-

Posts

4,107 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

Thank you both for the comments, much appreciated!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you, much appreciated. Thank you! Thank you! I appreciate all your comments!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Rusty. One of my summer goals is to learn more about Photoshop’s new AI features. Maybe I’ll create an image of Winnie on the high seas😊

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

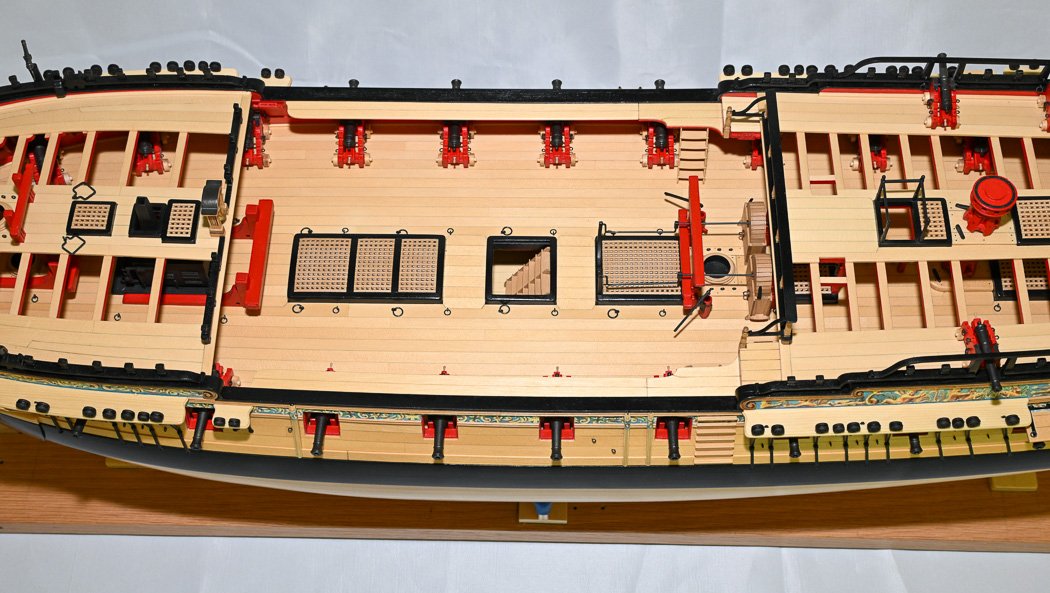

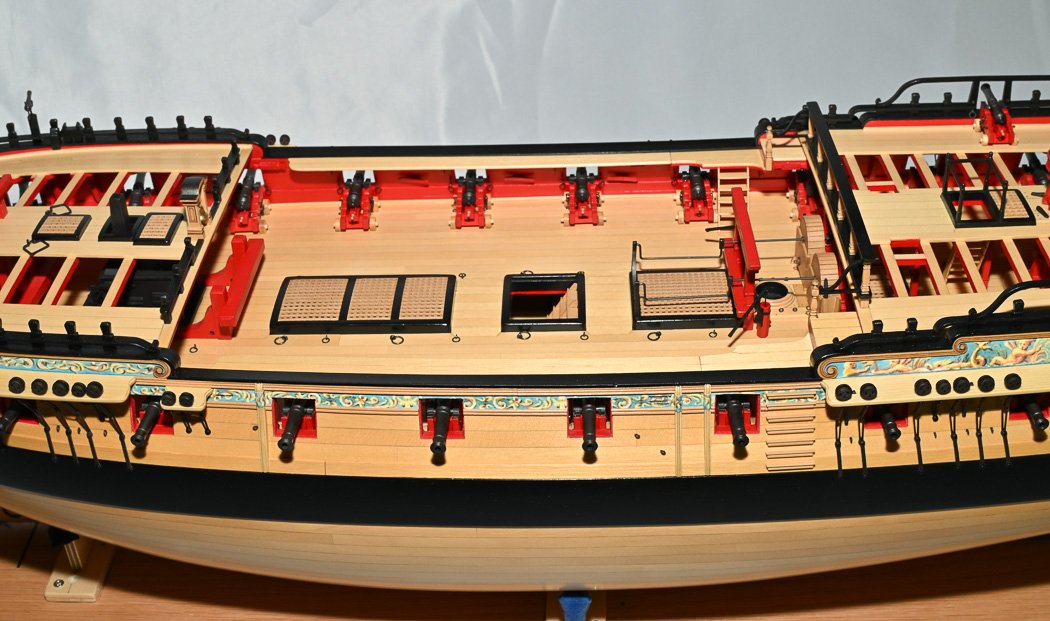

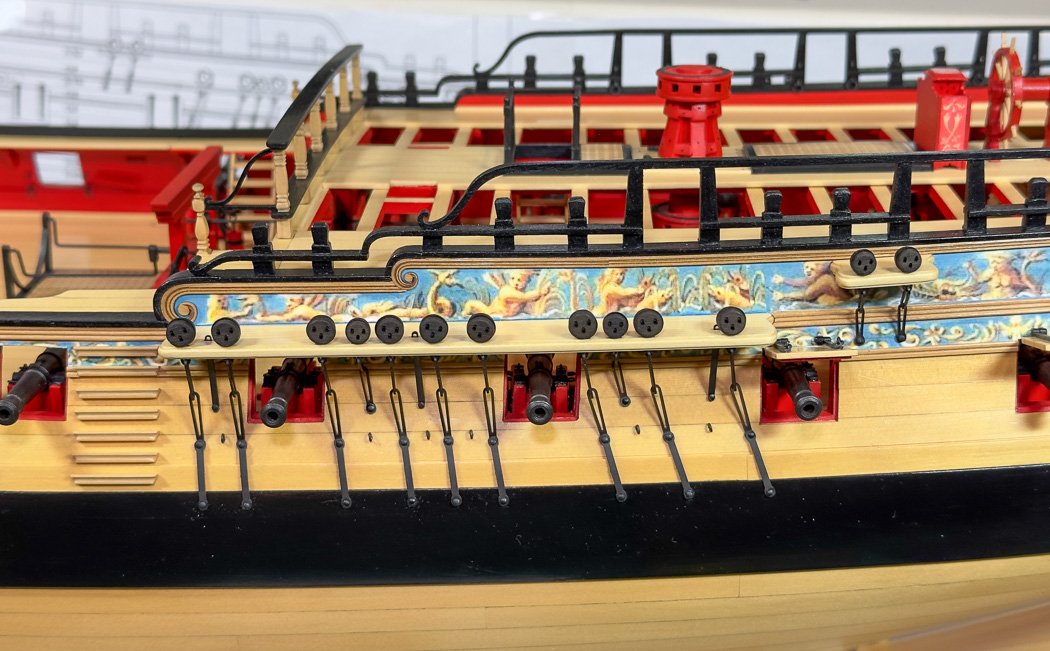

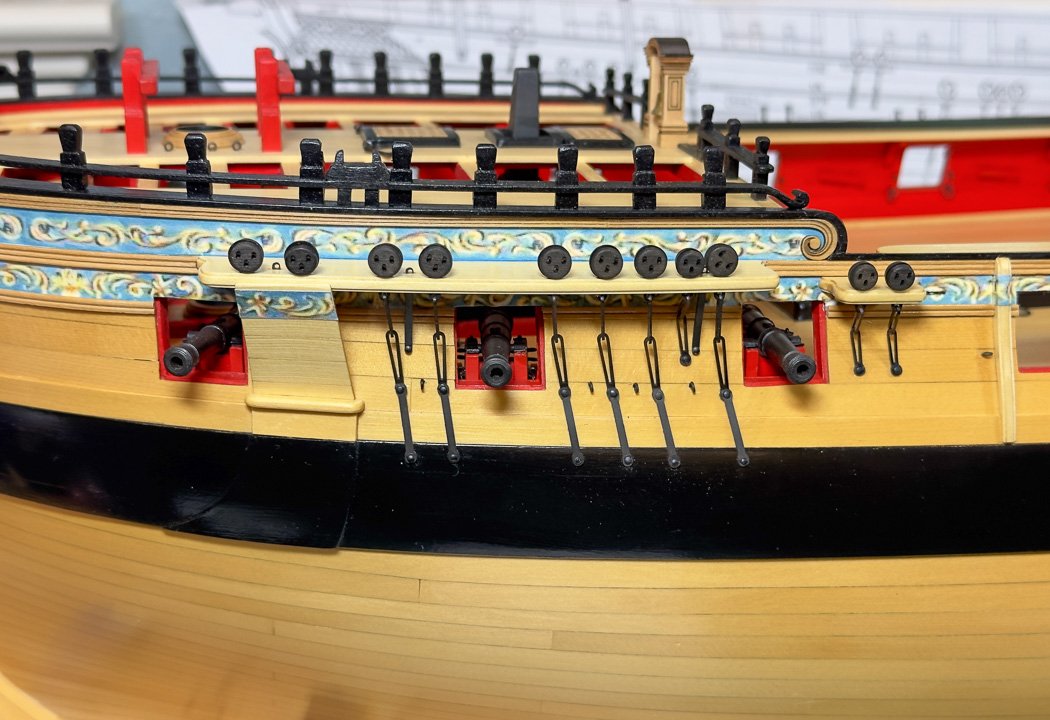

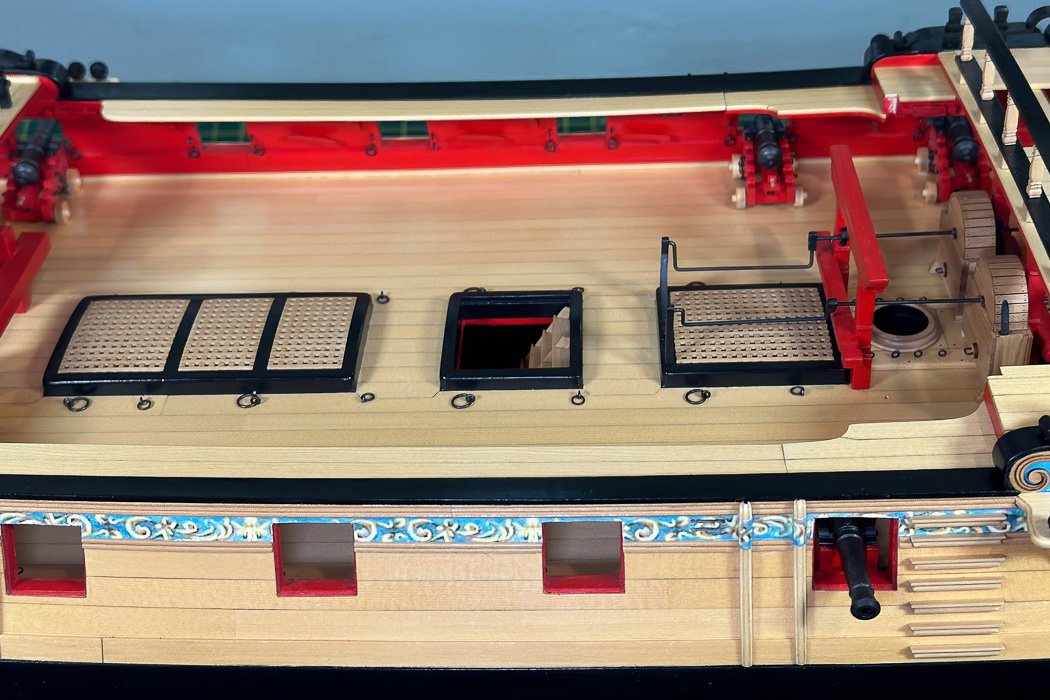

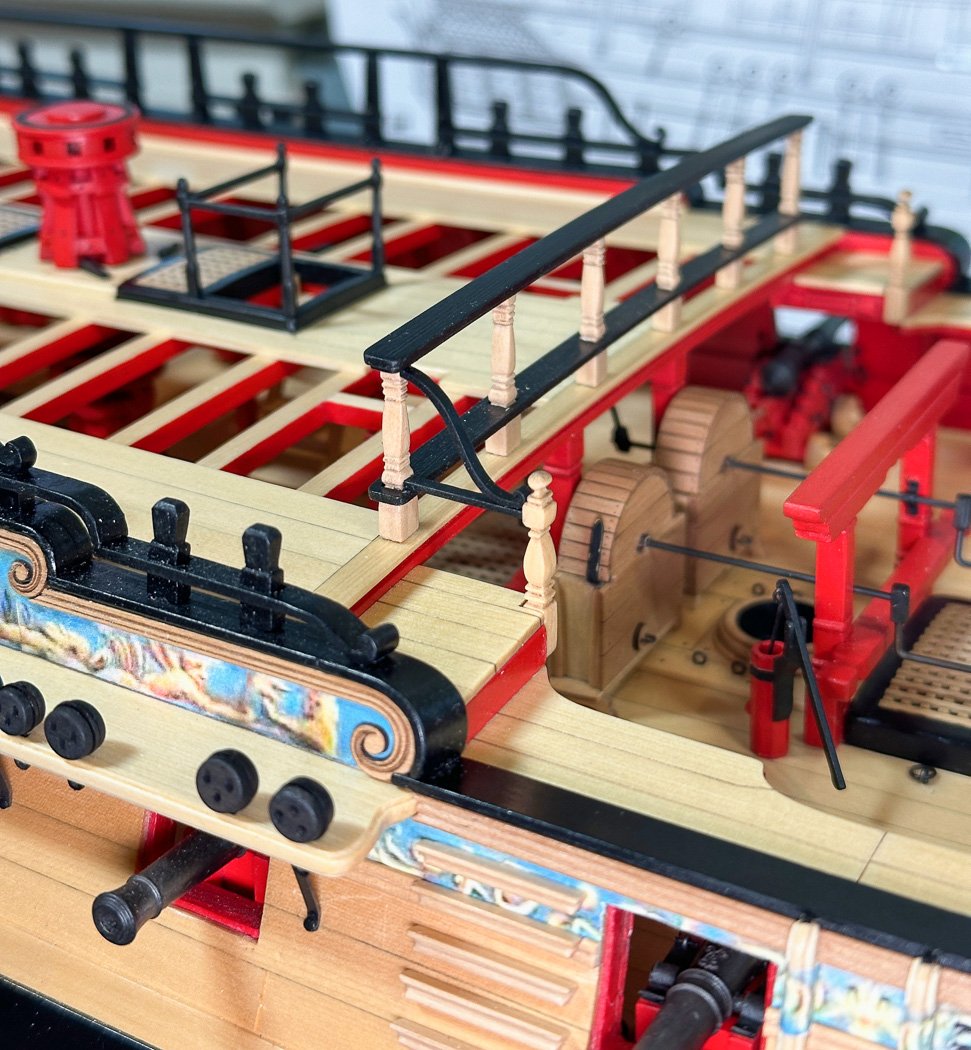

Chapter 11, the model save the headworks is complete. I thought I'd share some photos: So many cool design features stand out. As simple as the bill board may appear it was a