-

Posts

2,214 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by EdT

-

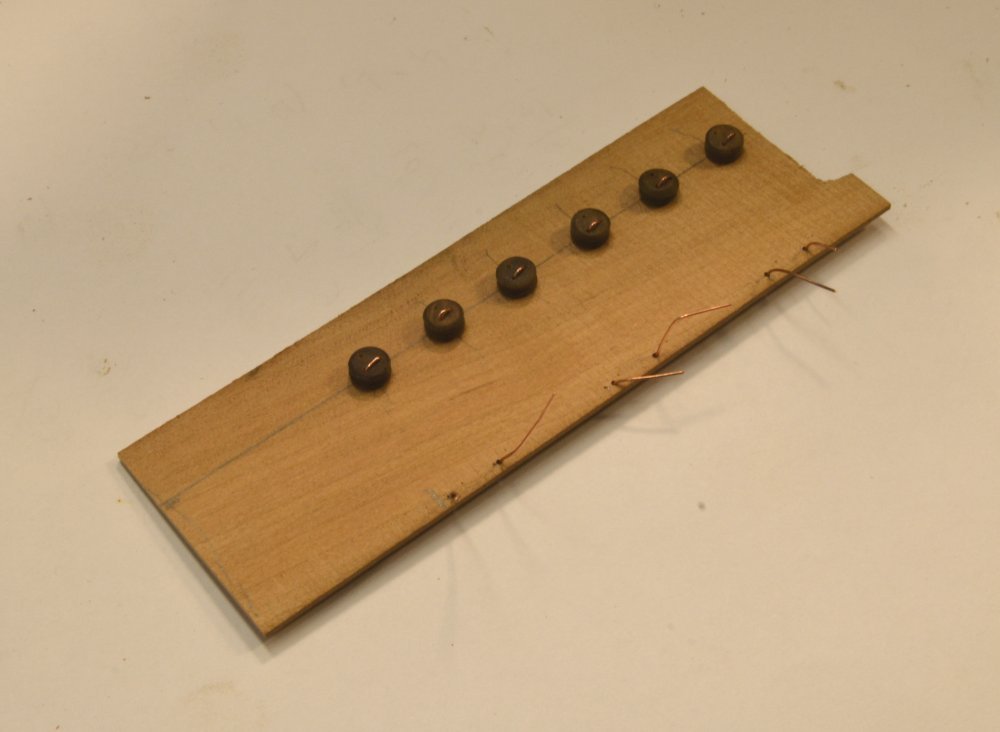

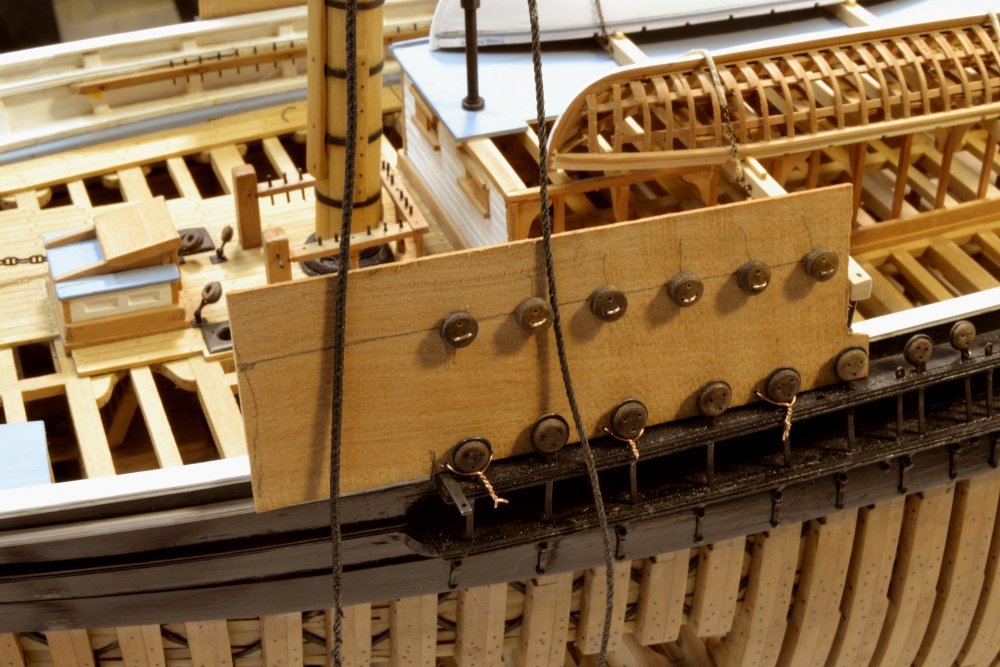

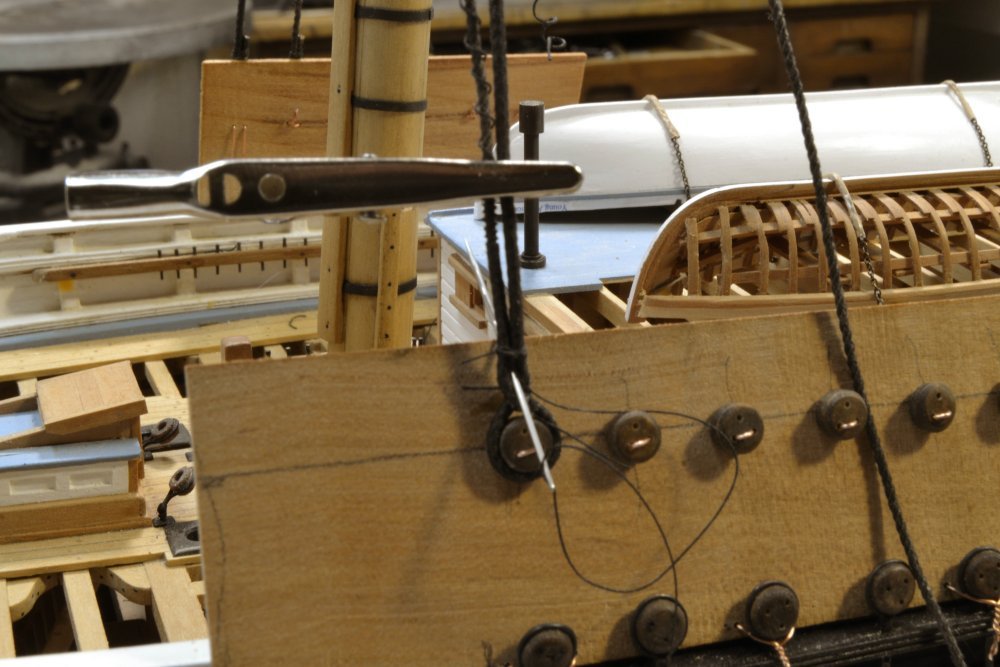

Young America - extreme clipper 1853 Part 206 – Lower Shrouds The two gangs of lower fore shrouds were made in the last part and were ready for the deadeyes to be turned in. I used the fixture shown in the first picture to position the shrouds at a uniform height and to hold things in place for putting on the seizings. The fixture is made from a thin (1/32") sheet of hardwood. It is drilled to allow the two lower lanyard holes in each deadeye to be threaded with wire to hold the parts in place. Wire at the bottom of the fixture is used to anchor the fixture to the channel deadeye straps as shown below. In the picture the first shroud pair on the port side has been seated over the first starboard pair, not shown, at the mast head. Those two opposite shrouds were secured first. The next picture shows the first port shroud wrapped around its deadeye and the throat seizing being put on. The short end of this shroud will be forward on this (port) side – aft on the other side. Some will no doubt observe that this is opposite the orientation on ships with cable-laid, i.e. left-handed, shrouds of the type used in, for example, the Royal Navy. I might also note that looping the short end forward and in front of the standing shroud is the way the rope would naturally loop if twisted "with the lay" – another opposite with right-handed rope. Twisting in this direction helped keep water out. Stay tuned. There is more of this minutiae later. This first served shroud is the most difficult to fit due to its stiffness. The next picture shows frapping turns being placed on the second seizing using a needle. Alligator clips are most useful in holding rigging. They are light, small, and grip