-

Posts

1,025 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by No Idea

-

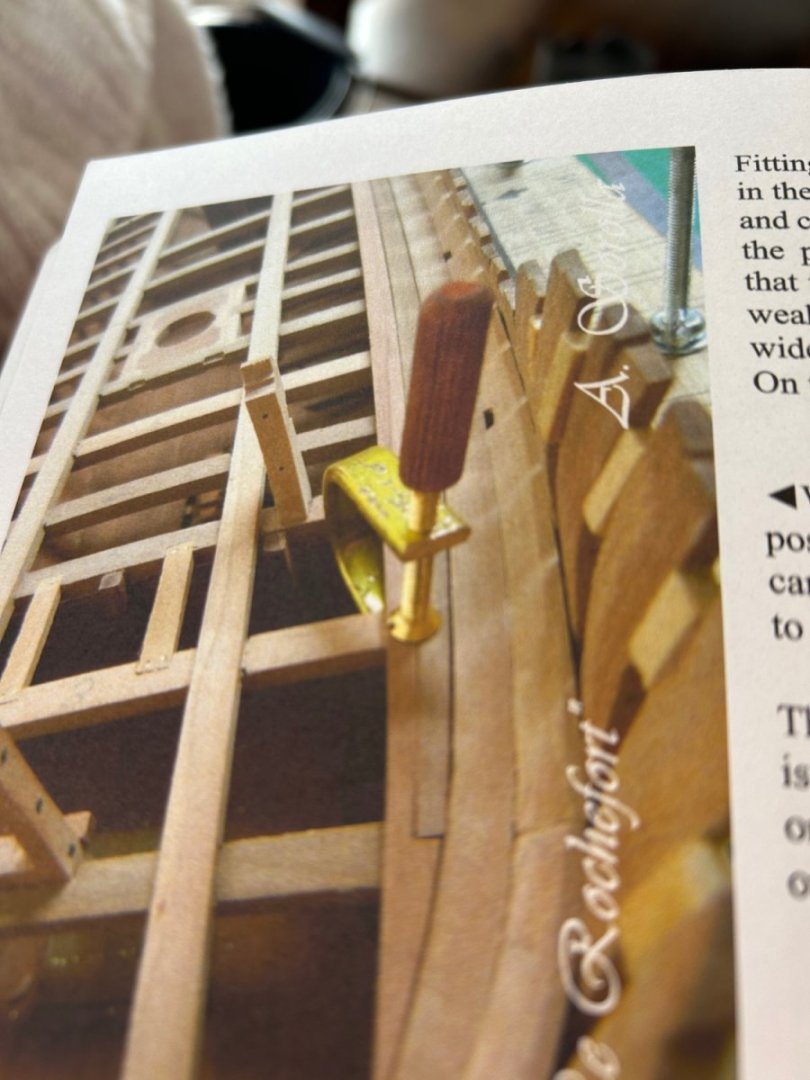

I think that the first 5 builders of the POF model are getting a very good deal here. Having scratched a frame in Castello I would estimate that the wood alone cost at least £300 ($400). This is the real deal and what a lovely ship this is going to be to build Not only that you know that its going to go together perfectly and also get the back up of the manufacturer right here. In fact I think the first 5 builders will be more than lucky and I can't wait to see their builds on here!

-

Hi Thistle17 - fence alignment is very important and also really easy to do with a DTI. Since my last post 8 months ago I too have had some issues with thick wood overheating and burning. As I know that my saw is set up exactly it could only be the blade. The 110T blade can bind up quite quickly so I swapped it for a 64T blade. This got the chips out much better and solved my problem. In fact this blade goes through wood like a knife through butter. It also leaves me a good finish on the cutting edge with virtually no chip out. I’ve also noticed that the motor runs a lot cooler too. This is now my go to blade for ripping planks.

