-

Posts

1,605 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by vaddoc

-

Dear all I moved away from enamel varnishes and initially used the Valejo water based ones. Somehow they never worked for me. I recently used the Valejo polyurethane Varnishes and they gave a good result, although adhesion to the substrate looked poor. Also they come very thick, I did not thin at all but still came out fine. Just a few days ago, I used the polyurethane varnishes again but this time I thinned with the Valejo acrylic thinner and also put some retarder. The varnish became milky, left horrible brush marks and when dry started pealing off the surface. Strangely, the mat varnish over the red colour was fine. How should the Valejo varnishes be thinned? No info on their website. What water based varnishes you use and have good experience with? What do you use for thinning? Could I use enamel varnish over the acrylic paint and how long should I wait for the paint to cure/dry? Regards Vaddoc

-

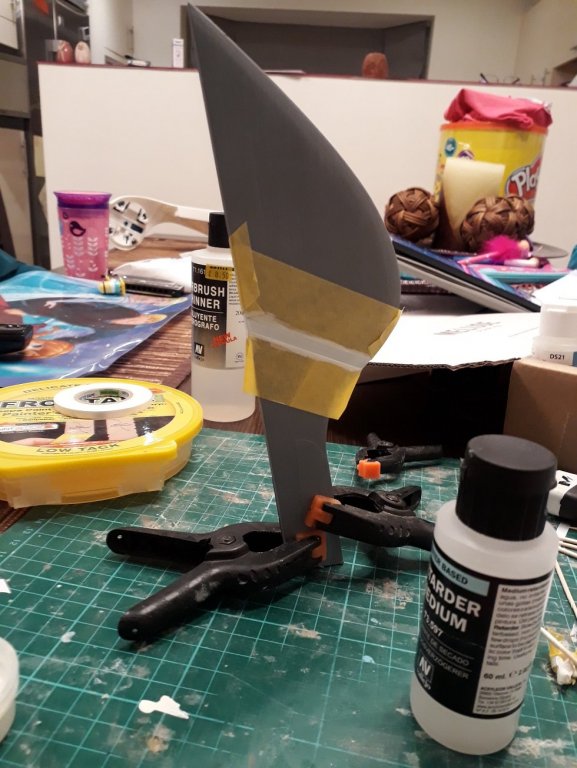

Many thanks Keith, Patrick and Mark. Patrick, no thoughts yet, I am still very far from finishing. Today was a bad day! I started work on the hinges. Initially, all went well and I made the hull ones. Then things went pear shaped. I was not happy with the gloss polyurethane varnish on the rudder above the waterline but I had decided to live with it. When I removed the masking tape, the whole thing started pealing away. The paint underneath and the mat varnish bellow the waterline are fine. Still, I sanded the blue segment with 1500 wet sand paper and started painting all over again. Then all my metal work started falling apart. Pieces soldered misaligned, coming off, too wide or too narrow...I made the same hinge 6 times, all wrong. I gave up in the end! I am still not happy with the water based varnishes, I need to work on this a bit. Vaddoc

-

For years I ve been using The Dremel moto saw. It is really all I need and is very user friendly. I build in large scales and often I need to cut very thick laminated pieces, it is powerful enough. The blades last a long time and are easy to change. Dremel sells side blades so the length of cut is unlimited. It is permanently attached to my bench with a fish tank pump blowing air. It still goes strong after 5 years of relatively hard use. I usually cut just on the edge of the line and finish off the piece on the disk sander, this gives superb accuracy. I absolutely would buy it again. Hegner of course is on another universe, both in regards to quality and price. I d buy the Dremel, and use the left over money towards a disk sander or the Proxon drill press Regards Vaddoc

-

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)

Shop Safety and Oops Repairs

vaddoc replied to BETAQDAVE's topic in Metal Work, Soldering and Metal Fittings

Indeed an oops Dave but you seem to have done a very good job. Beside fingers, does your cutter cut brass sheet without bending it and if so, up to what thickness? -

Very elegant John, and how nice for the museum visitors to actually see the model being created and get to interact with you. With all the frames in place this fragile curvy symmetry is certainly impressive.

