-

Posts

853 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by _SalD_

-

Hello all, Back from vacation and finding it hard to get back into drafting up the Armenia, perhaps after the holidays. There is something from our stay in Florida that I would like to share. There was a sand sculpting competition at the beach across from our place and it's the first time we were down there when they had the event. I have to say I was truly impressed by with the amount of detail put into these sculptures. All the sculptures are 7 to 8 feet high. If you would like more information here's the web site: https://www.siestakeycrystalclassic.com/ Just a few of the dozen or so sculptures First prize winner

-

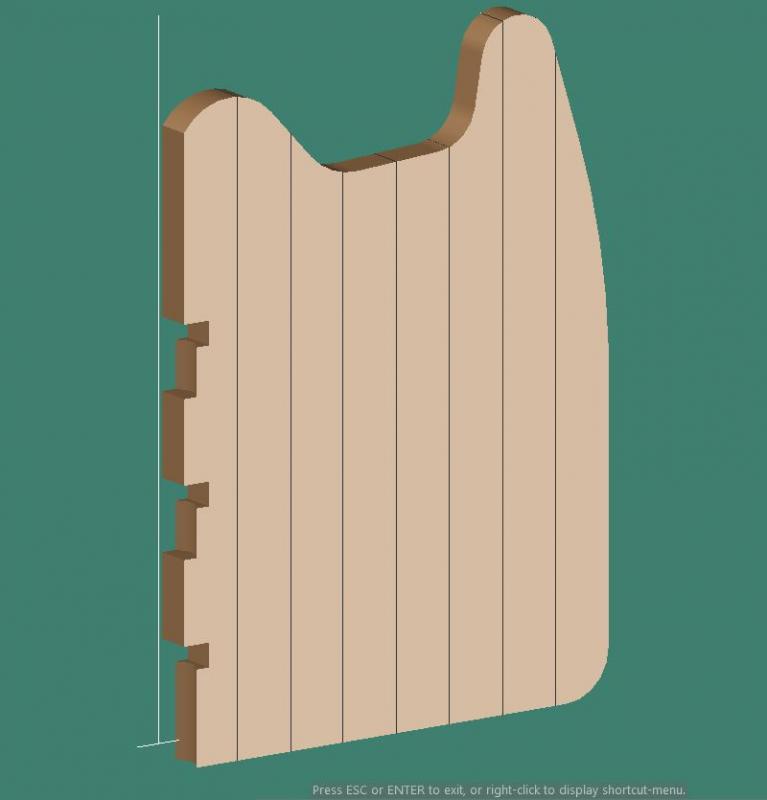

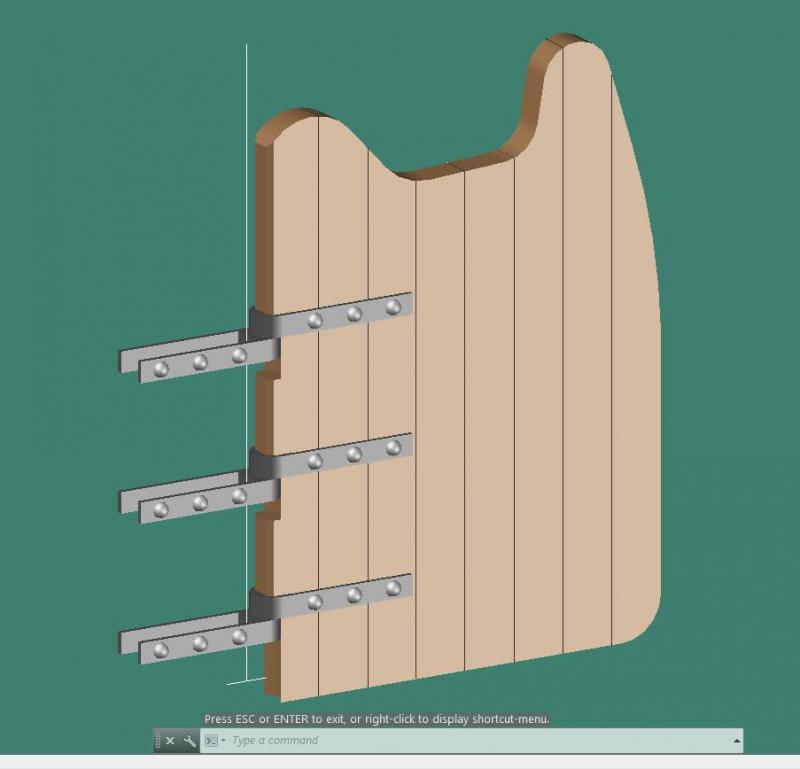