tightly. Note that some of my serving is unravelling in the picture because I cut it prematurely – before applying some glue. The next picture shows the gang of six lower shrouds on the starboard side. The excess seizing threads have been clipped off and the rope ends, as well as the seizings, have been wetted with darkened glue. The port side work is still in progress. In the next picture, both fixtures have been detached from the channels and the lanyard has been reeved on the #1 shroud on the starboard side. The lanyard is 5¼" rope, laid up from three strands of No. 60 linen thread and dyed with walnut extract stain. The excess lanyard will be wound over the shroud and seized after all twelve shrouds are finally tensioned and the sheer poles lashed on. Next time. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Again, thanks. All your comments are well appreciated. Rob, this outer parcelling was certainly to keep water out of the tightly packed shroud bights - critical structural elements that would be subject to rot. All served lines were typically wormed and parcelled before serving - the first level of protection against damp and rot. The serving overlay did nothing for this and was an anti-chafing covering. Model rope does not incorporate the first worming and parcelling, just the serving. Parcelling consisted of tarred canvas overlapped like roofing. Thanks for your vote on the white railing, Frank. Brass tarnishes fast and permanently unless polished regularly. I thought a lot about painting the railings and pump wheels before taking the plunge. I doubt that either were originally brass but they did look great initially. Maury, the white glue I used is pH neutral, PVA used for bookbinding. It dries very rubbery and fairly clear. I believe that wood glues, like Titebond, are formulated to dry hard so they may be sanded. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

