-

Posts

1,284 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bedford

-

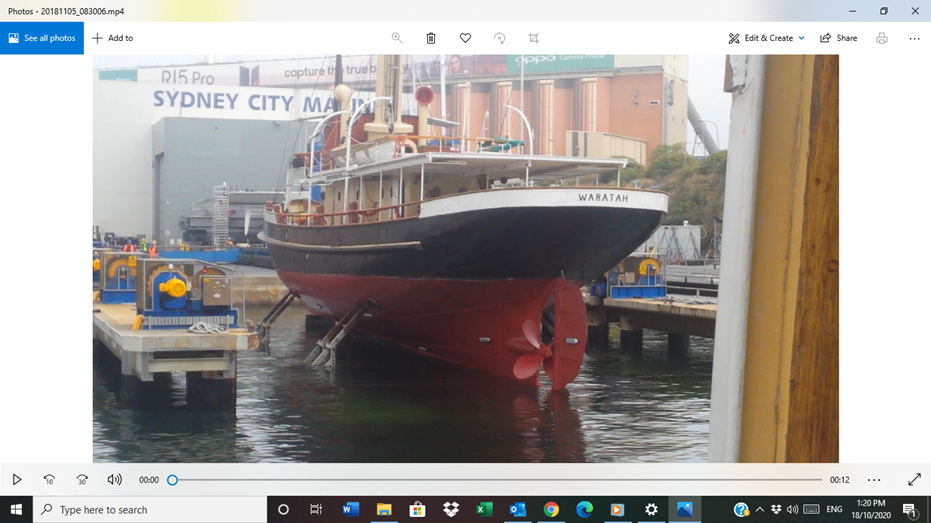

As a deckie who has used the davit system for lowering/raising such an anchor I would suggest the aft position is due to the stays. It would be extremely difficult to raise the anchor inside them especially with any kind of rocking. The process is to lower the anchor on the falls while taking in chain with the windlass until the anchor is hanging on the chain just below the hawse pipe. The falls are then detached and the anchor lowered. The retrieval operation is the opposite. That being the case the falls must have quite a length of line to reach that far forward. It's interesting to note that the falls are not stowed attached to the lifting eye on the anchor shaft, rather to an eye on the pin rail. On Waratah it's not as pretty but the falls are stowed hooked to the lifting strap on the anchor.

-

I think you'll find there are two types of electrician, the one who takes pride in a job well done and the one who just slaps it together the easiest way he can. I think we can tell which did that wiring job. I have the same problem on S.T. Waratah, a lot of the wiring has been done by the latter type and I am slowly trying to improve it.

-

Beautiful work as usual Eberhard. The photo of the aft deck / helm station shows beautiful work by the ship builders too, from a time when even a war ship was beautifully made.

-

I can chime in on the coal port question as well, given my work on Waratah. She has a main coal hatch on the deck forward of the wheelhouse which is about 3 x 6 feet but also has side bunkers which have round hatches of approx 20 inch diameter at a guess. These hatches have surrounds of about 4 inches in width so the overall diameter is in the order of 28 inches. I'd imagine that's about the right size for dumping a bag of coal into.

-

"Reasonably representing the real thing" he says while making the most beautifully detailed model!

-

Gary, I'm always glad to be of service be it confusing or not. The Waratah is great fun, just last weekend myself and the Commodore of the fleet gave her deck a salt water wash and scrub, oh the joy!

-

I'll answer your prop walk question, or confuse you. I crew a 1902 steam tug named Waratah, she has a right hand prop and the tow hook wasn't generally used because they had been deemed dangerous so a line was made off to the port towing bollard and the wear from the towlines is very evident. The reason the port bollard (which is mounted directly behind the cream coloured superstructure and about 1mtr off centre) was used is because the prop walk wanted to turn the boat to stbd and the tow line to port helped correct it. When coming into our berth if the master orders the engine go astern the stern starts walking out to port straight away. This all seems somewhat contradictory because you'd expect her to turn one way going ahead and the opposite going astern and to confuse you further, when going ahead without towing she tends to want to go to port and she needs about 3 degress of stbd rudder but that may just be because the indicator isn't calibrated properly. I wonder if when dragging the net they steer the boat to stbd to run a large sweeping circle?

