-

Posts

4,553 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Blue Ensign

-

Thanks, Håkan, Away from the macro lens it looks ok, altho' I'm still fiddling with it. B.E.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Fifteen My next thought is how to represent the decorative panels. oob kit arrangement. The kit offering, a simplification, would stand too proud, and not look good just stuck atop the linings. I am thinking fine mouldings, possibly no more than 0.5mm x 0.5mm. in section. I also want the panels to be inset and contain a decorative design. A tall order at this scale perhaps, but I’ve come this far…… I discounted use of timber to make the mouldings which would have a high attrition rate of breakage. 9581 I started using a printed frieze design but didn’t like the look. After a few false starts I settled on using 0.25mm x 0.5mm styrene strip for the moulding, glued to painted paper, with an impression of a design painted on. This arrangement has ultimate flexibility and will not overwhelm the scale. I started with the stern-sheet decoration. 9586 9589 The remainder of the panels fit between the thwarts. 95600 9598 9614 A time-consuming exercise making up these small panels, but they don’t look too bad from around nine inches, at least to my rheumy old eyes. Even so I have more work to do on them. The next task is the shaping and fitting the capping rails. B.E. 01/12/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

All coming together beautifully Ron, the crew figures look great. B.E.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Royal navy - stern colours?

Blue Ensign replied to Vane's topic in Painting, finishing and weathering products and techniques

An Admiralty order dated 12th July 1715 stated the outsides of ships be painted of the usual colour yellow and the ground black, but the practice seems to have been in place also in 17th century. This does not mean that the order was universally applied and we see from contemporary models that both blue and red were used extensively as the frieze ground, but possibly involved a high degree of artistic licence. Such licence is evident with the extensive decoration on small ships as depicted in models and paintings, which almost certainly wasn’t applied in reality. As a modern ship modeller I am not immune to dressing models to reflect the colours used by 18th century ship modellers, I rather like the effect. As far as Granado is concerned you could legitimately paint all the ground black with ornament picked out in yellow Ochre, the hull left bright or painted yellow, with the inboards red ochre. All down to personal preference. B.E. -

Well done Mike, a very nice build, and excellent finish👍 B.E.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you, Yves, Håkan, and Jim, I'm much happier now. 👍 Post fourteen Lining the hull. Moving on to fitting out the internal hull, the point of a build that most excites my interest. 9561 Multiple card templates were made and tweaked to match the sheer of the hull and run from the bow to stern-sheets. 9565 Once satisfied the patterns were transferred to 0.6mm Pearwood (spare fret from the Sphinx kit) I tried to get as good fit as I could but the fallback position is that the linings will be painted so a little filler won’t go amiss should the need arise. A full day at the work bench sees the lining in place, ready for fining down and hopefully joined seamlessly to the lower lining strips. 9568 9570 9567 At this point sanded and filled the internal hull is ready for a coat of paint. 9578 9577 9576 9575 The somewhat trickier business of the decorative panels is up next. B.E. 25/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 13. De-construction begins. Removing the wash boards and platform is the easy bit. 9531 I used a combination of scalpel, micro chisels, and etched saw blades to slowly pare away the first two bulkheads. 9538 I reduced the height of the bulkheads to a fraction above the line of the central thwart dividing plank. 9540(2) 9542(2) The job went better than I imagined, there was a slight breakaway of the planking at the bow, but the planks remained glued to each other, and a spot of ca resolved the problem. 9545 With the lowered foredeck, the barge now better reflects the elegant lines typical of the type, and I’m far happier already. 9553 9554 9557 I’m not out of the woods yet, there is the internal lining to fit, followed by the decorative panels, but at least I now feel I can continue with the build. B.E. 24/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Jason, I get them from a company called Modelu. Modelu – Finescale Figures (modelu3d.co.uk) They do them in various scales and I bought them originally for my 1:64 Fishing boat kits. Unfortunately, they don't do 18th c period naval figures, but they now do a range of fishing boat crew figures. Scale figures in various poses are useful for comparison purposes, it is a pity no one does seated rowers, I could do with around a dozen if the barge ever gets completed. Cheers, B.E.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Twelve Time to fit the thwarts. 9513 There is a natural spring in the unit which resists the sheer of the barge. To this end the unit is weighted into place and heat treated to follow the sheer. 9516 Ca is applied to the pillar tops and pva to the thwart ends. The sheer is evident in this photo. 9517 9518 With the thwarts firmly in position the next stage can begin. 9519 9521 Wood strips are fitted between the thwarts this will form the lower element of the panelling. 9522 A card template is used to get the shape of the upper panelling. 9523 With a coat of paint applied I can get a good impression of how the finished boat will look. 9525 Sadly, I don’t like what I see. 9529 That Fore deck position looks so out of kilter with the elegance of a barge, I don’t think I can live with it. The only option is to de-construct the bow area at the risk of destroying the model, but I would otherwise waste no more time on it. If I’m going to do it, it needs to be done before I add the linings, now where did I put that Dremel. B.E. 23/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well done, Glenn, I like the cut of her jib.👍 Vanguard's range of Fishing boats are very appealing. B.E.