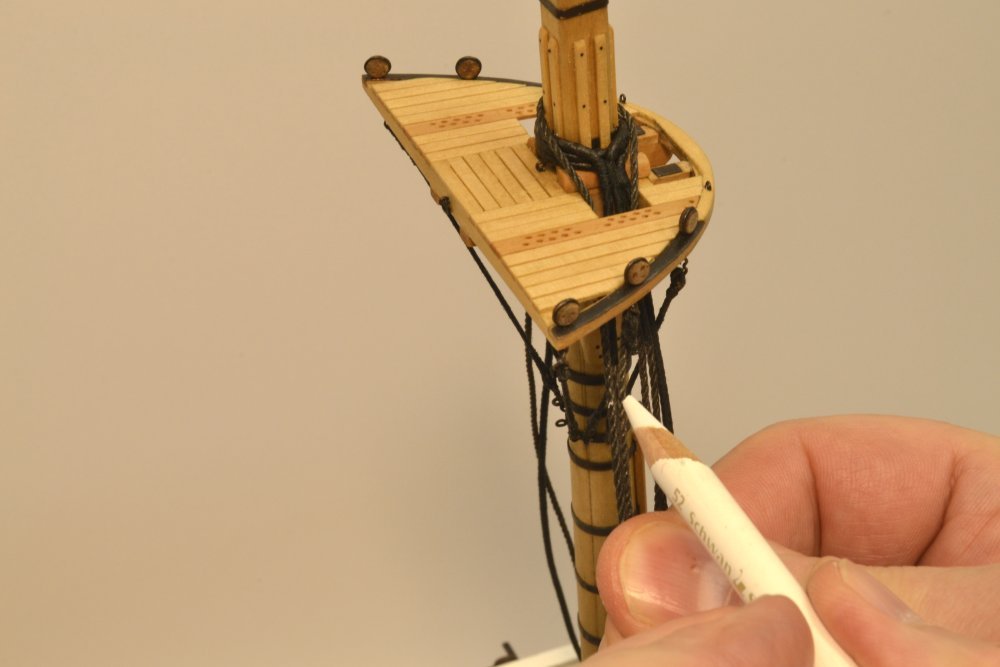

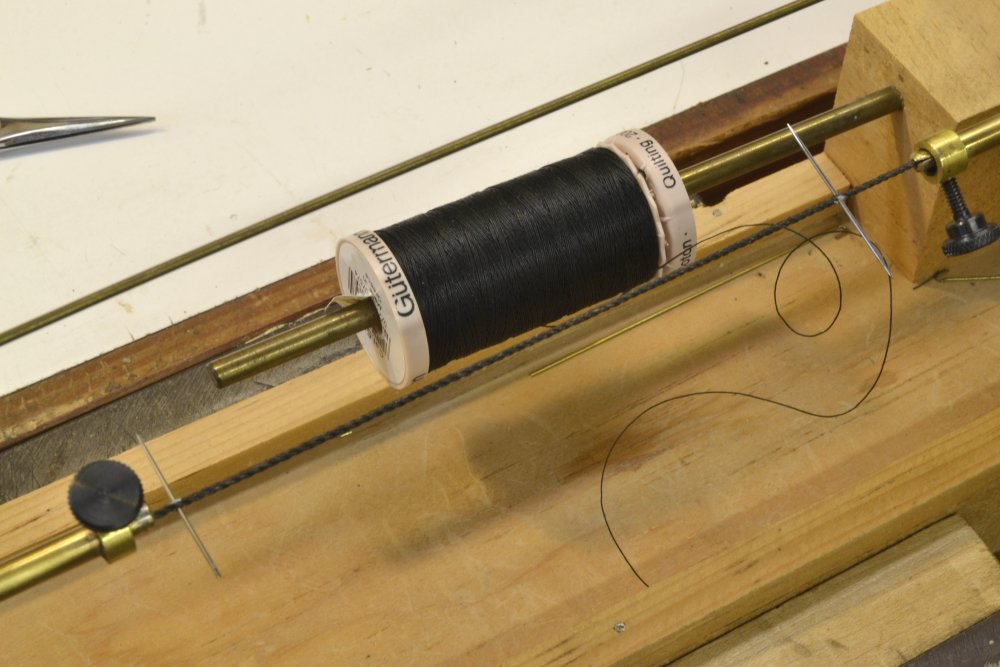

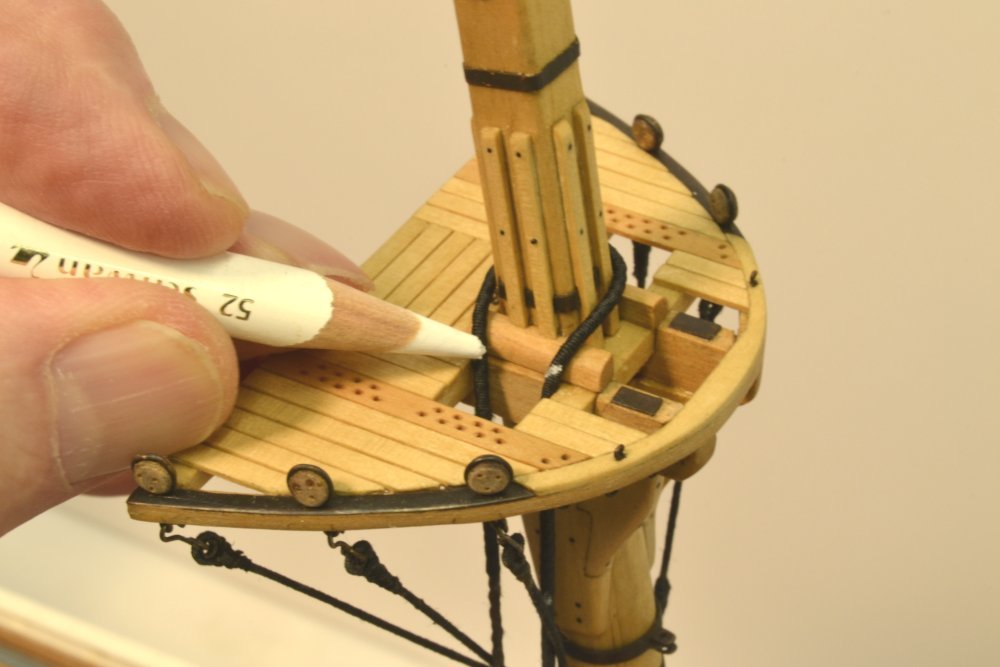

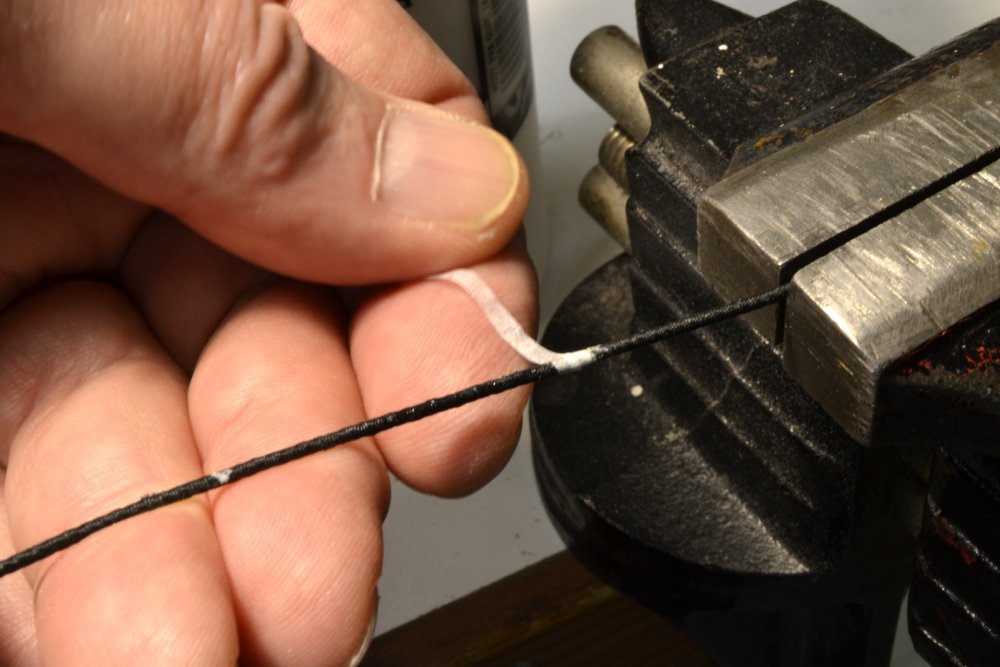

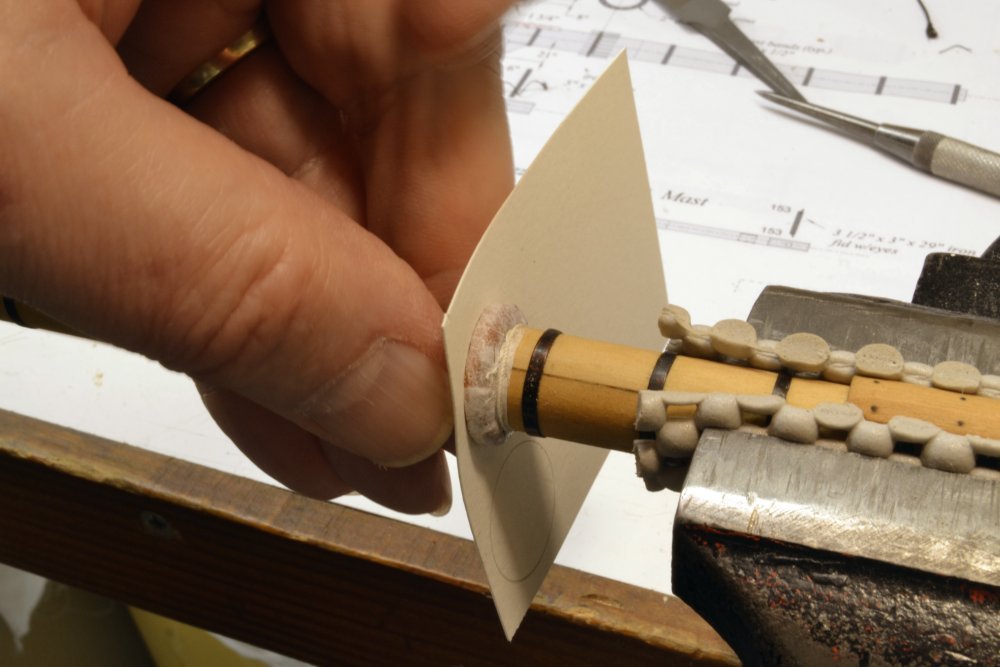

Young America - extreme clipper 1853 Part 205 – Making Lower Shrouds Before getting into making shrouds, I completed one more chore that has been on my mind for a while. The brass poop rail was becoming more tarnished by the day, so considering that it was losing its shiny appeal and that the original was probably iron, I decided to paint the rail white. See the first picture. I decided on white based on the photo taken at San Francisco. After degreasing with acetone, the rail was painted with gloss white enamel – two coats, slightly thinned. The lower fore shrouds shown in the following pictures are 10½" rope, laid up from three strands of Barbour Irish linen thread. An adequate discussion of rope making, cotton vs. linen, and size matching is beyond the scope of this log, but I have been working on a description for Volume III. My rope making "machinery" and process has undergone major development since my first efforts 20+ years ago – but is, of course, still not perfect. For dimensional reasons and the difficulty in making good four-strand rope without a central core, the shrouds are three-strand, even though four-strand was typically used for these. They are also right-handed, in keeping with American practice at the time. Shrouds were made in pairs that were looped over the mast head, starting with the forward starboard pair, followed by that pair on the port side and continuing in that way. In the first picture, the third starboard pair has been cut to length, looped over the mast and is being marked at the ends of its served length – at the futtocks - with a white pencil. The shroud was then removed and transferred to the serving machine as shown in the next picture. Before putting tension on the rope, needles were inserted through the rope at the white marks so serving thread could be pulled through to help secure each end. Starting at the right, after pulling the thread through, the rope was then served, initially over the thread end, then up to the second needle which was threaded and pulled through to complete the joint at the second end. In the next picture, an earlier served shroud has been looped over the mast and is being marked at what will be the top of the seizing to show