-

Posts

4,126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

I started with one once you started making your own parrels, you never cease to amaze.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

This will one great guide for me when I start my barge. Nice work and wonderful descriptions.

- 185 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks. That.s my goal. Thank you, using the plans was a new twist. I’m either brilliant or too lazy to manually make up a separate grid on paper 😂

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice work! That’s a lot of magnets you have there.

- 28 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Welcome! It’s a great hobby, glad you’ve joined our ranks.

-

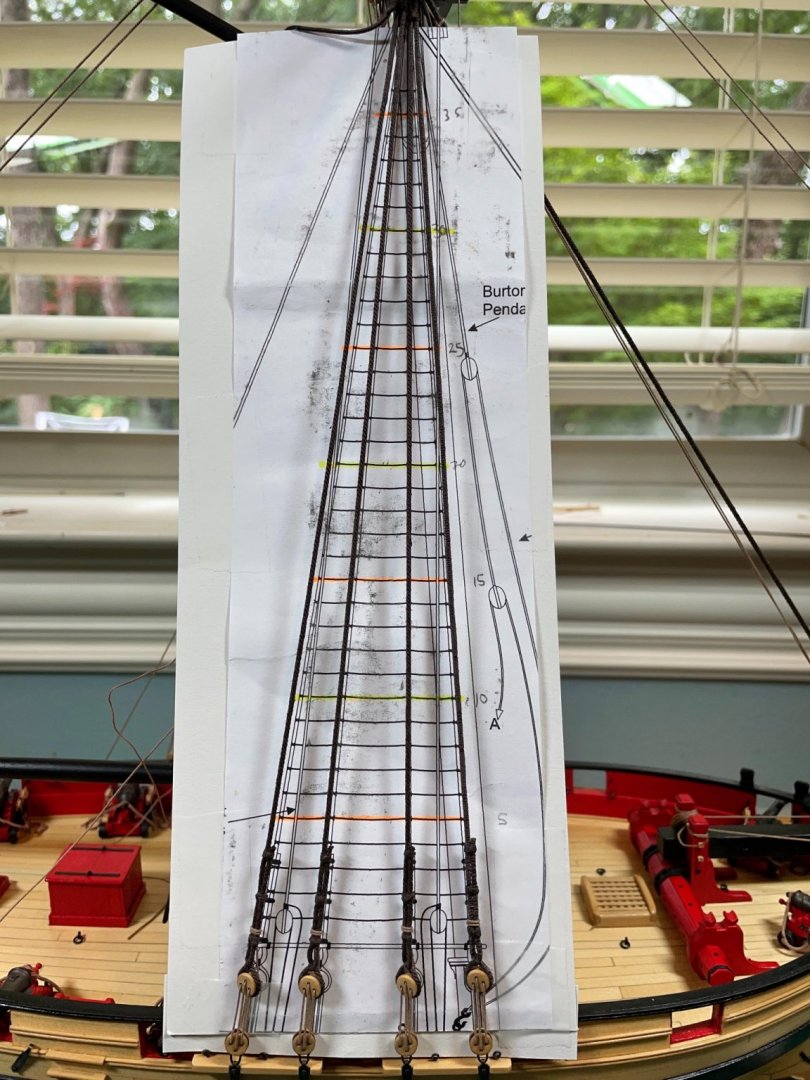

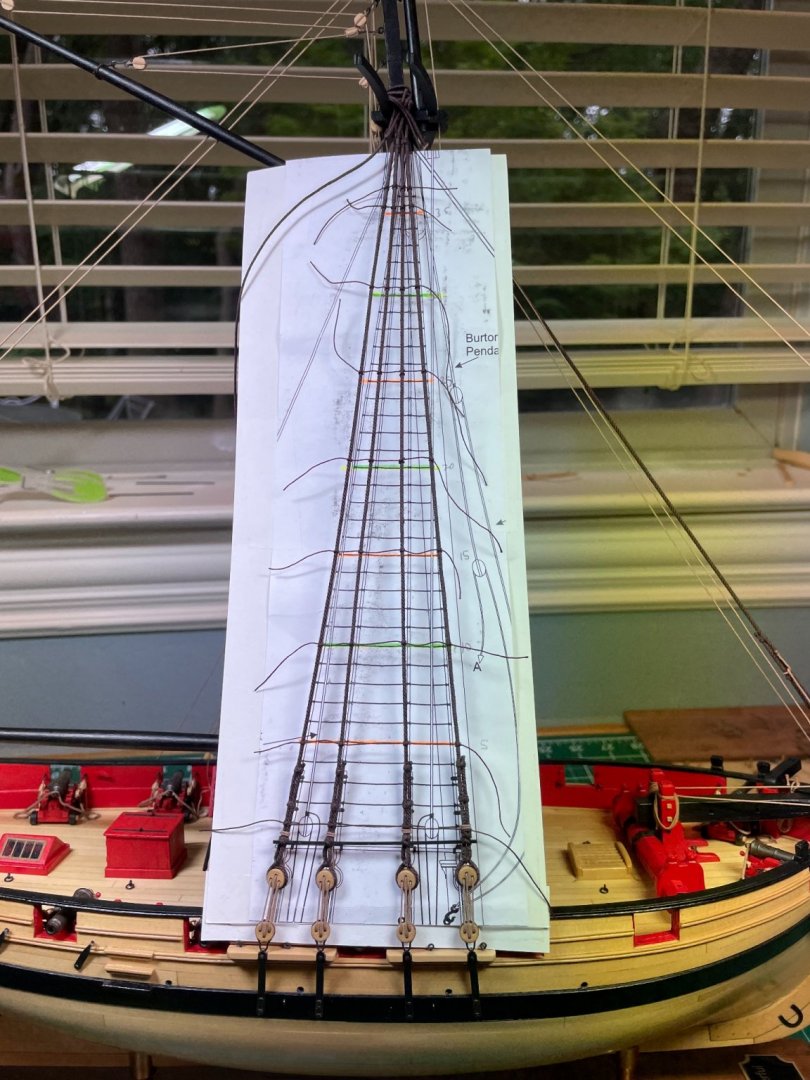

Ran out of other things to do, time to begin. The only good thing about fracturing my frame way back in the beginning and having to buy a second starter kit is that it came with a second set of plans that I could cut up, which I’ve frequently done. In this case I also scanned it, flipped the image file, printed it for the port side and marked both in 5 and 10 line increments. These I’ll do first, tens then fives to help avoid the hourglass problem. Also using all clove hitches, my favorite knot. There’s only 72 total, I can probably do this without further whining about ratlines😂🤣 All of this has been learned from others, once again the power of MSW at work. Except the clove hitch, as an actual boat owner (a fast inboard, no sails) I tie a lot of them with big rope. See, I’ve started. (They are lined up, the paper is leaning away at the top and nothing is glued yet)