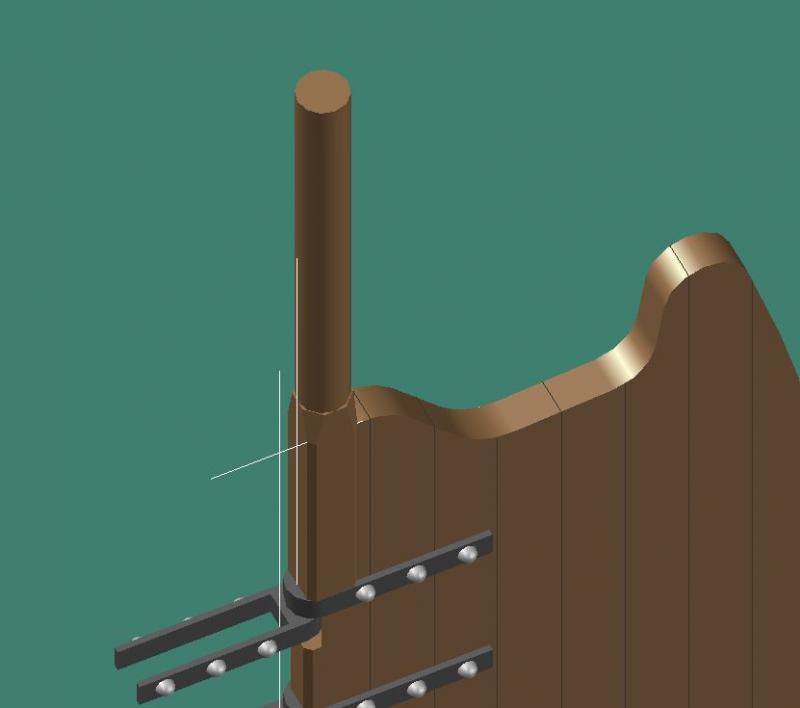

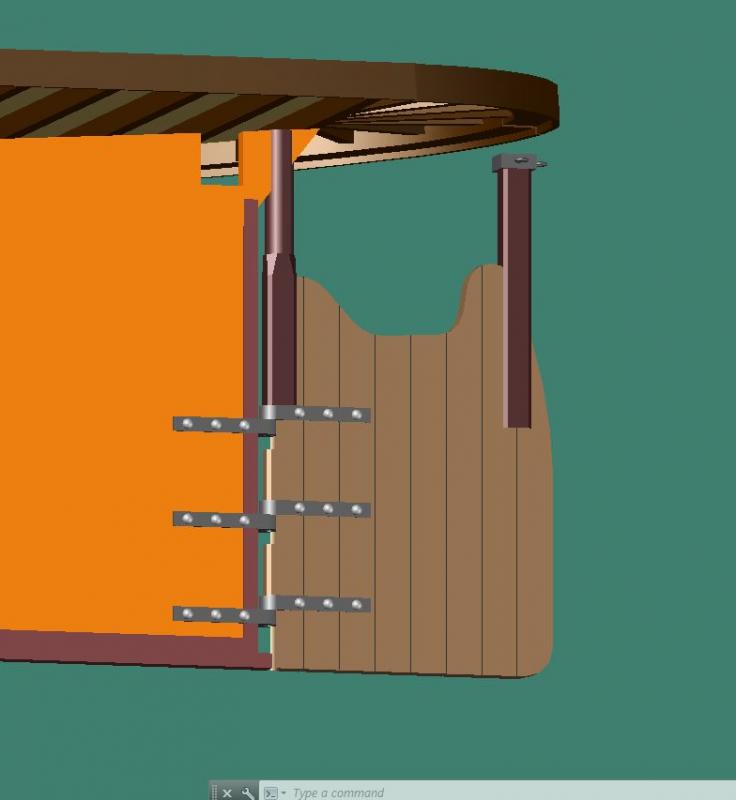

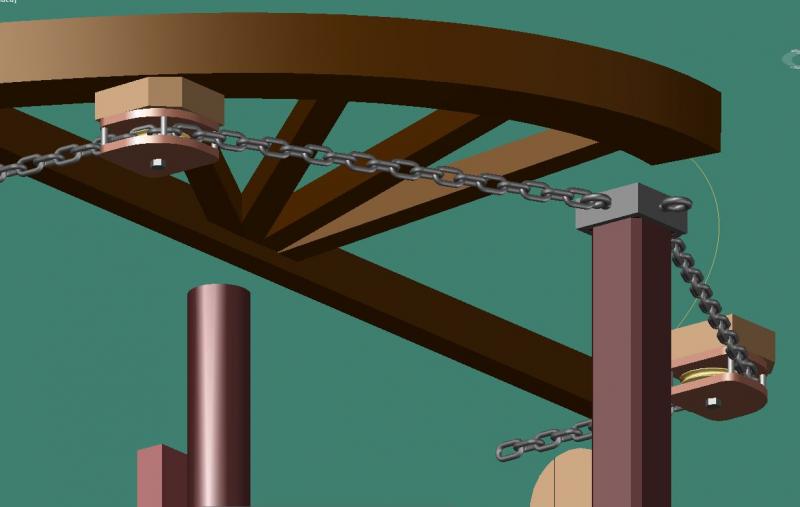

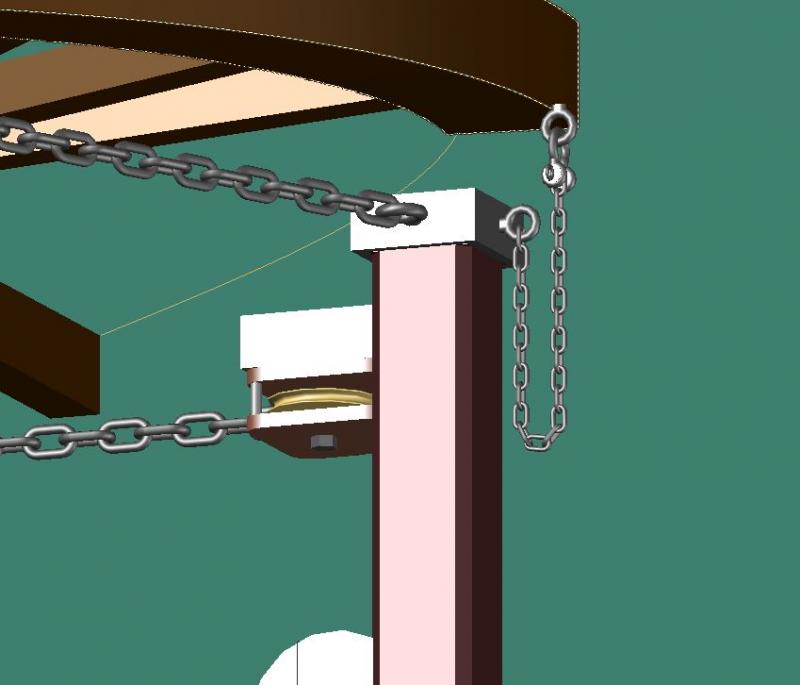

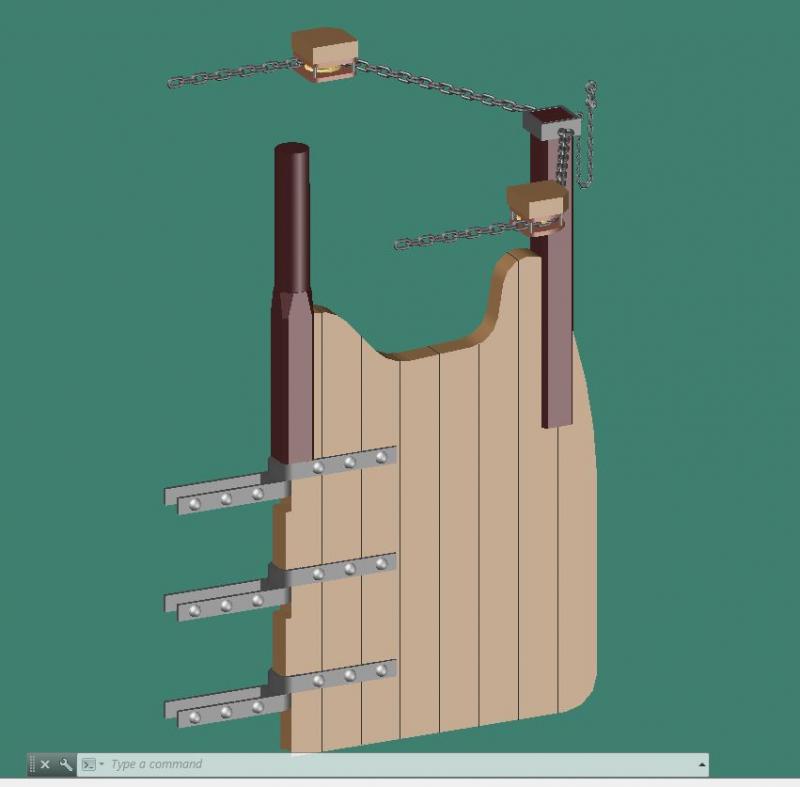

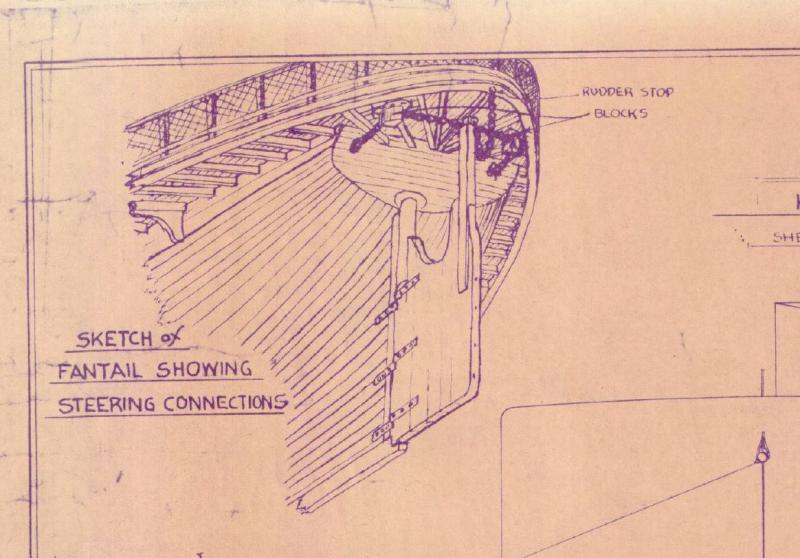

It’s been a while since my last post. It just seems I’m busier now after retiring than I was when I was working full time. Working on the rudder to try and finish up the hull. Started with the gudgeons and pintles Next was the rudder itself. It appeared to be constructed of individual timbers. Rudder post and steering post added Finally the steering chains and rudder stop chains were added. Fortunately I found a ‘lisp’ program, which runs inside AutoCAD that actually draws the chain links along an established line.