-

Yeah I didn't think you'd make a mistake like that but thought it should be pointed out just in case. There are people who really can't get their heads around gears and the like.

-

Beautiful work Valeriy but unless I'm missing something it appears that one of the "V" cut gears needs to be turned the other way, those teeth won't mesh like that.

-

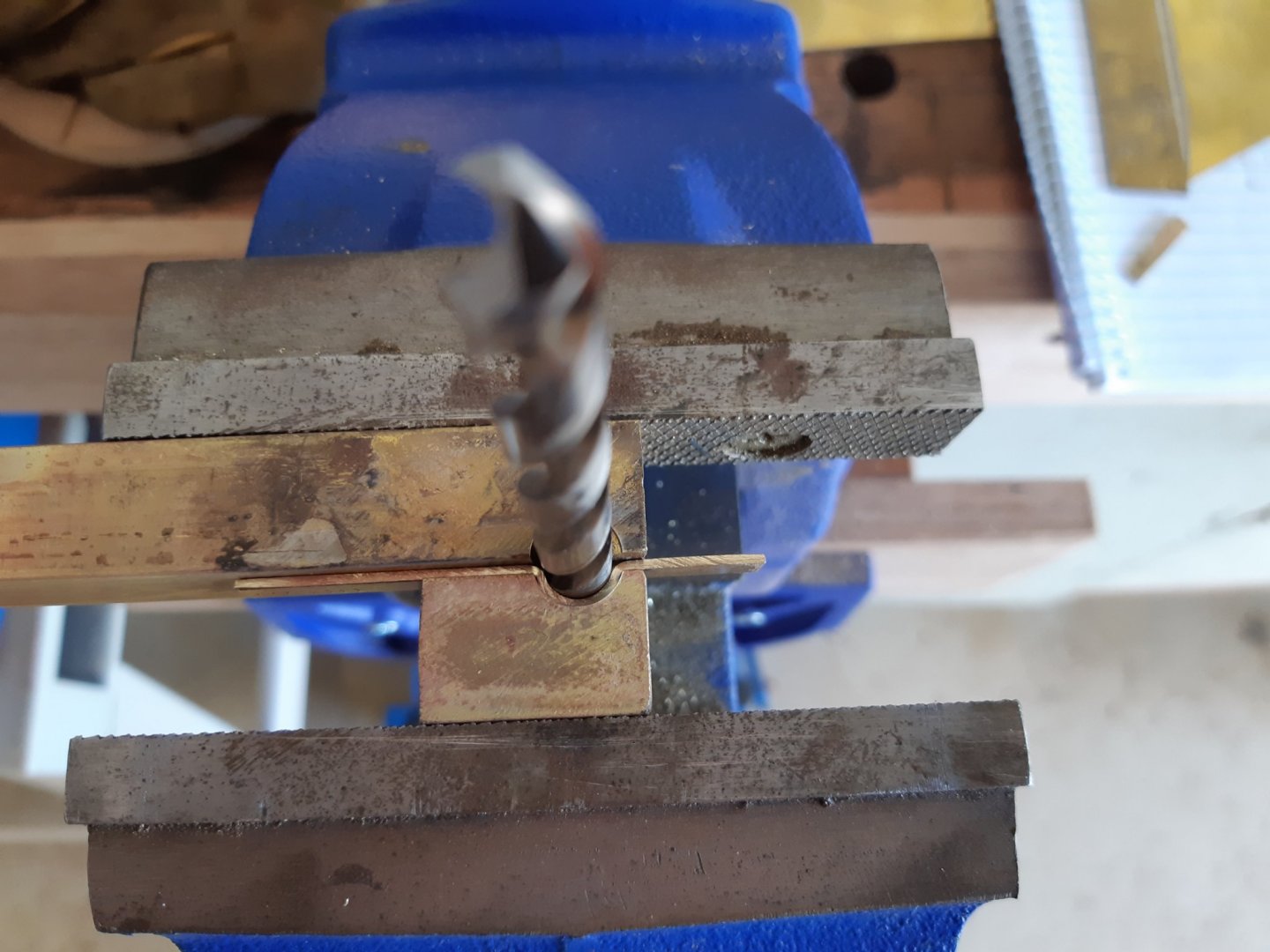

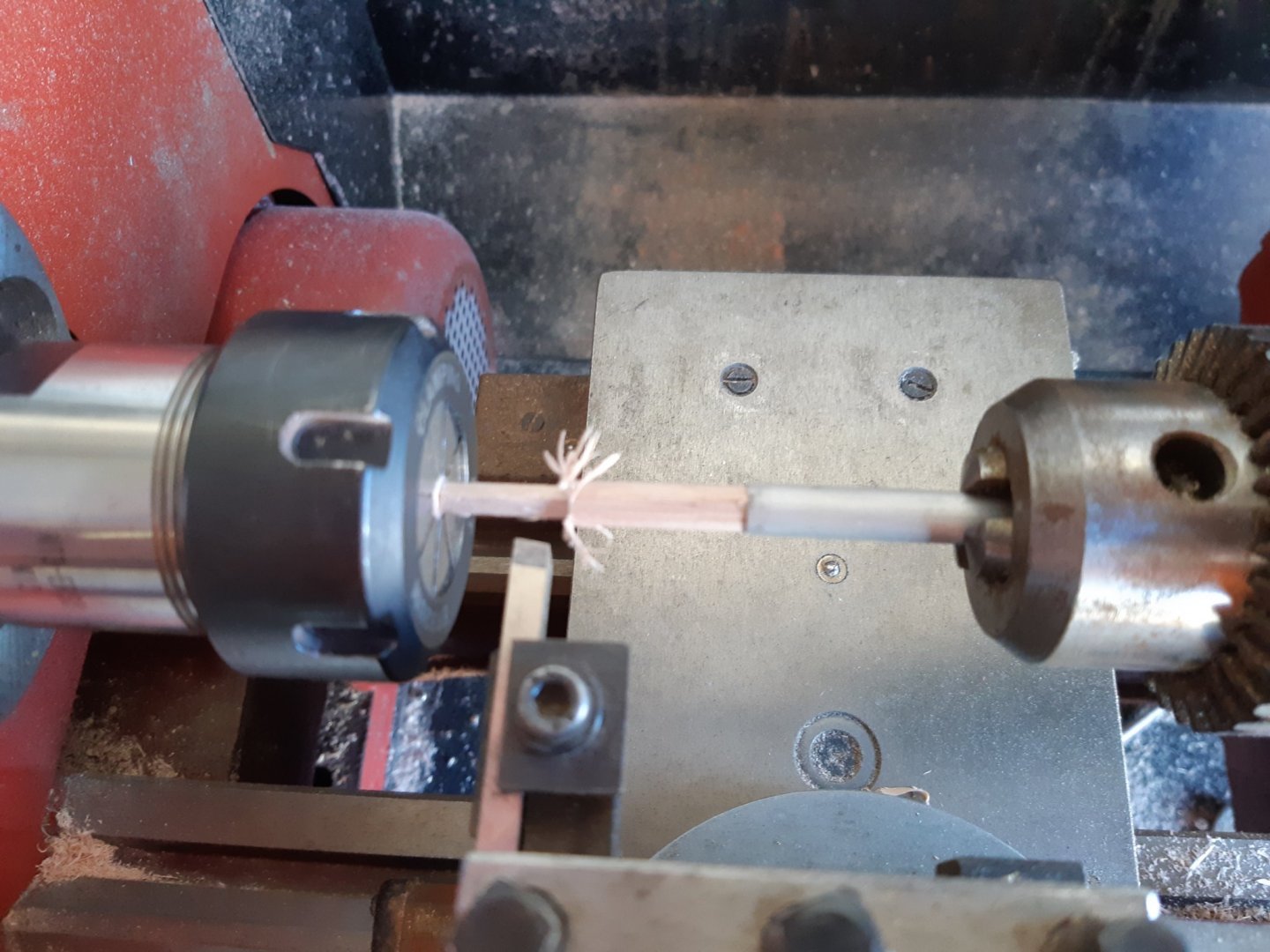

In the last pic above you can see two brass studs with conical heads. I have used these throughout the build and they are the small brass nails that come with ship kits. The heads on them are awful so I have reduced them in size and centered the heads by turning the angle into them. To do this in my lathe was difficult because even the jacobs chuck that fits the headstock would not hold them. After I bought a set of ER32 collet blocks and chuck I still couldn't hold them because they are only 0.87mm but I remembered a cheap old dremel knock off I had and the collet chuck was very easy to remove so it is now in the lathe tool kit and does a great job.