-

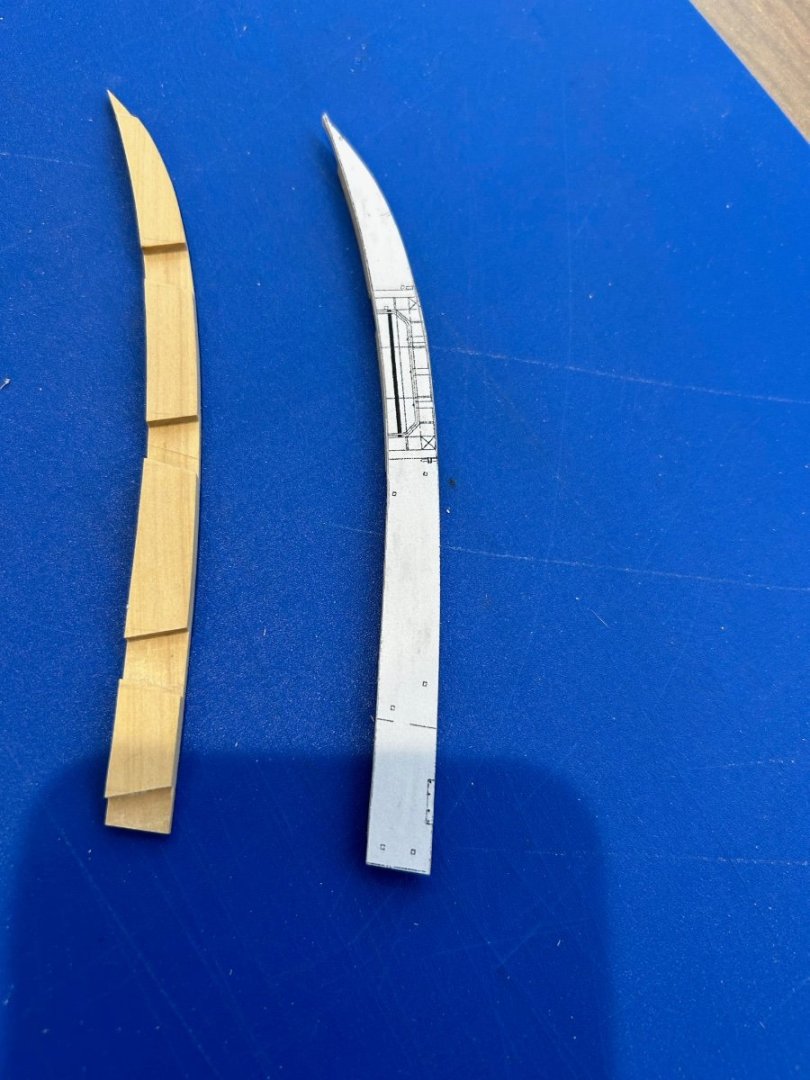

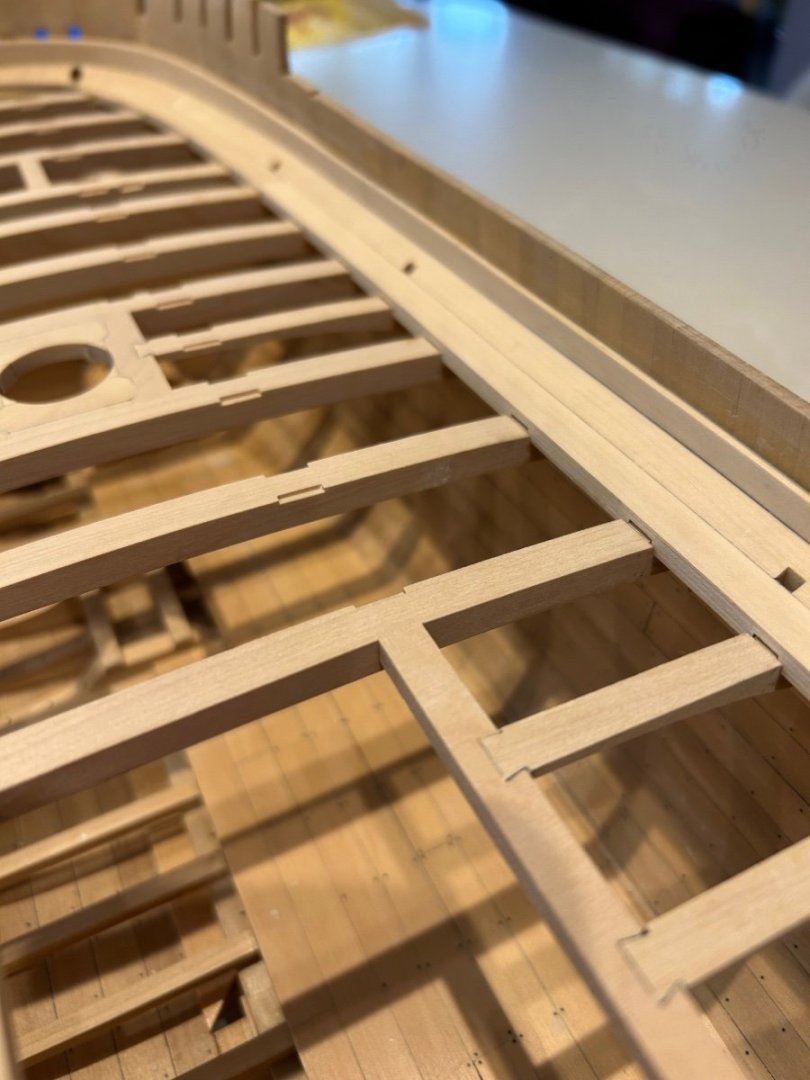

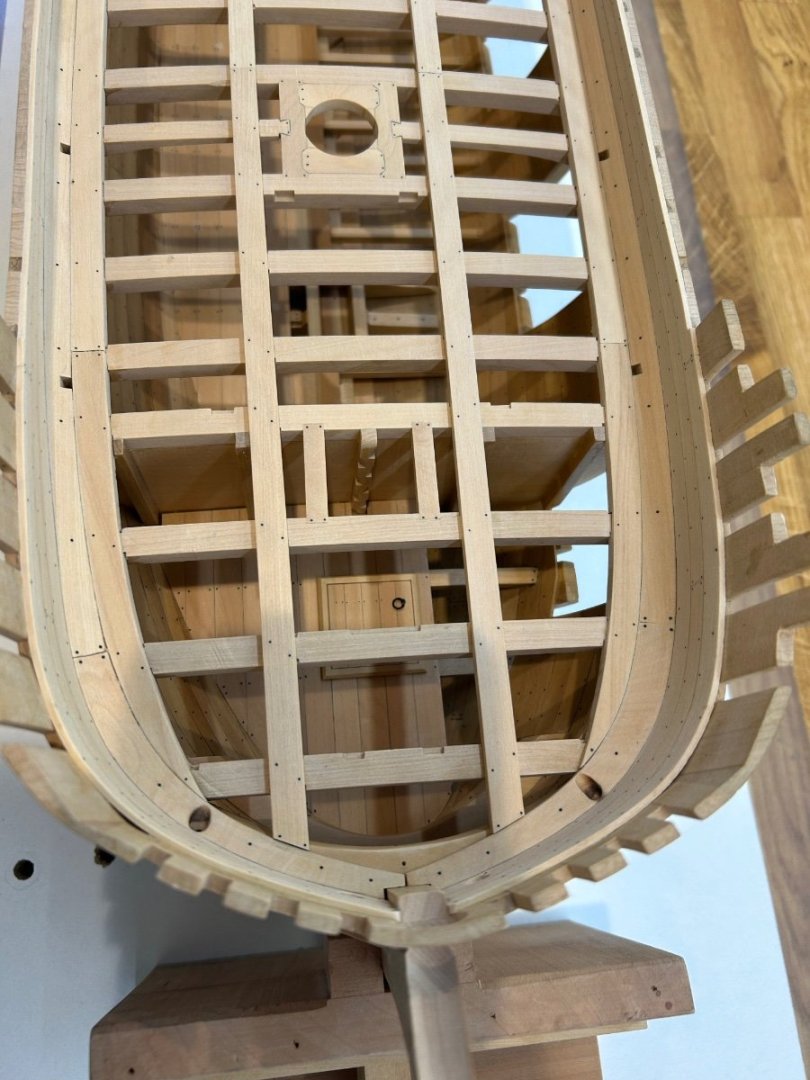

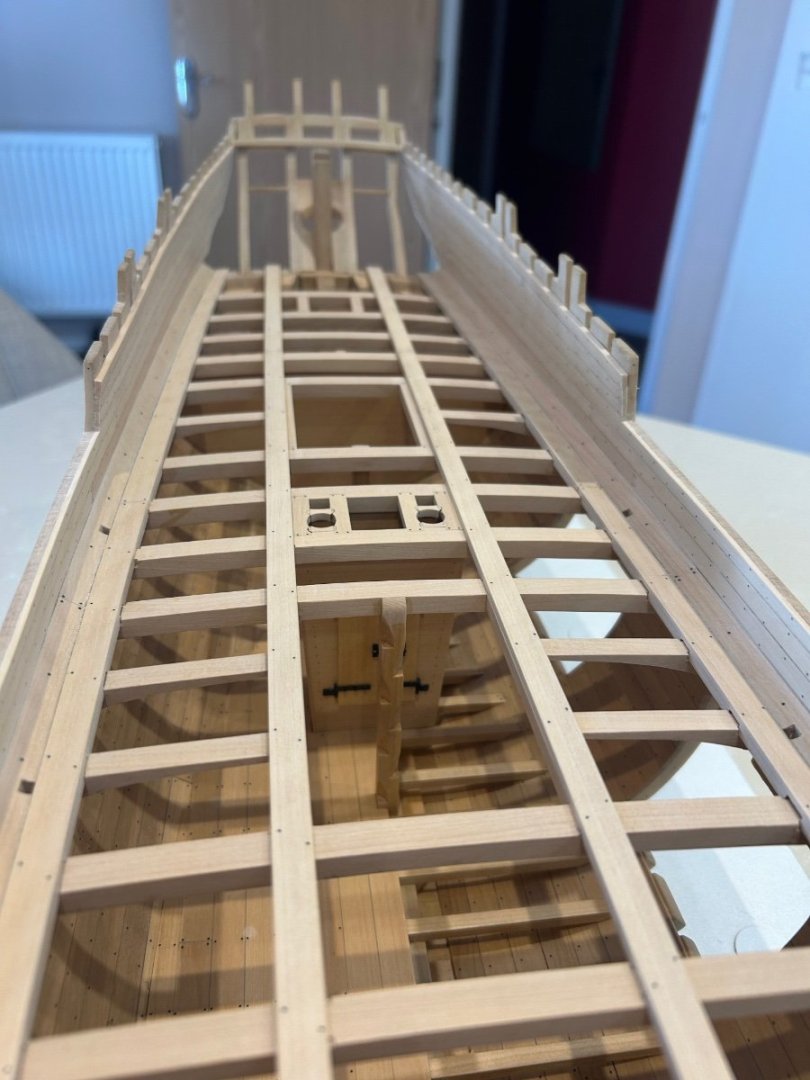

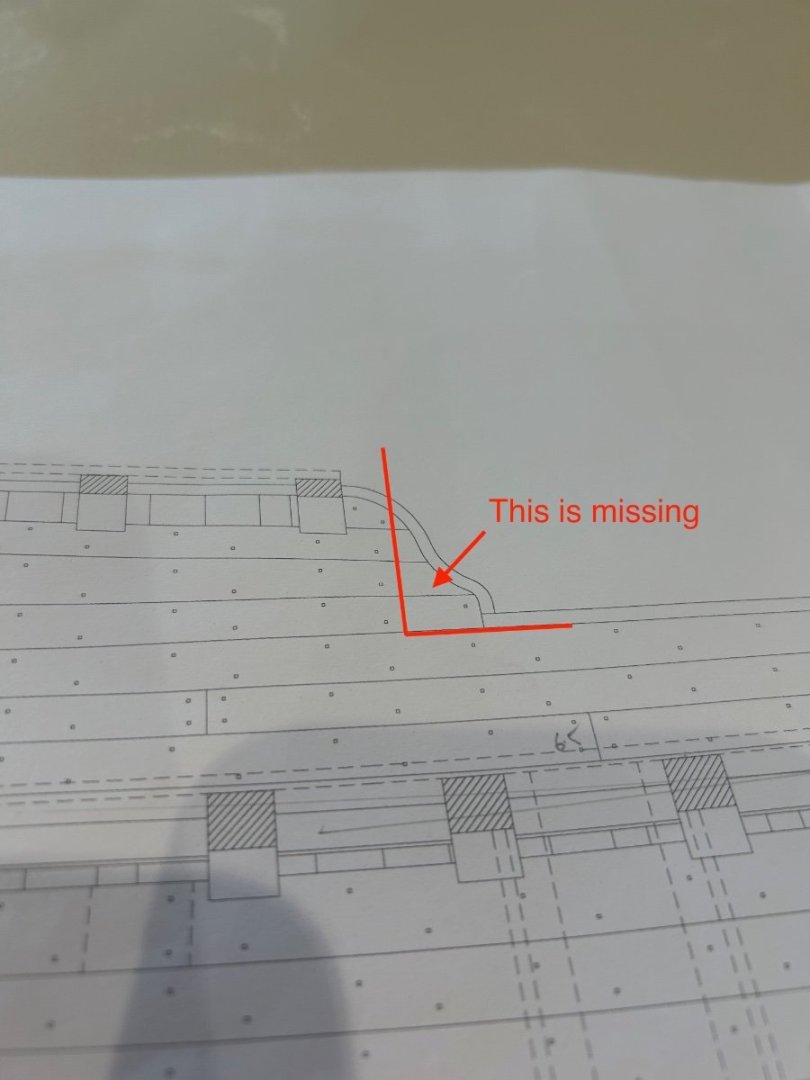

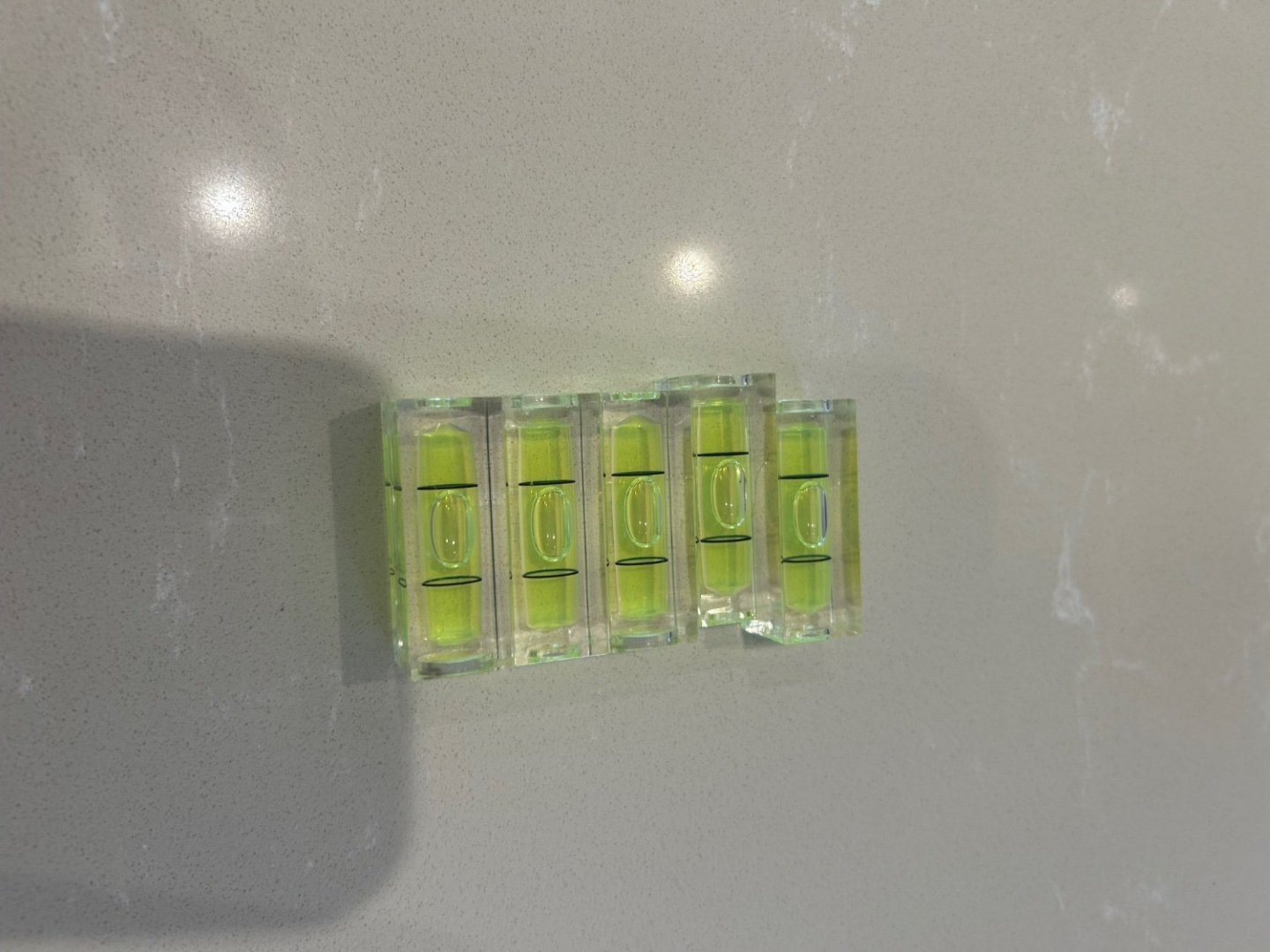

Hi All Time is not a friend of mine at the moment but I have been watching others build projects (enviously 😆). I have got some done hence the update and thanks to everyone that took the time to give advice and the very lovely comments. The first thing was to fit two more plank strakes on the bulwarks and then pierce the holes for the scuppers and hawse holes. Nothing really tricky about this you just have to be careful cutting the holes so that you don't tear the wood too much. Next was to make and fit the deck clamps for the smaller aft and forward decks. Learning from my previous attempt at placing clamps I really took my time marking these out with a digital height gauge. I think this took me about 4 hours to get right until I was absolutely happy with their placing. I also used a technique that @Tobias uses with tiny spirit levels athwartship. These things are so cheap and yet they allowed me to checked my levels even further. I used quite a lot of clamps to make sure that my efforts stayed where they were. Cheers Tobias Next was to plank the gap between the already fitted planking and the clamp. All I would say about this is if you measure and plan it accurately it's a fairly straightforward job. I can imagine it being a nightmare if you don't. The clamps are slightly thicker than the planks and just need tapering into the planks below. I've put a photo below to show what I mean. Note to self - use a lower resolution camera as these photo's