-

Posts

4,121 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

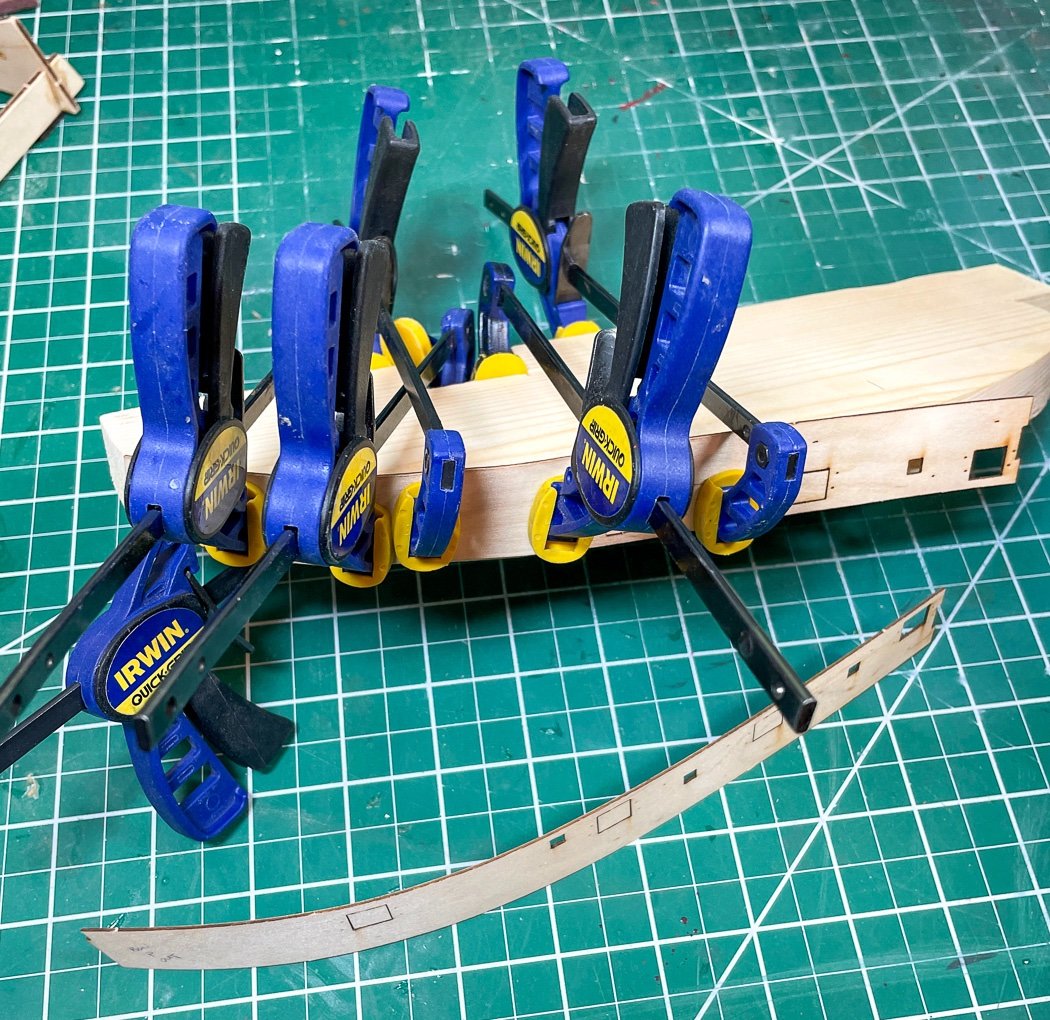

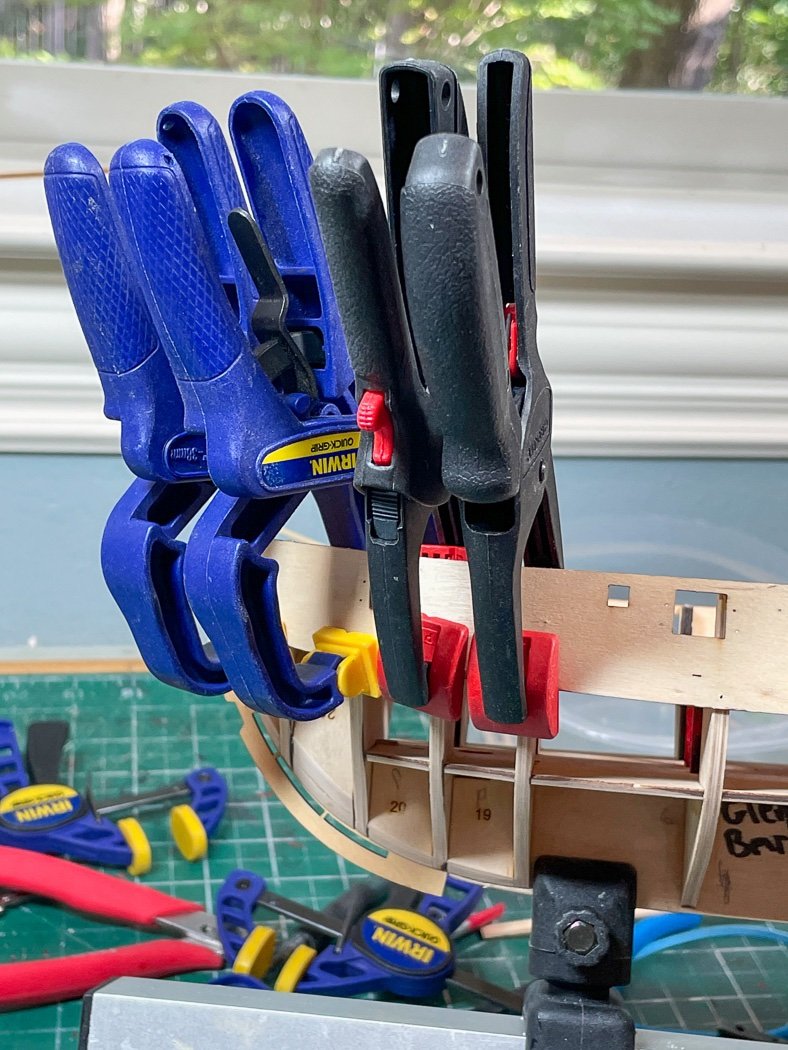

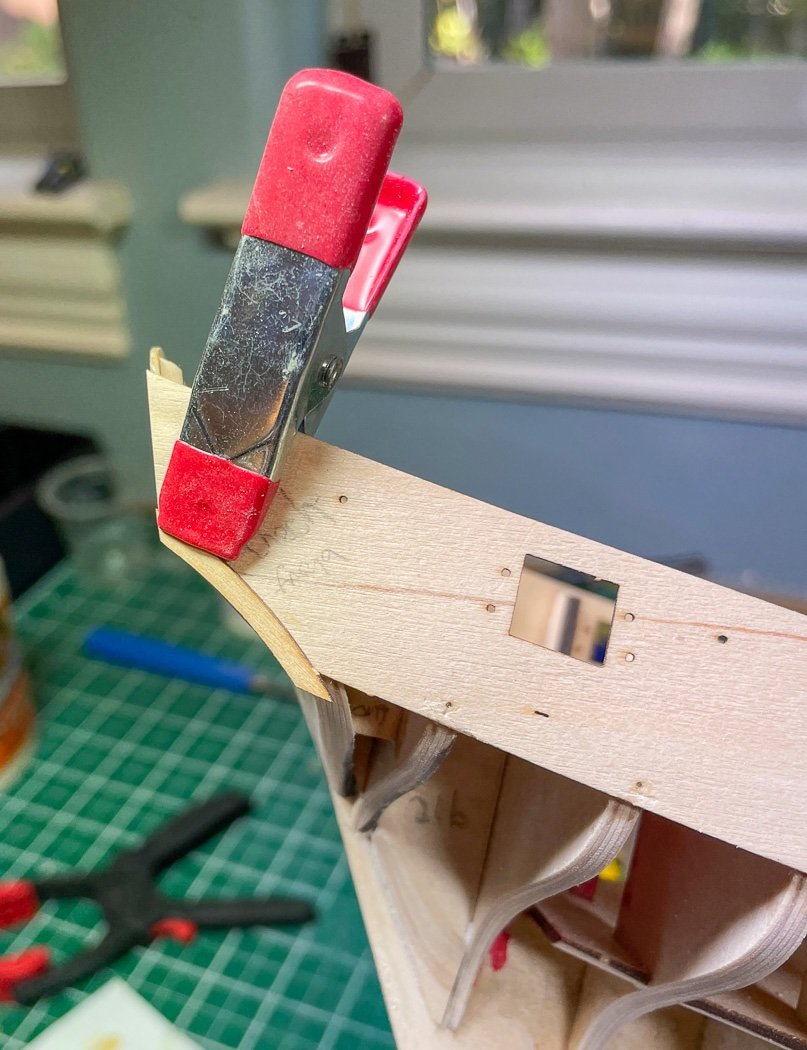

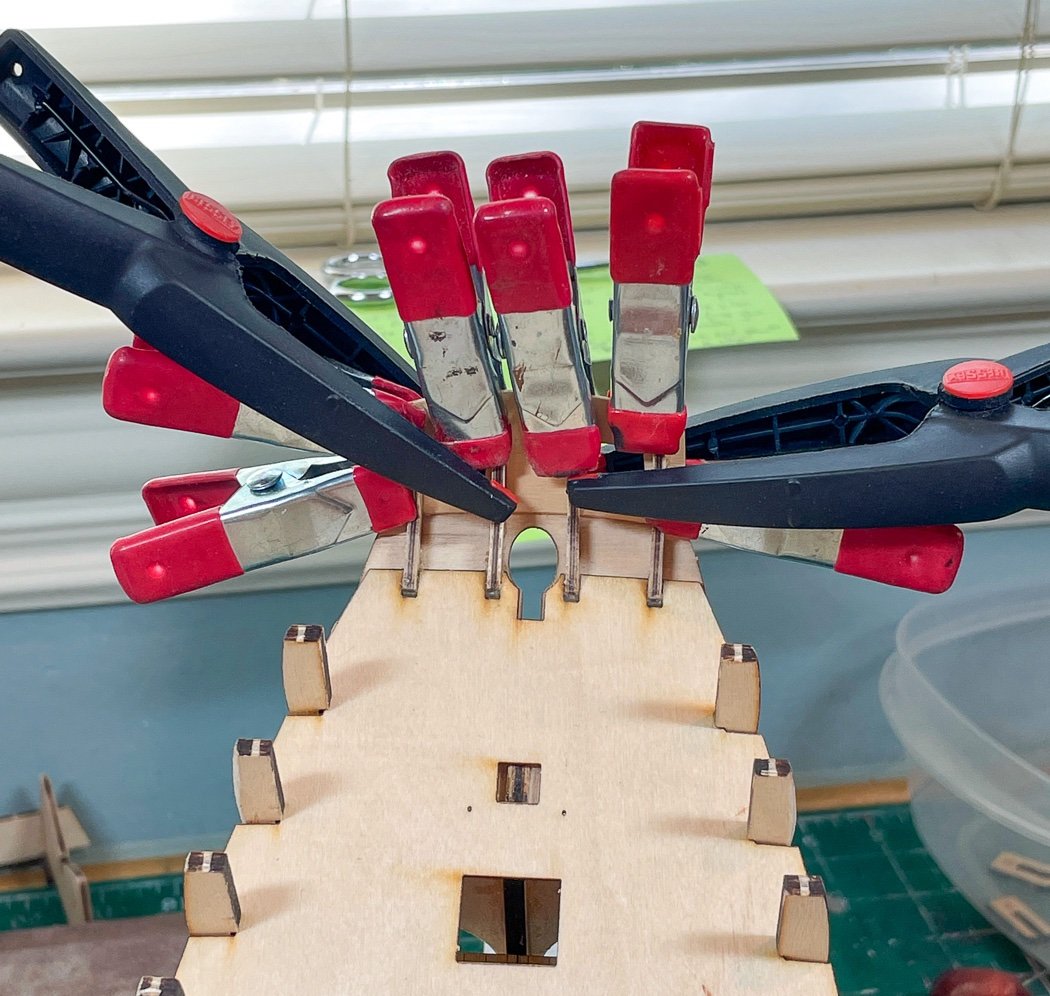

Gun Port Patterns Installing gun port patterns is not why I enjoy building models. I struggled getting a good fit with these four simple pieces of ply, quite a bit of fiddling about was required to get to a proper fit. When my friends see my completed models they invariably comment on how patient I must be - how little they know - especially when it comes to gunport patterns. While it’s debatable whether this step is necessary for Flirt with its gentle curves, I always begin by tracing a top view of the bow from the plans and transferring that to a piece of lumber. I keep all the old ones, only a little sanding with the Byrnes Sander was needed to match Flirt from whatever this former was used for before. I soaked the patterns for 30 minutes in a beer stein of hot water, clamped them to my former for an hour or so, then dumped the water and filled the stein with what it’s supposed to contain. I know its done all the time, but for whatever reason I don’t like to attach wet wood to my model, some unfounded fear of it warping the keel into a U-shape. Probably won’t happen, but why chance it. Then the fun begins, clamping the pattern to the bulkheads, lining up their tops - which of course working in three planes isn’t as easy as it sounds. I use wood glue to give me set up time, which I need, with just a little above the deck since the tabs of the bulkhead are doomed to the scrap pile later. I had done light scoring with a razor saw earlier on the sides of each bulkhead tap to help start that later