-

Posts

2,592 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

Good morning Druxey,

That's no everyday regular eraser... that's left over from my pencil draughting days !!!

Rubber cement was used a lot before cut and paste commands on a computer and these erases did the trick... but we had no idea there was a special rubber cement eraser. I'll have to look into it.

My darling wife brought up a good point last night... I should do a quick test on scrap to see if after erasing the rubber cement it has not leached into the wood so as to affect any finishing.

Regarding the tissue paper... I read somewhere that it should be soaked first, Of course I cannot find that now. I admit I went downstairs and took a look at the assembly and thought about taking it apart after having read your e-mail. I haven't got the heart to attempt to do that. So as much as I unbelievably hate the phrase ... "it is what it is" (I have to go kick myself now ... damn I hate it)

I only used the gorilla glue on the copper wire. Everything else is and will be yellow carpenters glue.

I believe the 22 ga copper wire may be a waste of time in most places.

Roughing up the monofilament line grabs and seems to carry the glue into the hole.

This seems better to me.

Presently looking at cutting and placing the rising wood and false keel

I will use the copper wire for the staples securing the sides of the false keel

I also have to make my jigs to hold the stem and stern post secure and perpendicular to the table.

Alan

-

Good evening Mark!

I have not read The Billy Ruffian by David Cordingly.

I do have and did read HMS Bellerophon by Colin Pengelly.

I guess I have another book to buy!

Thanks.

Alan

-

Started gluing parts together today

The remnants of the rubber cement were removed by simply erasing the surface….

… and there were paper thin feathered edges from my sander that need to removed by lightly sanded by hand.

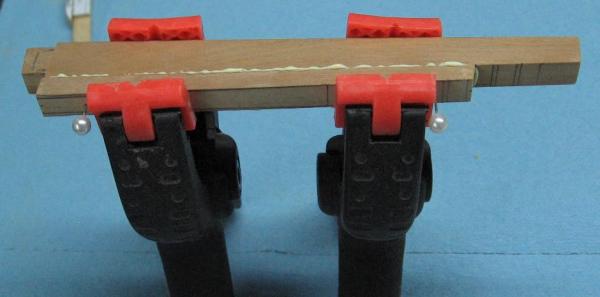

First piece glued was the Stern Post to the Inner Post.

Here are the before and after cleaning pics.

I did drill and pin them to assist in alignment. You can see the ball head of the straight pins.

The pencil lines are to help me with shaping later on.

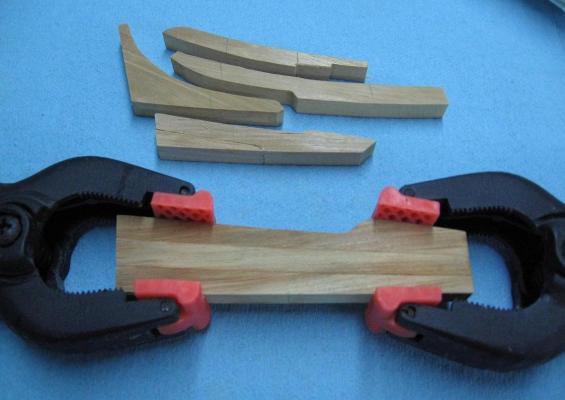

The stern deadwood was assembled piece by piece, clamping up and letting them set before attaching the next piece. This is where my marble pastry rolling slab came in handy. I set the assembly down onto the slab to assure the surfaces were flush when assembled.

I did insert two pieces of copper wire into the stern post assembly to assist in keeping it together. Not sure it was necessary nor that the Gorilla Glue got in deep enough. I tried working the wire in and out but I did not see any glue at the far end. I had to strip the insulation of the telephone wire and then roll the copper wire straight. 22 gauge wire is quite flimsy stuff and easily bent.

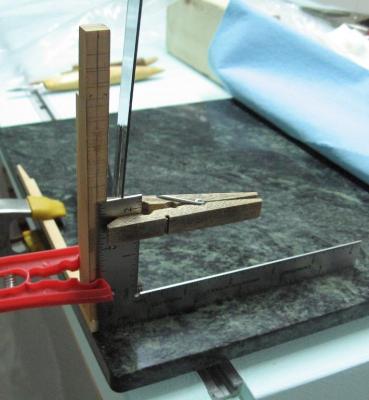

I cut the mortise and tennon joint in the Stern Post and Keel then assembled them. Clamping up the tapered stern post to the proper angle was a bit of a challenge. I ended up using a few different tools and good old fashion clothes pins.