show everything Ok so as always - what did I do wrong? Well I cut the planking too short - Its not a problem but I forgot to allow for the scroll to the gunwale. This is how I cut it. And this is what I missed Its not a problem as I will fix this later on when I plank the outside but for fellow builders this could save you from doing the same. I'll get some more done as and when I can - I think I need to be retired so that I can enjoy my hobby more!! Cheers all - Mark

-

Great new workstation - There's nothing better than having a nice place to work.

- 2,607 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Congratulations marsalv very well deserved for such a beautiful ship. I'm looking forward to your next build.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Byrnes Table Saw Configeration

No Idea replied to Guyuti's topic in Modeling tools and Workshop Equipment

Hi Guy - I have pretty much ordered all of the above for my saw and I use everything that I ordered too. Over the past few years I have found that a UK builder should order as much as possible as the shipping costs here are very expensive. So here is what I have learnt as a UK builder - I don't use carbide blades for anything other that cutting down big pieces of wood. The edge finish is rough and not suitable for modelling. Also if the piece of wood moves even slightly sideways as you are feeding it through, the blade will cut sideways and leave you with a piece of wood that varies a lot in thickness through its length. Buy at least two accessory packs as you will loose screws and its a bargain for us. All of the threads are UNC which we do not use here. We are metric here so go for the metric stop. Get as least 5 - 6 zero