-

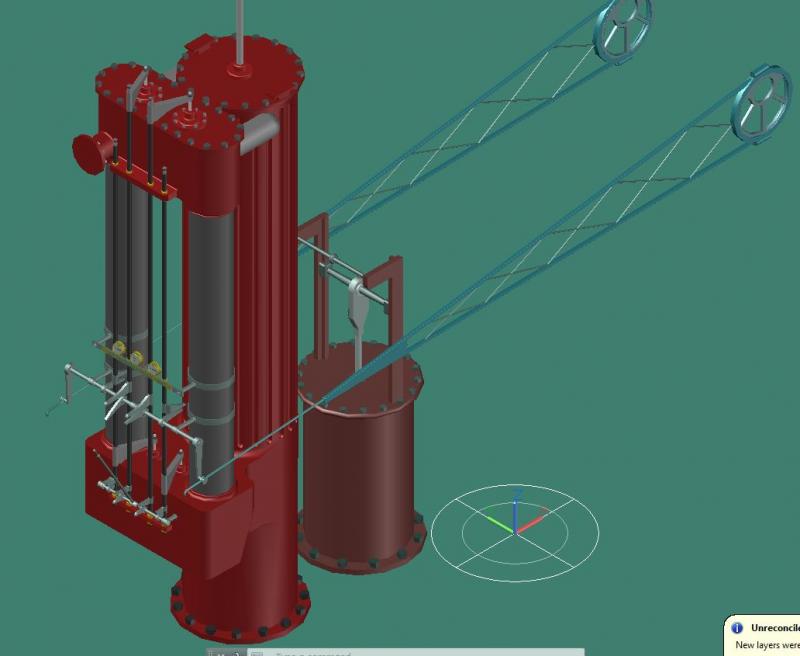

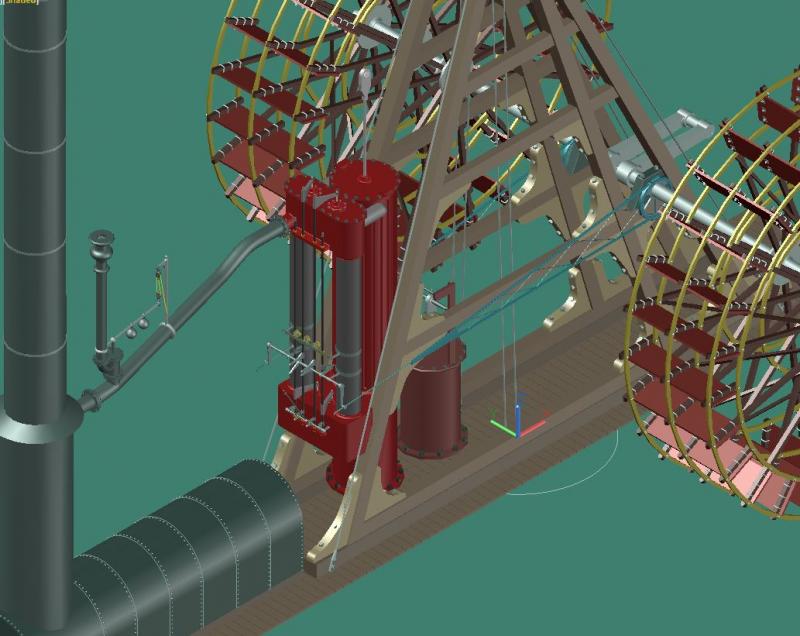

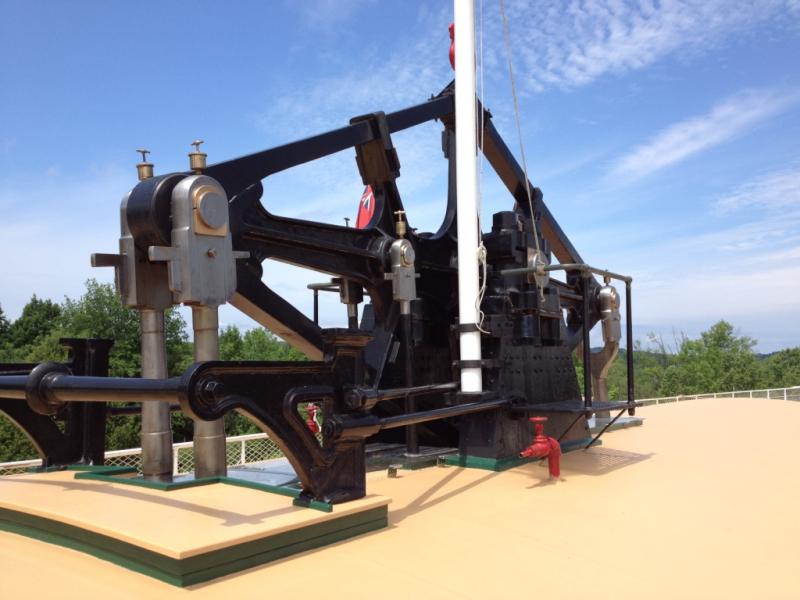

To put things into perspective I added a couple workmen to give an idea of how big these engines were. The upper figure is on the ship's