-

Posts

1,217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gahm

-

You are on your way to another great model, Bob! As Martin already mentioned the contrast between the light boxwood, the black trim and the copper bottom looks VERY good! Thomas

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you so much Carl and Dirk! And thanks for all the likes. - Carl, you are right, it takes a bit of patience to get all these hammocks done. But it is good practice for other repetitive tasks such as the ratlines - Dirk, complaints need to go to Jesse . . . he started this Thomas -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

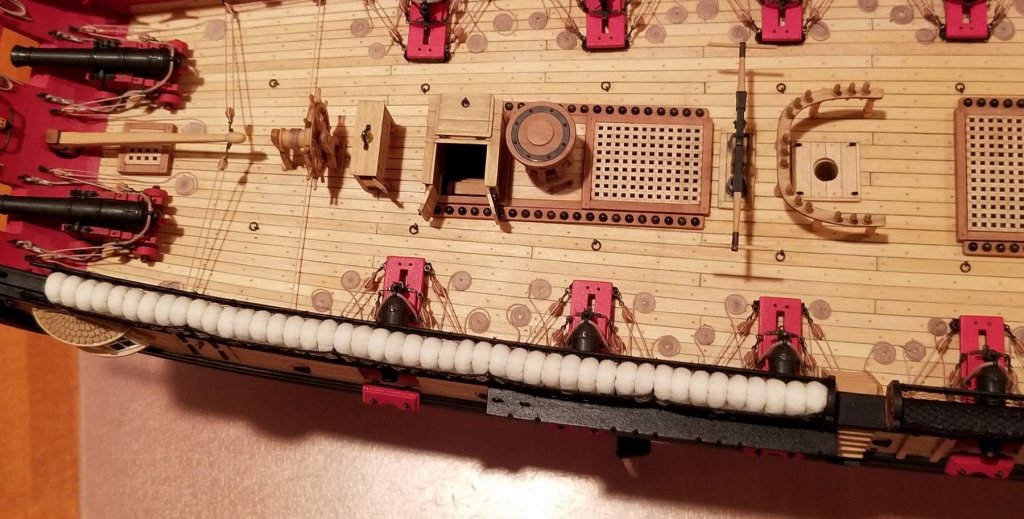

Before continuing with the remaining hammock nettings I wanted to make sure I had a good handle on the hammocks themselves. Building an acceptable representation of a hammock at the Syren scale of 1:64 turned out to be a real challenge. One of the major problems was that all the fabrics I could think of did not scale well at 1:64. The fabric texture was always far too coarse. So after some experimentation I settled for the process documented in images 1 – 4. First I cut a ‘kernel’ of 19mm length for the hammock from a 0.063” Syren rope. Both ends of the kernel were hardened with CA glue. The kernel serves two purposes: It helps to reproducibly determine the length of the hammock, and it prevents the hammock from ‘collapsing’ and flattening out when it is folded back to its final U-shape. The kernel was glued to the top end of a 30mm x 30mm eggshell colored Polyester fabric piece. I chose Polyester because of its super fine texture (which unfortunately was still too coarse to be used for the hammocks) and its high flexibility. This piece of fabric was roughly cut to the width of the kernel, wrapped around the kernel, the roll secured with CA glue, and both ends of the roll cut back precisely to the CA hardened kernel ends (img 1). To diminish the fabric texture I glued this roll to the top of a 30mm x 40mm (width x length) piece of very thin silkspan, wrapped the silkspan around the fabric roll, and secured both ends with 2 metal clips (img 2). These metal clips were then mounted in 2 vices and the hammock roll thoroughly soaked with water. Contrary to regular paper silkspan can be nicely processed when wet and it turns pretty translucent, which again allows to see the fabric roll and with that to have a reproducible measure for the length of the final hammock (img 3). The hammock was then formed by tying 7 double overhand knots (2 at the ends and five at equidistant intervals) using an eggshell colored 100wt silk thread, securing the ends of the roll with CA, cutting them to their final shape, folding the finished hammock in the middle to it its U-shape, and gluing both halves together with CA (img 4). Img 5 shows all the material needed to build enough hammocks to fill the first rack. Once all hammocks for one rack were made they needed to be arranged in the rack for the best overall impression. At that point the silkspan surface still showed a lot of individual fibers, which gave an undesirable ‘hairy’ impression. To change this into a smooth surface and to fix the whole arrangement in place all hammocks received a final treatment with a thin solution of white glue. The result is shown in images 6 – 10. Thomas Image 1 Image 2 Image 3 Image 4 Image 5 Image 6 Image 7 Image 8 Image 9 Image 10 -

The center line of your deck looks really nice! Well done! Thomas

- 550 replies

-

- confederacy

- model shipways

-

(and 1 more)

Tagged with:

-

Very well done, Bob! Without your description I never would have guessed that the plates are inscribed. As usual I just was blown away by the speed of your progress! Thomas

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

Great progress, Bob! And beautifully executed. It is always amazing to me to see how the looks of a hull changes as soon as black as a 'contrasting' color is applied. Thomas

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you so much everybody! These are REALLY nice comments! And of course they are highly appreciated. Thank you also for all the likes! Dirk, if you build enough spaceships, houses and fleets I may at some day catch up with your Syren . At least I will try . . . -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