the extent of the outer parceling that was used as an added protection against damp in the closely packed bights. With the shroud stretched between two vises, white PVA glue was applied and the shroud wrapped with strips of tissue, working from each end toward the center as shown below. The white PVA dries softer than Titebond making it easier to loop the shrouds later. After wrapping, the shroud was looped over the mast until the glue dried. The parceling was then painted with artist's acrylic paint. After the first coat dried, the seizing was put on as shown below. The last picture shows both gangs of shrouds looped over the fore mast head. An alligator clip is holding the final pair while the parceling glue dries. After seizing and painting this pair, the shrouds will be ready for the deadeyes at the lower ends to be turned in. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Maury and Micheal, thank you. Micheal, Longridge is already resident in my shop - always looking over my shoulder and shaking his head. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thank you, Jack. The photo store comment was a bit of gallows humor lamenting the loss of actual stores like that. We are as guilty as any, with UPS and Fedex drivers wearing a path to our front door almost daily. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thank you, everyone, for the comments and likes - much appreciated. Its taken some time to get through the work on the lower masts and tops. Many rigging questions needed to be studied and decided - one at every turn, it seems. Hopefully things should move faster. Druxey, the outer parcelling at the masthead was easy to do and a small nod to authenticity. I have for a long time had a mental picture of the photo in Longridge showing this, and often regret not doing it on my Victory. As with many builders, I suspect, the image of the somewhat unsightly wrapping compared to the lovely, neat stack of served bights was a deciding factor. The mid-19th century docs I am using are quite clear about it. So there it is. Sailor, I do not know the actual construction time for YA, but 6 to 9 months from laying the keel would be typical, with the unbelievable 60-day performance on John Bertram being the record (?). Pat, I did not consider the material you describe for the case. Are there still photography stores? cheers, everyone. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