-

Smaller gaff topsails may not use hoops or any lacing. It took a while to figure it out, the boat I am building uses one. Leather does not mention it but Tom Cunliffe in "Hand Reef and Steer" has a small chapter on flying top sails. There is also a You tube video hoisting such a top sail. I found somewhere on the net the following explanation which I saved: "It's true that the side the sail went up on will need to be the side it comes down, but it's nice to have a free choise as to which side it goes up. The halyard is essentially either-ended anyway, what's the hoist one time can be the haul the next. The sheet cannot be two ended but if the bitter end is at the end of the boom, you can bring it forward on either side. So you're free to set on starboard or port tack as is convenient, but at the end of the sail you must strike on the same tack you set on. Halyard goes to a shackle at top of mast. When sail down, there are two ends on deck on either side of running rigging /boom/gaff, so the sail can be tied to either end and hoisted on either side. There is a similar arrangement for mid sail to attach a second point to mast. The downhaul just goes straight down to deck. The tack goes to end of gaff, when not in use it is slack and tied to end of boom." http://forum.woodenboat.com/showthread.php?144433-How-To-Rig-Topsail Although this does not apply to your boat Tomculb, there is little info on gaff top sails and this seems a good thread to add this little bit of info.

-

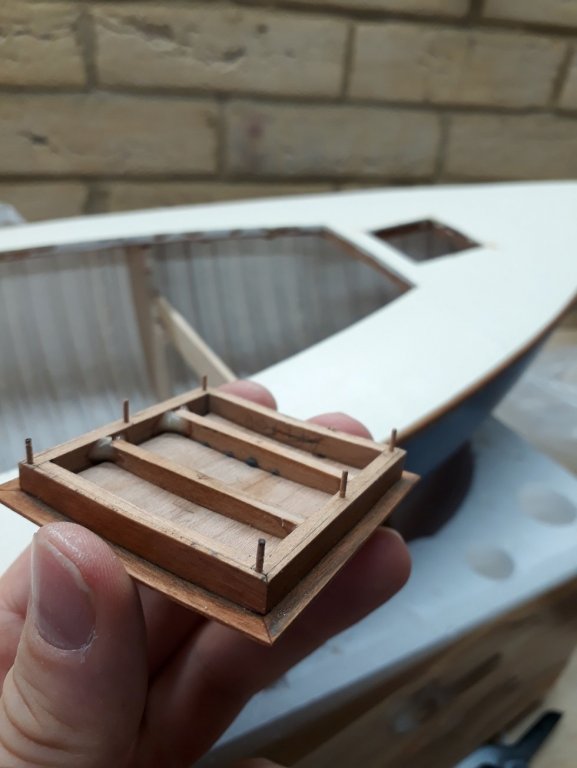

Many thanks Keith! My parents have been visiting and this was the reason I was able to do some work, since they were keeping the little ones occupied. Today is their last day though, so I stole some time to do a few more little things, this time with the help of my dad. Precious moments... Today was actually a big day! First I installed the tabernacle. Then, I installed the two pieces of timber (don't know what they are called) that will support and spread the chainplates. They are not really necessary for this boat I think but they add complexity and look cool! I drilled 1 mm holes, then counter drilled for the head of the micro screws I used with 1.7 mm drill. The actual hole on the hole was 0.8 mm. I used many screws as I think they will take a lot of load to support the 80 cm mast. Then I installed the portholes. This was quite fiddly as I used 0.5 mm brass nails (6 per porthole) and I needed really a 0.4 mm drill. I only had a 0.5 mm drill and so I had to use CA glue to fix the nails in place. No matter what I did there is a lot of dust inside the cabin so the portholes kept on getting dirty. I can live with this though! Next filled the holes with some left over wooden plugs that happily had the exact diameter needed. This were trimmed and the timbers are waiting a final sanding and Tung oil. The boat is a bit massive and actually quite heavy now as there is a lot of timber on. I think it is starting to look nice... Next will be the rudder and chainplates and at some point the bowsprit but I expect from tomorrow progress will go back to snail pace! Regards EG