process, light being the operative word. This is the step when I once again realize I can never have enough clamps. And here is where my impatience kicks in. Having finished the starboard forward pattern and having started the port forward I thought why not do the starboard aft piece at the same time. Don’t do that. It worked ok eventually, but clamps were flying off everywhere as I moved from one side to the other. I should have just stepped back, grabbed the appropriately filled beer stein and walked away, doing one section at a time allowing the time it takes, at least two hours, before starting the next one. Here is where the third plane comes to play. The pattern is curved by me to match the hull, the sheer is cut by Chris to match the run of the deck, so two out of three planes are covered, the third is the rounding curve of the hull top to bottom (tumblehome or flair). I had first dry-fitted the clamped pattern and knew this was coming, so I had soaked, curved, and dried the patterns three times before gluing it on. This serves to soften the unforgiving ply enough that it can be clamped to fit the curve. I had to choose top or bottom to clamp first, I chose the top. Once that dried I added glue to the area of the pattern that attaches below the false deck and clamped again. I should note that its not easy to place clamps, it’s a good opportunity to break a bulkhead tap. Fortunately I didn’t do that…this time. I have lots of clamps but only four of these ratchet type (I've now ordered more). They work much better holding the bottom edge of the pattern as needed to curve into the bulkhead. With the forward section done I added the port aft section - taking my time this time. The aft pieces are a much easier process, no