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

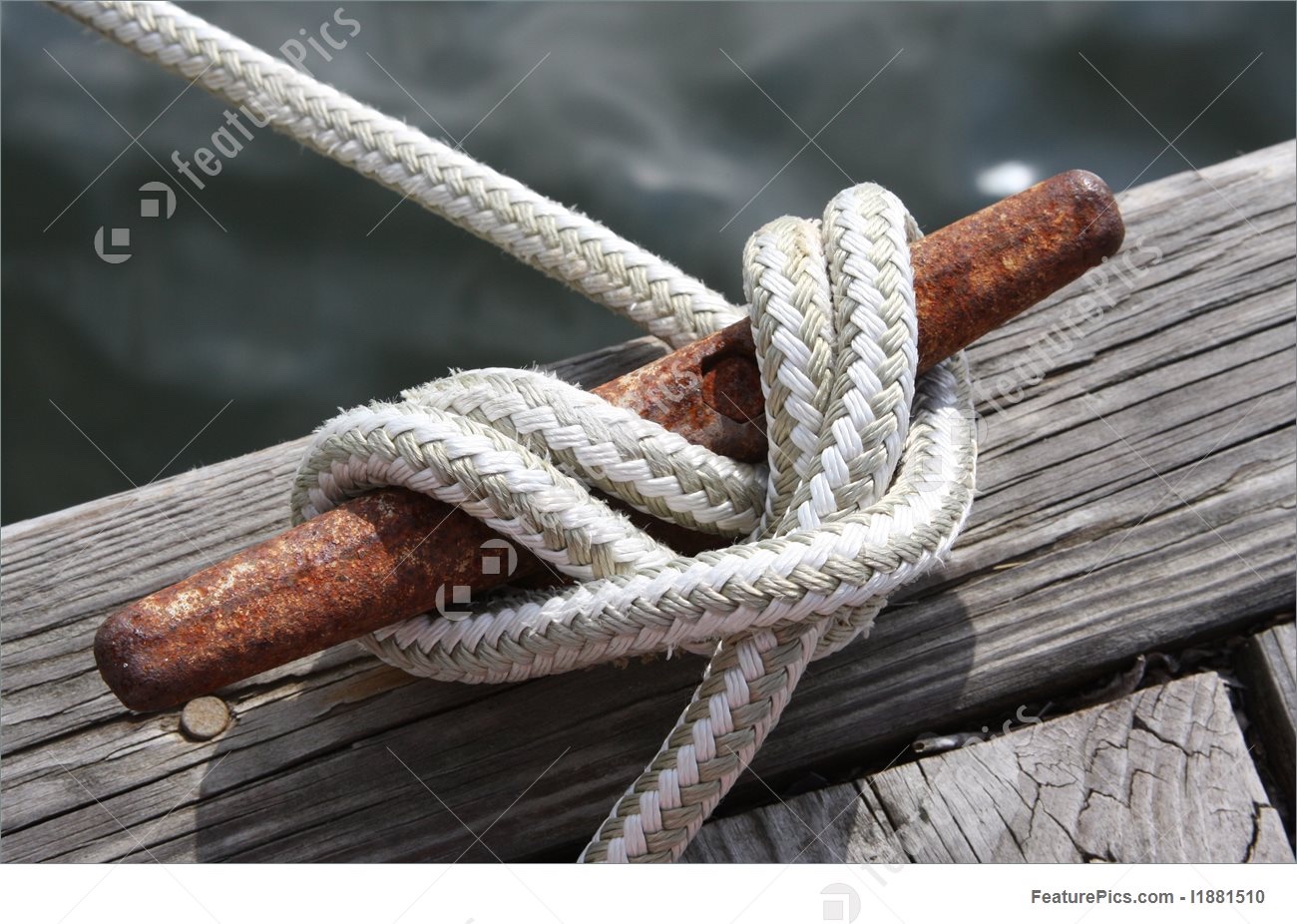

Not sure why or what type of cleat your referring to, but generally a cleat hitch like in this photo is the way to go.

-

That certainly wasn’t my intent, sorry you perceived my comments as such. My point was not your limits, but the limits of this kit. Gun ports follow the sweep of the deck and follow the sheer, they aren’t always parallel.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

Thank you. I often amaze myself when some things actually work😁

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, I hope that you do and glad you find it useful.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Chuck. I’ll tie and retire to avoid the dreaded hourglass, I just don’t enjoy doing repetitive work. But I do enjoy Cheerful so… I appreciate that Rusty, that is my goal. I think I overdo it sometimes but I guess it’s there if someone wants it.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Derek, I use your work as inspiration

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I think you pass the macro test just fine.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

So, I’m sending you the boat parts from my Flirt kit to make for me. This is really exceptional work, Such detail on a small scale. Too bad our mutual won’t see it, he’d probably have an informative comment to add. 😂🤣