The Stem to Keel boxing joint was eventually glued up and set properly. I did attempt to use the black tissue paper as you can see by the staining on the wood but had no success. I determined it was more trouble than it was worth. I first soaked the paper in a 50/50 water glue mix and after numerous tries place it on the joint surfaces. Quite a few pieces tore apart in my fingers/tweezers. When I finally got around to attempting to put the keel and stem together the paper scrunched up on me. I took it apart and tried again with new pieces… then had more of the same trouble. After two more attempts I said to myself “screw it”.

I also glued up the remaining sections of the keel; clamping them to the marble pastry slab and setting them against a straight edge…. sans tissue paper.

-

Good morning world.

Itching to get started this morning but cannot make noise while the better half sleeps.

Today I bite the bullet and begin drilling, pinning and gluing.

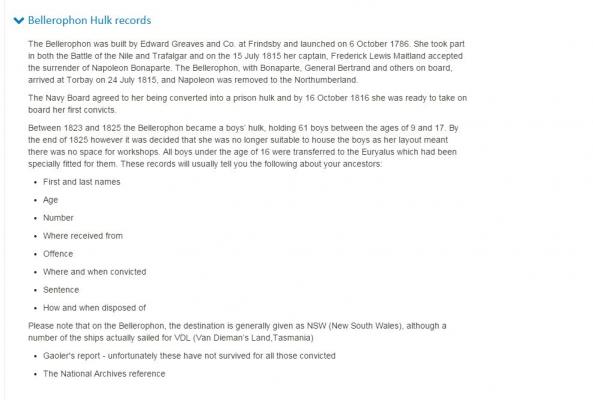

My darling wife (the super sleuth) made a discover yesterday while working on her geology hobby tracing her and my family.

Seems one of my Irish ancestors (James Flynn) was sentenced to serve his term on a prison hulk.

While searching for him she stumbled on a 7 year old boy (William Flynn... no known relation) serving his sentence on HMS Bellerophon.

In her end years the Bellerophon (later renamed Captivity) was used to hold young boys as prisoners!

I always imagined these were military prisons, holding AWOL and mutineer sailors and such... was I wrong or what.

The attached reads 9 to 17 year old boys but William was 7 and he was recorded as having been there once before!!!

-

-

Pssst... 45 is no where near old!

- mtaylor, indiesteve, Canute and 1 other

-

4

4

-

Good evening Mark.

I read your comment earlier today and of course it made a huge impression on me.

But now after some hours it seems like a challenge .... if only I had the talent!

On another more achievable note...

After considerable calling around I found a local source of 22 gauge solid copper wire (if I should chose to use it).

The only source is indoor telephone cable

I bought 12 feet at 20 cents a foot (= $2.40)

It is four strand so I have 48 feet in total.

A co-worker caught me checking the diameter with my vernier and asked what it was for.

After I told him he remarked that I should have talked to him as he has coils of it at home!

Isn't that the way it goes.... I could have bought a double-double with that money.

(I wonder how many are going to have to Google double-double?)

-

-

On a more serious note...

I have an old marble pastry rolling flat to use to keep items flat for assembly but hadn't thought to use it (or glass) for sanding

I have seen here on the forums (and so have used) nail file boards for sanding. That was handy and timely.

It is tough learning when to say "when" (to know when to stop sanding).

I've read where some use old fashion carbon paper slipped between pieces during dry fitting to mark / highlight the bumps to sand.

I have also found it is easier to stop early and dry fit pieces to check many times than it is to stop late and have a bad fit ... I have a good scrap collection started to prove it.

-

good start ... but now I am hungry!

-

Is it wrong to admit that I take great comfort in seeing the mistakes of more experienced modellers? (because I do)

It somehow makes them quite a bit more human... and so I move forward.

My son did indeed find thicker hemlock lath and brought it over last night so supplies are plentiful.

-

-

Thank you Druxey.

The long 's' and I are very good friendf prefently..

When I sat down to start I made a decision on exactly how I would approach it and I was committed to correct each long 's' and so I have.

Then there was 'rabbit' and 'fastned' and.... the list goes on.

I am very happy I have done this otherwise the darn contract would still be a myftery.

I found reading it was like reading The Last of the Mohicians... the longer I stuck with it the easier the language prose became.