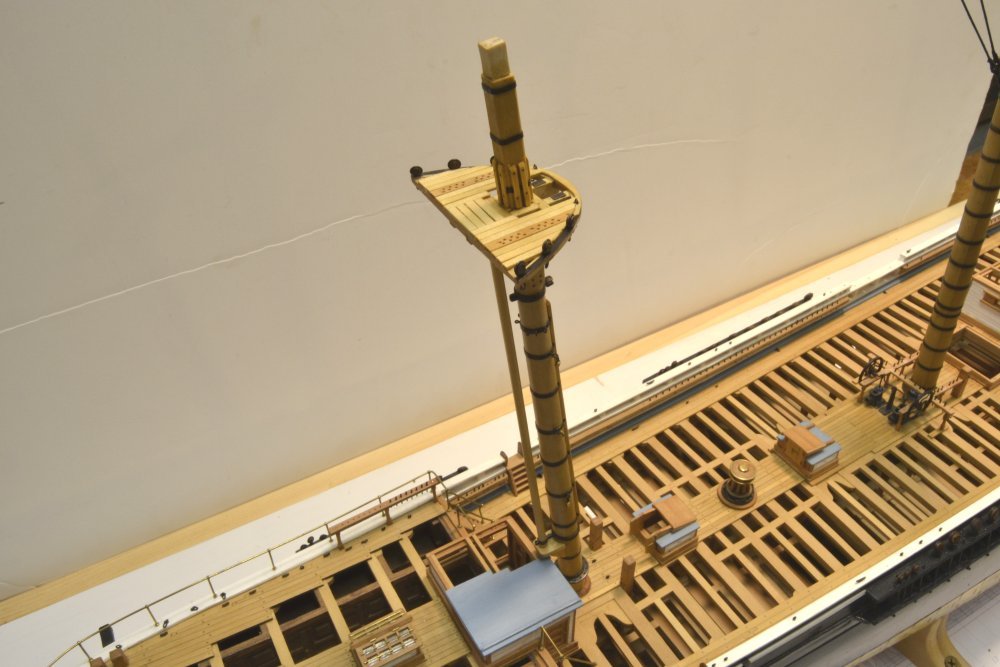

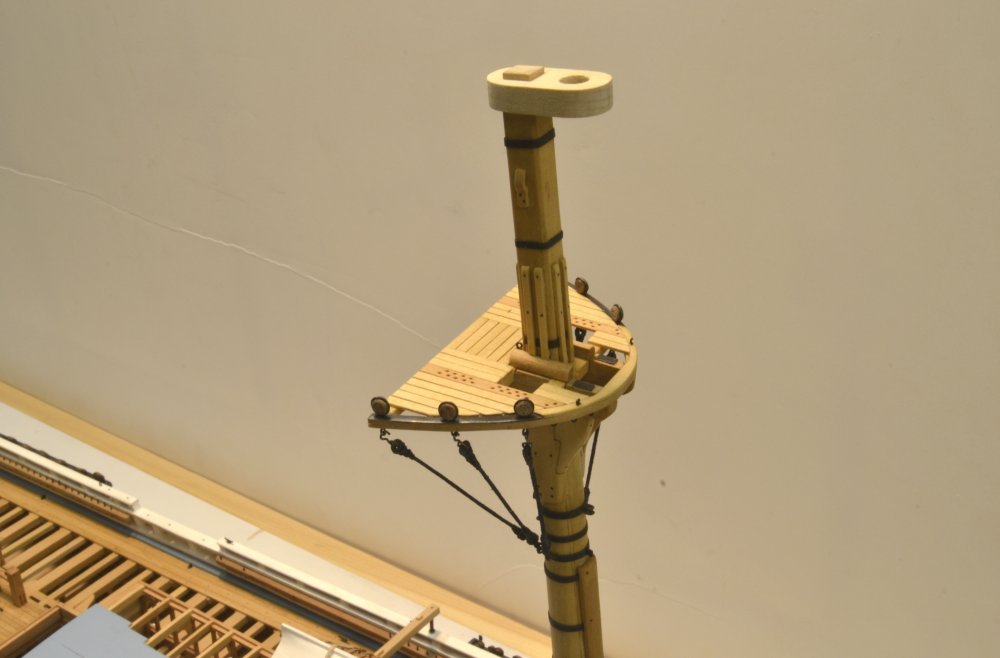

Young America - extreme clipper 1853 Part 204 – Tops and Futtock Shroud Wrap-up I am happy to be finished with the dust case and to resume the model work. The completion of the three mast assemblies with their pre-erection detailing, including their futtock shrouds, required just a bit more work and is now complete. The first two pictures show the mizzen top with its futtock shrouds installed. As mentioned earlier, these shrouds are served, fitted with brass thimbles at both ends, hooked to the deadeye straps at the top and secured to eyes on the mast band with lashings. The futtocks are 4 1/2" rope (5 ¼" on the main and fore), spun from three strands of linen thread, right-handed. The rope was dyed black with diluted India ink. Making these was described earlier in Part 196. The last task on the lower mizzen mast was fitting of the mast coat at the base. This is shown in the next picture. The next picture shows the model with the three completed lower masts fitted – still temporarily. The next step will be to make the lower shrouds. The next picture shows numbers 1 and 2 on the fore mast, port side, looped temporarily over the mast head. These two will actually go over the corresponding starboard pair. In each case the #1 shroud is served over its full length. The serving on #2 extends down to the futtocks as it will do on all the other shrouds. Parcelling has been wrapped over the serving around the mast head down to the top of the seizing, but has not yet been "tarred." More on all this in the next post. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Bil Crothers passed away in the spring of 2015. His last book was The Masting of American Merchant Sail in the 1850's, published in 2014. American Built Packets and Freighters was published in 2013. Ed

-

It feels exactly like that, Bob - a big white elephant. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Bob, The cross-section drawings show the 48" x 16" side chocks extending to the floor timbers. With the 10" wide limber channel, this requires notching of the limber strakes to allow the chocks to penetrate. This was the basis of the design I adopted and the way I did it, so my suggestion is to construct it as shown on the cross-sections - see Cross-section at 12 for the main mast step, at Q for the fore, and 32 for the mizzen, and of course, the step drawing.. All show the chocks extending to the frames and the knees on top of the planking. I did not detail required cutouts in the limber planks. Now, having said that, I acknowledge that the design of the steps, as with many other undocumented designs, is my interpretation of a commonly used step. The side chocks could easily be cut off at the height of the planks, but I felt that basing them on the frames would be more robust. Keep in mind that on these ships the drainage channel was below the frames, as described elsewhere in the book, so the channel above the frames did not need to allow open flow. It was mainly used (very infrequently I would guess) to flush or unclog the channel below. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

EdT replied to albert's topic in - Build logs for subjects built 1751 - 1800

Beautiful work, as always, Albert. Ed -

