-

Posts

1,878 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck Seiler

-

Some progress. Much time waiting for stain to dry and I went to the beach. Isn't it 75 degrees everywhere? I finished decking 6 of the 7 main deck panels. According to the plans, at this point I should have completed the bow, stern and furthest outboard port and starboard panel. Not sure why interior panels are not completed. I wanted to stain and preserve the deck before I continued with hull planking and so to ensure consistent color, I decked all but center panel. I was going to do all, but for some reason I remembered I should keep the center unplanked. Oh! Now I remember why I wanted to leave the center unplanked. My effort to be consistent went for naught. Despite being stained at the same time, the two inner panels are slightly different...no doubt due to difference in wood. NATURAL stain used. Hull planking continues.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

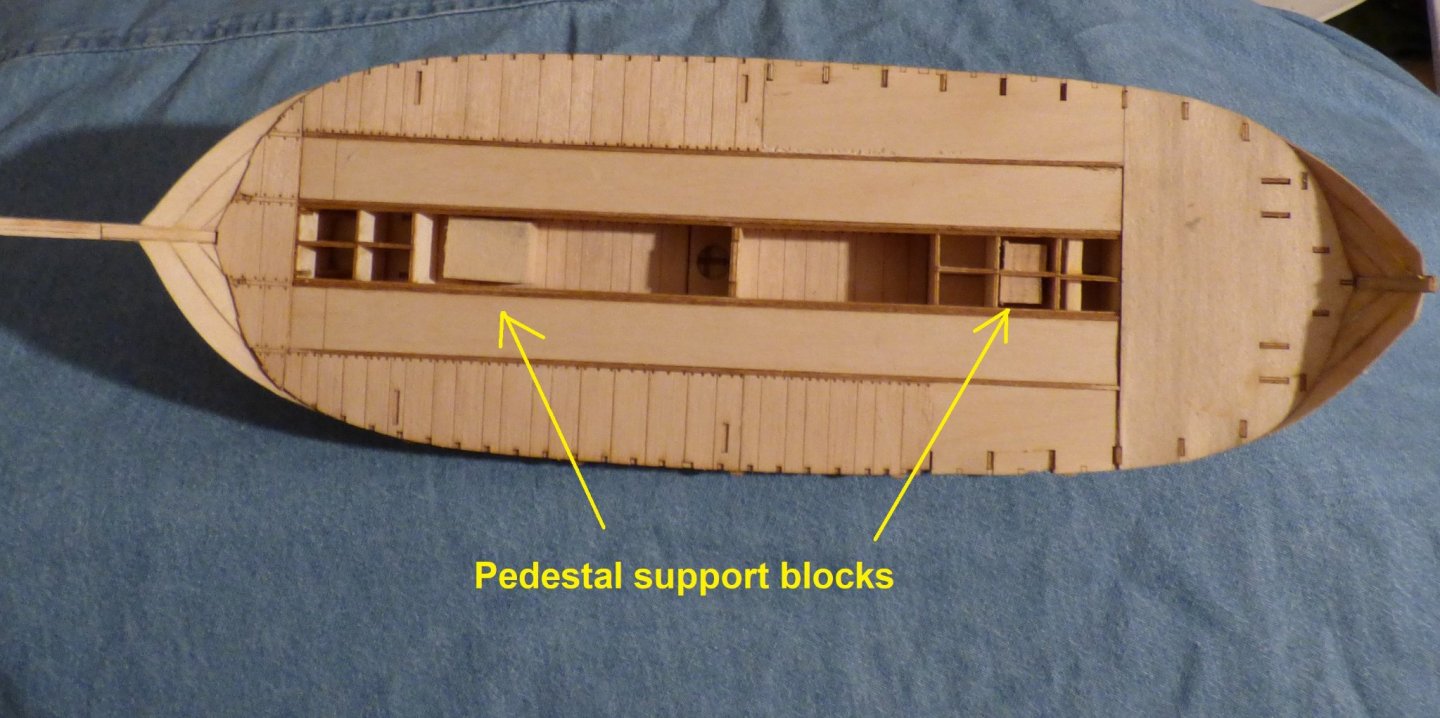

Practice complete and installation attempted. Two out of the five (4 of 10) holes were encumbered by bulkheads, but I was able to work around (or thru) that. Installation of all under deck beams complete. I still have one above deck beam, but that will come later. Not to bad, even close up. When stained, you should not see any issues. Putting the deck into place. Before I forget, emplace support blocks for the pedestals. I wish I had thought of this sooner...I would have placed the blocks below the 'lower deck'.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

