-

Posts

12,097 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Old Collingwood

-

Evening all back on with the pearl today, I finished off fitting the top foremast shrouds., then I lashed them around the top to secure them - they still need thier ratlines. I then decided to make the foremast lower spar - this is going to be wood made from dowel (the same with all the spars) first I used the pre-molded spar/sail as a template and cut the dowel to the correct length, then I marked each side of the dead center where the taper will start - I then used a combination of my curved scraping tool and sanding stick to shape each end - slighty time consuming and tedious, but I think I achieved the result - then I drilled the linking hole in the dead center and then fitted the two lift blocks at each end. It will be painted/weathered then glued in place and lashed around the foremast. Just the one pic showing he spar/blocks. OC.

-

Evening/morning all, thought I better sign in I havn't left the country - just been a wee bit distracted elswhere, I will be back on the pearl faster than you can say - Supercalifragilisticexpialodocious. OC.

-

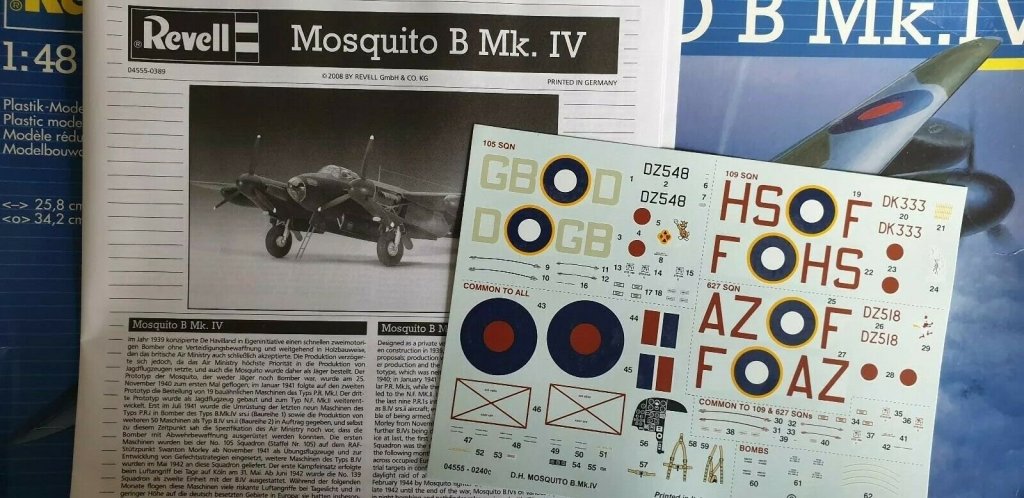

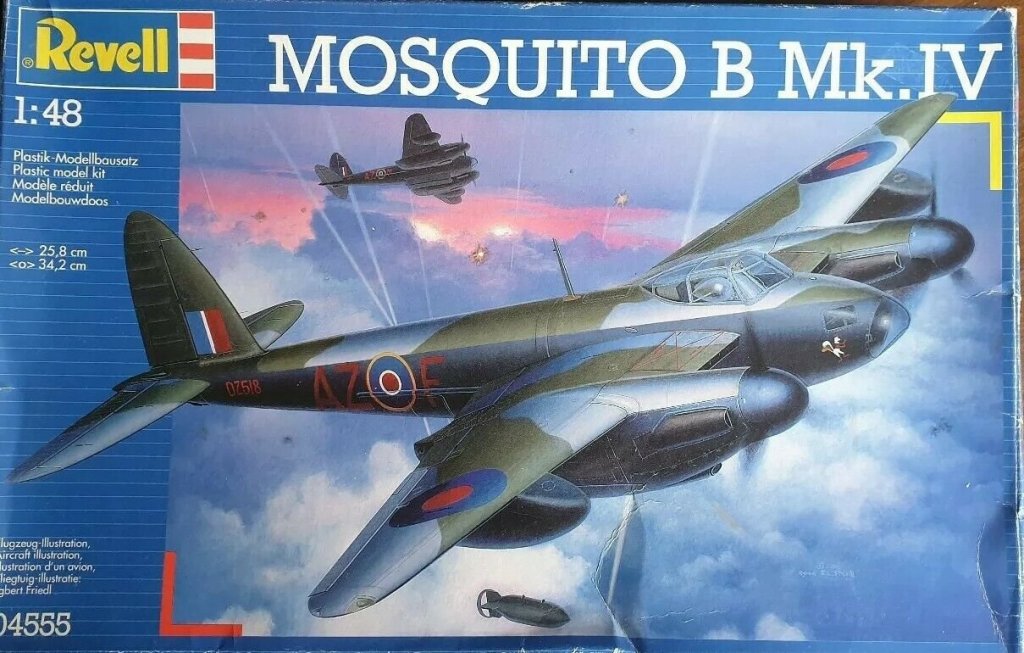

Thank you kindly denis, I have to finish the pearl first but after that - I will make a start, I will deffo spray paint it though with rattle cans as I dont think hand painting with a furry stick will do the fine detail justice - there are some very fine panel lines and rivet detail on the kit, I have read up on a few reviews and its a very fine kit. OC.

-

I have been given this (waiting for it to arrive) as thanks for some online help with an associate, just a little bit of background - in the period of 1942 - 1945 my late farther worked on many aircraft types - Spitfire/Hurricane/Seafire/Mosquito/Wellington/Lancaster and Short Stirling as an airframes fitter. So you can imagine my utter delight when I was told about being given this that I will be able to build in memory of my farther. OC.

-

Why not wrap it around some thin wood dowel the right thickness - but then leave the dowel inplace but not all the way to the ends, would be stronger and keep its shape. OC.

-

Amazing work - Just amazing - words escape me, you must feel proud. OC.

- 41 replies

-

- artesania latina

- hms victory

-

(and 1 more)

Tagged with:

-

Evenng all, more work on the foremast - I completed the futtock shrouds, then started work on the upper mast shrouds - so far two completed on the one side. OC.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.