-

Posts

6,651 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

On smaller boats the peak would have an eye in the boltrope that then is slipped over the end of the sprit. Indeed, that is the advantage of a spritsail, that is collapses quickly, once you lift the throat out of the sling at the mast, a kind of safety feature on small boats. The boat in the middle of van de Velde's painting seem to have a sort of standing sprit and the sail is hoisted with a peak- and throat-halliard running through blocks attached to the spar and the mast respectively. The sail still can be collapsed by lifting the sprit out from the sling at the mast, as is shown on the boat to the right in front of the larger vessel. However, all the boat shown seem to have tackles to manage the lower end of the sprit. This arrangement allows to move the sprit to a more horizontal position, which presumably balances the sail area better relative to the boat when running before the wind.

-

Talking about photography: when I am photographing objects with a high contrast ratio and when the surrounding illumination is likely to drown-out the shadows in other parts, I do not overexpose, but I rather manipulate the contrast range in Adobe Photoshop. Here I can 'lighten' the shadows and darken 'lights' (if needed), and then reset the contrast. From an artistic photography point of view these wouldn't be 'good' pictures, but here we are doing sort of 'technical' photography and want to show certain features of the object. This process does not disturb the overall exposure and contrast balance of the image too much and therefore is more pleasing to look at.

- 393 replies

-

I quite agree that up to the early decades of the 19th century not too many turned parts appear on ships and hence there is not much need to replicate such production processes. However, it also depends on the scale you are working in. If you are working in 1:48 or larger, the pieces are big enough to work on with hand-tools, but at smaller scales it becomes more difficult to achieve the needed precision without machine tools. I know, of course, that there are known miniaturists, who just use a simple lathe if at all. Does the Craftsman really have Babbitt-bearings? That sounds strange for such a small machine tool. Such cheap lathes wouldn't have had ground 'glass-hard' steel- or ball-bearings, but normally had bronze-bearings. Coming back to the original question: not everyone is very dexterous with the chisel or graver on a T-rest, particularly the occasional user. Therefore, at least one bench-lathe manufacturer offered a special kind of 'hand-rest' that would be easily replicated in the appropriate size on a lathe (as pictured on http://www.lathes.co.uk/lorch/page3.html: (incidentally, these are my fingers on Tony Griffith's Web-site ...) You would just need to clamp a metal plate or even a piece of melamin-covered chipboard to the lathe bed as a surface to move around the tool-holder freely.

-

kgstakes, what is actually wrong in your opinion with your lathe ? When pondering lathes it is important to draw up a list of the things and their enveloppe sizes that you are expecting to make. An old rule of thumb is to by a lathe that has twice the capacity you think you need 😉 Apart from that the other end of the size range also needs to be considered. If you are expecting to make (lots) of small parts, a chuck is not such a good option for a couple of reasons: it is less precise than collets and the spinning jaws are always a risk for valuable body parts, such as fingers. As you already have a lathe, you may want to look into a collet-chuck for it (I don't think the Craftsman has an internal spindel taper for collets). They are easy to obtain though ES-collets are more for tool-holding and not so good for work-holding. A 5C collet-chuck would be better. On the other hand, as you have thread-cutting capability on your lathe, you could make a collet-adapter four your own lathe quite easily yourself. You could then make one for WW-horological collets to work with really small parts. An engineer's lathe is not ideal for woodturning, as dust can easily clog the drive spindle. A plain lathe would be better. When you turn wood, you should remove the saddle and apron as much as possible without going so far to disassemble the lathe and cover well the spindle in front of the bed. Dito for the backgear etc. I would tape it up. Otherwise you would need a thorough cleaning session as wood dust together with oil makes a nasty combination that can clog vital parts of the lathe easily. To fashion a T-rest (or several sizes for convenience) should be quite simple. You would need to make a bed adapter that clamps to the lathe bed and to which a stem is screwed that carries the actual tool-rest. On the Internet there should be pictures of the (way overpriced) T-rest Sherline used to sell for their lathes, which should give you design ideas. I think that could be done without needing a milling machine, just using stock materials and simple tools.

-

Oh yes, those reinforced concrete signs used to be something very typical French, but they have largely disappeared together with the concrete 'mile-stones', the rounded top which was painted red (for the 'nationals') or yellow (for the 'departmentals'). The selection of signs is interesting: the one in the lower left corner points to the N13, which is now the A13 and runs past within sight from the house, where I am living currently. The N446 (now down-rated to D446) on the top right corner passes through a pretty area south of Paris, lots of woodland, but it become more open in the area, where sign is located, which must be in Monthlèry, given the distance from Orsay and Versailles. The others in the top row are mostly in the north of Paris, today not so famous areas and quite densly populated, but 70+ years ago would have been more rural.