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

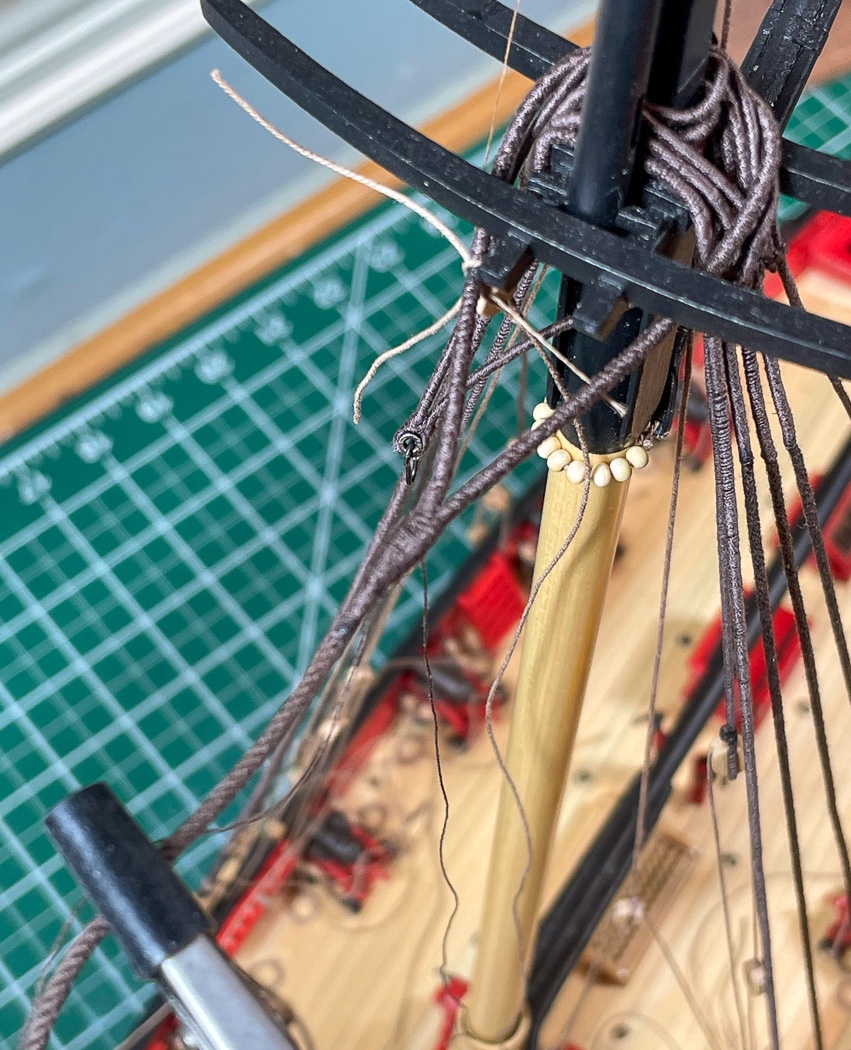

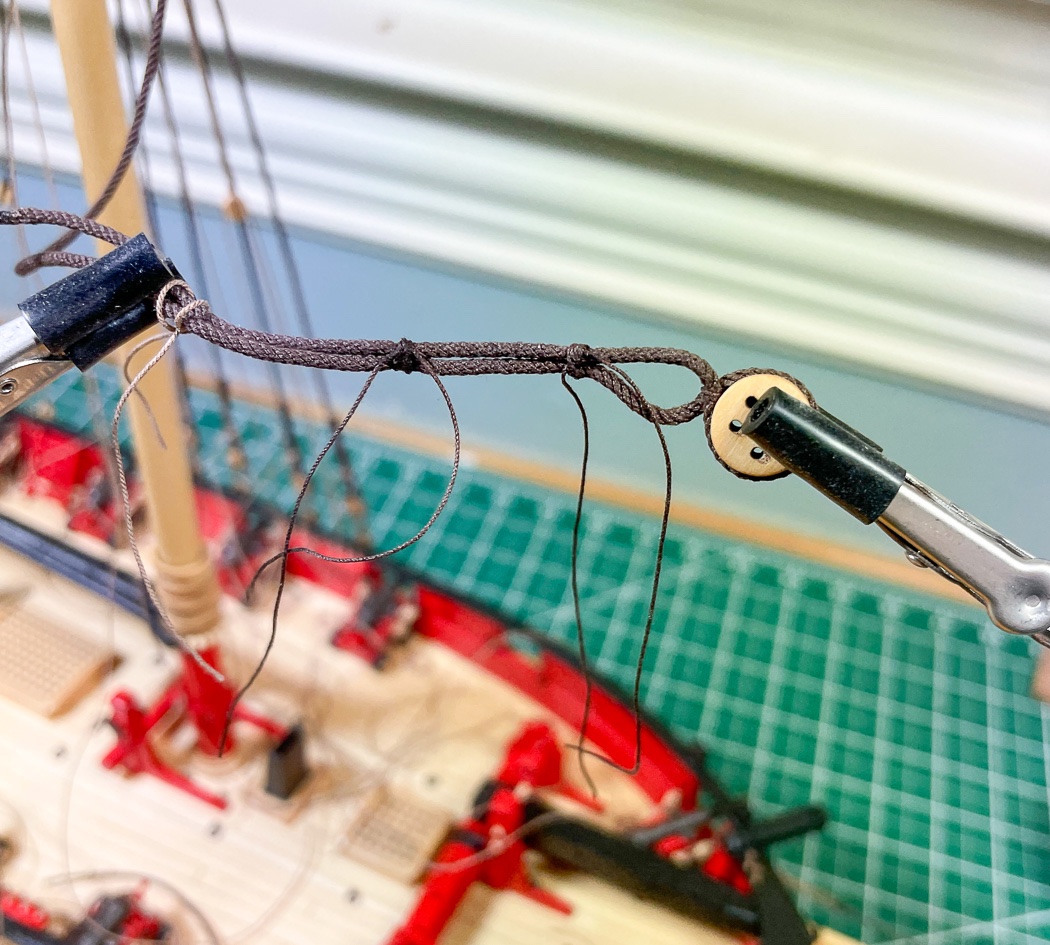

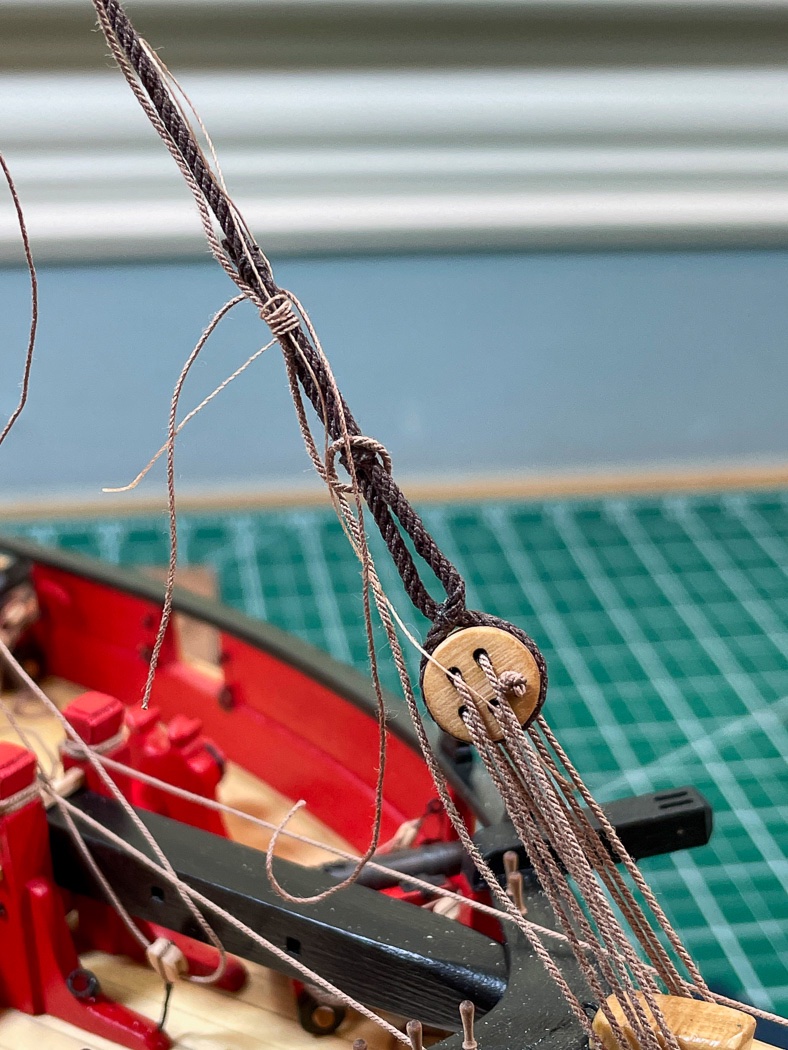

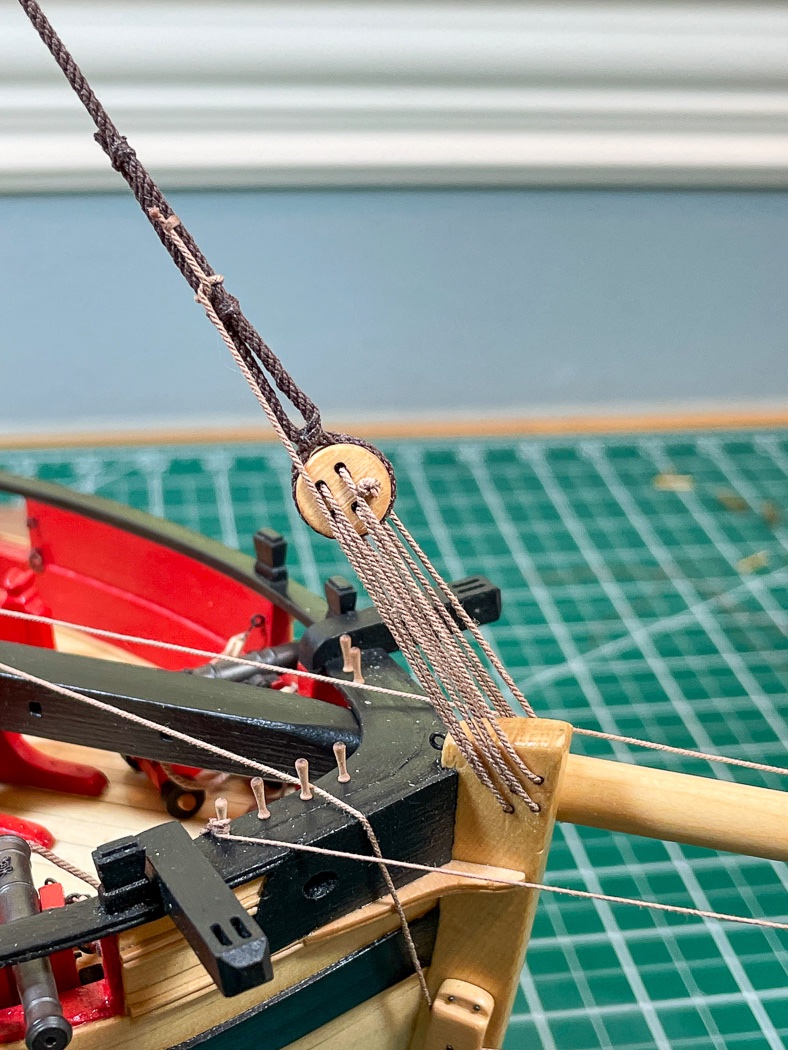

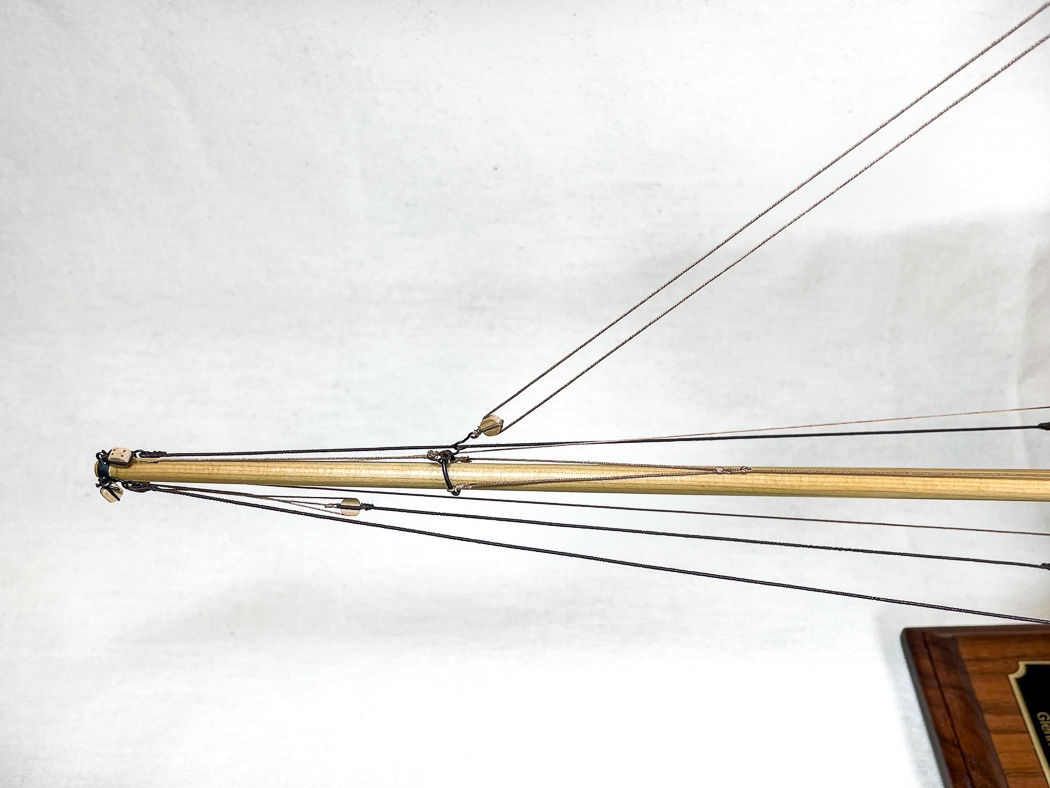

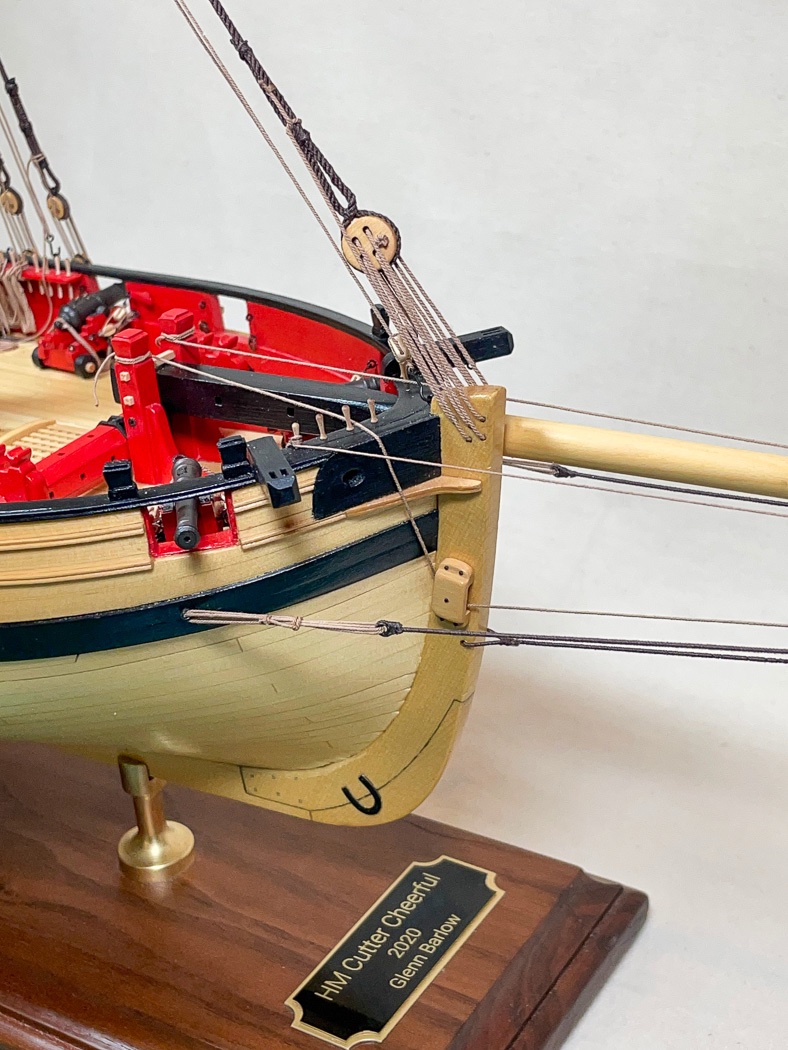

The Main Stay, Foresail Halyard, and Jib Halyard It bears saying again. I am grateful for all the build logs on MSW. I learn so much from so many, I hope my log helps others as I’ve been helped. Back to work, though work has slowed down lately. I think I’m either reluctant to reach the finish line or procrastinating because ratlines are now on the agenda. I do not like ratlines, Sam I am. The good news is there are only eight total shrouds so how long could it take…I don’t know because I haven’t started them… The Main Stay It’s just one ‘string’ but the main stay takes some time and thought to get right. It’s served around the mast to just below the eye, so I had to do a bit of measuring and testing to determine where that was. There is no precise definition of where to form the eye, I just eye-balled how big I wanted it to be it using the .054 Dark Brown rope that is used on the stay. I found a black grease pencil useful for marking the dark brown rope (or China marker I believe my Brit friends say). The black is hard to see but there is no chance it will show through the serving, so I prefer it to a brighter color. The measurement is a little tricky, the stay sits on top of a lot of other rope around the mast head, it’s important to make sure it’s snugly seated. The sling wants to get in the way so I had to check and recheck for a proper fit. Of course I served the stay extra long even having measured repeatedly, why not. Cheerful does not have a mouse on the main stay, instead it is a seized eye. This particular seized line required a different approach than my other seizings. In part