Young America - extreme clipper 1853 Part 203 – Dust Case The dust case mentioned earlier was completed this morning. The first picture shows the framing of the case after the initial paper covering was removed. As I mentioned earlier, the framing was made from scrap, so it is not fine furniture. It is meant to be an inconspicuous part of the project – to keep dust out and allow me to take pictures of the rigging without having to drag out backdrops. Both sides are easily removable. The top is Plexiglas® sheet to pass light from the fixtures above. Six screws at the base permit the entire case to disappear. For those who offered suggestions on covering material, thanks again. I went with Elmer's white foam board, which is what I used on the previous Victory case. It is glued to the frames with water-based contact cement. The next picture shows the port panel covered with the board. The panel is covered with two 30x40 sheets. You may just make out the center seam. Finally, in the next picture, the completed case, with the starboard panel removed. The case is certainly a major presence in the shop. Now back to the model work. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Mike. Comments and my replies might be confusing. I am going to use foam board, 1/4" Elmer's white, which is what I used on the Victory dust case about 10 years ago. I do not want to use slotted frames this time because I don't want the frames to be visible inside - no inside fasteners either - so the foam board will be glued to the insides of the frames in a way to minimize showing corners and joints. I should have this done in a few days and will show some pics. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I did not consider sheet styrene, Andy. Interesting suggestion. Thanks. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Interesting framing, Frank. I can easily appreciate the strength problems with this design, but you seem to be conquering them. Nice work. Ed

-

Thanks for the suggestions, guys. Fabric seems a logical choice. I did not consider this because I did not want the weave as a photo backdrop. I take so many pictures for the blog and the books that I do not want to tinker with getting the backdrop out of focus on each shot. I take almost all at maximum depth of field. Also, fabric collects dust and is not impervious to fine sanding dust that is ever present in my combination shipyard/woodworking shop. The corners need to be inconspicuous , but the side panels must be easily removable to work on the model, so wrapping clothing over the inside corners won't work. The idea I had for paper corners did not work as well as I had hoped. Fabric must also be stretched to avoid wrinkles, so the frames would need to be heavier to keep straight and seal at the sides. I used foam board for the Victory case, which, unfortunately is too small for this model. It is durable, can easily be wiped down, can be fit tightly at the corners, and, I hope, the center seams on the large (60" x 38") side panels can be masked in some way. So, I always had a solution, but thought I could go cheap with that large roll of paper on hand. Never works. I also confess to perhaps overthinking the problem - something I'm good at. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