-

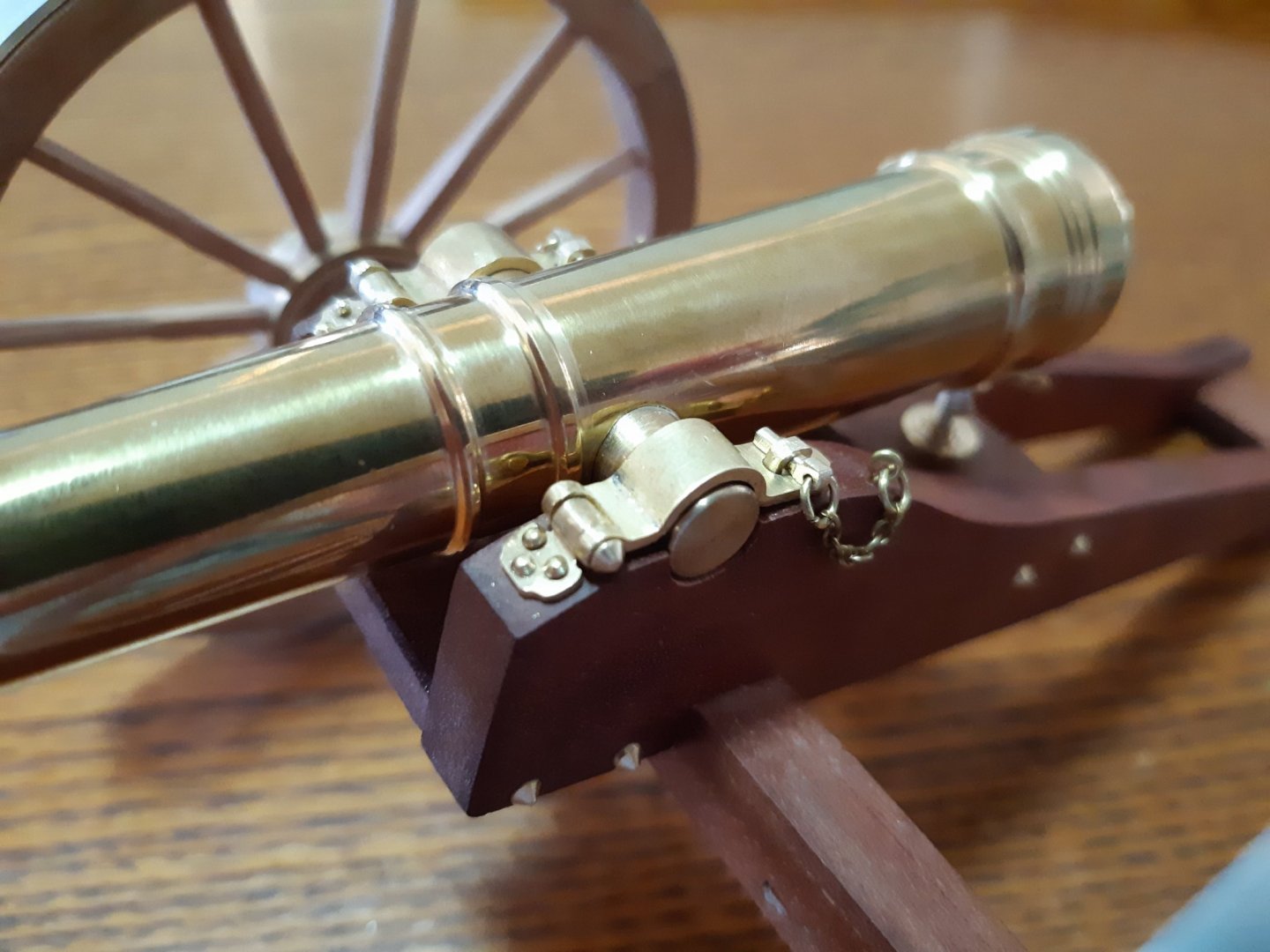

How about some trunnion clamps for want of a better word. I clamped two pieces of brass together in the mill vice, drilled through on centre, separated them and used them as press molds to shape the clamps before bending the brass around to form the hinge. I then filled the rolled brass hinge section with solder before running a drill through it to get a nice round body for the hinge pin. The fixed part of the hinge was milled from bar stock and drilled before being cut off with a slitting saw.

