-

Posts

3,585 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yvesvidal

-

James, I read your description of the kit, in detail. I have to say that CAF Models improved immensely their instructions and approach to building their kits. These instructions make sense, are clearly detailed in English (and not in Chinese) and they are providing you with pictures, which is a first in the History of CAF Models !!! The acrylic jigs are also a great addition. After building two of their earlier kits (HMS Bellona and Le Requin), I can tell you that their original instructions and directions were not that great....and you had to spend a lot of time, just wondering and trying to find a solution to the assembly. Yves

-

I am not sure, but it would make a lot of sense to have them there. Will you be posting some pictures of your fantastic model? Yves

-

Moving on with the installation of the beams supporting the quarter deck. The guide holding and aligning the mizzen mast has been installed. I also added a couple of poles underneath to make it sturdier. Now, I have to finish the door, glue it to the cabin wall and complete the assembly of the beams, at least up to the wall of the cabin: Below, you can see the extra support. Once the deck is in place, it will be quite solid, but you never know.... Yves

-

I am still progressing without following the official instructions, just going along with what makes the most sense for me. After installing the stern panel, I managed to glue the side extensions of the hull: All this is still very fragile and will require a lot of care to avoid breaking them. The large wooden grid on top will help re-enforce but cannot be installed until I built the planking on the stern from the inside deck. And before doing that, I have to build the quarter deck and its planking. The following drawings will give you a better idea of what I am trying to do and how it needs to happen: Of course, before completing the quarter deck planking the door of the cabin and the guns must be installed, on the gun deck. Therefore, the various hooks are set in the frames: Yves

-

Caldercraft Kits are among the best. Excellent choice. Yves

- 49 replies

-

- Brannaren

- Caldercraft

-

(and 1 more)

Tagged with:

-

The following is not properly described in the User/Assembly manual and as such, I am not posting any pictures of the CAF Models instructions. It is a very delicate (in my opinion) phase as the parts are really not fitting well together. The first thing I did was to build some kind of support for the stern bulkhead: This was done with multiple layers of 0.8 mm planks, I had left from the Bellona. Some curvature is done to accommodate the stern panel. Despite all this preparation work, it still does not fit precisely. The stern panel is made of boxwood (I think...) carved with a CNC machine. The carving is delicate and actually well done. The next steps consist in gluing the various parts that will define and stabilize that panel on the stern. Again, this is my way of approaching that task and there may be better and more intelligent way of doing it. Above, you can see the rectangular opening, used for the tiller. Below, the stern panel is painted in black and dry brushed (delicately) with Tamiya gold leaf color: The panel is then glued as well as possible, keeping the alignment of the rudder and keel. I have to say that the Monograph by Boudriot came handy as the CAF instructions and plans are very quiet on this subject. You can see on the left and right side, some light peeking through. Once the quarter deck and the rear veranda are in place, not much will be visible. This assembly is still very fragile and it is important to continue building the planking of the upper part of the hull: I have been agonizing before that task for a while, and even though it is not perfect, I am glad it is behind. There are more challenges coming, so stay tuned. Yves

-

The way this kit is designed is very similar to the CAF Model kit of the 1/48th HMS Bellona, that I completed a few months ago. The major difference is that in the CAF model kit, you have to assemble every single frame by using the plan. The result is that it is not as precise and perfect as this kit is, since all frames are pre-cut in the Portland Scale Ship kit. The plus for CAF, is that the frames are made of sherry tree wood which makes it more precious in a certain way. Otherwise, the keel and the core of the hull are very similar. The support or cradle for the hull is nicer in your kit. CAF Model has never been very good at providing decent support for their model. Yves

-

Not much to show but big progress in term of advancement for the rest of the build, with the correct placement and inclination of the mizzen mast. The mast stands at 10 degrees behind the vertical. I will try to post a picture of all three masts erected to give a sense of that "latina" rigging. Yves

-

I like your approach. It is a lot of work, but the result will be fantastic compared to the original printed deck. Plus, it is kind of fun to do some real decking.... Yves

- 35 replies

-

- Britannia

- Mountfleet Models

-

(and 1 more)

Tagged with:

-

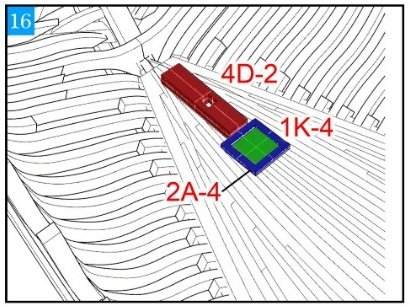

The main deck is pretty much completed, at the exception of the hooks required to rig the guns. The support of the front mast has been completed on both sides: a rather unusual piece of equipment on a period ship... I am not attaching the front shield yet, as I think it is too fragile and prone to breaking. This is what it will look like: I really need to concentrate on the stern at this stage. I have been procrastinating it, but the mizzen mast and the stern extension are calling for my attention: An overall view of the model, as it stands today: Yves

-

It all depends how the finished model will be presented. Since it is a waterline model, it may fit in a sea diorama and as such, will need to be painted to look more realistic. Otherwise, it could stay as bare wood. Since the wood seems to be basswood, I would at least do some Wipe on Poly applications, to protect it. Yves

-

Very interesting and so unusual model. Definitely worth realizing. Please post pictures of the 3D parts before assembly if you have them. It is always fun to look at them before and after assembly. Which scale are you shooting for? Oh, and the traditional question: are the parts (STL files) available from you, for a modicum? Yves

-

Why not paint it soft white? British ships had a lot of the cabin walls, painted in soft white with blue frames. Yves

- 1,118 replies

-

CaptainMac, I have the same kit in my stash and will follow with a lot of interests, your progress. Yes, the Chaperon by Model Shipways is definitely the most realistic kit proposed on the market as the Occre and other Spanish kits are offering woods which do not match what was used to build these paddle boats, in the USA. There are a few excellent realizations of the Chaperon on that forum, and I invite you to look into them for ideas and inspirations. Yves

- 23 replies

-

- sternwheeler

- Chaperon

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.