clearance inserts - They are as cheap as chips and you will need one for each thickness of blade. You will accidentally fit the odd bade incorrectly as it will trash the insert. Get some spares. Buy a couple of belts as they do wear out over time and you need to think of the cost of shipping one here. Buy as many blades as you can! I use three types of blade now. The 4" blade for cutting planks as it had much less deflection and the 3" blades for finer work. I go through a lot less of the 3" blades. Regardless of how often you use these parts I have not regretted buying anything and I can honestly say that Jim and Donna Byrnes properly support their product. There's nothing better that I know of in our hobby and I'm very glad that I have mine Mark -

I also thought the same as you - however when it came down to it I found it easier to correct the clamp. If both sides of the clamp are the correct height then you will get less roll on the beams throughout the length of the ship. Your idea can be done but you will end up doing a whole lot more measuring in the end. The clamps will look a lot more uniform too if you make them the same. We both had the same issue and same solutions to consider.

-

Kit review 1:48 La Renommée section - CAF Model

No Idea replied to James H's topic in REVIEWS: Model kits

What a fantastic kit it really shows the details of the small area of a ship that it covers. This is the sort of kit that I would happily build as the results are great. A top tip for any UK builders though - If you have a Games Workshop near you just drop the figures into them with a few quid and ask them to paint them for you. What they can do is amazing and far better than any of my feeble attempts. -

