-

Posts

1,025 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by No Idea

-

Hi Dave - if you are getting bleed you may not be using archival ink pens which are better than normal markers. I use this one https://www.amazon.co.uk/Sakura-Pigma-Graphic-Chisel-Black/dp/B004CSFQ96/ref=sr_1_43?crid=2PMTZ7TRGZFG6&keywords=sakura+chisel+tip+archival+pens&qid=1680449848&sprefix=sakura+chisel+tip+archival+pens%2Caps%2C128&sr=8-43 Apologies if this is the kind of thing you are already using - Mark

-

Hi Chuck I don't think you will need to worry about the price of your amazing kit. I would guess that so far my scratch build of Le Rochefort has cost me about £400 in just wood to get where I am and it's no where near finished. This does not include any tooling or consumables which would put a price on that I don't want to think about. The finished kit will cost what it does and I believe that the final builders will get a great kit at a price which will be a whole lot cheaper and more accurate to build than a scratch built ship. Fantastic work and if I wasn't building my ship I would build this one.

-

Hi Dave I use these pens and they do not react to shellac at all so you will be safe there 👍 Your rabbet that you have cut though towards the stern follows the line which is more like the bearding line which would be a little lower. Your rabbet needs to go all of the way to the stern post which also tapers the deadwood and will go the full length of the garboard plank. It's a simple correction and I have to say what great work you are doing on your build!

-

Hi Mate If you're building this as an RC ship plywood will be fine for your bulkheads. Any ply will do as you will need to give it a good coat of epoxy resin or fibreglass inside to keep it water proof. The reason being water will get inside when you sail it. As for the planking thats entirely up to you - You are going to have to coat it with resin and cloth on the outside so you are right you do not need anything expensive at all. What you really need is space inside to get the motors, esc, receiver and batteries in which do take up a lot of space. So make the bulkheads as narrow as possible to give you the room that you need. Here's picture of my Anteo's frame to give you some idea. Its hollowed out and rienforced to give space to get a boiler in. The same frame after double planking with Castello and mahogany. You will just need to use any wood as you will be painting it for a finish. Good luck - Mark

-

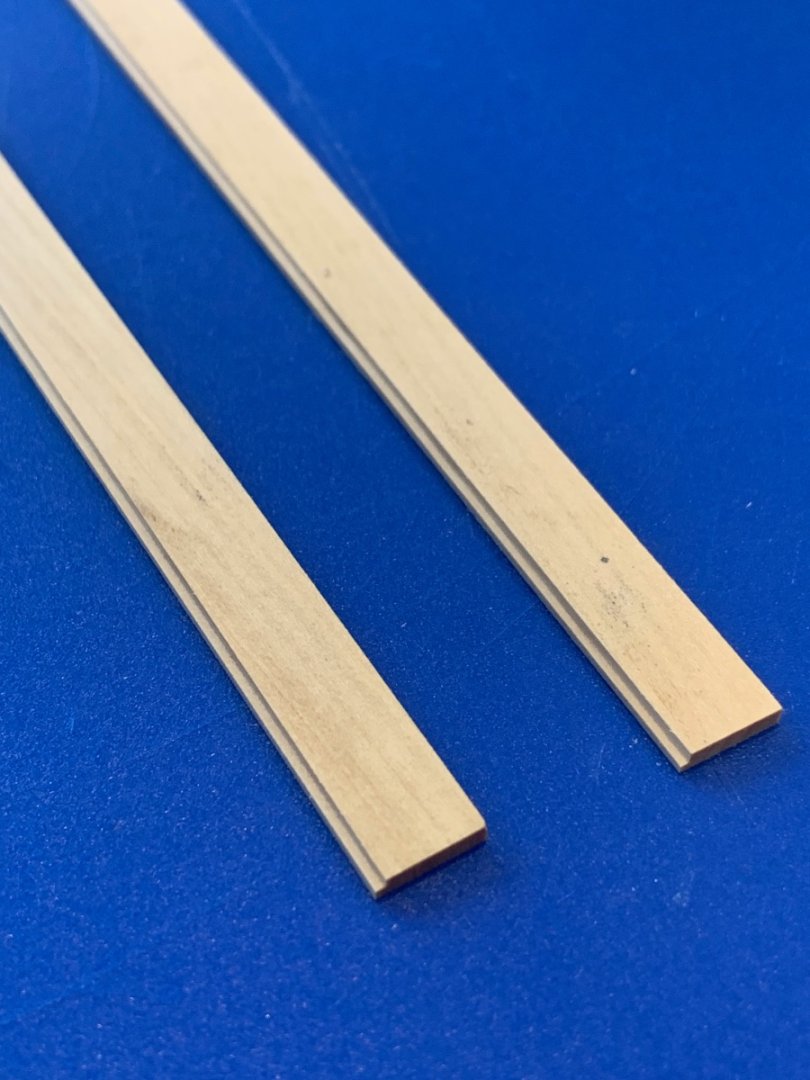

This is my timber supplier - honestly they know their product and I always tell them I'm a model ship builder. Although it's not cheap they have never sent me anything other than perfect wood for what I do. I cannot recommend this supplier enough.

-

Hi - I've not really had anytime lately to get much done on Le Rochefort. Hopefully things will ease off soon and give me a little more time. I have now finished the nailing on the hold deck I've also finished making Chuck's barrels and they are now stacked in place. I must mention though that they are historically incorrect as French powder barrels should be circled in chestnut. For some reason though I really like the copper - and its my ship so I left them as they are. Plundered from a captured English ship! Cheers Mark

-

A great start and very good luck with your build! I'll be following along and look forward to your updates.

