-

Posts

13,290 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Models that I've seen usually do not curve around quite so much. However, do you notice that triangular piece seen on the stern view? It sits on the outer end of the wing transom. Is this a separate piece or is it cut into the aft end of that wale plank? If the latter, this is something new (at least, to me!).

-

It is a very tricky area indeed, Mark. On my 64, I had to also carve a shallow rabbet on the inner side of that aftermost wale piece so that the bottom plank below it could curve around smoothly and in contact with the frames. Whether this was exactly what was done in full-size practice I cannot say, but seems reasonable. There was still a small triangular gap that was filled with a piece of plank outboard of the last bottom plank.

-

Hardly worth the trouble: the gale would have blown over by then!

-

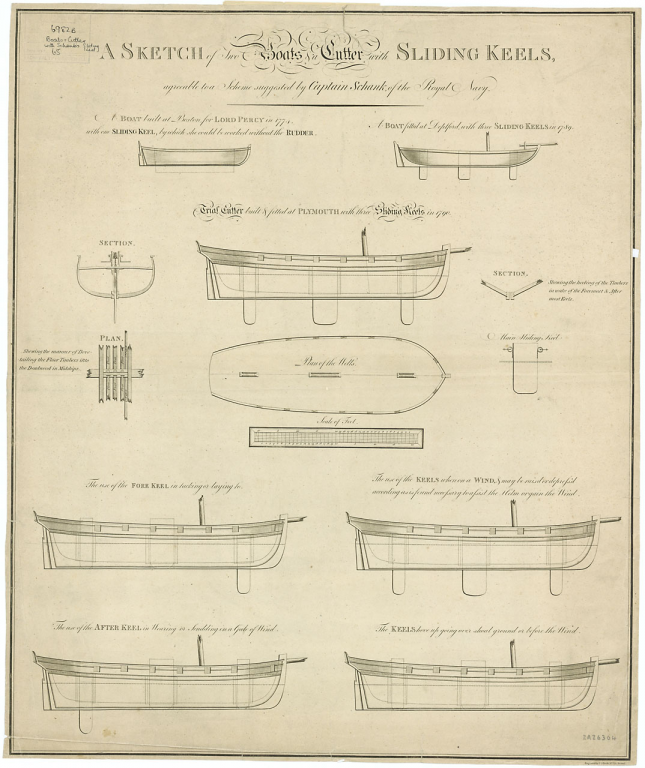

Not American, but the right era and size: search Schank sliding keel on the RMG web site under 'Collections'. There are several pages of plans of vessels as well as the raising/lowering mechanisms. An example is here:

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Congratulations on a fine finishing flourish! So, what's next?

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Watchmakers' tweezers, perhaps?

-

Deck plank detail

druxey replied to Srodbro's topic in Building, Framing, Planking and plating a ships hull and deck

Such joints are generally referred to as tabled joints. -

All I can see missing is a nice nameplate mounted on the baseboard, Maury. Otherwise, it's really nice to see a lesser-modelled subject. Congrats on a job well done.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Well researched and well reconstructed. I'm in awe of your courage in tackling a ship of this era and producing such a convincing result. Altogether a lovely job, Dick. Congratulations!

-

ancre Chebece 1750 by Jeronimo - FINISHED

druxey replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Finding the first grating assembled incorrectly must have been very annoying. Hats off to you re-making it correctly! Lovely cannon castings as well. -

I hate to mention this and hope it's an artifact of photography, but the hull appears to be developing a slight twist (check the last stern-on photo). If so and I'm right, it should be correctable at this point. Nice, clean work though.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice sketches, as others have already noted, Mark. That problematic last piece was apparently shaped rather than bent in the shipyard, so you are in good company. Carve the inner surface first, fit the joint, attach, then carve/file/sand the outer surface to shape, would be a good strategy. Good luck with it!

-

Aiee! What happened to good, old fashioned, simple smokestacks? These are far more complicated than given by their first impression. Well done, Dan.

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

I use rubber cement for my sanding blocks. Use it like contact cement. However, the sandpaper is more easily peeled off for replacement.

-

Yes, Museum quality UV-filtering glass is not cheap stuff. Thanks for the details of your casework. I hope the stain didn't go onto anything else!

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Exactly! The character was a perpetual busybody.

- 21 replies

-

- capstan

- hand windlass

-

(and 3 more)

Tagged with:

-

Well, that is a pleasant surprise! I hope they deal fairly with you.

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.