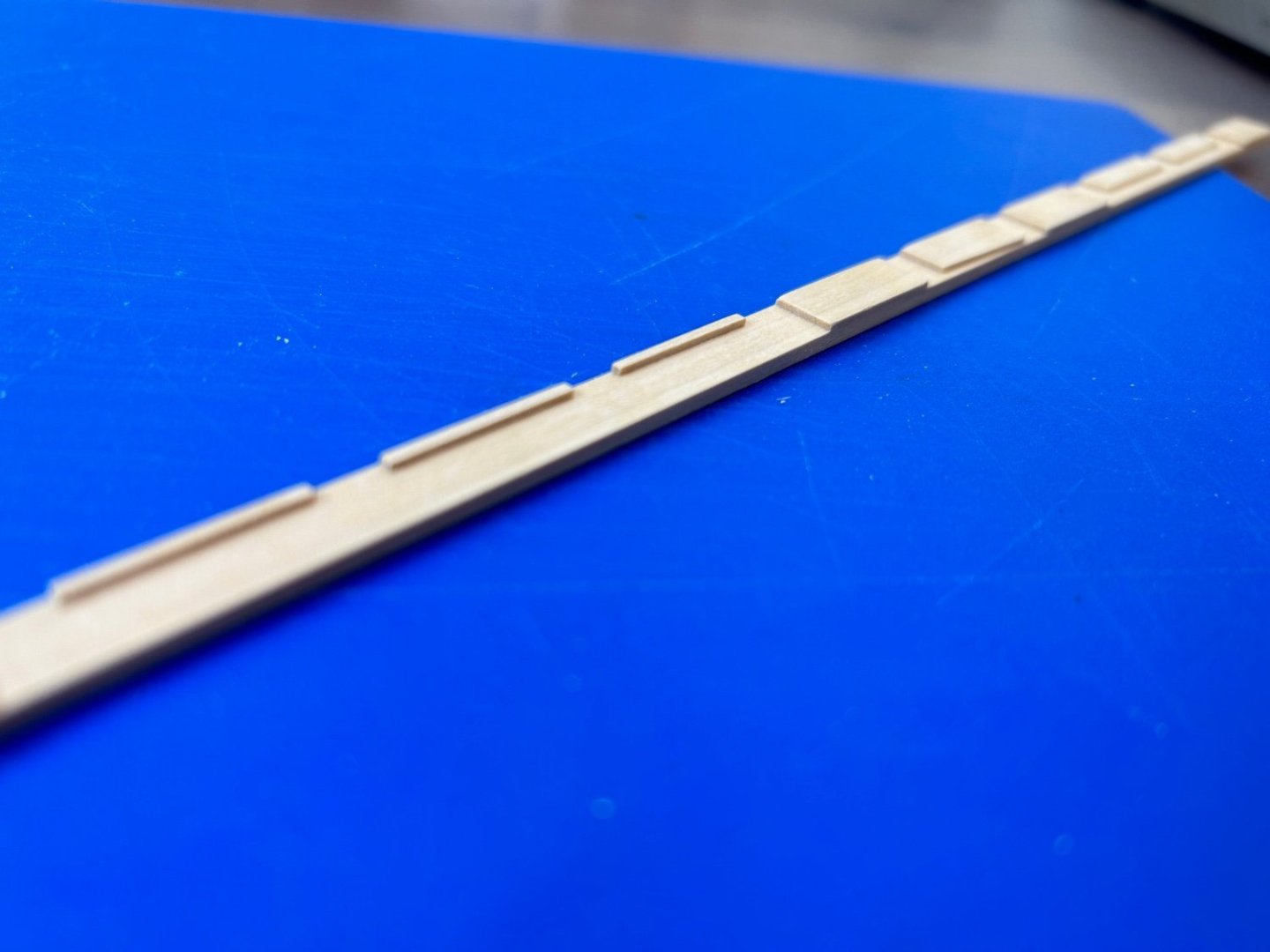

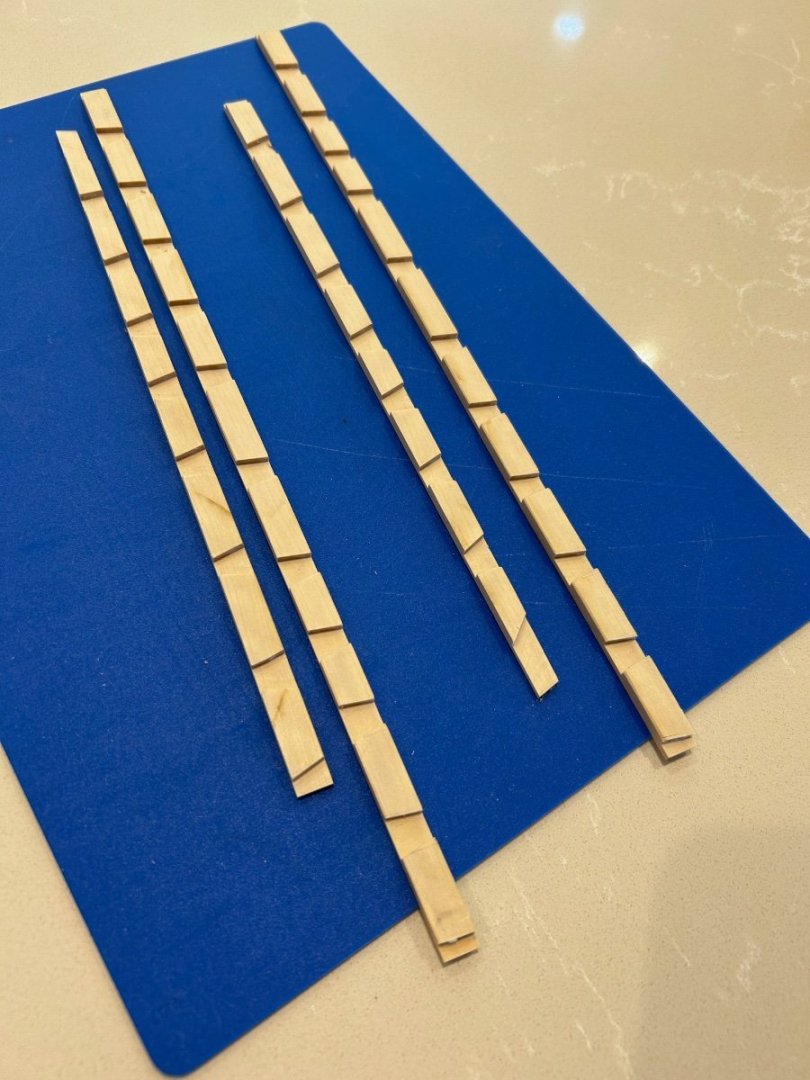

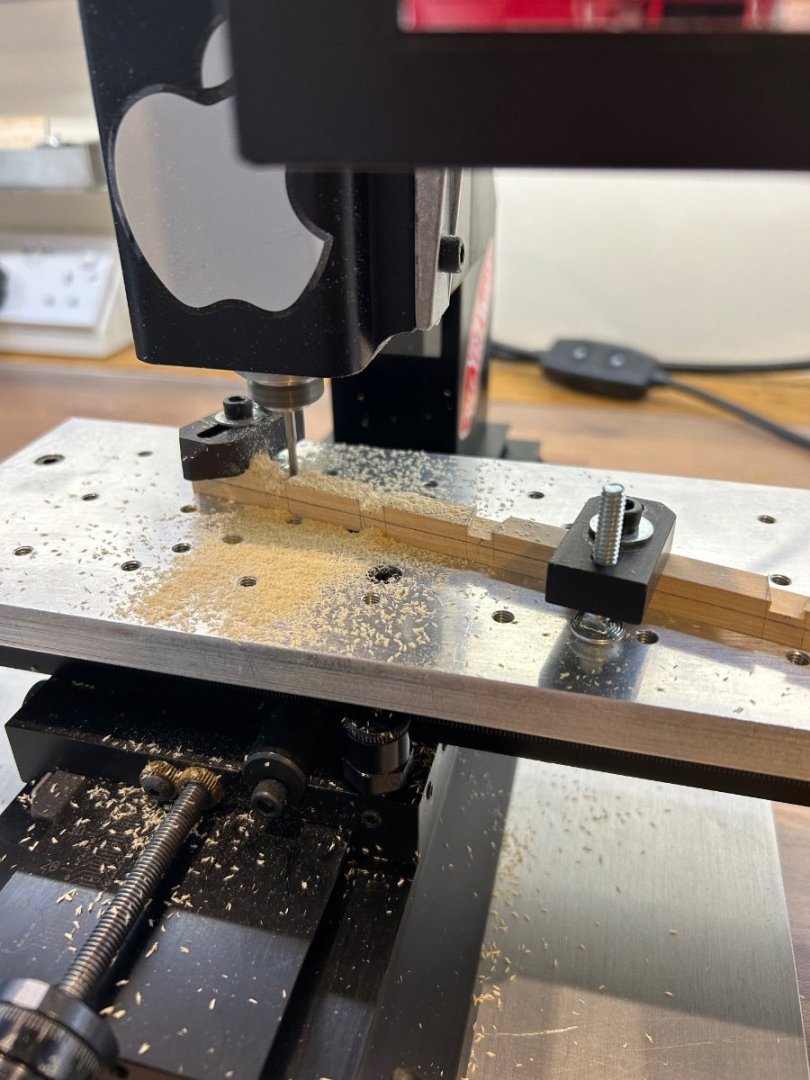

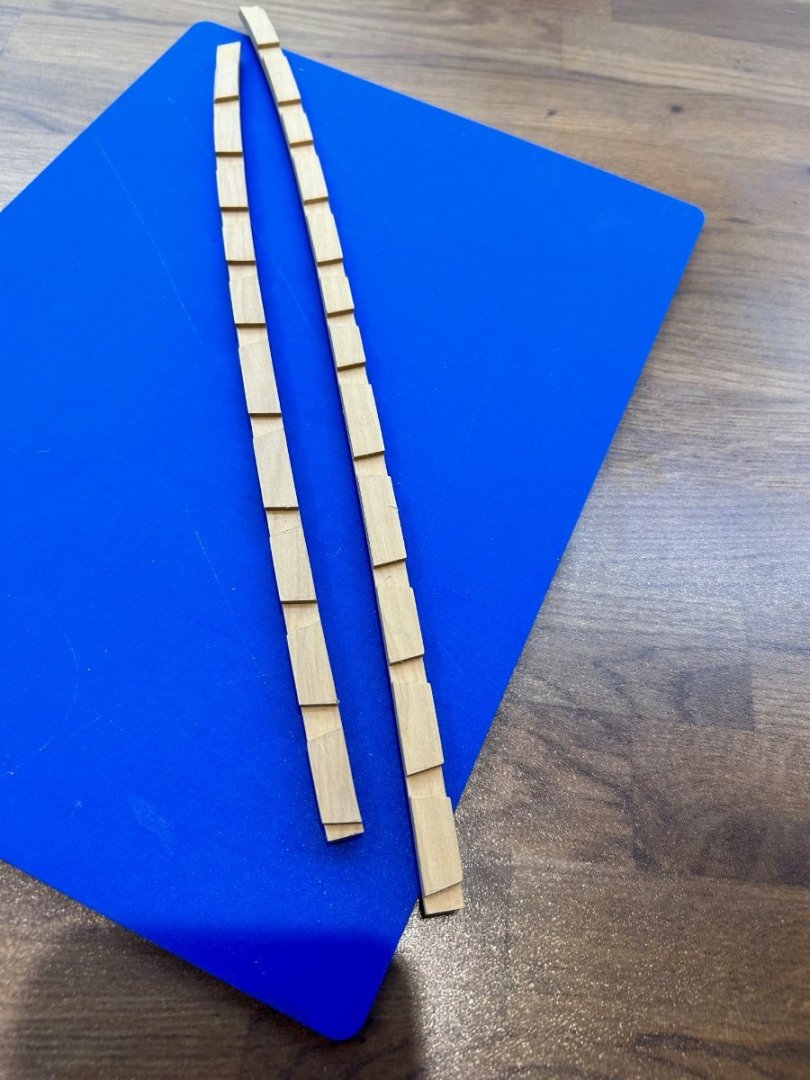

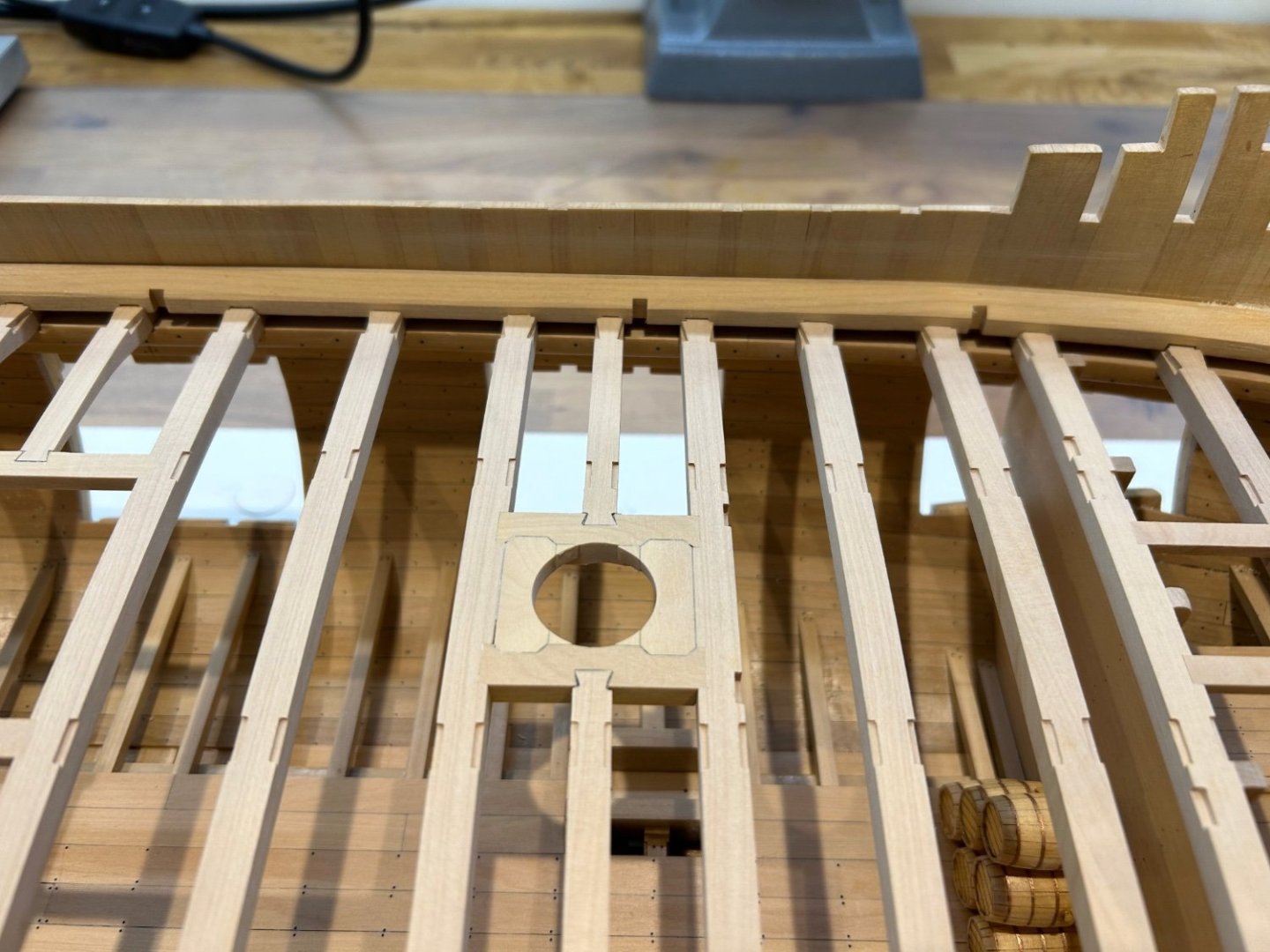

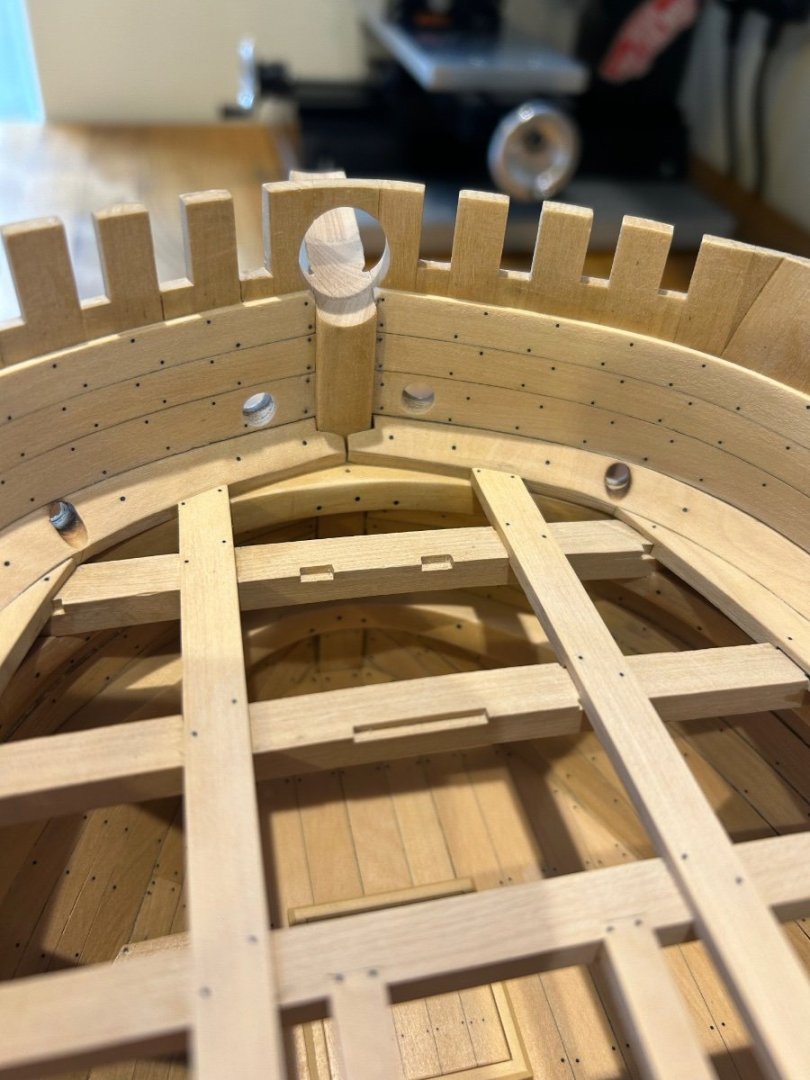

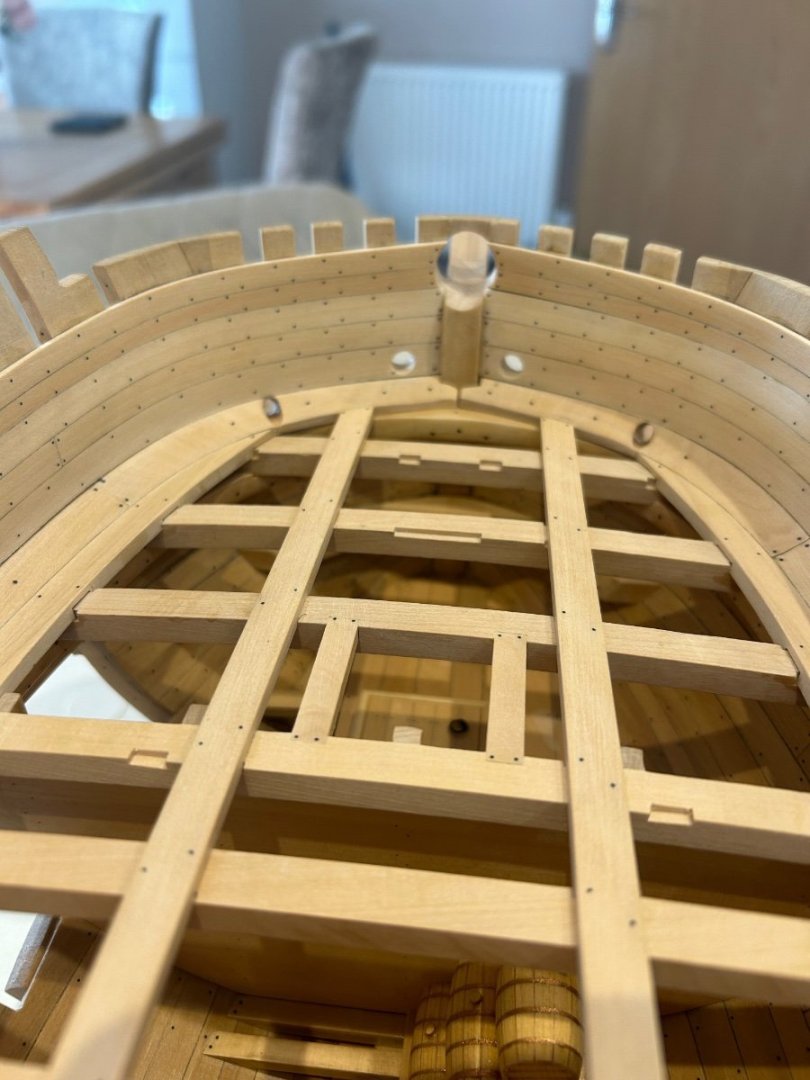

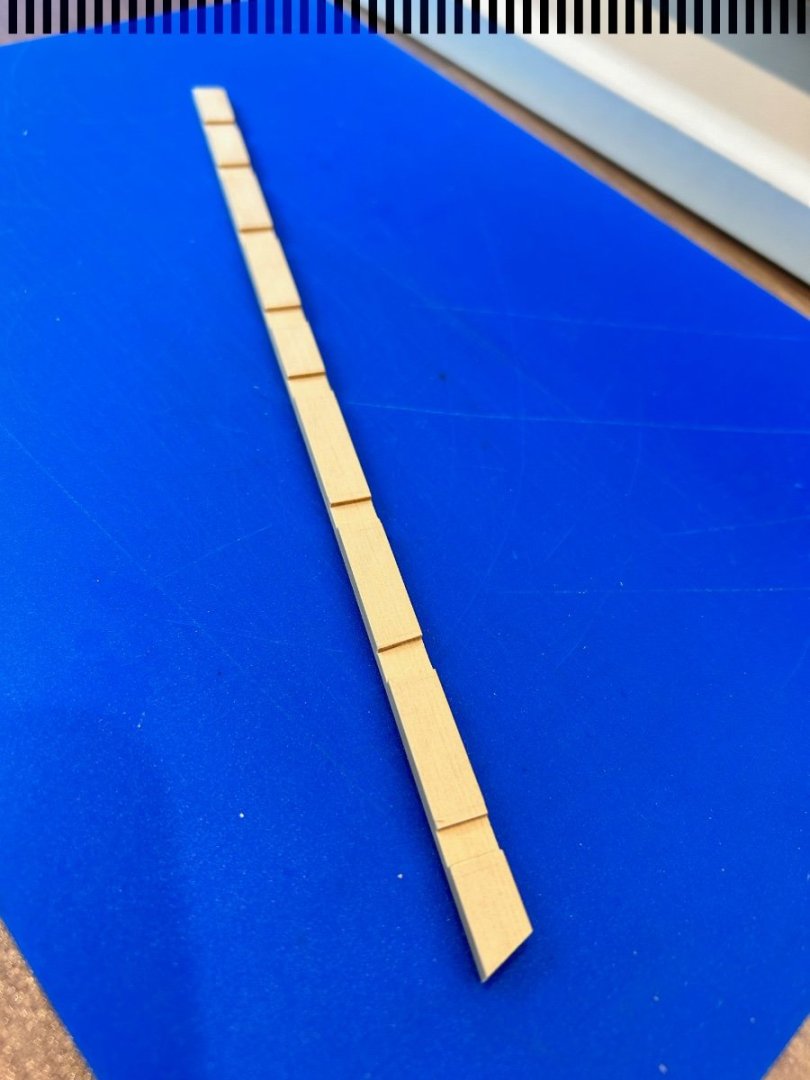

Hi Marc and thanks for you comments - You are right in some ways that everything is on show and it needs to be accurate but as I have discovered there are loads of ways to hide small errors - thank goodness 🤣 Sorry for the lack of updates I'm just really busy elsewhere at the moment so I fit in the ship building as best I can. So onto the binding strakes and I soon realised that there is an easy and hard way to make these pieces. As per usual I chose the hard way in my opinion to get better results. The first front pieces at the bow are simple and pretty much more of the same. Cut them to length and carefully mark out the cuts and get going on the mill. It's difficult to explain my weird markings on the pieces that I cut too, as I use them as a guide to what I know to be correct in my mind? It works for me - it's not for everyone. Next is where you can either make the job relatively easy or a bit more difficult. The binding strakes partially pass over the top of the deck hatch openings. I really wanted to maintain the integrity of "Width A" in the picture below to keep the strake uniform in thickness along is full length. So to do this I had to scribe the strakes around these obstacles. So instead of just cutting straight joining slots I ended up with the complex joints below. Have no idea if this is how they should be made its just the way that I