How thin? I used very small ( 1 or 2 mm) bamboo pegs for my channels on SULTANA and it worked great. I use that on alot of the fragile deck furniture. Drill an appropriate sized hole using a micro drill bit. I believe I used #76. Using my Dremel as a lathe (kind of) and fine sand paper (220 or 400) I work a small piece of split bamboo BBQ skewer to the correct diameter, then glue in using wood glue. Test fit first. Bamboo is very strong for its size.

-

What time frame?

-

Closely considering my next step, I noted that when I pierced the hull for the beams, I filed perpendicular to the plank. If the side of the hull were perpendicular to the wate3rline this would have worked fine. ...the sides are NOT perpendicular, so if the beam is placed in the hole square to the hole it is not parallel to the water line. In order for it to be so by forcing it or twisting it, the hole ends up being larger than required (the plank and associated support wood are about 3mm thick). Care must be taken to pierce the hull at the correct angle. I practiced using wood the appropriate thickness. The correct angle will be easy on the actual model. Much success. On to the real thing.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

You have to be careful to avoid those unicorns. I guess to understand how they steered you have to understand how they navigated. Prior to the compass I guess they remained pretty much within sight of land and the helm orders were "go that way and don't run into anything". In that, the helmsman had to see where they were going. I know the Vikings did some open ocean sailing with the use of different nav tools, but that was an exception. With the advent of the compass (1200 in Europe?) he only needed to know what point of the compass to steer. As long as the officer of the watch could transmit that info, I guess that was okay. I forget how small those ships really were. Looking at replicas of MATTHEW of BRISTOL and VICTORIA, both with open decks under the after castle, somebody with a robust voice could pass that info...as long as there was not much urgency or they were not in a storm. Oh well, they did it somehow and they didn't have whipstaffs...so that's the name of that tune.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Cheap and effective tools

Chuck Seiler replied to Ron B's topic in Modeling tools and Workshop Equipment

Shouldn't this be "Inexpensive and effective tools"? The cheap tool is the one that breaks first time one uses it. -

What did they use in the early carracks? Tillers? How did they handle the logistics of the guy driving the ship being remote from the guy steering the ship? The needs for a helmsman to react quickly to a helm order in a slow moving sailing ship in the open ocean is not necessary. How about in restricted waters?

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Wood glue

Chuck Seiler replied to H March's topic in Building, Framing, Planking and plating a ships hull and deck

Sometimes I will use a small dot of CA to hold the end of the plank in the rabbet (CA clamp) before using wood glue for the rest. One day while demonstrating ship modeling at the county fair, I used a wee bit too much CA and when I finger clamped the plank, I glued the model to my finger. When I told a group of observers what I had done, they thought I was kidding. I extended my arm and pointed...with a model dangling from my finger. 😁 -

MATTHEW of BRISTOL (1497) has a whipstaff, but that is a replica so I don't know how accurate.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Papegojan 1627 by mati - FINISHED - 1/48

Chuck Seiler replied to mati's topic in - Build logs for subjects built 1501 - 1750

With Chuck/Syren no longer selling rope, many of us will have to start making our own...or finding a new supplier. -

Papegojan 1627 by mati - FINISHED - 1/48

Chuck Seiler replied to mati's topic in - Build logs for subjects built 1501 - 1750

VERY nice rope. Well done! -

Wood glue

Chuck Seiler replied to H March's topic in Building, Framing, Planking and plating a ships hull and deck