-

Many thanks to all, I did not actually have the time to work more on the spreaders but good to know I am on the right path. I have been slowly catching up with people's work and I was able to spend only a few moments on the boat as life got very busy again. I started work on the rudder and also did a few other bits and bobs. I laminated two pieces of plywood and made a very strong rudder, sanded to final shape and cut two thick pieces of cherry for the side panels. For the tiller I laminated some cherry off cuts. This is the rudder assembly, the tiller is not yet sanded to shape I also installed the ladder. it is only held in place by these 4 tree nails Another task that I had to deal with at some point was to install the hatches. The cabin roof one was easy with some thickened epoxy but the fore hatch simply had no attachment points. I made a card pattern, drilled 6 holes and then used the pattern to drill 6 identical holes on the deck. Well, only 3 were actually aligned but even with just three tree nails it seems very well secured. Then I sanded, sealed and primed the rudder and then the long process of applying dozens of coats of paint started. Acrylics are easy to use but coverage is abysmal compared to enamels. Still, being able to paint in the dining room table is a big plus. Time to put the little ones to sleep!

-

Welcome Stickyfinger! Do start a log for your boat and remember, you can never have enough clamps... Vaddoc

-

My understanding is that Tung oil polymerises in the presence of oxygen. So with time it will turn into a plastic like polymer. The 50% dilution is to allow it to penetrate deeper, thus giving better protection. I have a container of pure Tung oil that I have been using for years (its almost empty now), squeezing the metal as the oil gets used up so that there is as little air in contact with the oil as possible. If I do not open the bottle for 4-5 weeks, it is then very difficult as the oil in the cap polymerises and solidifies. Opening the bottle earlier is fine so really it takes many weeks for a full cure. Tung oil finish takes a very long time as many thin coats needs to be applied, waiting a few days in between for some degree of cure to happen. I remember reading that in ancient China it could take a year for a Tung oil finished table to be ready. There is also polymerised Tung oil I think that cures much faster, the equivalent of boiled linseed oil. My 2 cents!