I will admit to being a bit hesitant to start gluing and pining parts.... but I can see myself starting very soon... visualizing.

My son claims he found some thicker lath in his pile late yesterday so I will be remaking the parts I must in the knee of the head and stem pieces as I start gluing and pining them.

Thank you all for following... it's going to get scary really soon.

Alan

-

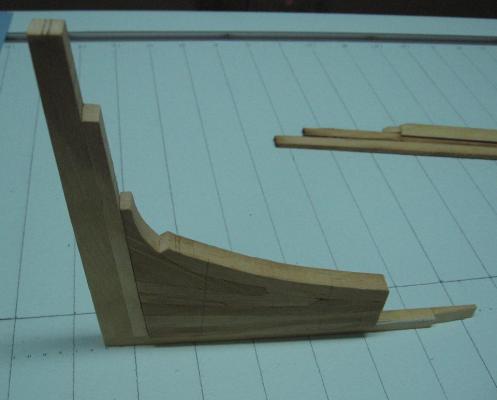

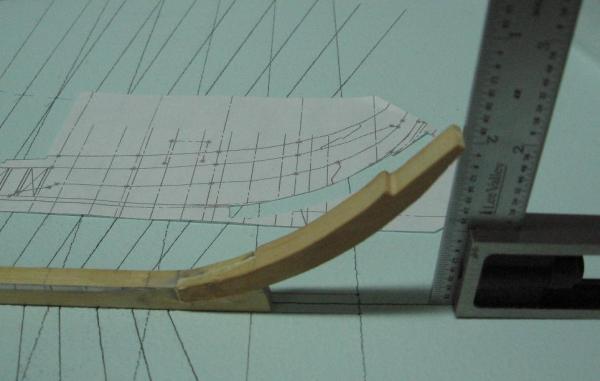

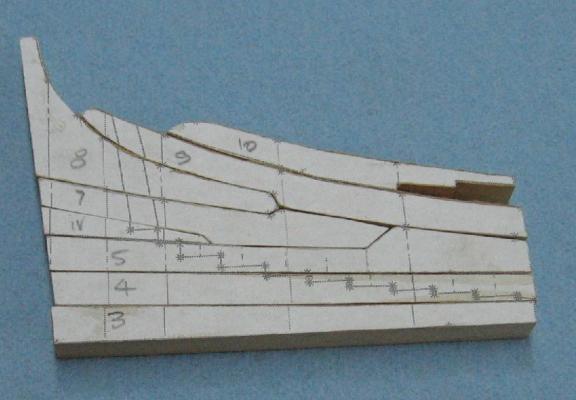

Today I cut and dry fitted the last two pieces of the stern deadwood and keelson (template items marked 9 and 10)

I also cut two strips 8" thick (1/8" to scale) x 22" wide (0.3438" to scale) for the rising wood that sits on top of the keel.

Actually my pieces are ever so slightly larger (approximately 0.01" in both thickness and width).

They would need to be cut to short lengths with scarph joints. I will not do that until I am ready to glue and pin it together on the keel assembly.

Today, I also remade my boxing joint piece. This would be the third time. I had trimmed too much on the upper scarph joint.

I have also been busy doing something very constructive over the last two weeks.

Never having been able to sit down and read nor understand the complete build contract I decided to transcribe it (type it out)... only the first 21 pages as the last few pages are payment schedule details that will not affect my build.

I've added some spelling corrections for today in brackets next to the questionable words; below each paragraph I've added explanations and descriptions for unknown words or phrases and I've added reference books, pages, image information so when I am at the point in the near/far future I can find it again quickly.

Presently I am transcribing page 20 of 21... this would be typed page 57 for me.

I've attached a PDF of the first 3 typed pages to give a better sense of what I mean.

-

Joshua

I typed in - Free Google E-Book and the following website popped up https://www.google.com/cse/home?cx=000661023013169144559:a1-kkiboeco

I typed in a book name I wanted (example: Anatomy of the ship Bellona) and there it was about third from the top listed as free and downloadable

Some books are not PDF but there are You Tube videos explaining how to convert the file to PDF

Some books are not free but they offer viewing of pages... when I stumble on some pages that are useful I take take a screen snapshot and save it for reference. If the whole book seems really good and no free e-book version is available I will try inter-library loan (books are loaned to individuals from libraries across the nation (not sure if you have this available with you library system). It may take a few weeks but then I can view the whole book and decide if I it is indeed that good and I should purchase a copy.