wanted to do it. I did find that doing it this way once again made the fitting very easy as they locked into place and followed the curve of the deck so easily. I'm very happy with the results and I have also caught up at last with the required nailing. A few pictures below I'm very tempted now to leave the main deck as it is now? I understand that everything that needs to be placed on the deck will require lifting to the correct deck height but what are your thoughts on this? I have no experience of doing what I'm suggesting but I think that it would allow anyone that looks at the model to see the work carried out inside far better. Please let me know your thoughts. So my next jobs are to make the bits, bowsprit partner, windlass supports and finish planking the inside of the bulwarks. Thanks everyone - Mark

-

Jim Byrnes Saw Rattling Vibration

No Idea replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Hi Chris - I had a similar issue with the belt rubbing on the guard at the motor end. After speaking to Jim he suggested that the motor tensioning spring was probably not as it was. So he suggested that I place a few small washers behind the spring and this solved the problem. It pulled the motor further up and also gave more tension on the belt. Even now I only have a small gap between the belt and guard but it certainly solved the problem - Mark -

Simple amazing work - I can’t thank you enough for sharing your skills as I personally have learned so much from your log 👍👍. I’m looking forward to your next build 😎

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

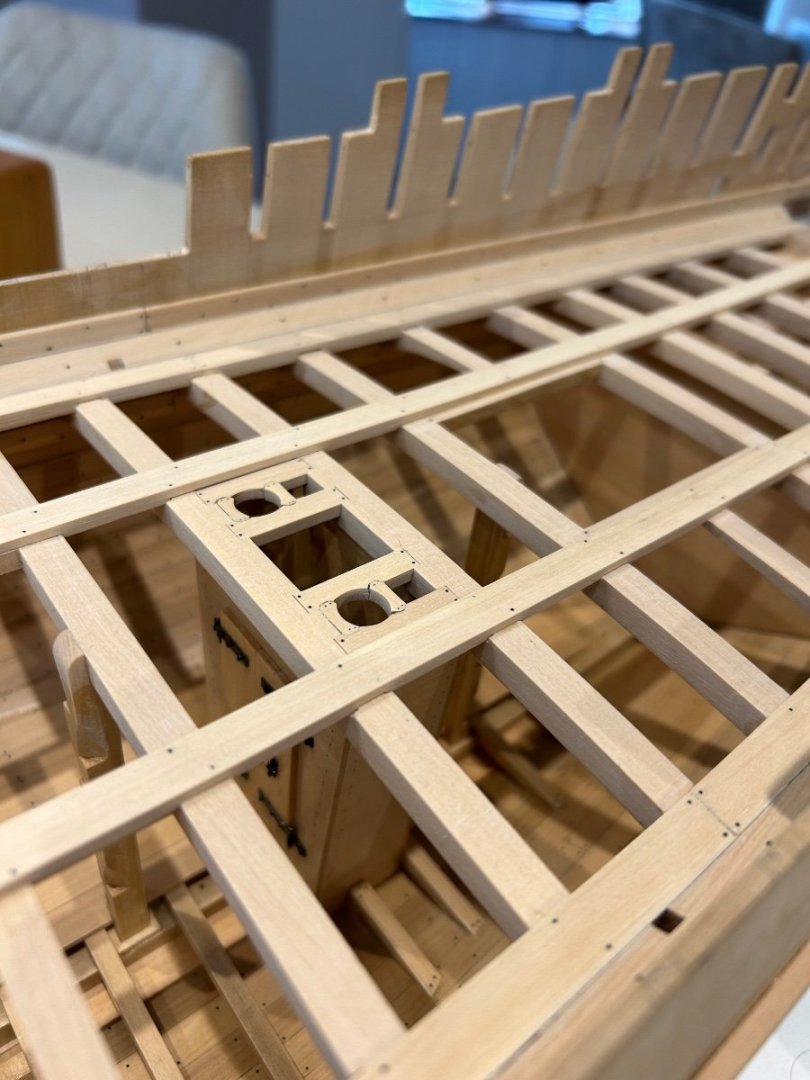