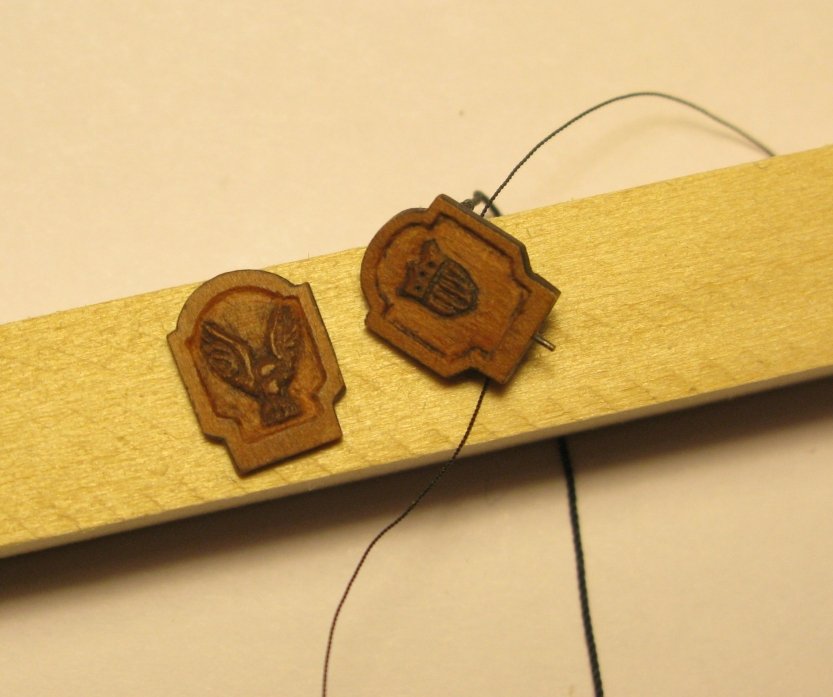

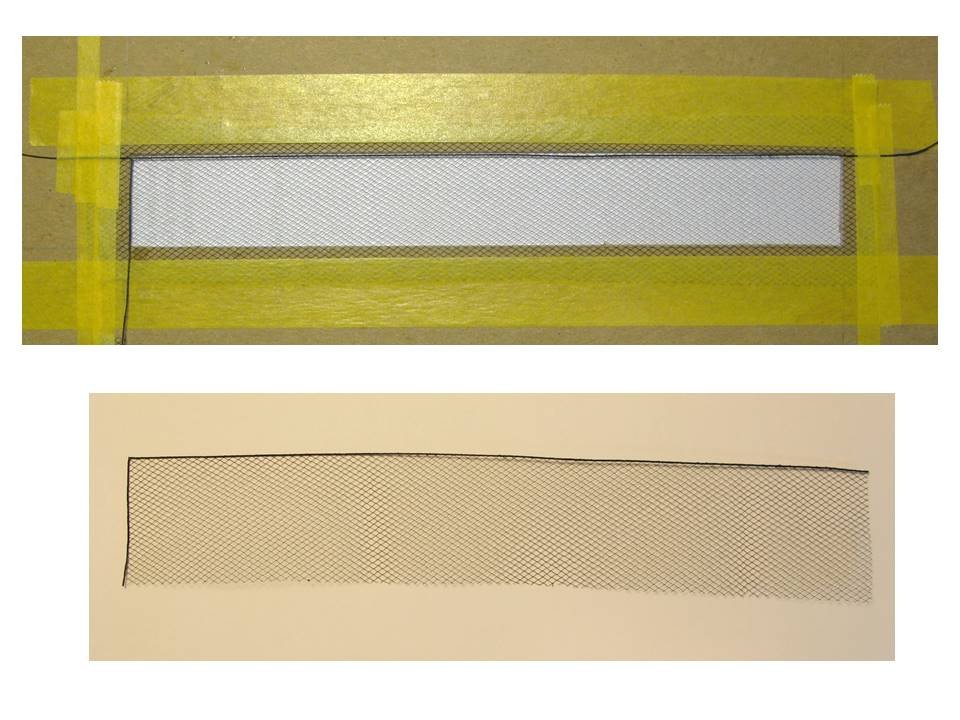

I started work on the hammock nettings. I changed the boarding panels so that the wooden rail could be attached to the back of the panels and not to the side. I also added a little ornamentation to the panels (img 1). I used the hammock cranes from the kit, thinned them down and mounted the whole arrangement as described by Chuck in the kit instructions (imgs 2 and 3). The netting itself was framed with a rope on 2 sides to give it a clear delineation against the wooden rail and the boarding panel side (img 4). Framing only 2 sides allows for easy fine adjustment of the final width and length of the netting when mounting it on the hammock cranes. The ‘unframed’ sides are then attached via black 100wt silk thread and CA glue to the rope which spans from the boarding panel to the last hammock crane. The last hammock crane is also used to attach the ‘unframed’ end of the netting. Images 5 – 10 show different states of the process. Thomas Image 1 Image 2 Image 3 Image 4 Image 5 Image 6 Image 7 Image 8 Image 9 Image 10 -

Bob, your deck looks great . . . clean and crisp as ever. No need to worry about your outstanding craftsmanship. I am sorry to hear about you having health problems. I hope you get over them quickly and continue with the expansion of your model fleet Thomas

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

Your planking looks REALLY good, BE! Watching this I would love to do a planking job myself right now . . . but I am stuck with hammocks Thomas

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautifully done, Bob! Thomas

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Gahm replied to albert's topic in - Build logs for subjects built 1751 - 1800

Albert, I think the question was asked before: how do you achieve such smooth surfaces with your carvings? They can't get better than this! Thomas -

Clean and precise planking job - very well done B.E.! Thomas

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Gahm replied to albert's topic in - Build logs for subjects built 1751 - 1800

Fantastic! Thomas -

This is an interesting way of doing the gun ports. But they turned out very good! Thomas

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.