-

Posts

2,812 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

I must be the odd one as I liked the contrast but what I liked isn't important. It is still very clean, sharp and damn beautiful to look at.

-

Thank you Dee Dee I like the "stationary" fabricated hoop and not just because I'm a cheap old bugger that can't waste a dollar... actually we haven't got $1 bills in Canada anymore (ours is a coin called the Loonie because of the Loon image) I am going to check out your link as this may be the kitty's derriere of a method! Alan

-

Interesting method I imagine the wax keeps the "molded" glued wood shavings from sticking to it so it can be removed from the cast shape. Finding a rod of the right diameter... like dowelling. I liked the "look" of the results of my slightly oversized piece and want to see if I can manage as the melamine stains nice and dark for contrast with the mast ..... but this looks like my plan B. Thank you

-

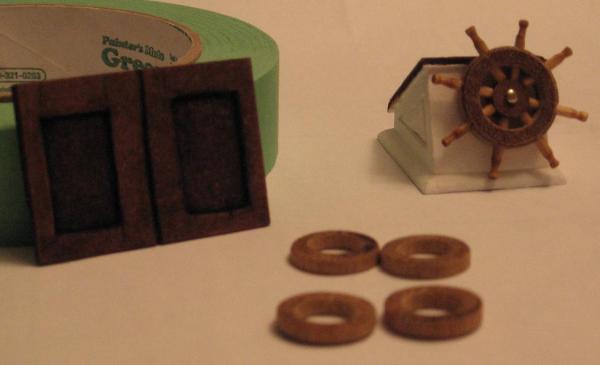

Thank you everyone for the likes Painting and staining some bits. Not quite done with the painting yet. The rings and little blocks are the mast shelf ring s that the sail hoops will rest on. I made 1 of 28 mast hoops for the sails (not in the photo below) I used two hole saws, one inside the other (5/8" and 1") to cut the hoop out of 1/8" melamine. It looks good by itself but when on the mast seems too large a diameter and too sloppy a fit. I'll have to try a 1/2" drill bit in a 3/4" or 7/8" hole saw cutter. This may end up being a two step operation which will then be very tricky to keep the holes centered to each other.

-

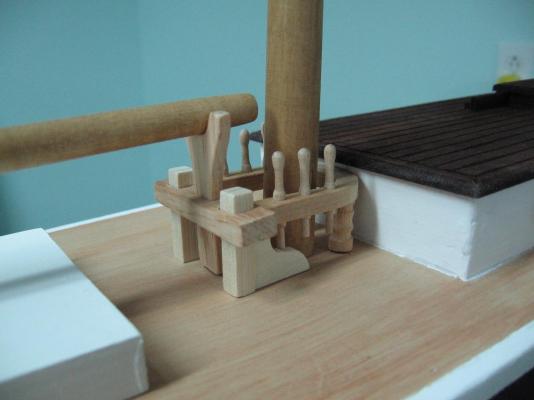

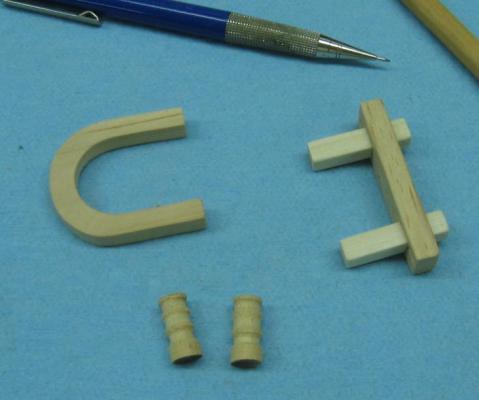

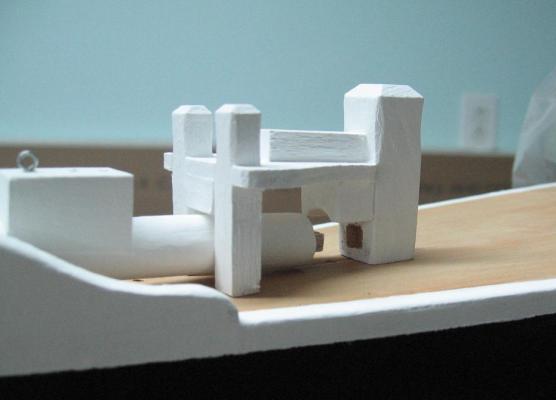

Completed the NEW fife rail and spaced the pins a wee bit. I think this version looks better ... also added the boom crutch The crutch and pins will be stained the remainder painted white Spent the afternoon twisting up 55 eyelets By my calculations I may need another 30+