Hi I have also heard about the use of Acetone and other products which is why I wanted to know what the most experienced ones do. Regards I would have to put myself in the "experienced ones" category; not because I am a good modeler but because I do alot of un-gluing. I use the 70% isopropyl. It is less stinky than the 90% and MUCH safer than acetone. -

Moving forward. I will continue to work on both models but I will not document both. Because I am having more success with Woody Dog, I will document that build and pick up there where Cardy left off. It will take a couple weeks to get to that point. Meanwhile, I have some issue to confront. Some I have already decided on, but will share them for comment and input. --It was always my plan to make Cardy Dog the privateer as designed while bashing the kit and making Woody more like the Bremen Cog that CATOPOWER (Clare) built. I still intend on doing that. --Tiller/whipstaff. In the various “Shipyard” cog build logs there were discussions about how the tiller/rudder worked. My thoughts were posted in Chris’ log (post 68 and 71). It didn’t make sense to me. As I was doing research for an upcoming carrack model, I thought about using a whipstaff, however there was no documentation to back that up. I saw no whipstaff on any current replicas that I could see, nor on any museum quality models. I will go with the tiller below deck WITHOUT blocks. --I got lucky with Cardy Dog and managed to make the paint color reasonably close to what was called for. Several people who saw it up close were surprised it was NOT wood. I need to choose my stain wisely. I will be doing test runs. +HONEY MAPLE might closely replicate the color of Cardy Dog, but tests (so far) do not produce the same depth of color. A lot of coat may be required. I may end up using this for the deck. +Also considering NATURAL for the deck. +Like Chris, I am considering GOLDEN OAK and GOLDEN PECAN for the hull. I used GP for my PHILADELPHIA inner planking and was very happy with it.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Dead flat stations

Chuck Seiler replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

...or in this case a "+" in a circle. -

1/48 HMS Surprise, who makes the best flags.

Chuck Seiler replied to ratskiss's topic in Wood ship model kits

That is what I have done also. All told I have made over 100 flags for various projects. My paper of choice is cigarette paper because it is thin but strong. Unfortunately it is also small, so it cannot be used for large flags. Onion skin paper is also good, if you can find it...or tracing paper. I am not sure if you mean Kleenex tissue paper. I would NOT recommend that. Very fragile and rips easily. Could rip loose and jam printer...or so I am told <ahem>. The tissue paper used for gift wrapping works. "Flags of the World" is the site I use. -