-

15' Dinghy by Bedford - FINISHED - 1:1 scale

Bedford replied to Bedford's topic in Non-ship/categorised builds

Thanks Popeye -

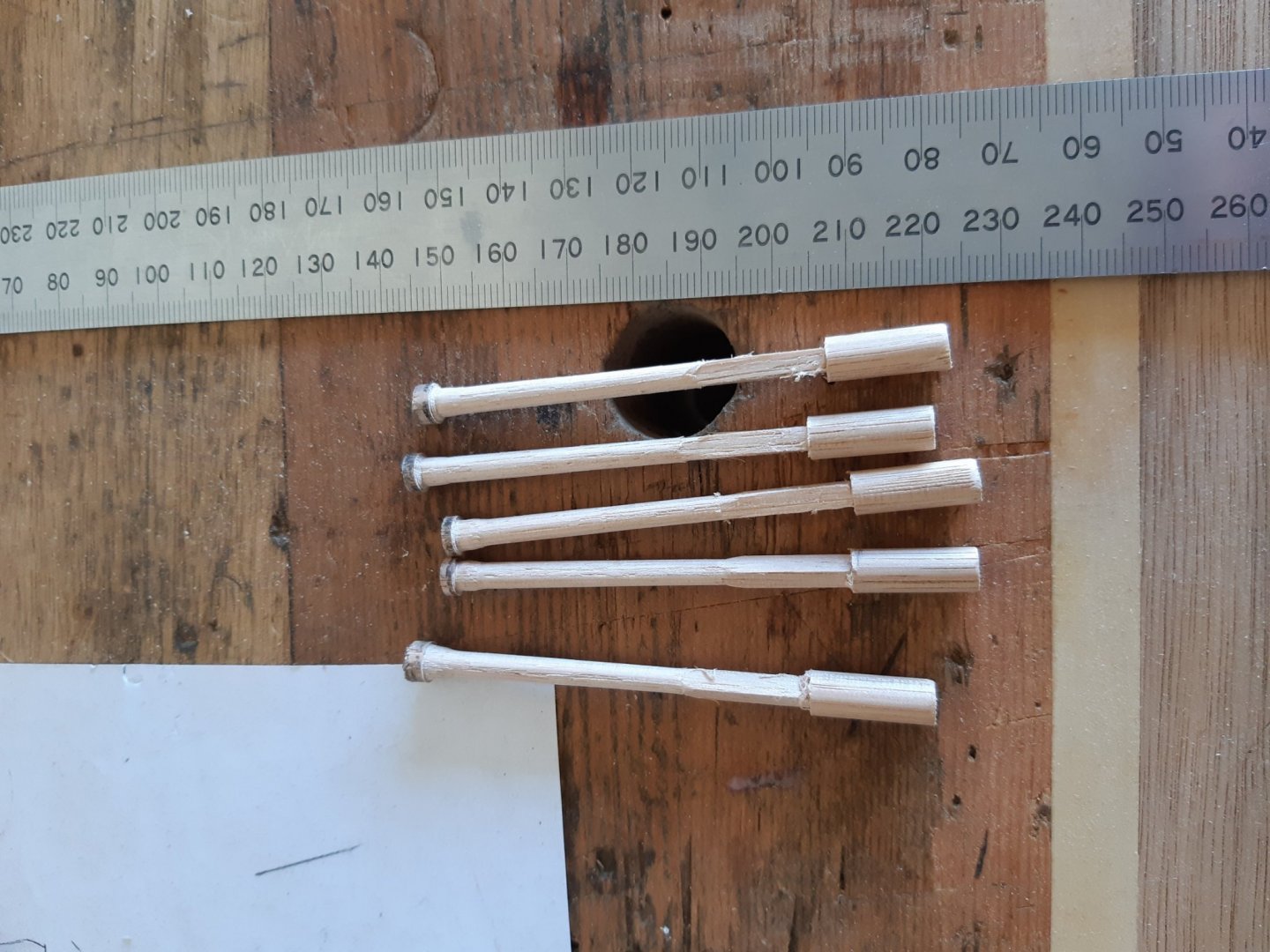

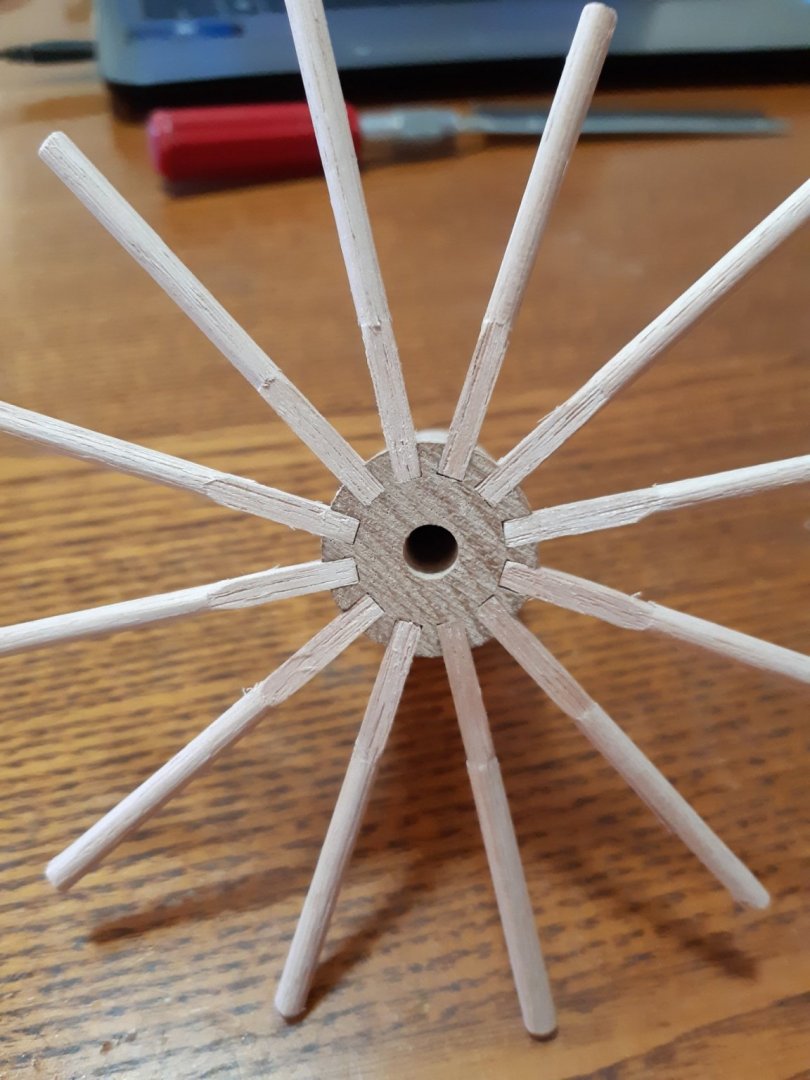

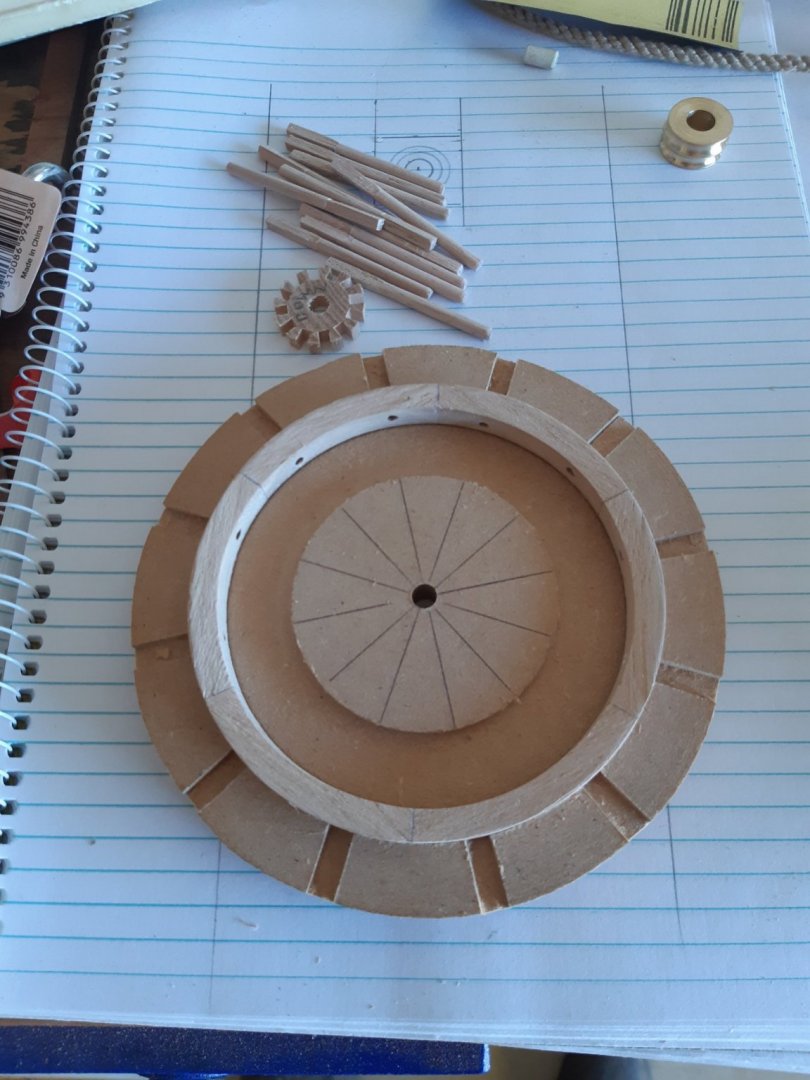

Then the hub and spokes, the hub was done in much the same way as the rims but instead of drilling holes I milled slots, again the resetting to allow the second set of cuts required a lot of measuring, checking and re-checking. The spokes where round stock (Tasmanian oak as with the rest of the wheel) which I set up in the square collet block to machine a 3mm square section before mounting in the lathe to round out the rest of the shaft. It was messy and Tas oak tends to splinter in the lathe so there where a few that ended up in the bin. The spokes are not glued to the rims or the hub. The built up body of the hub combined with the alluminium tyres hold it all together much like the real thing. On the subject of the tyres, I just happened to have a piece of alluminium stock that was just big enough to turn for the tyres at 110mm O.D. The tyres where heated in the oven to expand them prior to fitting. They are very tight on the rims and no glue was used.

-

Next came the wheels, these are the tricky bits. First glue up a hex drum with a dowel centre that can be held in collets to allow all the processes required. Turn it to a nice round shape deep enough to cut two rims from then remount in the hex collet block and drill 2 rows of 6 spoke holes before resetting in the collet block to allow drilling of the next set of holes. This took a lot of fine measuring to get right. As a result the wheels have 12 spokes.

-

15' Dinghy by Bedford - FINISHED - 1:1 scale

Bedford replied to Bedford's topic in Non-ship/categorised builds

Well I tell you what Eberhard, if you ever drop in for a scotch I'll take you rowing or sailing depending on the weather

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.