pre-shaping needed. The key though is to line up the curve of aft end of the pattern with the curve of the counter where it meets the transom. I know I didn’t build the ship too short, the pattern is purposely long, so I dry-fit to get it lined up and marked off the extra length with a pencil. I removed the pattern and cut off most, but not all of that extra length, intentionally leaving it still a little long to sand off later. I needed rubber bands to glue the pattern to the transom, not much to clamp back there. With everything glued on this is a good time to check the fit of the stern facia piece. It doesn’t have to be perfect, just close enough that it will match up later on top of the second planking with a minimum of sanding, it’s easier to sand now, if needed, then later. Of course, like here, it was good I installed the counter with its curve in the first place. While I didn’t get a photo of the before, the net result of all this is a well attached pattern…with waves/waffling in the area nearest the stem. I know from experience this happens and that between sanding and the second planking a little bit of wave won’t matter. Still it bugs me, so out came my best wood management tool, my travel iron. I saw Derek also did this on his Speedy. It actually works remarkably well. I just ironed, in max steam mode, the bow patterns like they were a shirt. The waves smooth and the curves look much better. And with that my Flirt has its gun port patterns completed. I now remember there is life…and enjoyment…past the installation of gunport patterns. Now, I can plank. I could put the beer stein away as I won't be soaking anything else during this build...but there is its primary purpose and that may come in handy from time to time.