-

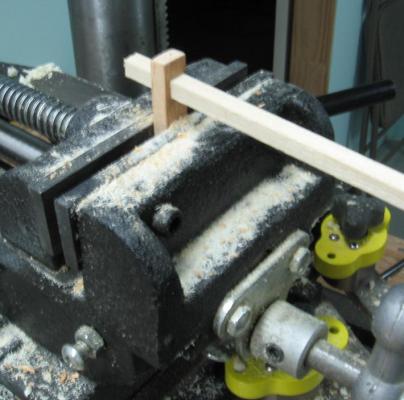

Part three Worked on the mainmast Fife Rail - made the end piece, drilled 1/4" holes for the square post and had to file the holes square to match - made the horse shoe shaped Fife Rail using hole saw, scroll saw and disc sander - made the support posts on my lath and the knee braces on my scroll saw - made two belaying pins on my drill press (used like a vertical lath) with files and sand paper Dry fit it all together The belaying pins seem too close together If I stretch the rail to space the pins more the scale of the rail seems like it will be too far off I am of a mind to leave it be (for now) and let it stew for a bit On the other hand it hurts nothing to make a second slightly longer rail just to see for sure! I have to finish the other pins and make the Boom Crutch

-

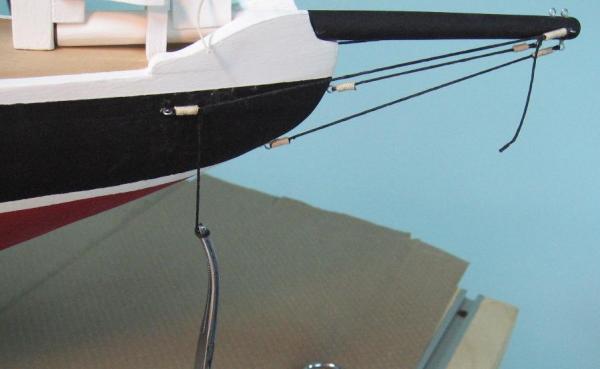

(Part 2) Started line work on the bowsprit Decided to use some of my sea cadet Boatswain and OJT boat shed skills and do some simple whipping I had always done whipping (in real life ... full scale) with waxed twine to finish the cut end of a line (rope) or a back splice could be made I used Black waxed line as my primary piece and tried black thread to do the whipping It disappeared to the eye so much so that I couldn't see the whipping at all I then tried white thread It seemed too small and the black came through highlighting the gaps I'd made In the end I used a thicker three strand 100% cotton twine (off white) and was happy with the contrast Whipping is done by 1. making a bend (fold over) the small stuff (twine) and hold it against the larger line 2. wrap the small stuff tightly round the large line working from the standing end and go towards the bend 3. pass the small stuff end through the eye of the bend that is left exposed 4. pulling on the standing end of the small stuff until the bend is drawn under the wrapping to hide it and secure it 5. trim off the two ends of the small stuff When I completed the other end I had an unavoidable sag in the line I pulled the end of the larger black line (holding the whipping close to the eyelet with my fingers) to draw it snug and taut. Then I trimmed the larger line and applied a dab of glue as my "belt an brace" for the assembly so it doesn't come loose somehow (it never did in real life but this is tiny work so I just don't know how it might hold up over time)

-

Saturday 6 December 2014 (Part 1) Worked on painting and assembling the masts and bowsprit Bowsprit and Samson Post assembled and glued in place Eyelets added to bow of hull in readiness to do some line work Mast assemblies installed to deck dry (not glued yet)

-

Thank you Michael It is all coming together in time for Christmas as promised. It is also a little sad as I have become attached to her. There is so much more I'd like to do (especially since I took the sail making seminar last month) but I have already done more than asked.... and I've blown the budget.... but knew I was going to be getting more then I was going to be giving when I started