-

That's what is called by the EU 'circular economy' 😉

- 71 replies

-

That's quite a process to take out the whole backbone of the boat, while keeping the rest propped up and in shape ... I have seen this done with sections of the keel etc. but not with the whole assembly. Essentially, the frames then were kept in place by the planking alone.

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

I too will follow this project with interest. Good research and thorough preparations 👍🏻

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

drilling hole through wire

wefalck replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

Proxxon offers a very similar model and I have used this without issues for 20+ years. It’s also found in many restaurant kitchens, used to caramelise the sugar on créme brûlee. -

Wouldn‘t there be a safety-valve and some piping that leads the steam safely out of the boat? And: where is the steam for the engines taken off? Is there a steam dome to ensure dry steam is drawn?

- 393 replies

-

You could simulate a bit of protective sheet-metal around the openings ...

- 393 replies

-

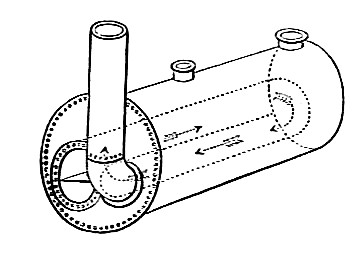

I believe many such riverboats had locomotive-type boilers, rather than than the more complex marine boilers. But this may also depend on the period, I suppose. A locomotive boiler has the firebox at one end, the fire-tubes going through the actual boiler room and the smokebox at the other end, where the flue-gases collect and are led up the smoke-stack. However, the boiler you modelled seems to be a return-type of boiler, where the fire-tubes are U-shaped and return towards the firebox, ending up next to the fire-box, before the flue-gases exit through the stack (see picture below). It seems that two U-shaped fire-tubes are placed into the same boiler, stoked by two fire-boxes side by side: Image from https://en.wikipedia.org/wiki/Flued_boiler. The power of a steam-engine is determined by the surface of the grate in the fire-box and surface of the fire-tubes along with the maximum permissible pressure. The above construction is one of the simplest forms of boiler and would not permit very high pressures due to the large diameter of the single/double fire-tube and the difficulty of keeping the large openings for them water-tight.

- 393 replies

-

A rivet does not necessarily need to be red-hot, but indeed, it needs to be accessible from both side. The planks of clinker-built hulls are rivetted together, but there the rivets are made from copper. During the Viking-age, I think also iron rivets were used, but they tend to rot the wood or corrode due to tannins in the wood. If the iron used for the rivets was sufficiently malleable, one could form the the heads on the outside using cold hammering. Another possibility is, that the bolts were not actually rivetted, i.e. a head was formed, but clenched, i.e. the points were turned over and driven back into the wood. This, howver, requires space inside the hull to work in. Given the realtively blunt bows of the time and that it would be at waterline level, this should have been possible. I gather, the term 'rivetted' refers to the fact that the plates were not just nailed on, as copper sheathing would be, but fastened with through-bolts/rivets. Today, one probably would use coach-bolts for such a task, but at that time threads and nuts were made still individually to match, no norms and only rudimentary thread-cutting technology. The thread-cutting lathe hadn't been invented by Maudslay until somewhat later in the 1840s.

-

The thingy between boiler and stacks is the ‚smoke-box‘.

- 393 replies

-

drilling hole through wire

wefalck replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

-

It was a typical shape of a commercial ship of the middle of the 19th century. I have lots of examples from Germany that shows that form until around 1860. Around 1846, I believe, a new bow form, the Aberdeen-bow was developed by Alexander Hall in Aberdeen, which became the forunner of the 'clipper-bow'.

-

drilling hole through wire

wefalck replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

Yes, the watchmakers called this inter alia 'pivot drills'. And you are right, carbide drills invaded this trade as well, as it allows to drill watch/clock pivots (i.e. the arbors of wheels etc.) without tempering and then re-hardening them, as was done traditionally. -

drilling hole through wire

wefalck replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

Actually, there are brass-drills out there with a steeper helical angle and differently ground cutting edges ... Another option would be watchmakers' spade drills. These are made for use with reciprocating drills, i.e. Archimedes drills, but also work with electric drills. In the US a source should be Otto Frei (https://www.ofrei.com). Watchmakers, actually used to make them themselves from steel wire. A further option are so-called EUREKA, straight-fluted drills, also from the watchmaking realm. They are stronger than the spade drills, but these days they seem to be expensive and difficult to find. I very rarely use carbide drills for hand-drilling and mainly only in the watchmakers' lathe, where there are very stable conditions with no lateral forces. -