- 106 replies

-

- Erycina

- Plymouth Trawler

-

(and 3 more)

Tagged with:

-

Well Yves, a case of monkey see, monkey do. I thought if it was good enough for a guy who was around at the time (1750) to show it, it was good enough for me. The black and white schematic was a traditional thing to be found everywhere in the flooring from stately homes, to cathedrals, to 1950's kitchens in the form of lino. In naval circles it probably just followed fashion of the time, except it was merely painted sailcloth, anything else would be considered extravagant. The French on the other hand, more conscious of creature comforts preferred parquet flooring in their great cabins, perfect for unlaying by carronade. They even had separate Bread Ovens; can you imagine! The British were, and are, more conservative, and their lordships of the Admiralty had an aversion to anything 'frenchified' despite having pinched the designs of their Seventy-four gun ships, and finally being seduced by the epaulette, that most French of French adornments. A brief potted history, not entirely tongue-in-cheek😉 Cheers, B.E.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Eleven Fitting the thwart set as a unit presents some difficulties. The unit must sit down on the central supports and the thwarts be trimmed uniformly on either side to sit squarely against the hull sides at the correct level. My approach is to use individual thwart substitutes to determine the correct lengths and apply those to the unit. The unit is then trimmed by degrees. The stern sheets required careful sanding and bevelling mostly towards the stern, to seat fully down at the correct level. 9494 Once again, the dockyard workers were called into use to confirm the levels. 003 Many contemporary models show panelling below the benches. Note also that the inside hull has been lined to below the thwarts. I fancied replicating the look below the stern benches. Great care must be taken in sanding and bevelling the thwart ends because the grain runs fore- aft making them prone to snapping if sanding is done other than with the grain. I suggest the thwart is held between thumb and fore-finger as close to the end as possible during sanding. Each thwart is progressively fitted until by applying light pressure on the central plank the unit sits down on the pillars without flexing the hull sides. It is necessary to get the thwarts and seats dry fitted to satisfaction before moving on. I glued the stern benches first but using the thwarts to ensure the levels met up. 9496(2) Getting the thwarts to look right is a major aspect of small boat builds. 9499 9498 C’mon lads, break over, back to the job. With the stern sheets glued into place I can turn my attention to the panelling below the benches. 9495 Forming the shape of Boxwood strip to fit. 9501 A lot of faffing around to get the panelling to fit, still ongoing at this point. 9506(2) 9509(2) 9510(2) Before the stern-sheets can be completed I need to work out the panelling above the benches. Onto the thwarts. B.E. 22/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