-

Nice work on the winch, it looks great. Like you I enjoyed Chuck’s challenge for us to make this on our own.

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

If you aren’t screwing a few things up you’re not learning. Adapt, Improvise, Overcome, this is why we do this for such opportunities.

- 71 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

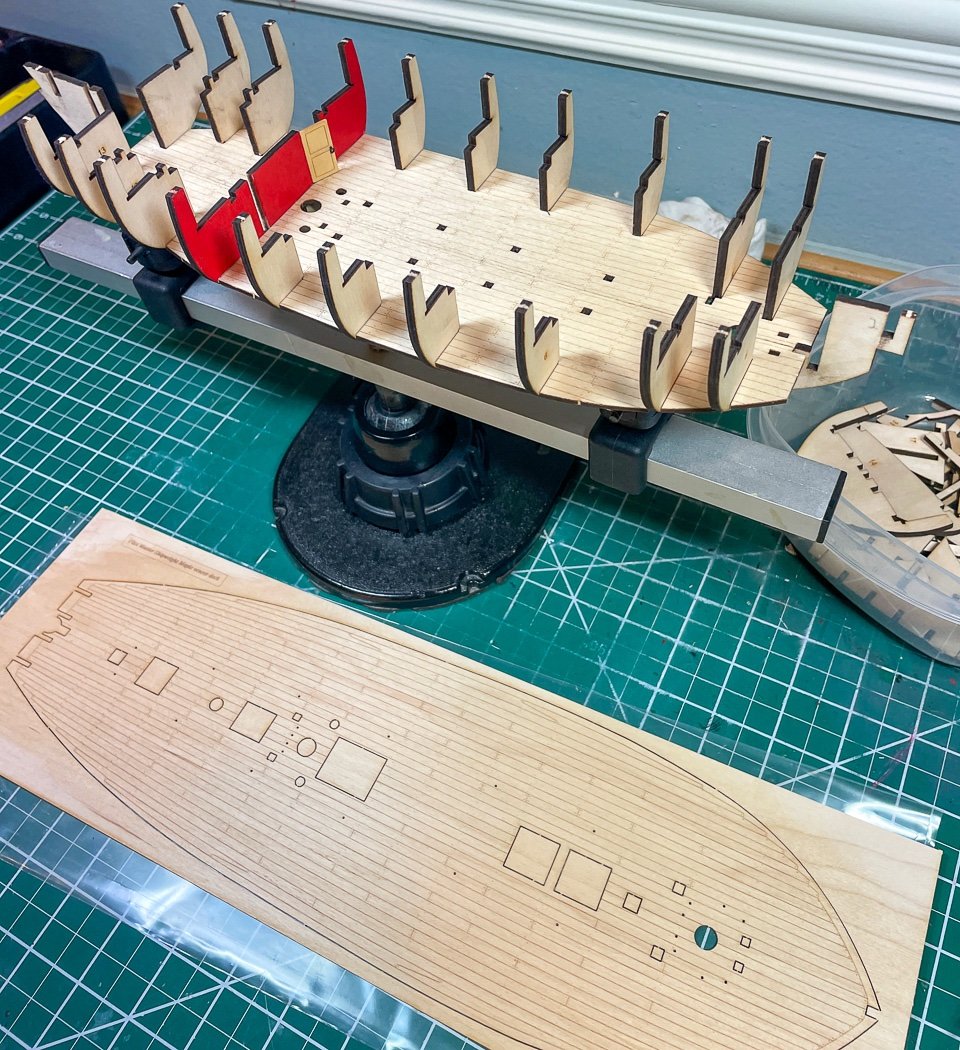

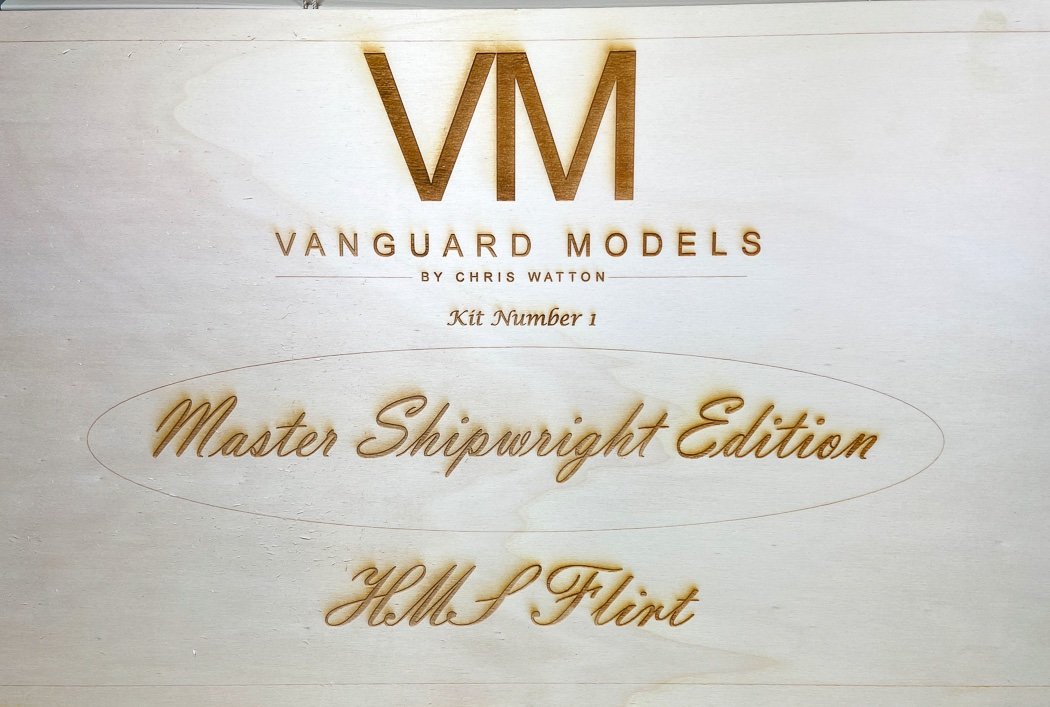

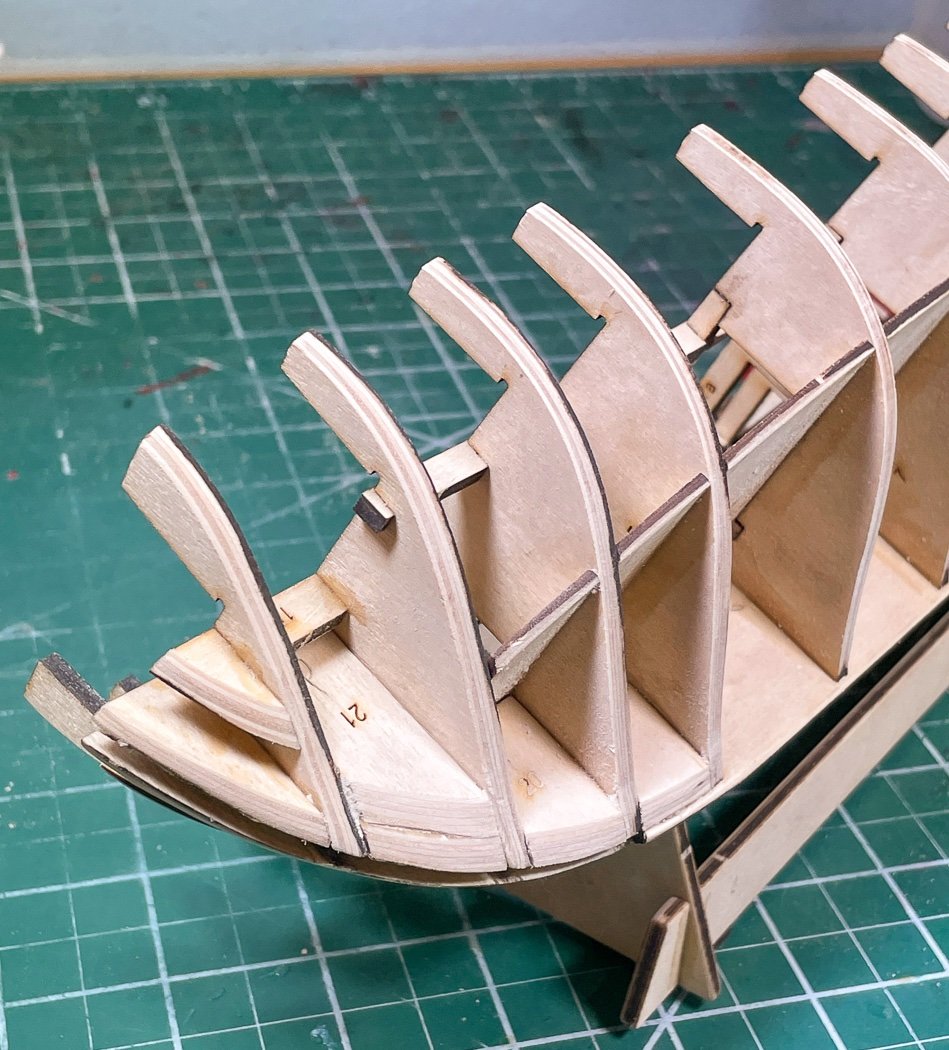

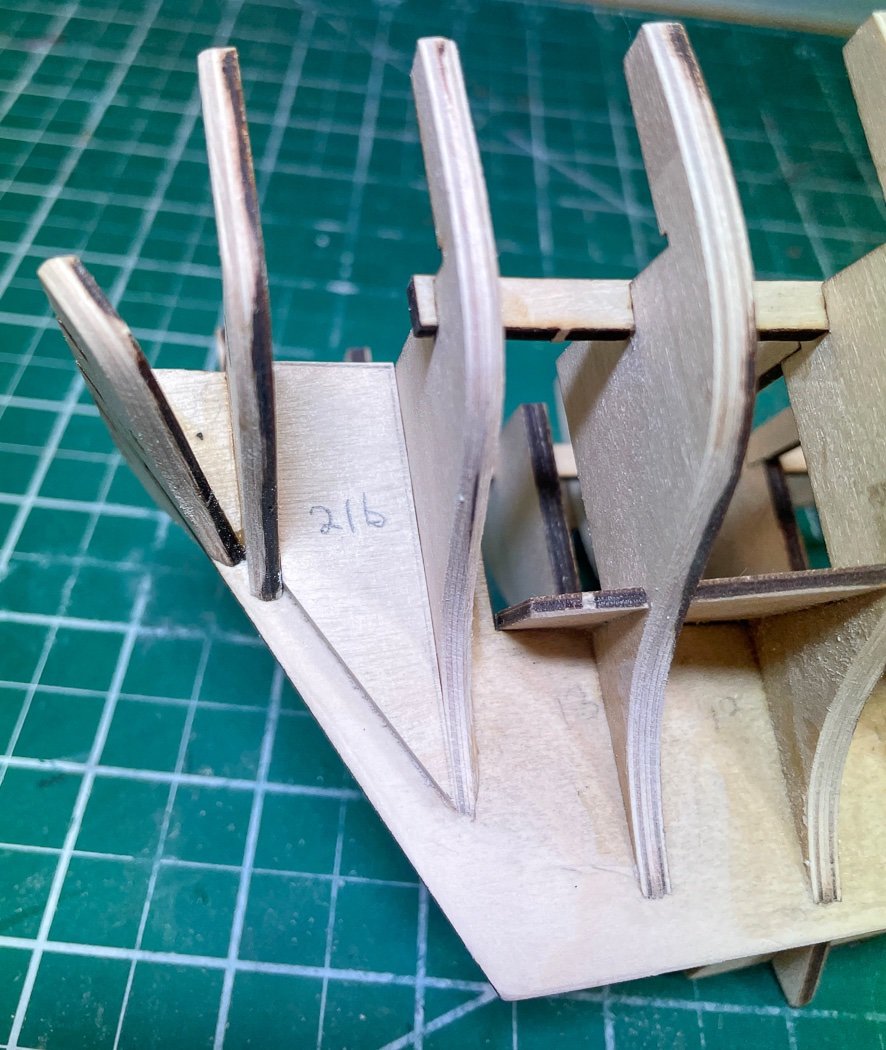

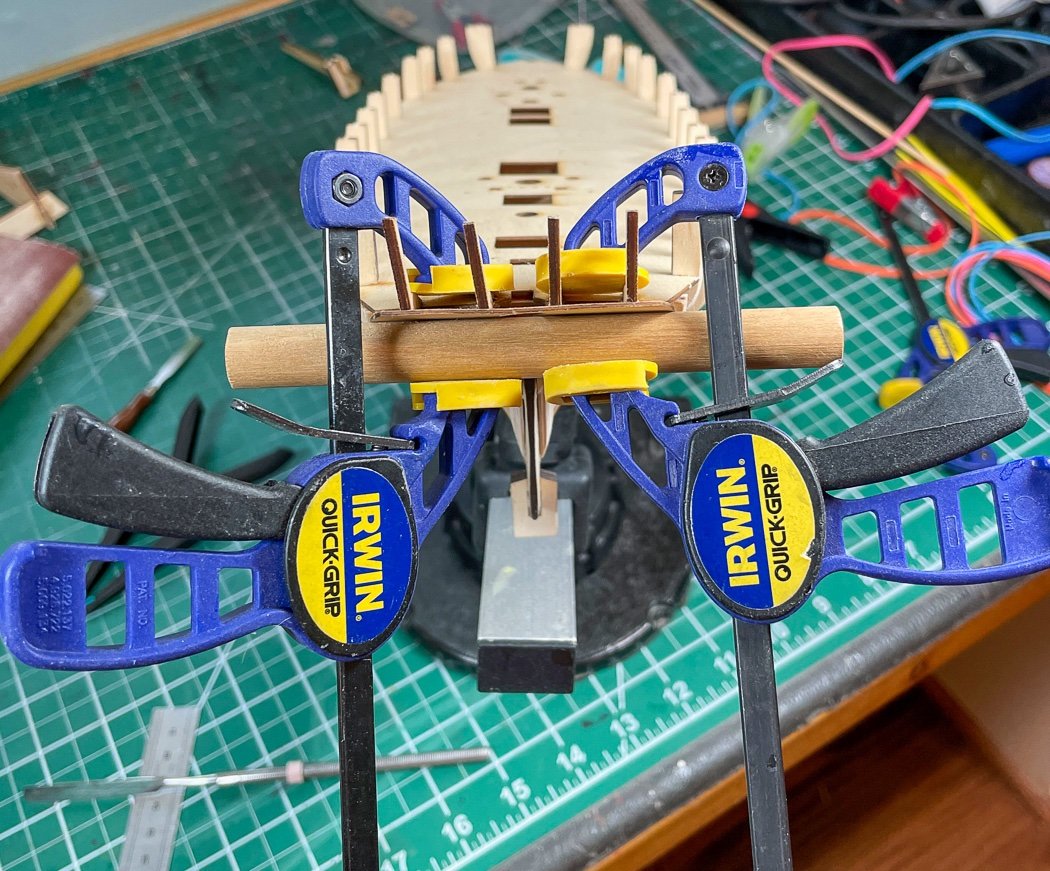

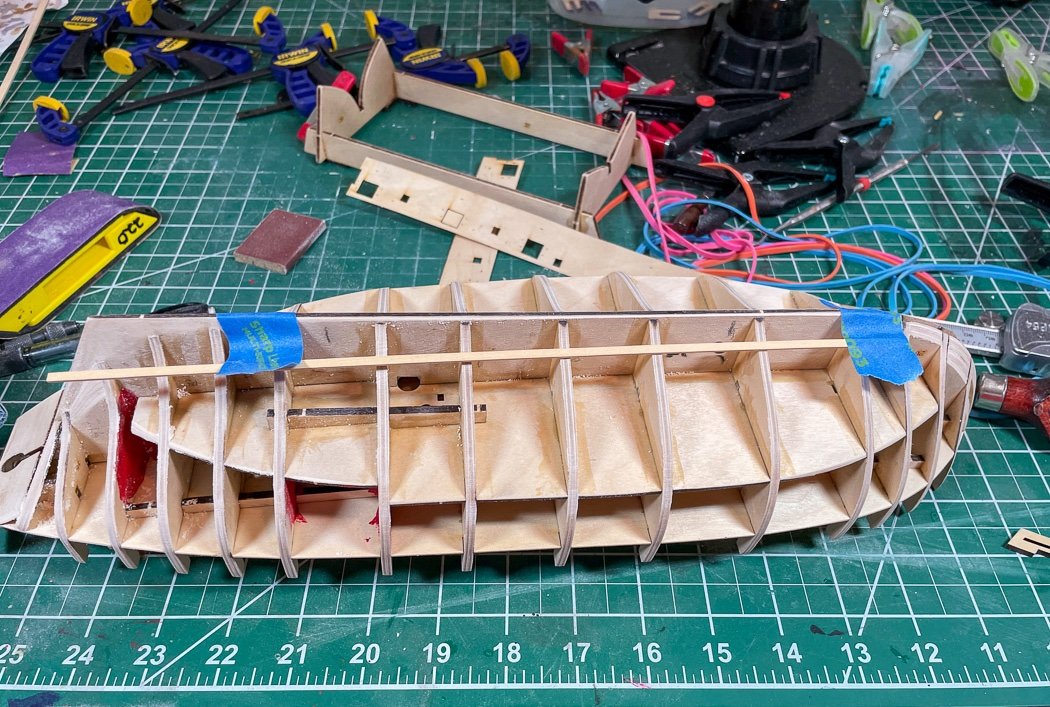

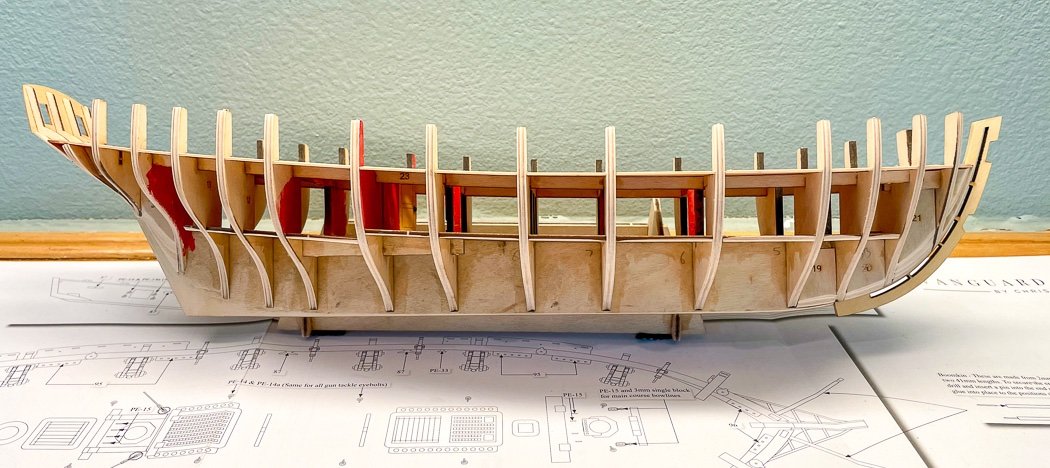

Welcome to my HM Flirt build log. This sister ship of the more famous Speedy is a Vanguard Models product and Chris Watton design. For those of you who joined me on my build of Chuck Passaro’s HM Cheerful I'm letting you know up front I’m taking a more casual approach to this log. One reason is while I enjoyed doing it, my Cheerful log took almost as much time to prepare as it did to build the model. There I felt like so much of it was a new discovery for me or a skill I didn’t have when I started, I wanted to share it all, and as I noted in that log, to motivate others to embark on their own Cheerful build. As for HM Flirt @James H has already posted an outstanding build of this vessel, his log and photos are amazing. In addition @DelF has a terrific log for his build of HM Speedy. While the models represent two different actual ships, they are similar for model construction. I highly recommend Derek for his clever techniques and build quality. So if you didn’t stop reading or already deleted your checkmark in the ‘follow’ column I hope I can entertain you a bit as I move through the build. I feel a little bad, Chris was kind enough to ship me the first Flirt, Master Shipwright Edition kit sold. He marked that occasion by sending this laser engraved board with the kit. I had elected to start Cheerful first so I’m not the first kit started, or even close to it. James’ log provides a detailed layout of the box contents, I