-

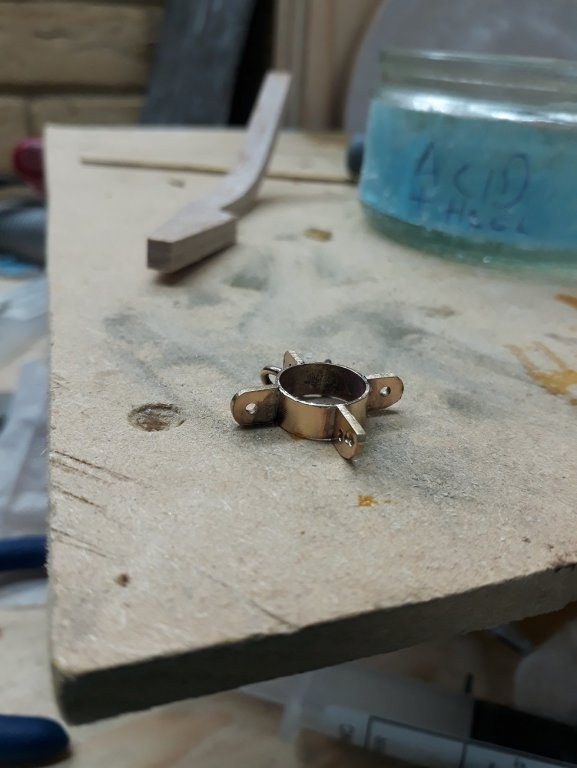

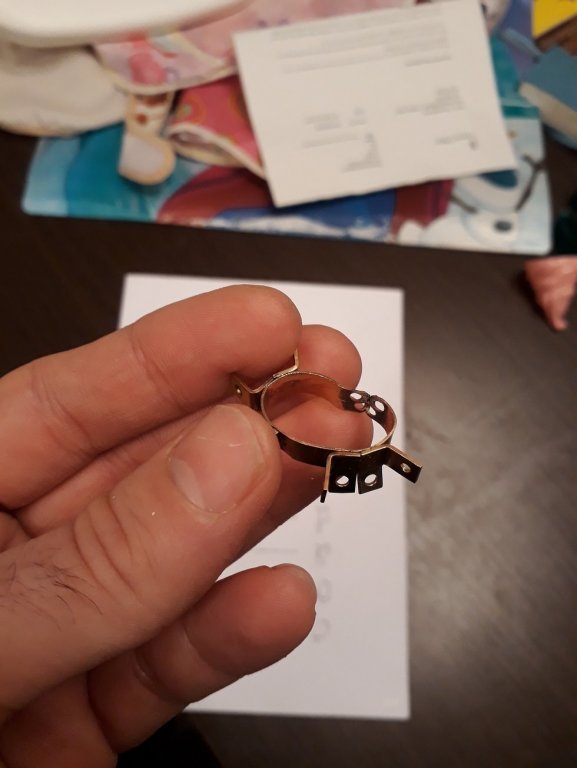

Keith, Druxey and Michael, many thanks I continued working on the hoops but also made the last brass band that will accept two shrouds on each side, the spreaders, the forestay and staysail and the throat halyard. It took a few hours to make and while I was polishing it, it got picked up by the steel brush wheel and ruined. So I started again. This time it took much less time and actually I think it looks better The spreader is the correct length to sit at the proper angle, the top shroud will be at a 15 degrees angle to the mast. The shape looks a bit wrong though, not sure if I need to reduce the thickness or just to round the edges.

-

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)

How to make pintles and braces from brass

vaddoc replied to woodeater's topic in Metal Work, Soldering and Metal Fittings

I have made many thousands of tree nails with the needle method in various sizes, my current 1:10 boat is held together almost exclusively by tree nails. I was using mostly cherry but recently the whole process start failing as the needle was burning the wood. Only by touching the needle with soap I could get it to work but this slowed down things. No problem with softwoods. What wood are you using? regards Vaddoc -

Steer clear away of walnut. Maple is fantastic for planking, cherry and pear are far more stiff and do not respond as well to bending. Maple sands very well, holds nails, glues well and is soft enough to cut with a knife even at 2 mm thickness. Holds an edge well and can be very white with no/little grain Beech as another excellent wood if you don't mind the wood pattern. Never used castelo or holy. Vaddoc

-

Excellent topic choice Bob. I ve been wanting a set for some time now but as you say the proper ones seem to be made from Stardust and the cheap chinese or indian ones flooding the market are just too cheap. It would be excellent if someone had experience to share. I came across this that seems to be made in Germany and is still cheap but not the generic type. Quality unknown. https://www.reichelt.com/gb/en/screw-tap-set-m1-m2-5-30-pieces-donau-mgs1025-p214261.html?&trstct=pos_1

-

Welcome David!

-

I think they were 0.5 mm x 4 mm Keith. I actually passed the hoops through the disc sander to reduce the height to half. Birch, beech or maple would be better choices though.

-

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)

Warped frames

vaddoc replied to jdbondy's topic in Building, Framing, Planking and plating a ships hull and deck

Soak the wood and then compress between two flat surfaces with a significant weight on top as it will be distributed across a large area. It will flatten a bit but not all the way. I ve found that for such purposes, it is better to laminate the sheets that the frames will be cut from. Lamination gives very strong, very flat sheets that resist movement. It is impossible to find flat plywood in the thicknesses we use. If I need a 3.5 mm sheet, I laminate 2 sheets of 1.5 mm each using finishing epoxy resin. I have a whole box of 2 mm maple sheets that I received dead flat and a year later are horribly twisted. I suspect improperly seasoned/kiln dried wood. Regards Vaddoc -

No worries Mark, "happily busy", what a lovely word combination. Druxey, a small advantage of walnut is that it is soft and sands easily. I finished the 4 hoops I glued yesterday. They are very strong. I sanded all surfaces to 400 grit (took a while...) but I think they came out alright. Tung oil really brought out the beauty of the wood. Next I need to research how to define the number of hoops needed for a given mast length. Regards Vaddoc

-

This actually would explain Patrick's detailed knowledge of the interior of these boats!