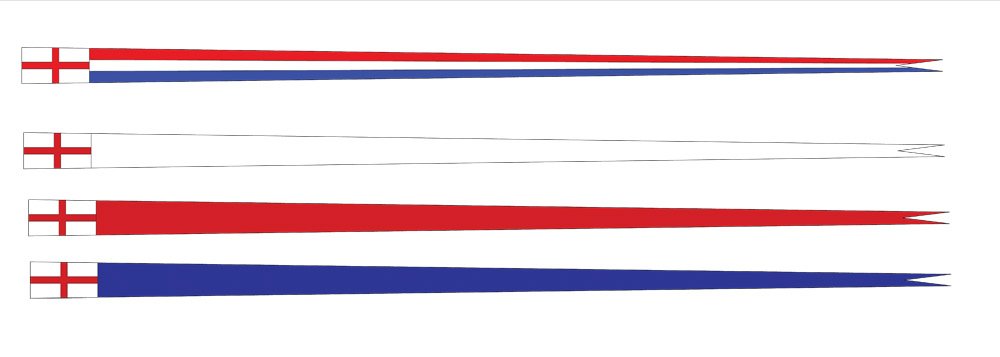

I think you have the shape spot on Ron, looks very convincing. A modification you could add is to paint the English Cross of St George in the Hoist section. These were the four commission pennants of the period. Colours of the Red, White, and Blue squadrons, and the Union (Common) pennant as an alternative. Red and blue (up to 1864), Common (up to 1850). The White remained in use post 1864 as the designated naval colour. Regards, B.E.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Post Ten Internal fittings are now removed for test fitting. The thwarts are an integrated unit combining the central Longitudinal plank. This is typical of barges of this period. 9440 The stern benches are also a single unit that look to require only minimal adjustment to fit. Before they are fitted the seat stanchions that run down the centre of the footwaling are required to be fitted. Section 38 of the blurb refers to the fitting but does not mention that the stanchions are of brass etch. 9438 They are numbered sequentially on the blurb and a careful check of the etch shows that the ten stanchions are position specific, fore, and aft to accommodate the sheer. They are not however, numbered as per Section 38 of the blurb. The way the kit is set up the stanchions dictate the height of the thwarts, and the hull ribs will need reducing in height where they impact on the thwart ends. I decided to use the etch supports partly because I felt they gave the best chance of getting the thwart height correct. 9467 9465 The biro gives the relative size of the barge. 9470 I was still keen to check that the thwart height was correct. 9469 Unlike the usual practice of risers along the internal hull to support the thwarts, this kit relies on the central columns and the ribs cut to suit for support. 9468 With the scale figures in place, I am pleased to see that the height is good. It is also clear why barges of this era were rowed single banked. My use of ‘test’ thwarts has given me the line for the risers, and I don’t really understand why they haven’t been employed on this kit. 48Bb(2) Once the thwarts and benches are in place small wooden block panels are fitted between the thwarts along hull. This is a simplification of the proper arrangement, perhaps understandable given the scale, but it does look a tad unconvincing to my eye. The inner hull should be lined over the ribs and decorative mouldings applied. I have an idea of how to do this from my Model Shipways Pinnace build, but that was at 1:24 scale. Before I admit abject defeat, I will have a play around and see what can be done. B.E. 20/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Nine At this stage I am departing from the suggested build sequence, to work on the outside hull. The kit arrangement involves using spare hull planks to form rails between which a frieze decoration (brass etch) is fitted. To my eye the 2x0.8mm strips look a tad heavy and I have opted for 1mm wide strips to represent the rails. 9434 The top rail is fixed level with the gunwale, follows the sheer, and extends to the flying Transom. The rails are fixed using spots of ca. 9450 A paper frieze pattern is used in preference to the etched frieze. This is simply printed on 90gsm printer paper, sprayed with artists fixative, and glued using slightly diluted pva. 9452 The lower rail is then applied following the pattern line and terminates at the transom proper. 9449 I think this arrangement gives a better scale appearance. 9446 With the rails in place, I can now tidy up the lower hull and fix the waterline. The macros also reveal that some of the ribs need a little attention. B.E. 19/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you, Yves, Jim, and Andy. @ Andy, - good spot, but I was aware, it was easier to go with the grain for cutting out, and the deck is to be painted. Cheers, B.E.