won’t repeat that here, but I do want to highlight a few things. Any builder starting their first model or enjoying their tenth should buy from Vanguard Models. From basic to advanced (I’ve already ordered HMS Sphinx) Chris provides the best pure boxed kit available. His designs are innovative, the accompanying instruction manual is thorough and detailed with both text and photo descriptions of every step, the many plan sheets are precise and comprehensive, the PE is plentiful and equally innovative, he includes accurate resin cannons, and as an option a beautiful pear block set. On top of all that the wood, both laser cut sheets (he does it himself) and strip wood are of the best quality. No brittle, discolored walnut breaking apart before you can use it. While the regular version is pear (a beautiful wood for modeling), the Master Shipwright edition is all boxwood. There is nothing like opening up the package and seeing all that gorgeous boxwood. (On a side note, I’m not sure if he’s producing any more Master Shipwright Editions, you’ll have to check with @chris watton, he’s here on MSW Forums). Just a small diversion before moving on with the build. This is the just completed model my 8 year old granddaughter and I built over the summer. Her choice of colors and painting. She and my wife made the sails, I helped guide the build but the majority of the work is hers. I made the stand from left over Alaskan Yellow Cedar and added the brass plate to commemorate the finish. Anyway…proud Papa. Back to the build. I started as we all do by fitting the bulkheads to the former. The Master Shipwright version provides these in birch ply, as I shared with Chris I think prefer MDF at this scale, at least the quality of MDF in Vanguard kits. The ply isn’t the easiest to fit together and sanding takes a lot more work to get the same result on MDF. This is high grade ply made to be just as it is, quite firm and durable. I double down on gluing, first in the slots and then along the slot seams using a brush. The wood will break before these joints do. -4866T Though I didn't take a