sharp addition. As I've mentioned, I dyed the deadeyes ebony. The dye, as opposed to black paint, allows the grain to show (though hard to see in photos) I'm pleased with how they complement the colors of the overall model. The open deck allows a nice glimpse of the stove - such a fun thing to make I'm glad it's not completely hidden. The decision is still pending on whether I place the swivel guns on the bollards. I'm not sure how I feel about the look, accurate or otherwise and I'm not completely confident drilling the holes for them to fit. I'll revisit it as I start work on the headworks. The midship cannons were the last thing glued in. I was holding off while my friend and I fitted the base he's making to have a place to hold. Once the gang boards were mounted they became more the thing to avoid than cannon barrels. I'm happy with my decision not to rig the guns this time around. Although I appreciate those that did, in this case I like how it provides for a nice clean look. Or maybe I just didn't want to rig 32 guns. The transition to the quarterdeck, from the lower deck letter to the breast rail provides for a lot of detail and many, many hours of work over the past 2 ½ years. It's all worth it when it all comes together. Those posts took a lot of time. So glad I took that time. I made the elm tree pumps two years ago but didn't add them until the ladders, rails, gang boards, and everything around them was complete. That was a good call, I would have broke them multiple times otherwise. The stern is when all the fun is. Between port lids, more cannon, swivel guns and predominant deck furniture there is lots to see and lots of mini-projects to get there. One very minor thing I'm happy with: I was able to wrap and match up paper friezes for six of the swivel guns. With the angle and only two sides showing that wasn't an option for the two on the quarter gallery roof. I'm no paint specialist but I kept playing with Winsor and Newton Cerulean Blue, Titanium White, and Grumacher Mars Black until I got a nice match with the paper frieze. I know it's a small thing, I considered going the Sherman Williams store for a computer based match but not sure what I'd do with the minimum order of a quart. I've shown versions of this photo several times, I never tire of it. For me it's a piece of art all by itself and yet another signature tribute to Chuck's design and penchant for detail. So here she sits ready for the final chapter. I'm taking some time off for other summer activities, I'll see how long I can go before jumping in to start chapter 12. Thanks for stopping by, your likes and comments are always appreciated.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice to see you back at work. I remember those doors…