-

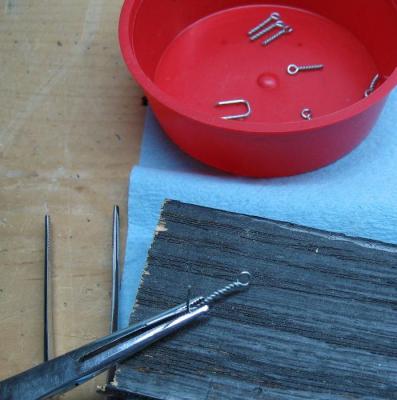

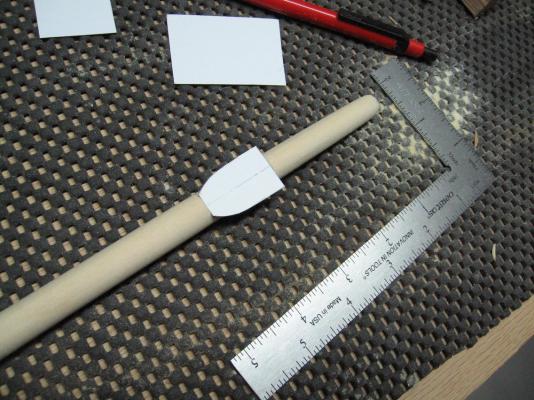

Friday 05 December 2014 Added block to bowsprit to attach jib boom and jib stay to - drilled out 7/16 diameter hole to match bowsprit diameter in location of assembly - cut through hole at 5° angle to match bowsprit assembly angle so top of block will be horizontal - sanded all sides to required thickness then sanded edges soft (removed sharp corners) - glued and clamped After all the fitting in place to get this right the bowsprit paint job was damaged so I will need to freshen this up. Started making tiny eyelets to tie off to - hammered finishing nail into my work bench to bend to - twisted 22 ga wire to the nail - cut the nail head off as I couldn't slip the eyelet off! - trimmed off end Stained the masts, booms and gaffs Will paint the unstained portions white

-

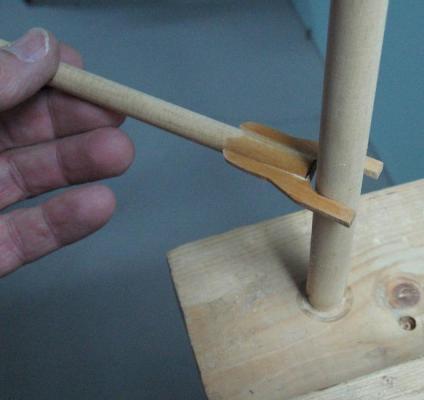

Thursday 04 December 2014 Worked on Booms, Gaffs and their Jaws I chose to make each jaw in one piece - cut a slot in the end of the boom or gaff - chiseled steps in the jaws to fit - chiseled channels in the steps to hold glue Worked on the Port Hole assemblies - scribed the window cut lines into plastic sheet - cut out the glass pieces - dabs of glue in bulkhead port hole recesses to hold the glass in place - glued the port hole rings over top Assembled the Rudder and attached (glued) bits and pieces to the aft end I used small store bought brass nails on the rudder I had to cut these considerably shorter and file a new point to them

-

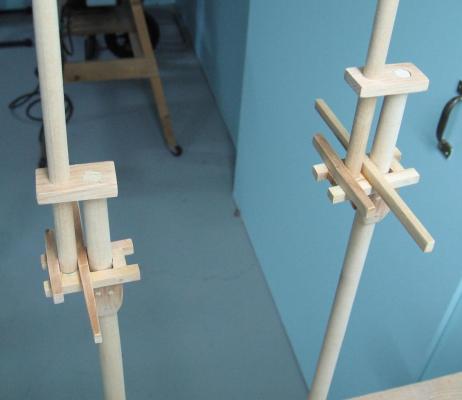

Tuesday 02 December 2014 Completed the painting of the underside of the hull red Need to do touch ups to the white and black to be completed this stage Completed the assembly of the cross trees and trestle trees to the masts Dry fitted all together Started working on the main boom again

-

Good morning Tadeusz I have this same item as I thought it would save me some time... I rarely use it and if I did I'd still go back to wet stones to finish off the best edge ever and (as the other fellow mentioned and I forgot to) a few wipes against the leather strop to boot. A really good edge makes your work much easier and almost look masterful... especially when your not a master. Alan

