-

Posts

1,036 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by No Idea

-

Hi Tim and welcome to MSW mate - I live not to far from you and we often visit Hereford as its one of our favourite cities in the UK. Good luck with your choice of new build and if you start a build log you will get loads of helpful advice. Mark

-

I think the work you have done is beautiful - the spacers are just about right and I know this as I made mine far to big. I tend to use abrasives around a round dowel when sanding the spacers as it gives a small and controllable contact patch. I also agree with druxey rounding off is not an issue if you don't go free hand - good luck!

-

Planking improvement

No Idea replied to Picard's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Picard - firstly I think your planking is actually pretty good and it just so happens you are comparing your efforts to a very experienced builder. So this may not be popular but many issues with planking including my own is time. Planking takes a lot of time to get right. It just cannot be rushed and takes a lot of planning and fitting - if a plank doesn't look right its probably not but often its easier just to glue it on. Keep going buddy - make mistakes just like everyone else including me as its a great learning curve. Incorrect bevels tend to lead to wide gaps between planks and incorrect tapers make the planks look crowded at the stem. This is just my thoughts - Cheers Mark -

Chris I think that most model ship builders are their own worst critics. Looking at your pictures your build looks very nice indeed and I wish you luck through to completion. I'll be following 👍

- 69 replies

-

- fly

- victory models

-

(and 2 more)

Tagged with:

-

La Palme by Tobias - 1:36 - POF

No Idea replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Hi Tobias - nice work mate. I see that the stem is now full of planks but you still have a few to install. How are you going to get all of the planks running to the stem? Are you going to trim the one's installed or taper the outstanding ones into the clamp? -

Hi both - This is one of those things that I'll need to decide nearer the time as it's so far away. Thank you for your very kind words I'm hoping to get the ceiling finished in the next 2 weeks. Our Granddaughter (She's 10 weeks old and beautiful ) has been taking up much our spare time but what a great way to spend it

-

Tilting mount for Proxxon Vise for MF70

No Idea replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Here you go Mike https://www.renishaw.com/shop/Product.aspx?Product=R-PCA-135075-12-6 -

Hi clogger - wow mate your build looks amazing 🤩. Fantastic job and I hope my finished ship looks a good as yours. I should have said that I never intended to rig my ship purely down to its size. Yours is the first Le Rochefort that I’ve seen rigged as such and it really finishes it beautifully. Maybe I’ll change my mind if I can find a place big enough to keep it. Thanks for sharing your picture 👍

-

Keel klamper alternative

No Idea replied to zamboknee's topic in Modeling tools and Workshop Equipment

I'm with you on this Roger - I do have a panavice but my ship never goes into it. I prefer to have it on my lap or in a fixed cradle which is made up of scrap timber. -

That is awesome work marsalv - I don't actually know what the small blocks on the bowsprit are for but you have put them on so evenly and neatly. They must have taken ages to align like that.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

A little ripper from Veretas

No Idea replied to PeteB's topic in Modeling tools and Workshop Equipment

These little planes are great I use mine every time I’m modelling. I put a small drop of thin oil on that piece of cardboard and so far I have no corrosion on mine. -

Check out Kevin Kenny's review and set up of the Foredom tool its very good. I love mine as it has so much torque at very low speed. The best on the market but they are also very expensive. I used a Dremel successfully for many years and although they do the same job the Foredom makes it easier with better control.