photo beforehand I thinned the deadwood and along the sternpost before adding any of the bulkheads using my finger plane and chisels (easier to do with the former laying flat). I elected to thin the area to 2mm, I still want enough for the sternpost to attach to the former. There is plenty of meat in the first planking, I can thin as needed to eventually match the sternpost to the thickness of second planing. I added filler parts 19 and 20 to the bow area, and thinking I knew what I was doing without consulting the instructions I added part 21 next to those. However part 21 is for the stern area, not the bow. It won’t hurt anything to be there and in fact probably helps, so I just fabricated part “21b” from the bulkhead sheet scrap and added it to the stern, problem solved. The instructions call for fairing these filler parts and the first and last couple of bulkheads before installing to the former. I was a bit reluctant to do this but was glad I did, especially with the unyielding ply. I used my Dremel with a sanding drum and was careful not to overdo it. This just in, wood doesn’t go back on once converted to sawdust. I’m going to use the maple engraved deck that comes with the Master Shipwright Edition. I lightly sanded it with 320 grit, added a coat of WOP, and repeated those steps twice more. I think it looks great and for this model it will be the deck. I’ve planked plenty of decks, I’m looking forward to this simple approach this time around. The lower deck is also engraved ply, in addition to supporting the frame it adds a nice touch to what little can be seen through hatches and deck ladders. Just for fun I added red paint to this area and later to other pillars and beams partially visible on the lower deck. There’s also a door, I’m not sure if it will be seen but it’s cool knowing its there. After first installing the four stern frame parts I added the counter. I soaked it in water, rubber banded it to a piece of PVC pipe I keep for the occasion and let it dry. I soaked it again then glued and clamped it using a round dowel, and idea borrowed from Derek, to