-

Posts

2,875 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

Saturday 12 Nov 2016

Been away from it too long but feeling up to it again.

Today I fitted the chocks between the frames. Presently the glue is drying and setting.

Tomorrow I will drill and install the bolts and start on the next set of frames.

I chose to install the top most chock first to set the space properly.

Subsequent (lower) installations were a bit of a challenge as the more I installed the less I could pry the frame open to receive the chock.

Each was sanded down to fit snugly. I filed vertical grooves (pockets) into the chocks to hold the glue because most would be scraped away as the chock was slid into place.

The lowest ones were the worst as they were very thin. I wanted to installed one more lower as they should be in groups of three between joints but it was a bit too thin for me. I might try tomorrow when I'm fresh.

Presently the whole table is covered to keep the dust off over night. I do this after every session.

-

I can find nothing of the detail your asking for.

I have copies of standing rigging from here: http://www.modelexpo-online.com/images/docs/MS2260/MS2260-Syren-Instructions-Chapter-18.pdf

but it is American (US Brig Syren 1803) and somethings don't agree with other books I have.

You might like to review it just the same though.

Sorry I was of no help... and late to boot.

-

did you say you had Rigging Period Model Ships by Lennarth Petersson, Chatham Publishing, London, 2000, ISBN 1 86176 061 2 ?

-

That certainly looks like a solution.

I haven't had any luck finding it as yet amoungst my mess of data.... but I have learnt I need to organize it all better.

-

I may have something but it will take awhile to dig out as I am nowhere near this point in my build but have been collecting info for two years.

If someone beats me to it you can bet I'll add their info to my "library".

-

-

An actual miniature eye splice... I've dreamt of doing this but having made many a splice in real life lines of various sizes with fingers, feet, fig and spike I have a feeling it will remain in my dreams

My copy of The Masting and Rigging of English Ships of War 1625-1860 by James Lee covers quite a bit of this. The diagrams are very helpful but when then don't exist the verbage needs re-reading multiple times before I can start to make some sense of it. If you need anything from it in particular just ask and I'll be there for you.

I'll look at the section for the bowsprit rigging tonight and then PM info to you.

Yes, if you are offering a copy of the photos I am gathering everything I can to help me with my build.

Time for me to get off to work.

-

Why thank you. It must be one of the side effects of smoking a pipe. The same thing happens when you drink too many tots of rum and then look in the mirror.

I am happy to have helped. Your rigging photos are my cheat sheets for 5 years from now.

-

I will PM you what I have.

-

-

-

-

Monday 10 Oct 2016

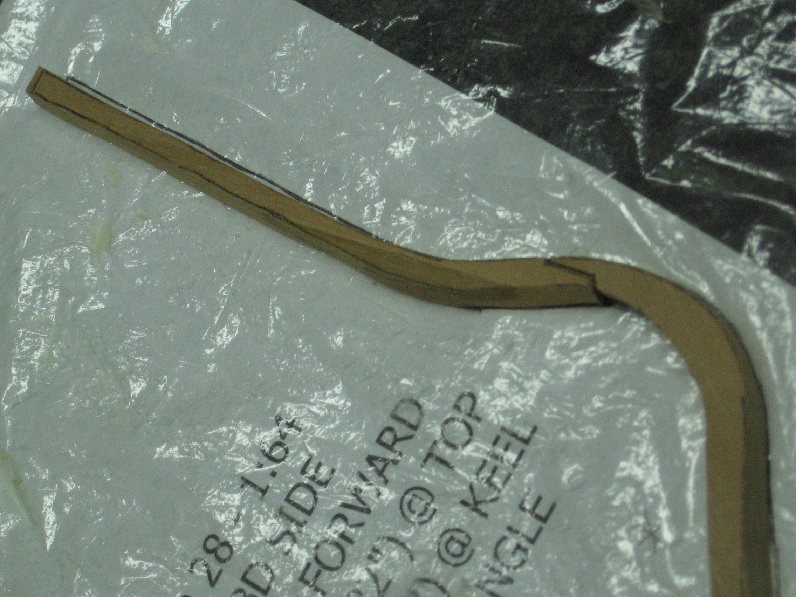

Leave it to a Theatrical fellow to (almost) quote George Shaw. I think I almost do Druxey... the tutorial earlier in the year didn't hurt much. In fact it certainly helped today.