Another update from me - The inner waterway which is pretty much more of the same but is easier to make. Its made up of three sections per side. The parts were then glued into place - I found that the dovetails pretty much hold these parts in their correct place. They do nee to be clamped though to bring them down to the sheer. Then I made and fitted the first plank up the bulwark so that I could finish the bevel on the waterway. This was then all sanded down and blended in and I'm pleased with the result. So thats brings another part of the build to conclusion. The next job is to make the binding strakes. @DaveBaxt this is where I work - Its not a big area but I find it more than adequate. Its always this tidy as its our spare room so I need to make sure that the mess is always cleaned up. Cheers Mark

-

Hi Dave and thanks very much - I'll get a couple of pictures up of my work room sometime this week so that you can see where how it's all set up. Prepare to be underwhelmed though 😆 As always mate - thank you. I know I've said it many times but those parts are very difficult to make. The shape changes constantly and if you get the angle wrong there's a gap somewhere. The pay off though I think for any builder is when they eventually just click onto the mating dovetails need very little clamping. This is why I build - the feelings great. Thanks HH - I actually think its the other way around - Its your work thats clean and never ceases to amaze! I made a start on the inner waterway and I'll get some pictures up this week. Having just finished my nemesis parts I was expecting more of the same. But no................hooray its not the same at all. It's a much simpler part to make......well so far anyway! I have discovered that the dovetails on the beams are a little short and I think this is yet again down to my photocopier. Its no big deal really I just need to take my time. Cheers Mark

-

Honestly thanks for the very nice comments and the likes here - I won't lie I have found these particular parts very difficult to make and get a good fit. You have very much helped me through this particular part of my build. If anyone else is building Le Rochefort you don't have to cut the dove tails if you don't want to. You can simply cut a slot the width of the beam and it would be so much easier. I did it this way as I just want to make it as true to the drawings as I possibly can. However once done how satisfying is that feeling 😀 So I carried on cutting out the dove tails and also roughing out the bevel After a little fettling they did fit As always I've learnt some new skills and overall I'm very happy with the way these parts have turned out. You can see that I have also rough cut the scuppers too. My patience is definitely improving too which I like. So now that they are installed I can now start on the inner waterway. Cheers Mark

-

Hi Bob - yes I do use these but it's the deep reach that I need. I do have lots of types of clamps including G clamps but I think the type I'm looking for will be very useful.

-

Thanks for you reply’s - I think that I will end up making them which you are right it’s not difficult to do

-

Hi Everyone Can anyone help me - I want to get some of these small C/G? Clamps and I cannot find them anywhere. If someone could please point me in the right direction I would greatly appreciate it. Cheers Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.e60c6f4ad134aab2fcb9aaca53269596.jpeg)