because of the large .054 served rope and because it’s very visible, I wanted it to look good. My normal seizing technique just wouldn’t work to my satisfaction, so having marked where I wanted, I cut the end of the served line at a sharp angle (using the toe nail clippers, here they exceed both cuticle cutters and scissors). Important obvious note, the serving has to be sealed so it doesn’t explode as its cut. I elected to use CA to seal the end of the serving since the cut would be covered by the seizing. I then glued that angled cut to the running length of the stay, again using CA. (I didn't like how the serving looked terminated on the running end, so I cut off the one in the photo and did the whole thing again. BEFORE I did any of that I added the foresail Halyard block very loosely seized to the stay. This block, along with the tackle seized to the block are fitted to the main stay inside the loop and close to the trees. Even with the quad hands this would be a difficult block to add to a completed stay with its awkward location. It was SO much easier to slip it on before closing the eye, you can see it unfinished two photos above and the block seizing completed after the main stay is installed. (failed focus on this photo) To do the main stay seizing (you can see that loose foresail block in this photo as well ) I started by tying a square knot with 50wt polyester thread just below where I had glued the eye. I had used .012 rope on the shrouds and deadeyes and tried it here, it looked too heavy, the thread is a better look. I left enough of the short end to pass it up through the center of the seizing then proceeded to wrap with the long end of the thread until I was far enough over the splice to suit my eye. I’m normally big on precision with the number of wrappings, but here I just stopped when it looked right. Actually I went further, decided it was too much and backed up. I