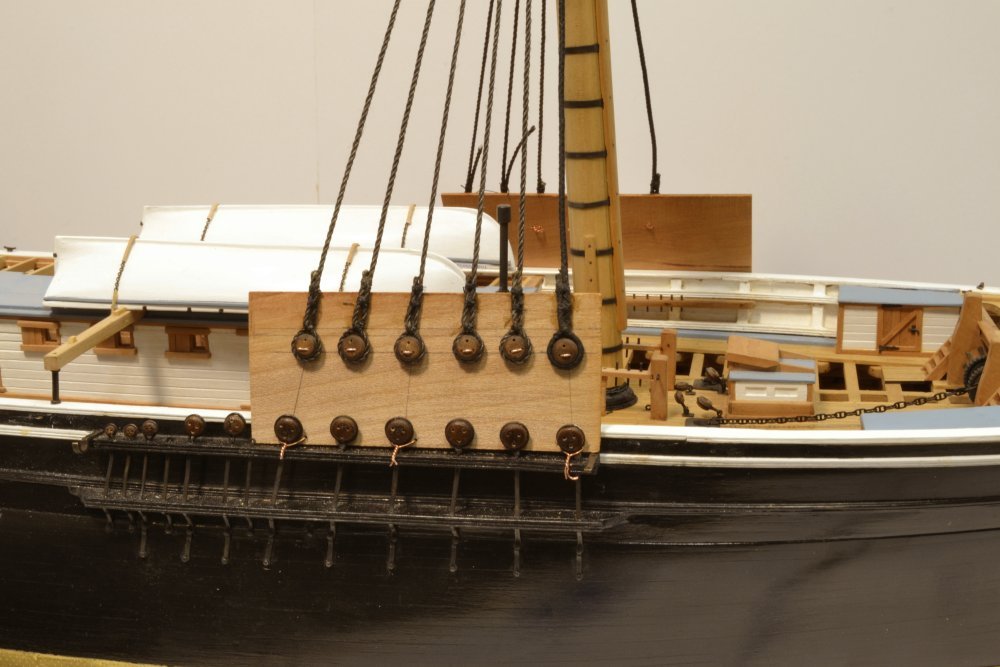

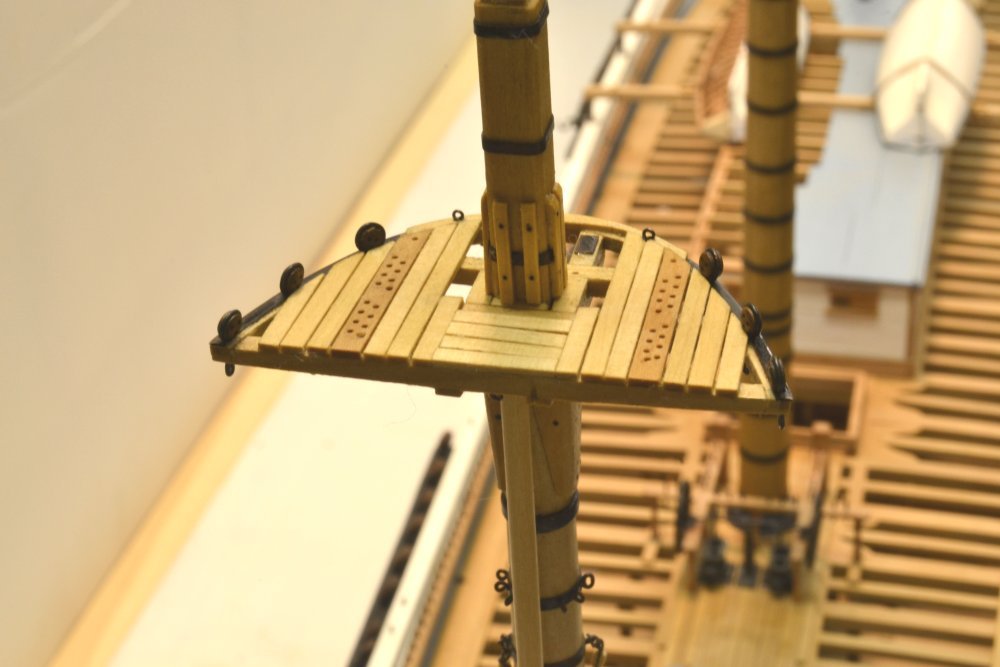

Young America - extreme clipper 1853 Part 202 – More of the same - Tops Seeing pictures of Young America's tops may be getting tedious, but repetition is the soul of ship modeling, so I will show some more. There is not much else to do at this stage. First are the six mizzen top deadeyes, almost ready to be installed. These are 8" (~.11" in diameter) – not the smallest. There are some 6". These were dyed, finished with Tung oil, and then drilled. This keeps the heavy soak in oil from clogging holes. In the picture they have just dried after dipping in LOS with their straps attached. They will get a light buffing with Tung before being fitted. I've tried different sequences. This seems to be the best. The next picture shows these - after some more finishing - installed in the rim of the top. The top and mast head have been trimmed out with bands, eyebolts, topmast fid plates, and chafing battens. The next picture is a view from astern. And finally, the full lower mast from above. The next picture shows the foretop with the roughed-out mast cap fitted. These are coming up on the agenda. They have some interesting ironwork for the lower topsail yard fittings and for the lower yard topping lift block fastenings. All is at a bit of a standstill however, as the shipyard has become a woodworking shop for a few days as may be seen below. These are the frames for the dust case mentioned in an earlier post. It will also serve as an ever-present photo background for the rigging work. Its turning into one of those projects that lasts, because of trying to do it on the cheap. The wood is scrap from my collection – not a problem – but the plan was to use less expensive photo background paper over it, instead of the foam board I used on Victory – until one newly papered frame got punctured leaning against a not-too-sharp corner and a floor broom tipped over and fell through one. Foam board is on order ($50). Stay tuned. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Thanks, E&T and others for the likes, Bob, you are more scientific than I am. I put about 1/8" of water in a small plastic bathroom cup, dip a small brush in LOS gel, and then stir it around in the cup, then use it immediately - either brushing it on or dropping small parts into the cup. Color of the clear solution is my measure - not too dark. Ed.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Terrific work, Frank. Its great to see some of these methods applied to a completely different type of hull structure. Two Sherlines! This is serious mobilization. Ed

