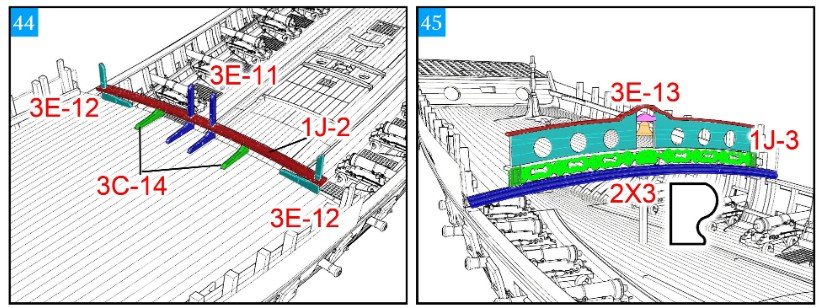

A few progress on the bowsprit: This is a delicate assembly and I approached it in stages: The tiny part above is not included in the kit, but helps tremendously in stabilizing and aligning the front bowsprit. Highly recommended. The figures have not been installed yet, as I am afraid to damage them (at least the one sitting on the tip of the bowsprit). Yves

-

It is definitely "punching" through the water..... 😄 Yves

- 51 replies

-

- Puncher

- escort carrier

-

(and 1 more)

Tagged with:

-

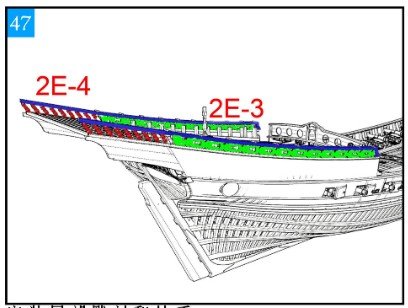

Beautiful planking. There is a lot of care going into it and it shows. Yves

- 62 replies

-

- Nordkap

- Billing Boats

-

(and 1 more)

Tagged with:

-

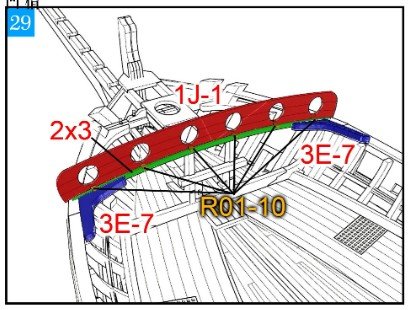

Moving our attention to the bow. For Javelin, a few more round holes.... Each hole has a tiny PE part located at the bottom, and used as a holder for a portable cannon. The hand held cannons are not part of the kit, but I have seen some models with them. I really like the intricacies of that bow, with its tilted mast. It makes for a rather interesting and unusual section of the ship. And the overall view.... Yves

-

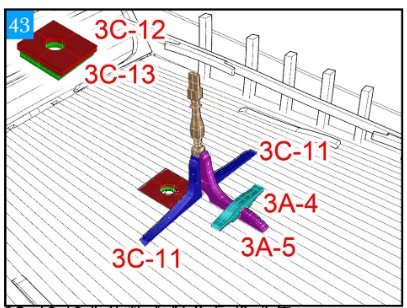

A few progress on the rear quarter deck. Rather delicate assembly due to the dry and thin wood: The first step is to glue the decorative railing in the front of the planking. 2 x 3 mm soaked in alcohol and left bending on a jig: Installation of the stiffeners under the deck: Following the instructions.... all parts are pre-painted, of course: A little bell to attract the attention of the crew: The kit does not provide the end pieces of the freeze. I will have to think about something..... Overall view: Yves

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.