tied another square knot with the remaining long end and the short end of the thread on the bottom where it isn't seen. I painted it with very watered down white glue, now I have a main stay eye. On to the other end of the stay, I turned in the large 5 hole deadeye purchased from Syren just as I did the shroud deadeyes, clove hitch at the overlapped base and two seizings above (7 turns instead of the 10 at the deadeyes) per the plans. Here I went back to .012 rope because for the “heft.” The seizing of the lanyard is also a bit tricky. I ran a .025 lanyard connecting the stay to the stem, those 5 holes on the stem are finally used after the stem being one the very first things added to the ship so long ago. To finish it off requires a single hitch above the first seizing on the stay, then the running end of the lanyard seized to the stay. No problem, except all that is kinda hanging in the air and that hitch has to be kept taunt. I could have employed the quad hands, but room to work would be tight. Instead I tied the lanyard far up the stay with one short piece of tan rope and tied another to hold the loop of the seizing thread while I passed it around the stay between the seized loop with sharply pointed tweezers. In the photo I was using 50wt thread but after completing it I decided it was too heavy so I cut it off and re-did it with fly-tying thread. Just a quick moment to thank @DelFfor the fly-tying thread recommendation. I admit I was a bit skeptical at first, but since then I’ve used it to seize almost every block on the model. To me, it provides the right look and scale, and is well worth the not insignificant effort to see it while doing seizings. Not finding a good color match for the light and dark brown rope on Amazon, the thread came from some random fly fishing website found during a google search. Here is the finished stay at the lanyard end. Please note the proper stopper