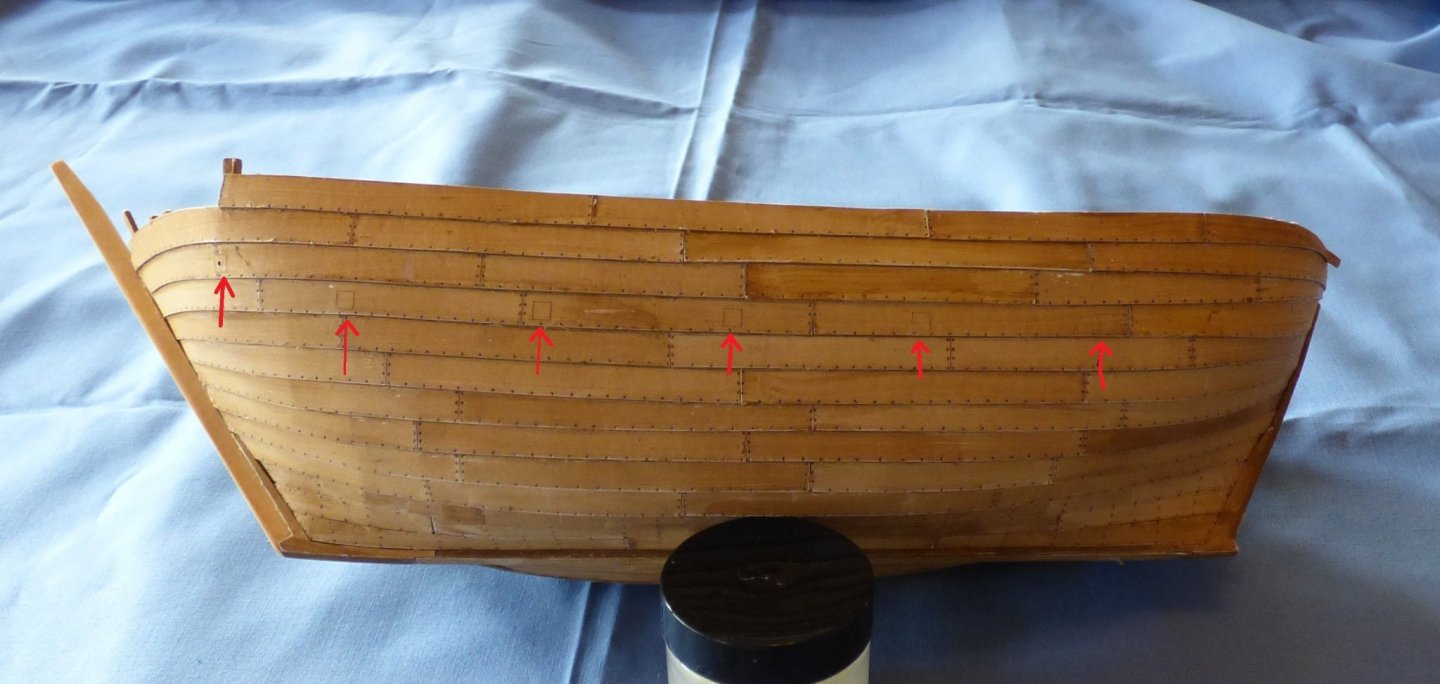

The Michala Street Shipyard and Beer Emporium is once again operational. I won’t be accused of outstripping the Kaiser shipyards of WWII but there is progress. When last we met, I discussed starting the wooden version of the model (Woody Dog). I have done so for reason I will discuss below. I am enjoying the wooden version much more than I did the card version (Cardy Dog). I’m not sure if it is because I have made it once already so I am more familiar or because am better able to work the material. That will impact some decisions moving forward. Above is progress of Woody Dog as of a few weeks ago. One of the issues I had with the model, and this is true of both wood and card, is that the material is thin and often had to be laminated in several layers to use. In most cases this turned out okay, but in the case of the deck beams, which extend out thru the hull, it was not working for me. This shows the location where the stubs would be. I decided to pierce the hull and insert wood stubs. Since I had already planked over the deck, I did not know where the bulkheads were in relation to the holes. I started the Woody Dog build so I could determine this. The forward-most beam would be a problem since most of the beam is above deck and exposed…and already installed. I could remove it, but decided it would cause more problems than it was worth. Extra care would be required when cutting these holes. Lining up Cardy Dog and Woody Dog as best I could, I marked the locations of the holes. In retrospect, it may have just been easier to continue the Woody Dog planking until those strakes were installed. Ah well. Hole cut. “Beam” inserted for test fit Beams trimmed and glued into place. A closer look shows some problems with the procedure. Some dressing up will be required. Still working on the hole for the above-deck beam.

- 130 replies

-

- wütender hund

- hanseatic

-

(and 2 more)

Tagged with:

-

Die Kogge Von Bremen by kentyler

Chuck Seiler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

I would be interested to know how detailed the planking instructions are. One thing to remember is that (working up from the keel) the first three strakes are caravel planked (side by side) and all subsequent strakes are clinker or lapstrake. -

Die Kogge Von Bremen by kentyler

Chuck Seiler replied to kentyler's topic in - Subjects built Up to and including 1500 AD

Somehow I am unable to edit once I leave and I don't remember how to create a link. Hefre is the link to catopower. https://modelshipworld.com/topic/23434-hanse-kogge-by-catopower-shipyard-172-scale-card/?tab=comments#comment-690640

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.