get and keep it the designed curve. Next up was the transom, I had to maneuver the stern frames a little to get them in the right positions, hence the extra clamps. And really why use one or two clamps when eight are so much more fun, and no the ship didn’t tilt backwards…much. I used Titebond wood glue for everything described so far. I gave it a day to dry before moving to everyone’s favorite part of a build, Fairing The Hull. There is no overstating how important it is to take my time and do this right. It took me two days, with breaks in between, to get it done (I’ll have to note the high quality birch ply made it more fun, adding to the time). The instructions recommend using one of the lime strips as a batten, I prefer a much thinner more flexible wood strip to run along all the bulkheads (the blue tape is just for the photo), using it to identify and remove imperfections to get a smooth run. Up, down, in the middle, at the ends, 3-5 bulkheads at a time. When it contacts everything it spans without gaps I’m almost there, I do it all again because I know I missed something, then one more time after I’m sure I’m right, cause I’m not. This is more obvious at the bow, very often I find the overlooked part of fairing is not stem to bulkhead 2 to 3, it’s the turn from 3 to 4/5, when the sharp bow starts to become the wider beam. Also always a challenge and a later regret if not done right is the steep slope required from the counter to about three bulkheads forward. I got the starboard right but had to fight to get the port side to comply and stay equal to the port. With my dusk mask set aside and my room dust filter turned back to normal from its highest setting the frame is faired and ready for gunport patterns and the first planking. I didn’t mention it, but notice other design features Chris has added. Both the lower and upper deck are also frame support, two lengths of beam are installed running fore and aft for both deck support and squaring up the bulkheads. An innovation I’ve never seen is the boxwood stem piece with slots that serve as the rabit for the