I tackled Frames 28... after having woken up to +2°C and decided I best close the water fountain off the patio, drain the garden hoses and blow out the sprinkler system this morning. It may be early but if I wait much longer it will only get colder and less enjoyable to do.

I bevelled the scarph joint... in the correct direction (almost screwed it up). I also left the overall length about 8" (1/8" or 3mm) proud at the top (head).

I will put it up tonight or tomorrow. I want to let the glue dry thoroughly as I still need to taper the thickness slightly.

Should mention I did each of these individually and then when almost done I remembered Druxey's trick off gluing two pieces of wood together (rubber glue) and cutting in pairs to save time. I will try this next time!

- aviaamator, popash42, dvm27 and 12 others

-

15

15

-

Sunday 9 Oct 2016

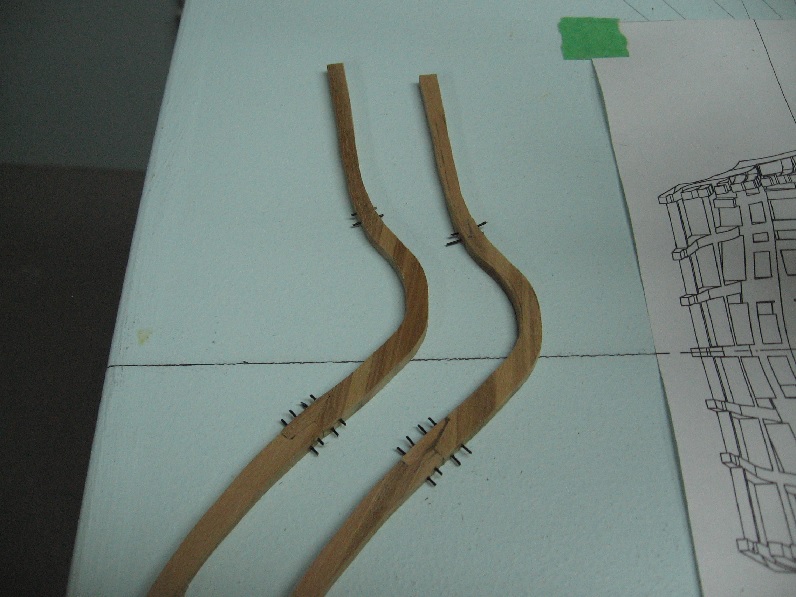

I did manage to steal a few hours for myself (between peeling potatoes and washing dishes... and eating... Happy Thanksgiving to all fellow Canuks out there) to complete the last group of three pairs of short cant frames.

There were three scrapped pieces and a fourth that flew away from me from the sanding belt. I searched for it for about 10 minutes and finally gave up and cut out a new piece. As I turned around to go back to the other end of the room I saw it in the chippings on the floor around the planer. I made a new piece and as it was better I threw the old one out.

I have a magnifying glass attached to my scroll saw table to help me focus on my cuts. I find it helps tremendously as I also have early stages of macular degeneration in my left eye and it plays havoc with lines.

Here are some photos. Going to try frame 28 today. It is a long one with one bevelled joint.

- BANYAN, AnobiumPunctatum, cog and 13 others

-

16

16

-

-

Saturday 08 OCT 2016

It took me three tries but the third was the charm.

The secret seems to be measure 50 times and cut minuscule slices and sand microscopic bits off until it fits.

Following that rule of thumb the others worked out fine!

Had to stop after three sets as my upper back, between my shoulder blades is getting sore. It all relates to my neck fusion. I'll be good to go again after a short bit of rest.