- 18 replies

-

Welcome to the forum mate - I'm only down the M6 from you living in Dudley 😀

-

Forming a rabbet

No Idea replied to DaveBaxt's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Dave - I cut all of the straight sections on my build using my mill. A “V” cutter did it for me with no problems at all. I didn’t use a vice I clamped the parts directly to the bed. The rabbet around the bow was cut by hand using a chisel. I use the small veritas chisels which are a great size for our hobby and I make them absolutely razor sharp to make the job easier. I could have easily used a 1/4 chisel though and achieved the same result - Mark -

I also think if you haven't done any silver soldering at all before you may not know what you're looking for in a finished joint. The flux tends to go dry and then blow up from the joint a little - it then looks like it's getting very hot and its so easy to take the heat away too early. When the solder runs it looks like liquid chrome running around the joint. I've silver soldered stainless steel to brass without any problems but it does take a lot of focused heat.

-

Hi All Work on Le Rochefort has slowed somewhat because I have returned to work after having a few weeks off so I only get to work on it at weekends again. Anyway I've now planked the hold deck which has turned out very nicely. The Castello that I'm using is just lovely to work with. I've not put the nails in yet as I've run out of carbon rod but I'll have some for next weekend. The first 2 planks are not nailed as they are removable to get to the limber boards. I'm putting 6 powder barrels into the hull - I did start another thread regarding this and I opted to buy 6 barrels from the Syren model ship company @Chuck They are 1" tall and are pretty much the perfect size and being made of yellow cedar they match in quite nicely. So I started a little production line and made the frames for the barrels and they fit together very easily. I didn't remove any of the laser char as the wood has very little burning anyway. Then each stave is bevelled which literally takes seconds to do and is glued on using CA. I had to go and buy this glue as I just don't use it for anything else and yep I did stick my fingers together 🤣 The result is a very nice authentic looking barrel in my opinion - The kit comes with black hoops but as these are powder barrels I needed either withy or copper hoops. I opted for copper and just masked it up and gave it a quick spray. They do take a bit of patience so I'm going to make them as I go along rather than try and do them all in one go. I think they are going to look very nice in the finished ship. Having said that I don't think I'm going to make a cooper anytime soon So that is pretty much the hold completed so I can now move onto constructing the main deck. Cheers Mark

-

I think this is genius Chuck - I have no doubt that there are many kit builders who would like to build a really decent expert looking POF ship without all of the hassle of cutting the individual pieces and trying to understand plans. I like your emphasis on the accuracy of construction for the builder as they go along too. Good luck with the cant frames.

-

I agree they look very clever and thanks for sharing - I'm going to look further into these too. Talking of clamps - Looking at your deck clamps running out to the dogs legs I would have been very worried about breaking them off or damaging them in some way as they do look a bit vulnerable. I mean you've done it and they look fantastic but I think I would have put some sort of cross support in first. I just couldn't imagine putting any sort of pressure onto all of that lovely work. Top job 👍

-

Byrnes saw belt source in UK/EU?

No Idea replied to bruce d's topic in Modeling tools and Workshop Equipment

We just need a UK blade supplier now! That would be utopia. -

Byrnes saw belt source in UK/EU?

No Idea replied to bruce d's topic in Modeling tools and Workshop Equipment

Good man Bruce well done - The UK users of Byrnes saws will be very happy with this info 👍 -

Thanks Allen - Le Rochefort was designed and built to move powder from the shallow port to the fighting ships anchored in deeper water. That is why her hold has very specific design features such as a fully planked interior which was also caulked. The hold deck beams are another unusual feature as I understand it as barrels were normally placed straight on top of the ballast. She also has water tight hatches and the crew had specific instructions regarding the use of the on board stove. The main deck beams are not supported by knees but instead uses a deck shelf which is attached to the deck clamp to give it strength. This was to improve the capacity of the hold itself. So moving powder was her main job and was designed to stay as dry inside as possible. I think that you are correct in saying that the barrels would have been stored on their side and I think this is the way I would like to go. Luckily I'm a non smoker so its going to be quite a safe ship with its dangerous cargo 🤣 Thanks Mark

-

Thanks Chuck I didn't know that you made barrels and they look excellent - I've just ordered 6 of them from you. I just need to think of a way to make withy bands. Maybe rope would work I don't know. Here's a question for you all though - were barrels stored upright or on their side in the hold?????????

-

Hi All Yet another update on Le Rochefort. So firstly were the limber boards. These are nice and easy to make 👍 A small strip of wood is placed up against the keelson in my case I cut it 1mm x 0.5mm which did the trick. Then the actual boards needed a rebate cut into them which I did on the table saw. Sorry I only took 2 photo's but once made they just slot into place and have no nails as they are supposed to be removeable. You can see them again fitted in the next photo's. So then I moved onto the hold deck beams - These are very very difficult to get right and its an angle challenge all the way! Its so easy to start off level and then start to go off of level as you move along the hull. I did make an error as I did not space the forward 4 beams correctly and ended up short on the bulkhead. Now I could have removed them but I took the easier route and simply added another beam. There are also 2 half beams that sit next to the pump well and they require a post to support them. I have also only placed a beam on one side of the mast step as I'm not planking the other side and did not want to loose this detail. Enough words here's the result. So the next job is to cut the planks for the hold deck and then half timber it so as the beams etc can be seen through the side holes. Cheers Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.