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Eight I took the obvious and simple approach. 9397 The bulkhead was faced up with a piece of 0.6mm Pearwood sheet. 9404 A new platform was cut out of the same stuff. 9405 The plank lines were lightly scribed into the surface. 9410 Wash boards will be fitted around the edge. 9412 I still can’t help feeling that the fore platform should sit below the gunwale level. Every contemporary model I have seen shows this, as indeed does the Vanguard Pinnace kit in the same series. I did wonder if I had somehow made a mistake in the build, but the kit photo’s show pretty much the same result. I can’t contemplate chopping out the bow bulkheads to lower the platform, I fear it would put too much strain on the delicate construction, so we are where we are. 9414(2) The final option is to add wash boards which go some-way to redress the balance and give a more authentic look, but it is a compromise. 9415(2) I happened to have some spare wash boards from the Yawl kit. 9429 The detail devil in me can’t help noticing one other anomaly. The first thole pins are shown adjacent to the fore platform, at the same level. It was not uncommon for the first rower to sit on the platform but with the kit configuration the rower would be above the tholes which makes no sense. This is an attractive model, and perhaps many will care little about the details I have highlighted. Some may say at 1:64 scale it is sufficient for the purpose. I would, however, urge Chris to re-visit this kit, re-design the first two bulkheads to lower the platform to the same level as the thwarts (as per the Pinnace kit) and reconfigure the oarlocks to single banked rowing on each thwart. ‘nuff said, on with the build. B.E. 18/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Seven The gratings are secured in place using tiny spots of ca but I have found with my previous small boat builds that small enough not to spread thro’ the gratings with an annoying shiny reflection, is not always sufficient to hold securely, we shall see. 9395 I took the precaution of cutting a pattern to fit over the gratings to protect the surface during the extensive messing around inside the boat to come. 9394 The ribs are easily fitted given the notches in the grating pattern, and they do stiffen up the hull. 9393 There is an adequate supply of strip for this purpose. There are one or two little bits to fit as per sections 32- 35 of the blurb, but back in section 13 there is a part B25 indicated, which as far as I can see is not mentioned again. 9389(2) I suspect it may have something to do with the Foredeck but If it is, I think the instructions need re-visiting to be more specific in this area. 9388(2) It’s not an easy match in any case, and the foredeck fitting has issues. If the notched back edge is intended to slot into the second bulkhead, then the first bulkhead should sit below the gunwale. 9292(2) The first bulkhead and bow pieces are level with the gunwale. (The bow stem extension has broken off, but that is easily fixed.) 9393(2) This bulkhead, from the photos appears to form the vertical face of the fore platform. 9390 This rather unflattering macro of the bow end demonstrates the issues. (Part of the Pearwood bulkhead on the port side snapped off during trimming.) The problem is how to model the fore platform. To use part B25, the first bulkhead would need to be rebated to accept the part, not an easy task at this point. My thoughts are that the second bulkhead be infilled and brought level with the first bulkhead, and a piece fashioned to fit. If this stands a tad proud of the top line planking, it can be used to support a bow wash strake. I need to ponder this awhile, but until it’s sorted, I can’t really move forward with this build. B.E. 17/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

