-

Posts

9,503 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Lad

-

Russ - if it had happened in the normal course of events, I probably wouldn't have mentioned it, but the fact that cut it just as I was thinking that I needed to be careful ......... Pat - Not sure yet Pat; one of the curators has been making comments like, "Oh, that's nice. We don't have a pearler in the collection yet." John

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Nearly there! Had a good day for work at the museum last Monday (been away since then so unable to post) and have now come close to having the 'Pritt' completed. Just have to do the sidelights, which I had hoped to have complete for next Monday, but things aren't looking good at the moment. My first job last week was to trim off the fag ends from the ratline lashings. As I started trimming I thought to myself, "Better be careful here, or you'll cut the topmast shroud". Next snip and I cut the topmast shroud! It was an interesting exercise to extract the cut shroud from the masthead and splice a new one in place again, but it was soon done. Here's a photo of the dreaded cut shroud plus some photos of the model as it looks at the moment. John

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Hello, and a warm welcome to the forum from 'Down Under'. John

-

SS Mariefred by captainbob - 1:96

Jim Lad replied to captainbob's topic in - Build logs for subjects built 1901 - Present Day

Good to see that you're starting on one of those beautiful Swedish stermers, Bob. John -

Excellent work (again), Nils! John

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

I have a head band magnifer, but don't use it now. I use a simple pair of magnifying reading glasses. The advantage of the glasses over the magnifier is that you don't have that 'beak' sticking out in front of you to bash into model detail while you're rigging. John

-

Hello Blaine, and a warm welcome to the forum from 'Down Under'. John

-

There you go, Popeye - no trouble at all! John

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

Hello, and a warm welcome to the forum from 'Down Under'. John

-

I was away on holiday when you posted your original request. It may be of interest to you that sailing barges, or scow schooners, were a big part of the New Zealand coastal trade in the days of sail. There are a couple of preserved craft over there and quite a bit of documentation. John

-

Popeye, now we know how big the dolly winch is compared to a penny - but how big is the penny? John

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

Hello Bjønar, and a warm welcome to the forum from 'Down Under'. John

-

Introducing myself and already seeking advice

Jim Lad replied to kdm's topic in New member Introductions

Hello Keith, and a warm welcome to the forum from 'Down Under'. John -

A great action shot, Mark! The 'Maluka' looks like she's really charging down the harbour! John

-

Hello Dan, and a warm welcome to the forum from 'Down Under'. John

-

The model looks superb, Nils. It was quite usual for large ventilators to be turned by a gear mechanism. John

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

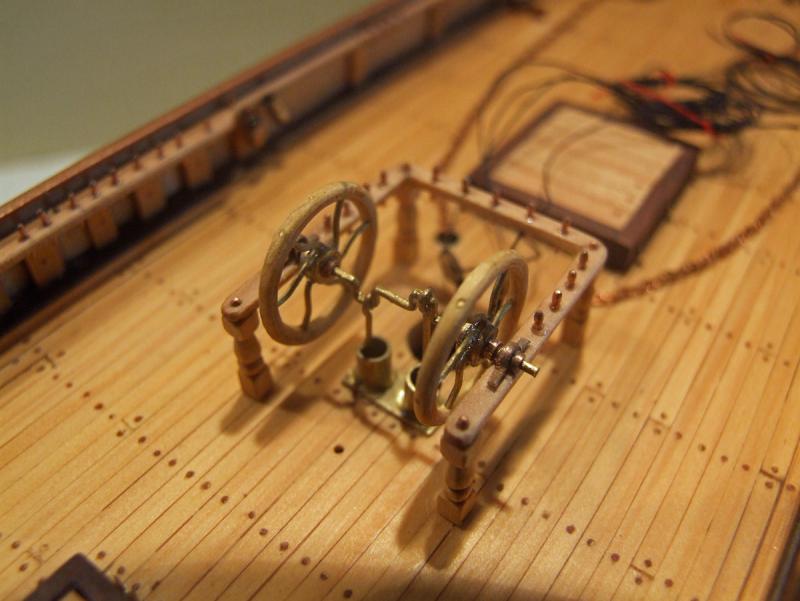

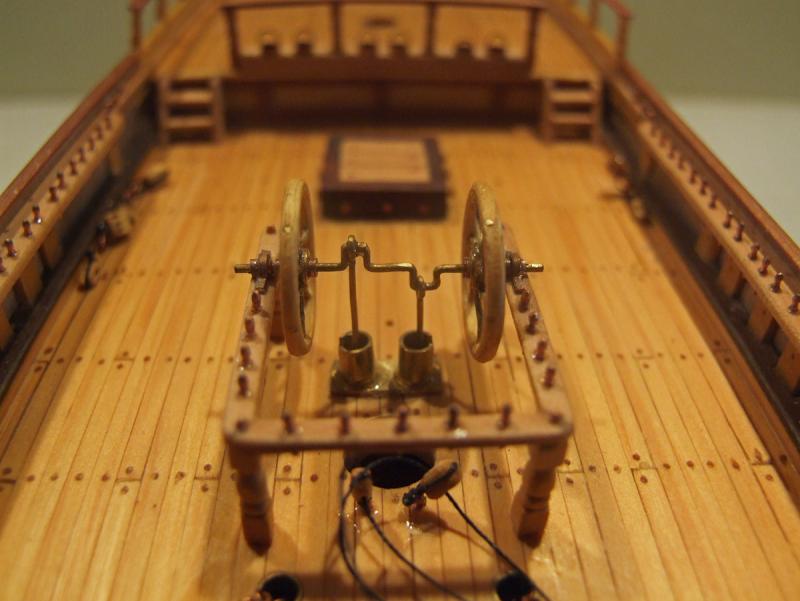

Popeye, Just for reference, these are the pumps on my model of the 'Nautilus' for reference. I would think that your pumps are the same type. John

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

next thing, Popeye, you'll have to put her in the water and try trawling for tiddlers! John

-

Lovely lines on this one, Russ. I love work boats! John

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

More first class work on those companionways! John

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.