Presently the best real purchased books in my library are the 4 volume set of The Fully Framed Model. My copies are quite new but to look at them today you might think I've had them awhile.

Alan

-

Joshua

I am not quite as smart as I might seem with my response.

I am just beginning my first scratch build (in a very long time) and learnt the term myself not to long ago!

There are quite a few free Google e-books available (I've snagged a few) that have turned out to be real gems (for me).

Alan

-

-

People focus in on the strangest things, eh.

For me it is you neat

brassSTEEL right angle gauges!Coming along very nicely

(PS: looked like brass to me . Must be the lighting)

-

Good luck!

let us know how your test run goes.

Alan

-

Good morning Josua

I use Draftsight every day and the free version is quite good but not perfect.

I've been draughting in pencil since 1970 then switched to AutoCAD R12 in the early 90's, then Solidworks 3D and Inventor 3D.

Had to take courses for all of them to be productive.

Now as I said using Draftsight for straight 2D stuff.

There are many other free programs out there and you will hear the same about them.

I am sure some are better than others.

I'd suggest you upload them and try them out.

I imagine that if you have any level of experience in CAD draughting (drafting) you will be able to tell which you prefer fairly quick.

If this is your first attempt at drawing in 2D with a CAD program, it is easier then it might appear at first, you will need a good tutorial to learn the commands. Apparently draftsight offers them, I've never looked at them.

Alan

-

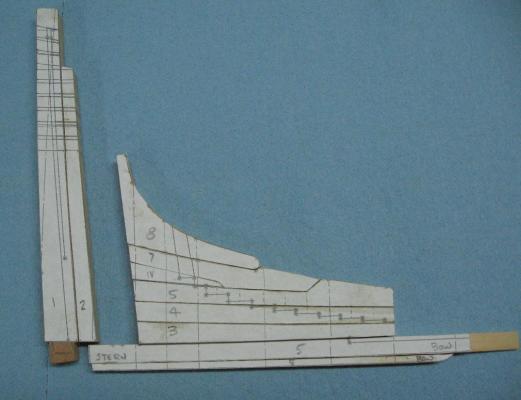

Below is the photo of last weekends Stern Post (1) and False Stern Post (2) along with the earlier Keel and False Keel

Today I made the Deadwood pieces and the Deadwood Knee (8) with one piece left to fit above it. Hope to have it done tomorrow.

You will note the one piece marked with the roman numeral (IV)... that's because I made this piece three times before it fit proper. That little wedge piece was a tough one to fit.

I've to remake the Keelson pieces... yet to make the Rising Wood.... and taking a good long look at the Stem assembly pieces which were the very first parts made.

I think I may take another shot at them as I've been doing a slightly better job lately. Milled down more hemlock lath but cannot seem to find another ceiling piece in the pile. Those are thicker (1/2") and will mill down to the necessary 26 inches (0.4063" to scale). Presently I am getting 24.8 inches (0.3875" thick). The ceiling pieces must be at the bottom of the pile, under the tarp, covered with snow in my son's yard.

Somehow I don't think 1-1/8" inches (0.0188" = 0.46 mm) will make much difference in the end, but it would be nice to be a wee bit closer. Possibly I can keep the inboard pieces. I'll have to sleep on it.

Oh yeah... the monofilament line came it and it looks good!

Have to keep reminding myself to slow down as I am itching to glue something together.

-

Found the following which may be of some value (2 selected pages in attached PDF) Officer's Wardroom accomodations

Bellona - Conway - Anatomy of the Ship - The 74-gun Ship.pdf

-

-

I just cut and sanded the stern post and false (inner) stern post.

Left some material at the bottom of the stern post for the tenon into the keel. The fit of these two pieces are perfect! (photos to be posted later)

I have not tapered them as yet.

I will wait until I have the stern post pieces together and then taper them as one.

The stern post assembly is 1'-11" square at the head down to the deck transom, and then tapers to 12-1/2" on the keel

The keel is 12-1/2" athwartships at the stern tapering from some "x" distance from the original 16" athwartships at midships.

As this is a mere 1-3/4 inches of tapering of the keel per side, which equals 0.027 inches at 1:64 scale I am not too worried about where to start any taper as no one will likely notice it.

Sea of Galilee boat by Wintergreen - FINISHED

in - Subjects built Up to and including 1500 AD

Posted

Just joined in... I like what I see... and I'm ready to learn,

Nice work!