-

Thank you Druxey The black band seems a bit narrow to me but I cannot go any lower or I'll encroach on the rudder elevation Sunday 30 November 2014 Continued with painting - lower white band on hull - upper white band on hull and deck - one coat of unbleached (undiluted) white on deck - one very light coat of watered down Autumn Brown (ceramic paint from my darling wife's stash... with permission and tutoring!!!) applied with a fanned brush drawn long along the deck to simulate wood grain (my wife knows a thing or two about painting). That deck turned out better than I ever imagined. Why faux wood grain and not an application of thin planking? "BUDGET" That is why I am using most of my scrap wood on this project. In the end it will be 1000 X more then he ever expected (and I hope to catch that expression in a photograph) I was originally thinking of drawing in lines to simulate the planks but I'll likely screw it all up and I think this is one of those times a person needs to know when to say enough. Next is to paint the red bottom, touch up the white, attach some of the bits and pieces and get back to the booms and gaffs

-

I would use this type item on a new dull blade or edge to get it started I always finish with wet stones Once you have established an edge it is easy to keep it extremely sharp with wet stones If it gets a bad ding in it I might go back to the grinder to start again

-

Saturday 29 November 2014 Painting and staining today (and tomorrow) Also a pic of the booms and gaffs... they need more work yet. I am very happy with the staining and hope the painting ends up looking as good I also started assembling the build photos in some chronological order to bind together to go with Charlie when she is done. I think they will all (father-in-law, daughter and son-in law) enjoy seeing all that went into her. I am going to be spending some time figuring out the standing and running rigging. If anyone has a cheat sheet they would like to share I am quite receptive to the idea! (hint, hint)

-

You are going to wonder how you survived without it!

- 962 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thursday (evening) 27 November 2014 Completed assembly of the trestle trees - dry fit last block - marked location - glued and clamped will lightly sand tonight and make the two caps I also cleaned (vacuumed) off the hull which revealed a couple more minor dents that were filled And I determined the sizes (diameters and lengths) of the booms and gaffs (again by ratios) and cut my material Still plan to start painting this weekend!

-

Thursday (morning) 27 November 2014 sanded the bow cowling assembled and clamped part of the trestle trees time to go to work

-

Wednesday 26 November 2014 Glued and pinned the bow cowling - cut off the excess wood pins with a carving knife - sanded flush - clamped down Drilled out the port holes - measured and marked locations - scoured outer marking with 7/16" diameter brad bit. this will outline the recess or spotface for the clear plastic window to be set into - drilled through with a 3/8" diameter brad bit holding a back up piece of scrap wood in behind to avoid spinters It happened on the second hole I did and then I was worried. I hit a nail! Used mini chisels to cut around the nail and through the wood Used small files to cut off the nail and shape the hole Turned the main and fore topmasts on the lathe using a wood rasp file and sand paper - cut off excess on band saw - put the mast into the chuck of my drill press and finished the shaping with sand paper - squared off the foot with the belt sander

-

Thank you everyone for the encouraging words and votes of confidence in my drastic action with the cabin height I have pieces of plastic to use as window glass for the port holes and am thinking of drilling four holes through the cabin bulkhead, countersinking slightly to set the faux glass in, white washing the inside of the cabin so if looked into it is a bit brighter. Monday 24 November 2014 - Drilled and pinned the cheeks to the masts with a slight interference fit (no glue) so I won't have to worry about this falling apart - cut the pins off flush and lightly sanded - cut and sanded the trestle tree pieces Tuesday since I am up early this morning I may as well go do another sanding of the hull as painting her will happen soon

-

Part 2 Went back to the masts and started on the cross tree assemblies - marked the location of the support cheeks - rasped, filed and squared off cheek pocket with a knife - made a stiff paper template of the cheek and fit it to the pockets - transferred shape to wood and cut out with the scroll saw - sanded to shape - dry fit and finally glued and clamped in place to set overnight I then worked on the cross trees 4 trial pieces (you can call them errors ) before I got anything near what I was attempting. Trestle trees will be next

-

Sunday 23 November 2014 Part 1 Worked on the cabin port hole rings. My inspiration was a garden hose snap on O-ring as it seemed the perfect size. After numerous attempts with the lathe I had to come up with a plan B - set up dowel in clamp, squared to drill bit and drill hole though the end (the tough part was centering it) - cut four pieces about twice as long as needed on the band saw - prepared a "holder" and square up ends and thinned to size on disc sander

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.