-

Bob, I have found that copper can be blackened with LOS without effecting surrounding wood. The wood needs to be clean of any metal sanding dust and the LOS needs to be fairly dilute. When leveling off boltheads, files produce less fine dust than sanding but the surface should be wiped clean before treating. LOS solutions seem to neutralize to water and inert white solids and leave no reactive residues, unlike salt based blackeners like the blue selenium based solutions. You may also wish to rinse with clean water. While I have found this to be the case, some testing is always worthwhile to understand the right LOS dilution as well as the need for pre-cleaning. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Lovely work, Micheal. A lot of neat stuff here. I like the sawing clamp with the knurled knobs - a good idea for aging fingers like mine. Ed

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Wow. She looks absolutely fantastic, Nils. An amazing piece of work - with so much complex detail. Ed

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

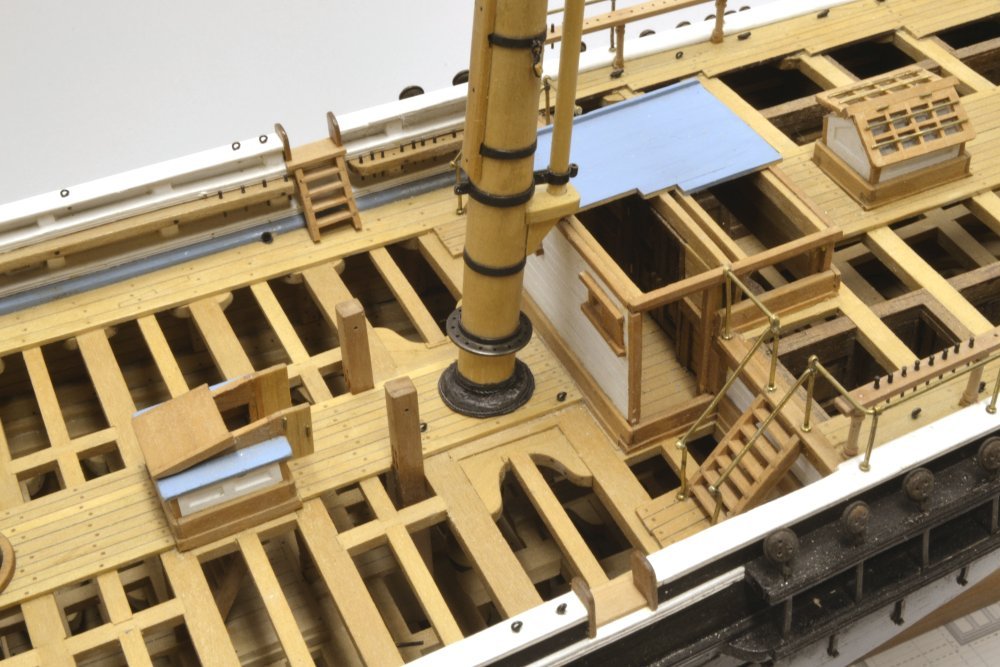

Young America - extreme clipper 1853 Part 201 – Lower Mast Coats When I decided to wedge the masts with pieced wedges, it was clear that some sort of mast coats would be required to cover the openings between wedges – not to keep out water as in real life practice, but to simulate the real coats and to improve the appearance at the bases of the masts. Apart from terse descriptions, there was not a lot to go on in making these. My usual search through photos gave some ideas, but ultimately the solution came from the question, "What would I do to make a watertight canvas 'flashing' over the mast wedges?" I am comforted by the thought that many ships' carpenters asked similar questions – and came up with a variety of solutions - as the few pictures I have seen illustrate. The canvas for the model coats is tissue and in the first picture a strip of this is being wound around the glue-coated main mast and its wedging. Several strips were used with plenty of glue and not too much effort to smooth out the result. Canvas would most definitely have wrinkles when forced into the required shape. The next picture shows rope being tied around the top to clinch it tightly around the mast. In practice the coat would have been caulked and tacked around the mast and deck, but rope cinches would keep it from tearing out from the nails and risking damage to the high-value cargo these ships often carried. At the bottom, a flange was simulated using card and fitted around the mast at the base as shown in the next picture. When this was glued in place and allowed to dry, a second rope cinch was added at the base. The next picture shows the coat being "tarred" with fairly thick, dark grey, artists' acrylic paint, After drying the coat was brushed with black, thinned, acrylic wash to highlight the wrinkles in the canvas and the ropes as shown below. Those that have been following the project will note that the glistening brass pump wheels, by now well tarnished and lacking their original appeal, have been painted. Next job for the painters, the equally tarnished poop monkey rail. Other true followers may also notice in the picture that I have finally gotten around to adding the central posts to the fore and aft fife rails that were previously omitted. Ed

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.