knot ripped from the pages of my Ultimate Book of Everyday Knots, a book I recommend for everyone including outside model building. Amazon has it Here Foresail Halyard Next up is the ratlines, nope I can put it off a little longer. Next up the foresail halyard. Having seized the block on the stay earlier this was now pretty easy. The running length goes to a block seized with a hook attached to an eyebolt just behind the stem (so that’s why I put that eyebolt there so long ago). Another note I’ve said before but bears repeating. Not every eyebolt/belaying point are highlighted early in the instructions for most any model. I always look ahead to the rigging section and study the plans to locate these. They are frequently so much easier to add early before room gets tighter. Like this one it can be forgotten for months until I actually need it. The running length runs down through that block, back up top and belays to a cleat at the base of the mast. This is makes for a really long piece of .018 rope. The challenge for this halyard is to balance the tension on the line enough so that it looks right, but not so tight that it’s pulling the stay out of alignment or into an award pulled out look. The halyard doesn’t really need to be very tight, over-tightening doesn’t gain anything. And now for the ratlines.- No wait, I can still put those off. Jib Halyard, In-haul, and Out-haul This one is fun. Three distinct tackle that work in sync with each other to manage the jib. I made up all three as a first step knowing I’d install them as a working unit. A .018 line seized to a block at the mast cap runs down through a block seized to a hook (I installed that eyebolt but left it unglued before placing the mast cap, so again an easy install on the block). That hook is seized to the hook on the traveler ring I had remembered to add way back when installing the bowsprit. It’s just going to flop around