planking. This part is notched and slotted between the fillers, it the last thing added to the frame. It wasn’t there to be scarred by the fairing process. It is also the base for the interlocking stem that won’t be added until later, thus saving it from a beating. How many of us have scratched and damaged the stem, normally a part of the frame from the beginning. Cool stuff this Vanguard Model. A few further thoughts on fairing: I leave the back edge of the char on the forward bulkheads and the front edge on the aft bulkheads as a guide when fairing to make sure I keep the hull’s proper shape. I also start taking micro-measurements of the width and height of bulkheads at the bow and stern at multiple spots to match port and starboard. It’s pretty easy to get carried away and get it all lopsided. It’s also important to not say good enough. Most if not all the char other than the edges I mentioned should be gone when you’re done. Oh, and I think parts 21 and 21b worked out just fine once faired. Gunport patterns and first planking are next. Time to get out the plank bending station. I guess I wasn't very brief after all.

-

I’m not a fan of tree nailing, in fact it was Chuck that convinced me not to. He doesn’t do it on Winnie. However it’s the modelers choice, whatever you like.

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I will enjoy watching your build. Like you I just had to press the button. I may go also go without masts and rigging, I’ll wait till i get to that point and then decide. Either way, darn that Chris with his innovative design and that James with his photography. I’m thrilled Chris has sold 50 through pre-sales alone.

-

Not sure where you heard that, Pear is excellent for planking, I’ve not heard of using beach wood. You can see pear used on any Vanguard build log as that’s what Chris supplies with his kits.

- 71 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

New member from Scotland (Falkirk)

glbarlow replied to Razorbill's topic in New member Introductions

Which one is which🤣

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.