I think it was back in the early 1980s when I last painted any figures at this scale - I have since moved on to 1:87 ... Got what must have been one of the earliest figure modelling guides published in the UK, didn't check but think it is from about 1968 or so - since then techniques have moved on considerably 😉 Today I would use a light grey undercoat, basically to be able to better see any imperfections in sculpting/conversion. The Old Masters used a complementary colour undercoat for skin areas, meaning a light green and then applied the skin-tones in several light washes. The complementary colour underneath makes the skin-tones more luminescent. In my later years of 1:35 figure modelling I used artists' oil-paints for any skin areas (and also for leather details). They could be worked much longer than the Humbrol enamels I used otherwise. However, if you want to work with oil-washes, this requires really long drying times between layers, days or weeks, otherwise the high medium-content of the washes dissolves the previous layer. Today, I basically only use acrylics, mainly from Vallejo (their original business was artists' paints ...). Working with washes is fast, as they dry sufficiently within tens of minutes. Talking about brushes, you may also want to look for so-called 'spotters', this are finely pointed brushes with short hairs. I am not so dexterous or don't have enough practice with standard brushes. The latter can hold more paint, which can be adavantage. Don't go for expensive sable-brushes for working with acrylics. Apparently does not good to them. I use mainly the synthetic ones from the British Da Vinci brand.

-

I picked up my copy by chance some 10+ years ago on a flea-market in Orléans, but the 'Vence' is now available also as ebook from the French National Library: https://gallica.bnf.fr/ark:/12148/bpt6k11684265.r=vence bateaux?rk=128756;0 Otherwise, ANCRE sells reprints at 40€: https://ancre.fr/en/reprint/47-construction-des-embarcations-latines-vence-1897.html. Originals, can by quite pricey at 80 to 100€ or more. What part of Spain are you in, btw ?

- 61 replies

-

- ancre

- Santa Caterina

-

(and 1 more)

Tagged with:

-

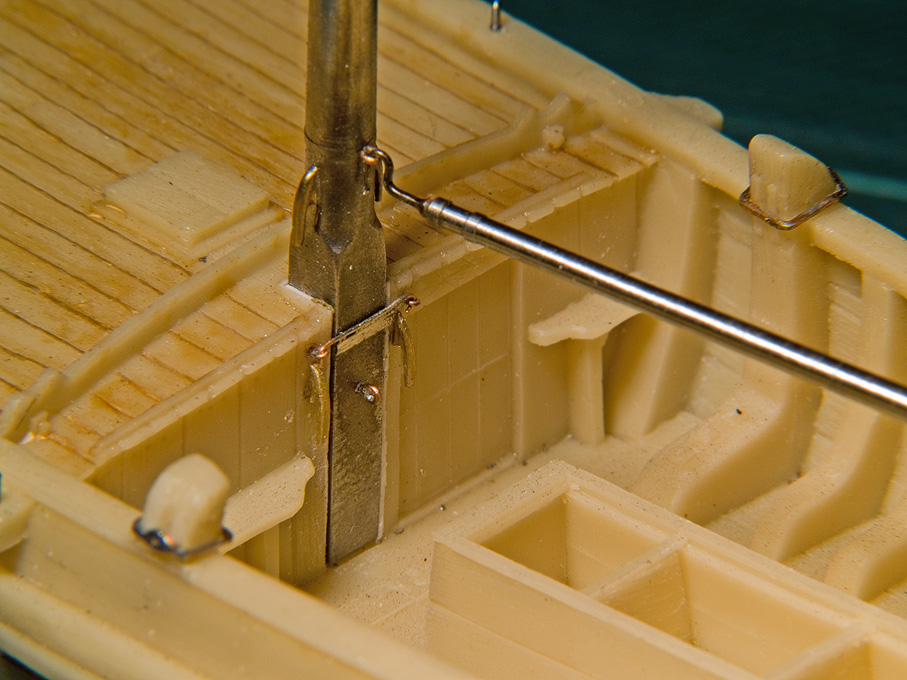

I only know the Emspünte by name, no details ... I wasn't aware that they use this kind sheerleg-like frame to raise and lower the mast, when passing bridges. This kind of thingy is steel used on modern yachts that operate on inland waterways. A friend of mine had a sailing boat on one of the many lakes in northeastern Germany and it had exactly the same device that puts the forestay higher and at a less acute angle to the mast, so that one can lift the mast more easily. Indee, the mast would have been sitting in what we call a 'mast-chair', two sturdy posts left and right of the mast with a sturdy bolt going across on which the mast is pivoting. There would a sort of latch at the bottom to lock the mast in place. The image below show a slightly different arrangement on the model of a Dutch boat that I built some years ago.

- 286 replies

-

Goog luck witht he shrouds/ratlines. It's not as bad as it seems, when approached systematically. Tune into some nice music that takes your mind off less pleasant things. And Merry Christmas to all here !

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.