there for a minute. On a side note, the mast is looking pretty cool with all those served ropes. (another focus problem, I’m getting sloppy) The out-haul starts with a stopper knot (again from my book of knots, I normally just do a figure eight knot when a stopper is required, but like the main stay lanyard its very visible) runs from the traveler ring forward to the sheave cut into the bowsprit (so that’s what that’s for) back to the fixed block I’d made on the starboard side of the stem, then up and over belayed to the bowsprit bitts starboard post. Finally, the trickiest of three lines, the in-haul, is actually two ropes joined together (no thimble this time). It requires a V with its ends tied to either side of the traveler ring (I gently glued these with the lightest touch of CA to keep them on the sides and not slip down to the bottom of the ring) with the peak of the V seized to another rope (all of these are .018). To have the V centered I attached the two ends to the traveller then seized a loop at the resulting center. The result is the in-haul with its two seized lines laying along top of the bowsprit and belayed to the port bitts post. I left the loops at the joining of the two ropes a little large to give a better look of the joined lines, no reason to squeeze them tight. The tricky and fun part is pulling the right tension on all three, back and forth and together to arrange the traveler ring into a fixed position on the bowsprit. Per the plans I chose this to be 80mm from the far end of the bowsprit, which kinda looks right. And this is how it all looks like this in the end. And now it’s time for the ratlines..unless there is something else I can find to do first…. Thanks for stopping by. The likes and especially the comments are always appreciated.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Everything builds on a future thing. Those sills become a 1/64th rabbit later. The sweep and heights are both critical. You can get a little leeway with sanding them so better to be a fraction high than low. You pegged it, they are fiddley. Glad you’re enjoying my log as I will yours. Fun to see where I was a year ago.

-

Your research and sourcing for accuracy is amazing and informative. I just tie the little stringy stuff around the wooden thingy. Though for the record I did look to my book of knots to tie a proper stopper knot for the jib out haul.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I really had to bring out the nautical dictionary just to follow this one. Who came up with these names 😂🤣

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Your approach is so much more skillful than my “the oars were stored below deck” version. 😂

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Well done Tim. Skilled work and very impressive. Here’s the place I’ve ordered all my models brass name plates. They have any number of variations on size and mounting (I use adhesive backing). They are always fast, responsive, and inexpensive. https://halexawards.com/index.htm I look forward to seeing your next log😊

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Thanks for sharing. I did see that video but didn’t find it was what I was looking for. I have now come up wit something based on several other references. I’ll have to perfect my application of those and will share it once I do.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

If anyone has a clever way of doing rope coils for the pin rails I’d love to see it. So far mine aren’t up to my expectations

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, I appreciate the comment and glad you find my log useful. My photography has suffered this past year, I’m looking forward to getting back out in the field. Speedy is a great choice.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.