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes they are, not sure how model specific they are. They need to be lightly sanded and weathering powder applied but they are great.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Only the swivel guns to go to finish Chapter 11. A quick update on what was the long process of adding the chain plates to fix the deadeyes to the channels. Basically a lot of holes to drill in a straight, level, and angled lines. Another exercise in patience, planning. placing, and adjusting each of the three mast sections of channels and deadeyes I am a big fan of the acrylic strops and chainplates - so much easier and such a much better look than fighting through their metal equivalents. I’m not going back. I also had a new opportunity to make many eyelets along the hull following the plans. At this point the twist around the drill bit in the vice and the cut, snip, fit is mindless, easy work. Maybe someday I’ll count how many I’ve made for Winchelsea - or maybe not. The model is transformed with these additions - looking completely like a ship at this point (don’t look at the stem, that’s Chapter 12). It’s really quite something. I'm going to take some better photos after I finish Chpt 11. I still haven't glued in the remaining guns, but that's coming up soon. Thanks for stopping by - some swivel guns are up next.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Frayed lines

glbarlow replied to Dindsy's topic in Building, Framing, Planking and plating a ships hull and deck

It’s your first model, cut all that junk line off and re-rig it with better line and blocks from Syren or Ropes of scale. The practice and second run through will be good experience. There’s no hope for what’s on there now. -

Thanks Rusty, much appreciated from someone’s who’s work I’ve admired for a very long time.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Chuck, for your support along the way and for this fine model.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Much appreciated Eric! Thanks Matt, enjoying your Winchelsea as well. I appreciate the kind words, thank you.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well done JJ, amazing design work! I can't imagine a hike to the Himalayas parking lot let along any further. Be careful and enjoy the trip. Having just "located" the channels your design element marking them and making them easier to install is a excellent feature.

-

Channels and Gangways An update as I near the end of chapter 11: My friend is making a stand for me. He’s an artist, he selected this particular wood piece of Wenge because the model will appear it’s ‘breaking the water.’ This is not something I’d ever thought of, but pretty cool. The color of the Wenge with its elm inlay, especially once finish is applied, is a nice accent to the model. Good to have artist friends with big tools. The channels are complete port and starboard. The stress of cutting away mounting and cutting into friezes to fit the curved ends of the channels is behind me. I’m happy with the ebony wood dye used on the deadeyes with its result of the boxwood texture showing through. They stand out in their own right and are a nice compliment to the rest of the model. I have completed the gangways, as did Chuck I elected to position the knees after attaching the long gang board. I was concerned about midshipmen falling overboard but having just received the latest Sea Watch Rodgers collection of 5th rates (given my Not vast nautical knowledge). I saw ropes and posts were mounted along the rail. Not something I’d want seen on our Admiralty board model, but I feel better about the midshipmen now. The newel posts and their fancy rail are yet another signature element of the model. For a level fit to match up to the newel post my lower rail is mounted to the breast rail post rather than its rail, plus I like the look. As Chuck notes, getting the post level on multiple planes, especially given the platform follows the sheer and camber of the deck, took some patience and a jig or two. A major milestone: With the addition of the ladders and installing the elm tree pumps I completed more than a year ago my Winchelsea is complete between the bulwarks (short of my gluing on the remainder of the guns). Work continues. Thanks for stopping by.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Most likely my next build after Winchelsea, it’s just sitting in my cabinet waiting for me.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It’s just a pre- announcement of a ‘copy’ being pieced together now by some Chinese hack. 😳 I just read it as well (as a guest, I was kicked out long ago). Interesting how some members are complimentary while the staff and admins work hard to disparage Chuck at every turn. This comment by a member “ I emailed Chuck with updates and progress pictures and found him to be very personable, interested and encouraging. A much more personal investment of his time and interest than one might otherwise expect from the head of a commercial venture.“ must have really hurt.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.