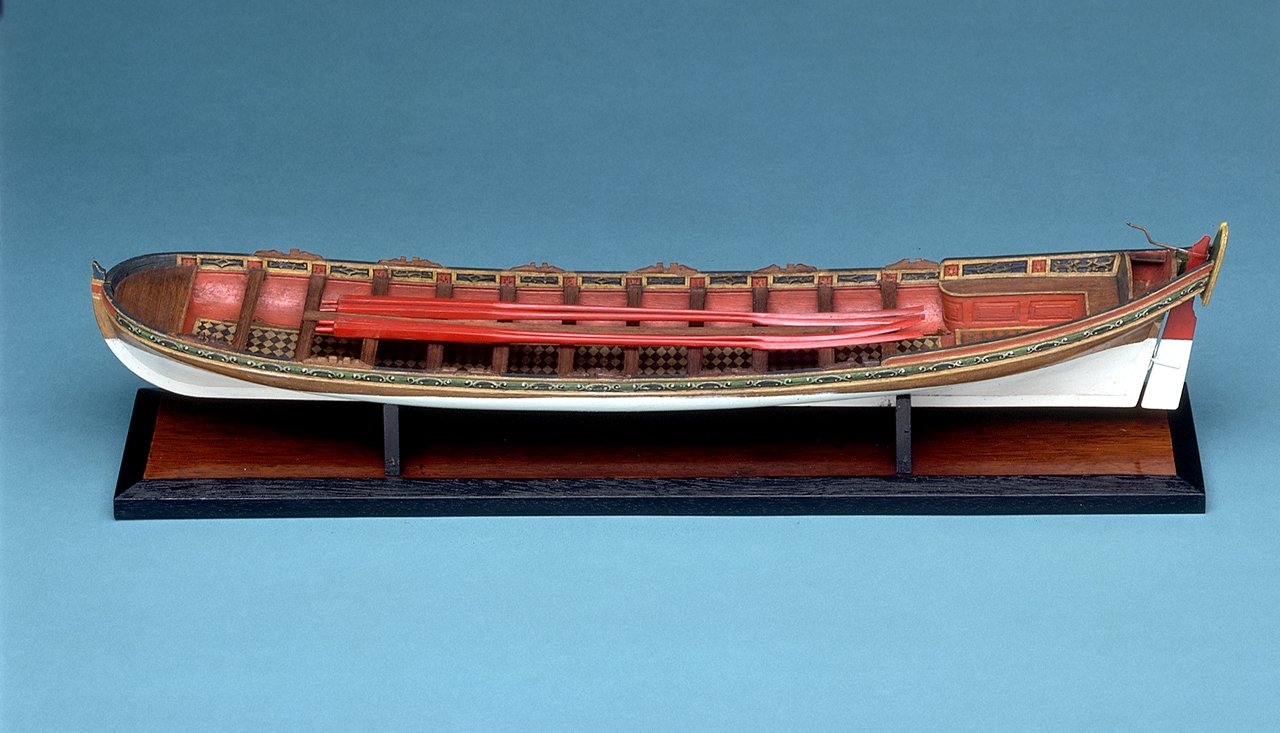

Thank you, Allan, The kit is set up for double banking on alternative thwarts which seems unusual. I will be adopting the single banked arrangement as shown on the contemporary model (1750) above. ps: It is interesting that the model NMM SLR0489 is described as having twelve crew rowing double-banked. To my eye they are rowing single banked, unless I have misunderstood the terms all these years. 🤔 The other anomaly is the barge is shown flying the Royal Standard which struck me as a little odd. Still the model is very nice, and one I am using as a reference. B.E.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks Jason, Post Six. In this post I have concentrated on preparing the Foot-waling, which for kit purposes is represented by brass etch gratings. Traditionally, based on contemporary models, barges were boarded out, but I have decided to use the provided pieces, not least because the central bench support pillars are marked and drilled for insertion, which makes things a lot easier. The gratings are also pre-notched for the insertion of the frames, an excellent idea which saves the hassle of spacing calculations and positioning. Using the etch does mean that the gratings must be painted to replicate wood. 9364 My approach is to chemically blacken the etch which provides a good key for subsequently painting. The blurb gives a method to follow to achieve the finish and is broadly how I do it. I am using Vallejo paints throughout. A base coat of dark sand, which is light in colour, is applied. 9366 Second coat of Ochre Brown. Too yellow for my eye, I had in mind a more scrubbed wood look. 9381 To this end a mix of Ivory/ slightly coloured with dark sand and a spot of Black/grey was mixed almost full strength and stippled on with a dry brush. Getting there, I think. The kit scheme indicates painting the hull white up to the top three strakes, which then contains the rails with the painted frieze between. I prefer the look of bright work between rail and waterline, and I applied a couple of paint coats both to gauge the line and highlight any areas that need attention on the lower hull. 9367 9370 I have used ivory for the lower hull, which I think gives a more scale look. 9379 This is not the end of the lower hull painting, but I think I have the waterline about right, and this will be re-visited later. 9375 The internal hull has been cleaned up and I am fairly happy with the gratings look. The next stage is to fix the gratings in place and fit the ribs. B.E. 16/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Seamanship in the Age of sail by John Harland gives the complete process from getting underway from anchoring, to coming to anchor, and stowing the cables. A very useful book. It is exhausting just reading about handling the cables; cleaning and setting them to dry before stowage, and the highly skilled task of passing them down to the hold and faking them in the correct manner for subsequent use. B.E.

-

Post Five I continued to use the provided strip for the planking and there is more than sufficient for the need. A representation of the Garboard is fitted first, followed by a final spiled plank. 9331 I terminated this one on the third bulkhead leaving just the forward part that meets the stem and abuts the Garboard. A drop plank of sorts was then formed to complete the planking. 9332 I didn’t get away without a little filler in the bow area, but once the frieze is added, along with rails, and the waterline is painted in, it should look ok. 9335(2) 9341(2) With the bulkheads twisted away there is not too much cleaning up to do. 9345(2) During construction the Flying Transom detached so this needed to be re-fixed. 9339 There is a lot of fettlin’ to do to shape the extended planking to conform to the Flying Transom arms. The aim is to achieve that elegant sweep typical of Barges (and Pinnaces) I think a few extra photo close-ups would have been helpful in the blurb to show the set-up more clearly. 9350 An additional planking section is required to be fitted over the arms, and shaped. (still w-i-p) 9358(2) A brass etch transom panel is provided, but there are no photos of this in place, and it is not mentioned in the blurb. 9361(2) I have decided not to use it except as a template to make a wooden version on which an appropriate design can be applied. The macros are brutal at this stage, but with a fair wind and following sea hopefully a silk purse will emerge from this sow’s ear. Onwards, B.E. 15/11/2022

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well expressed, Jason, It is a useful tool to set down one's reasoning both to help formulate approach and answer those 'why did I do that' moments some way down the road. I think your choice is spot on, but there is always wriggle room with this sort of thing; between plan, Admiralty order, and fitting out I suspect that in reality there was an element of 'availability' involved. No one is going to gainsay you as you have worked using contemporary evidence, personally I like the four-carronade configuration. B.E.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.5aff0f15c7dba712fedab523f76093ae.jpg)

.jpg.cba2dd2122792f2c1bf8ecdbb19d76f2.jpg)