-

-

Friday 07 OCT 2016

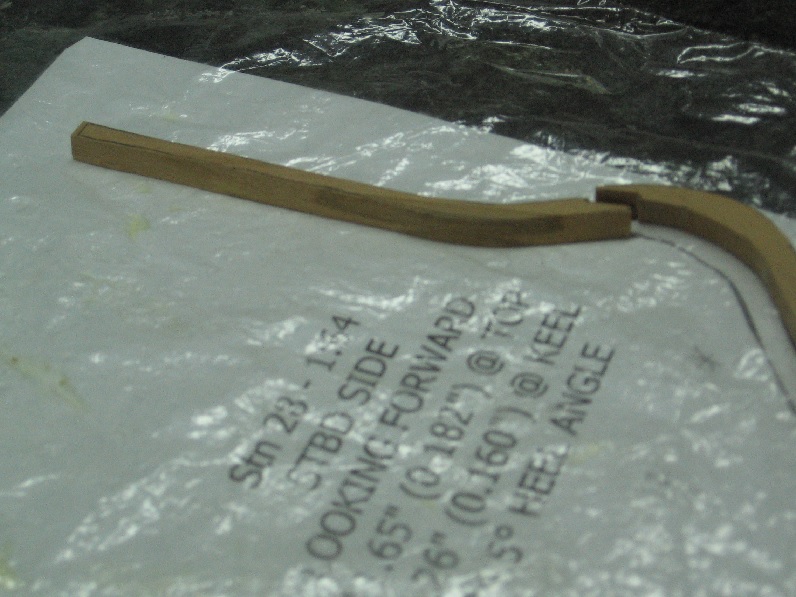

Made my very first frame today. Frame 28-Aft. A short frame that runs from the stern deadwood to the lower group of transom pieces.

Turned out better than I thought it would... but it is scrap. Everything is perfect except for the fit of the foot to the dead wood which you can see in the photos. The head mates perfectly. The thickness tapers perfectly. It is just the fit down below.

I can't even hide it under the keelson as it stops just before frame 28.

Let's see what I can manage the second time, eh?