-

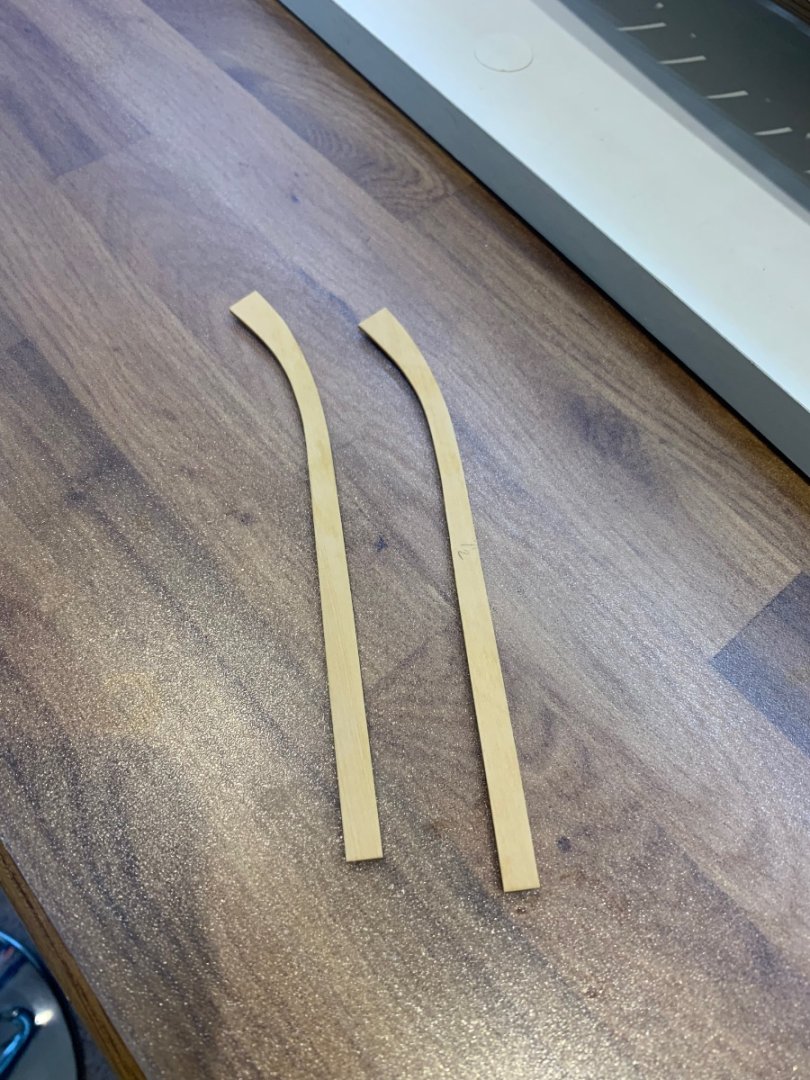

Tobias that is spot on mate 👍 Not really an update but just a few shots of how things are going. I'm working on the bow and stern at the same time to get things done. As I've discovered planking the inside of a hull takes the same amount of time as planking the outside. So a few pictures of spiled planks, clamps and unfinished fitted planks too! The planks look stepped as the thickness decreases as they go down towards the keel. Things are getting easier as I'm learning new skills everyday. Its coming along nicely but these things take time and a lot of measurements - Cheers Mark

-

That is beautiful work and looks like a proper mirror image from starboard to port.

- 72 replies

-

- Glad Tidings

- Model Shipways

-

(and 1 more)

Tagged with:

-

If you look at Chucks video the point that the plank touches his jig has a larger surface area. This would help spread the forces away from a very small focal area when bending. Using a pin would make the contact point tiny and therefore increase the forces in that tiny area. It’s got to go somewhere so the wood will start to lift instead of bend. l had this problem until I made a better jig to bend the planks on and allowed the plank to be bent with less pressure in a very small area. So try making a jig and also make the hold down the same gap as the plank is thick. Cheers Mark

-

Again so cleverly thought out using what you have at hand. I know I’ve said it before but your technique here is fantastic. I also like the way it wastes very little wood in the process. I think your finished result is beautiful. I also think that you don’t need to work on your woodworking skills. You’ve got them already 👍

-

Some great advice but there is no short cut to getting a super smooth finish. I built Billings Fairmount Alpine using epoxy as a sealer and I too used Halfords Matt primer to see the imperfections. Any imperfections were filled using a fine two pack polyester car filler. It just takes hours of patience which you obviously have. The finish you have achieved is fantastic and a real credit to you. Here’s my effort after probably the same hours that you put in. Looks about the same I would say

-

ancre Le Gros Ventre by ChrisLBren - 1/36

No Idea replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

That really is lovely work nice one Chris 👍 -

Fixing paint job

No Idea replied to Sam A's topic in Painting, finishing and weathering products and techniques

Hi Sam and welcome to the forum. Thats an easy repair and you have answered your own question. Firstly let the paint already on fully dry and then sand out the marks that you made. As you have an airbrush mask off the areas along the length of the hull that you do want to spray grey. Then just spot spray the area that wants sorting out and your done!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.