-

Posts

1,308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TBlack

-

HMS Sphynx by TBlack - 1:64

TBlack replied to TBlack's topic in - Build logs for subjects built 1751 - 1800

-

Keith (bro), The client, my uncle, wants it left bright. So I'm just using varnish. As you can see from the photos in #7 above, there are dark places in the wood that are fully soaked in. I'm assuming there was some kind of treatment done to the wood by the original carver, I've tried with fine grit paper to remove the dark places aft....no luck unless I go really deep. Not willing to do that. The dark places are just going to have to stay (a little bit like life, in general!). Hi Spyglass! Thanks for checking in. Yes, I also think it was meant to be a small pond yacht, but never got beyond what you see here. That piece of metal isn't lead, but steel. Also, interestingly, the hull is out of one piece of wood. It's soft, maybe pine? Tom

-

Keith, Hate to tell you this, but you have another older brother, Stanly, born in '46. The benefit is he knows CAD and I don't! Oh!, and another thing, you might have long teeth, but mine are all falling out! Tom

-

Keith, I'm not sure what a lot of money is, but I'd be proud to call you my brother! At 77, I'm the older brother, right? Tom

-

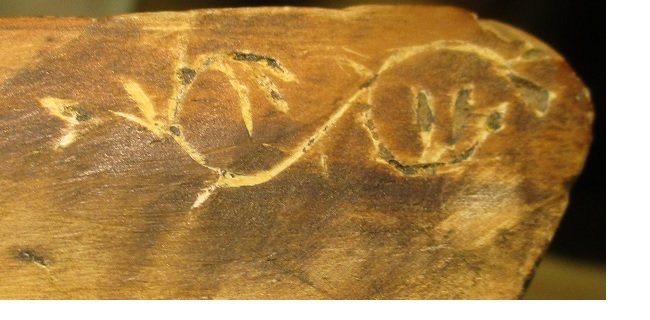

I've made some executive decisions. The scale is going to be 1:32 (3/8" = 1'). The end product will loosely resemble a Bristol pilot cutter. Henry Ford once said, "Never complain; never explain". I shall follow that adage. Anyway, I've been sanding. One side done: Notice The detail at the bow; here's a close-up: I don't know how to clean it up without damaging the artwork.

-

Having multiple photos vs. a set of plans is both a blessing and a curse. On the one hand the photos show you exactly what the ship is supposed to look like and what goes where. On the other hand the photos show all the details not included on the plans which creates an obligation. BTW, Keith how are your eyes holding up? Tom

-

HMS Sphynx by TBlack - 1:64

TBlack replied to TBlack's topic in - Build logs for subjects built 1751 - 1800

Gentlemen, Thanks for the “likes”. Druxey has been particularly helpful with the rigging and mast tops. Keith Aug has been inspirational in the fabrication of the gratings in the ship’s boat where the openings are just less than 1/64” square. The hull is planked in Apple and cherry for the rest of the darker wood. Couldn’t manage carving on the transom at 1:96; had to do substitutes. Tom -

HMS Sphynx by TBlack - 1:64

TBlack replied to TBlack's topic in - Build logs for subjects built 1751 - 1800

-

Coming late to this conversation, as usual, but I've been building a model of the Sphynx class frigates in 1:96 scale. I'm trying to keep the overall length of the model to a reasonable size. At 1:96 the overall length from jibboom to transom is a bout 2 feet. I started out at 1:64 and soon realized that there would be few places in a home that could accommodate the length. In any case, I find the hull lines much more pleasing than the Swan class for about the same bang for your buck. Tom

-

Endeavour Rigging Topmast Fore Preventor Stay

TBlack replied to Mr Pleasant's topic in Masting, rigging and sails

I'm going to crash this party and suggest that the end of the line, after it goes thru the second half of the double block is wound around the lashing between the two blocks and made fast there. Tom -

I built this kit several years ago for a friend who had bought the kit; opened the box; and decided it was beyond his ability. It ends up being a nice product and a decent size for home display. And, Richard, from what I can see, so far, so good! Tom

- 41 replies

-

- artesania latina

- dallas

-

(and 1 more)

Tagged with:

-

You have been busy. Sorry to have missed the journey between hull and now. I'm also wondering about the materials you use to get such crisp results in a small scale. Also, given those hull lines, does she roll a lot?

- 42 replies

-

Alex, Great to hear from you again! I'll buy your description. Some of the replies don't seem to recognize the 20 gun Sphynx class frigate. Aside from that, how is it going? I bought your plan and have a version of the class, albeit in 1:96 scale (half your size), so I can't do all the detail that you have done. We'd love to see how you are progressing. Tom

-

I'm currently building a model of a Sphynx class frigate. This is a 20 gun ship, so it's a small frigate, but a frigate nevertheless. As an aid, I'm referring to David Antscherl's book, Rigging A Sixth Rate Sloop of 1767-1780. (volume IV). In terms of size, armament, rigging these ships are very similar, so why is one called a frigate and the other a sloop?

-

Advice needed - model ship made by my Grandad

TBlack replied to Stee F's topic in New member Introductions

Harold Underhill built a model of a BRIG, Leon, and described the construction in a 2 volume work entitled Plank-On-Frame Models first published in 1958. Your grandfather's work is identical except the foremast would need 5 yardarms to complete. Is it possible that he hadn't finished his work? Leon was a real ship, built in Norway in 1880 (the model is flying a Norwegian flag). Underhill doesn't give much history of the vessel, so I can't help you much there. Judging from the pictures you've supplied, I'd say your grandfather knew what he was doing! First rate work. Also, it looks like it's 2-2.5 feet long? Are you sure you have no place to display it. How about hung from the wall, like a picture? Tom Black -

HMS Sphynx by TBlack - 1:64

TBlack replied to TBlack's topic in - Build logs for subjects built 1751 - 1800

It certainly has, and very well laid out, too. Just finished the standing rigging. Here's a progress photo:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.