- Robin Lous, WackoWolf, mtaylor and 9 others

-

12

12

-

-

October 02 2016

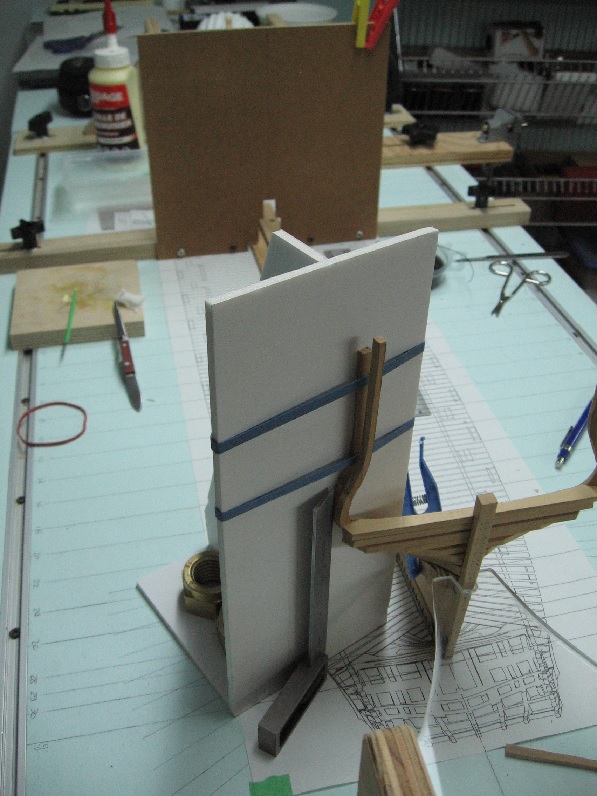

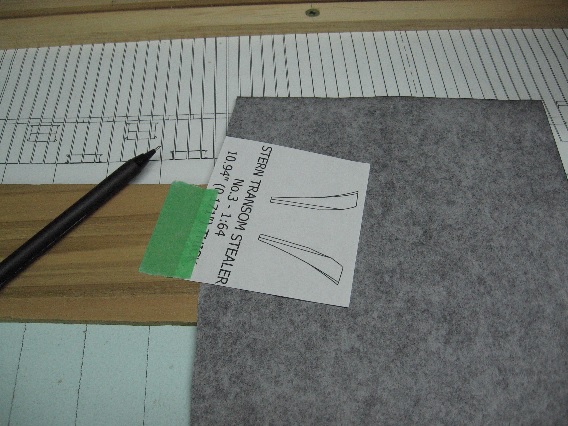

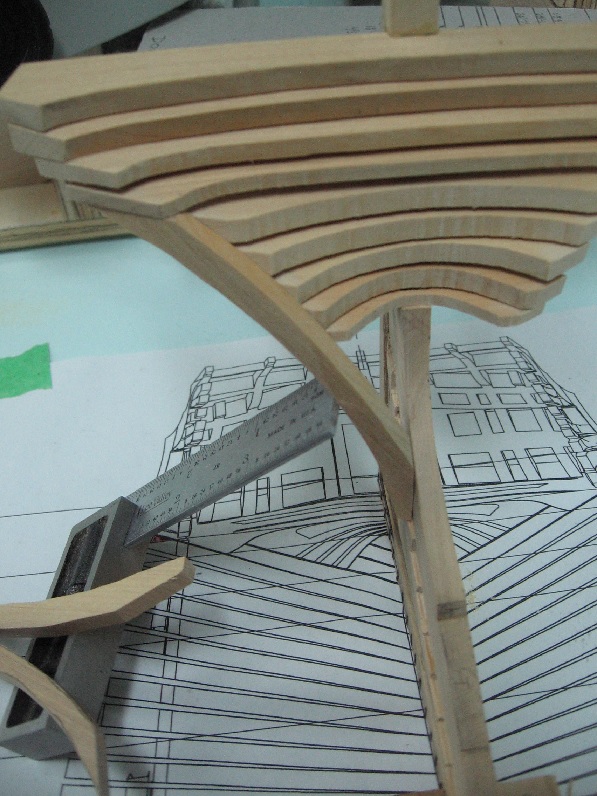

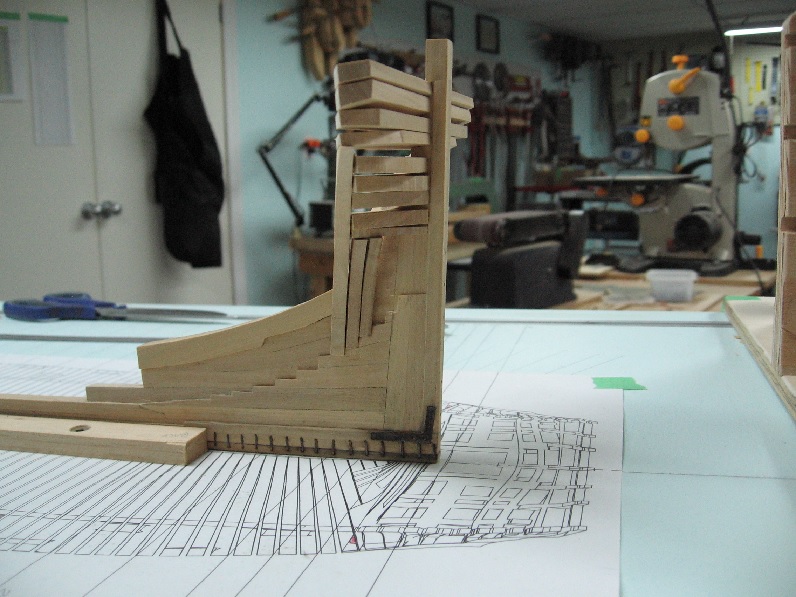

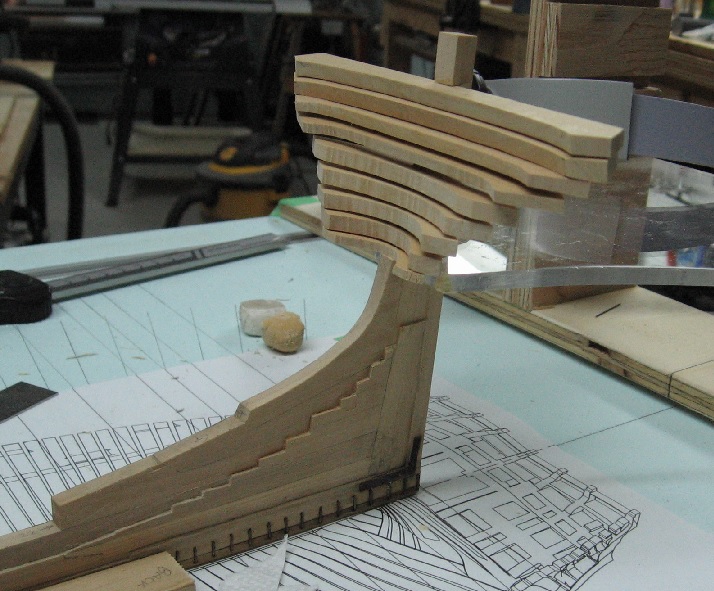

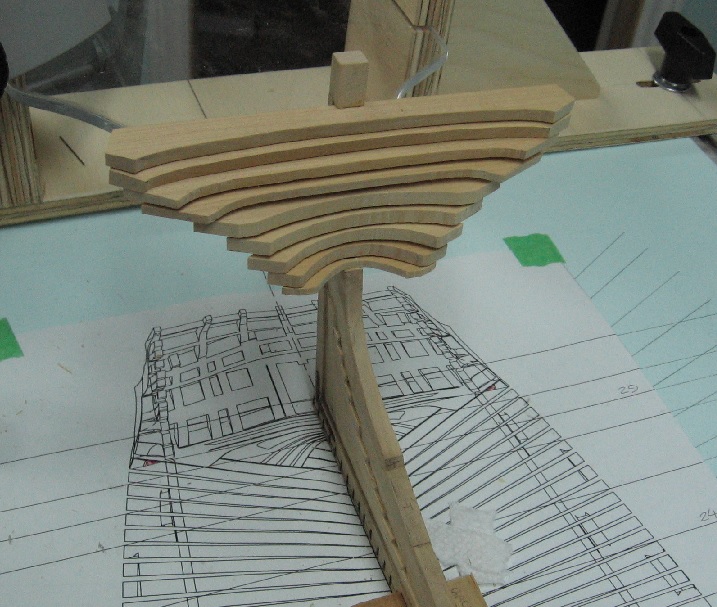

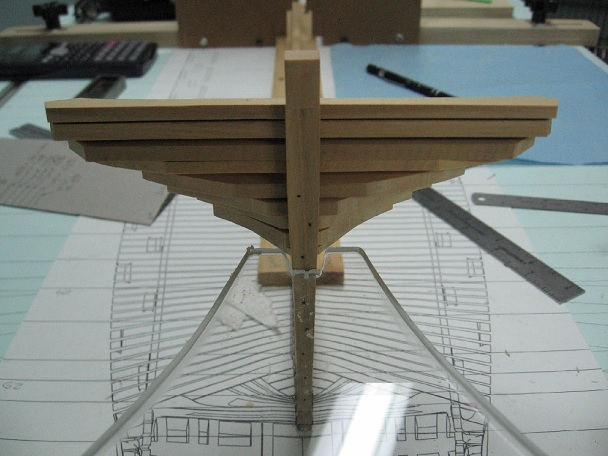

I managed to glue all the transom pieces to the stern post this weekend.

Notching the transom pieces to slide over the post was so tight that the glue was scraped off when sliding them together so I file a couple grooves on the sides of the transom piece notches to retain some glue when assembled.

Doesn't look half bad and starting to look like a ship.

I'l have to add a few more bolts to the stern post.

-

Good evening Mike.

I have to agree with you on the scrapers. Your work looks amazing.

Thank you for posting the info on the mini scrapers earlier. I have a full size set and from your posting info I found a place in Canada that didn't charge $50 for shipping $17 worth of merchandise.

http://www.woodfrog.ca/default/woodworking/hand-tools/scraping/lynx-mini-scraper-set.html

They are quite tiny!!!

-

It is a jig!

very inventive and at no cost!!

- Bluto 1790, Canute and mtaylor

-

3

3

-

After 3 years of mechanical draughting in high school (WH&VS... yeh Go Tigers!), having been exempted from Engineering Drawing in college, started working as a Junior Draughtsman in 1975.... that's 44 years before I figured out how to do it wrong!

I'm going to blame it on computers... they are making us dumb.

-

Reading the scale incorrectly was easier than I could have imagined.

Using my 1/4" = 12" triangular scale I measured (something like) 26'-6" off the NMM plan print.

Using my home made 1:64 scale I set the scale at the 6" mark and then marked off at 26' for a total of 26'-6"

The first foot of the scale (where it starts at zero to 1' and is divided into inches) was skipped completely.

I had actually transferred 25'-6".

And that is how it is done!

There is no such thing as a smart misteak.

I understand regarding the paper towel comment.

As the lower transom piece was set up and glued I simply needed to keep it from wobbling.

There was no clamping pressure applied between it and the Wing Transom. The set squares were holding it in place

When I checked it this morning it was perfect... the glue was set and I removed the paper.

I'll try to make slivers of wood for spaces next time.

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

in - Build logs for subjects built 1751 - 1800

Posted · Edited by AON

All: Thank you for he likes. It is very encouraging. I was telling my darling wife about the missing last chock and even she asked: "will anyone see it?".... I could only respond that I see it now.

Carl: so do I! It is because they are cant frames. Once I get out of this area (and those at the bow) I should be "smoother sailing".