-

Thank you all for your likes and comments. Carl, this simple jig worked amazingly well. No failures and all hoops came out identical, very quick process too. Druxey, never though of it. However terrible though, walnut finishes superbly. I think once sanded and with a coat of Tung oil on, the hoops will look good and they will be very sturdy as well. Mark, I am a seasoned landsman so I am really struggling with the rigging. My source of info are actually logs like yours, a few sketches from various versions of Debens, a you tube video of a vessel built at Whisstock yard, a couple of books and of course the all-knowing internet. I have no rigging plan or deck plan. I actually had to measure the various lengths of spars on the screen and scale up! It seems though that Whistock yard liked the backstays to end up lower on the mast. Have a look at these photos: Deben 5 sketch Snapshot of top mast from the you tube boat Now you can understand my decision to go for dramatic rather than accurate. 😁 Although I think in the end I wont be far off. It does look however that the Deben carries quite a lot of sail for its size. But then again, all gaff boats seem to have powerful sails eitherway Vaddoc

-

A month has passed and time for another post. Many thanks Patrick, I am actually quite excited with the ability to make metal objects. This post will actually be silver solder heavy! I had very little free time and a large part of it was occupied making nursery projects with my 4 year old daughter. I made Goldilocks, a bear, space rockets out of plaster, paper owls etc. All pretty over-engineered of course, the teachers at the nursery could never have guessed how many tools and what variety of materials was actually used...Great fun! Back to the boat, I did a lot of thinking and web research and read a bit more of my gaff rigging books. I now have a less vague idea of the rigging. I also cleared the topsail issue, which will be rigged in an unusual way. The boat naturally will be very over-rigged, the more ropes the better! I varnished the tabernacle and used enamel varnish. I had forgotten how good enamels are. Very hard, excellent coverage, maybe I should switch back. I then spent all of my time making the brass fittings for the mast. I first started making the gooseneck: Later on however I scrapped these and made them again. I then made the first mast band This however had to be scrapped as well as I had not understood the rigging well. following this I made a detailed plan of the rigging and re-measured everything. I then made the band that goes at the top of the mast, it will accept the top shrouds, forestay, (?flying) jib and topsail halyard. I have also perfected my technique for making shackles and every now and again, just for variety, I make one in various sizes. These need to be polished. Some of the metal work appears in this photo, many more will need to be made. I also did some work on the bowsprit With the above under way, I though I would start making the mast hoops. Unfortunately, the only thin strips I have are walnut, which is a horrible wood to use for modelling. I really don't want to buy more wood though so I I gave it a try. The mast is 16 mm diameter so the hoops should be 20mm. I made a disc from some plywood and cut a notch. Then I soaked the walnut strip in water and used my mother's old hair thingy. Walnut wood is an unpleasant wood for this purpose, it breaks, has a wavy interlocked grain, terrible. I wish I had some beech. In any case, I wrapped the strip around the plywood disc and used PVA to laminate it. A screw holds everything in place and will be filled later on with a tree nail. Tons more work to be done but I feel a little bit more confident now Regards Vaddoc

-

Just found time to check things out Patrick. Lovely work, I particularly liked the fleet photo, a few years of hard work and dedication within a square foot or so. But...where is the gold paint? Cheers Vaddoc

-

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)

Greetings from sunny San Diego! (couldn't resist)

vaddoc replied to AlanZL1's topic in New member Introductions

Welcome Alan! I visited San Diego a few years back, absolutely loved it. Do start a log, good fun as well! Regards Vaddoc

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.png.58fa352c0537048dc6fc97829e750f4a.png)

_LI.jpg.d2fff2a951a051aa897acf7f7121de49.jpg)