main deck and the lower figure is below deck. I cannot take credit for drawing the 3D man, I borrowed them from my former place of employment. The person is roughly 6 foot tall.

-

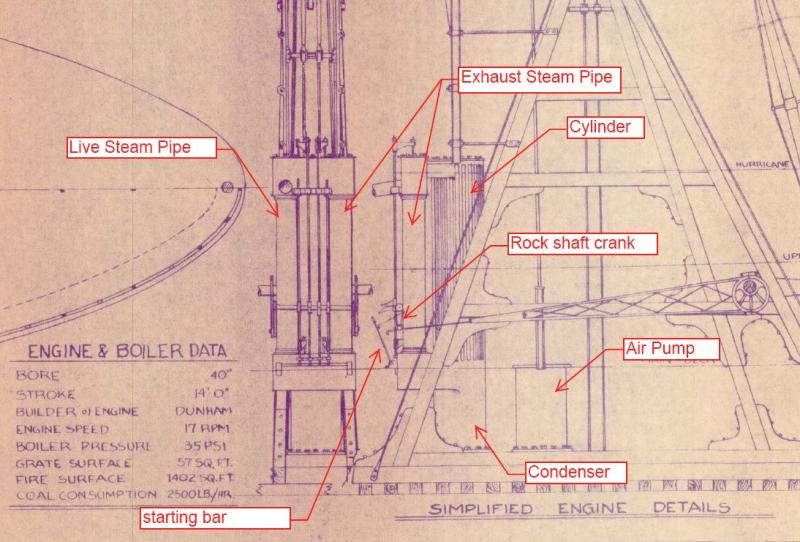

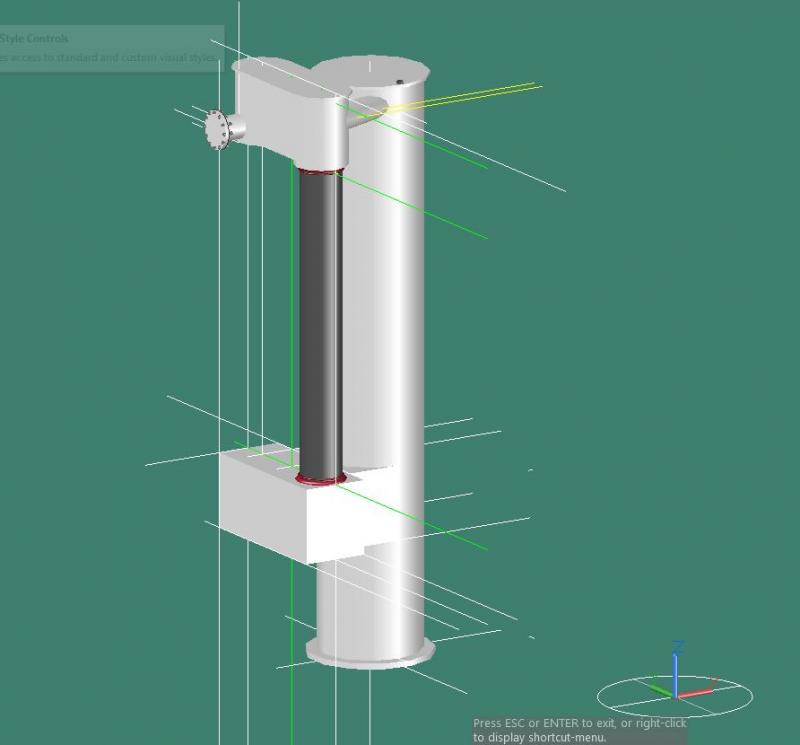

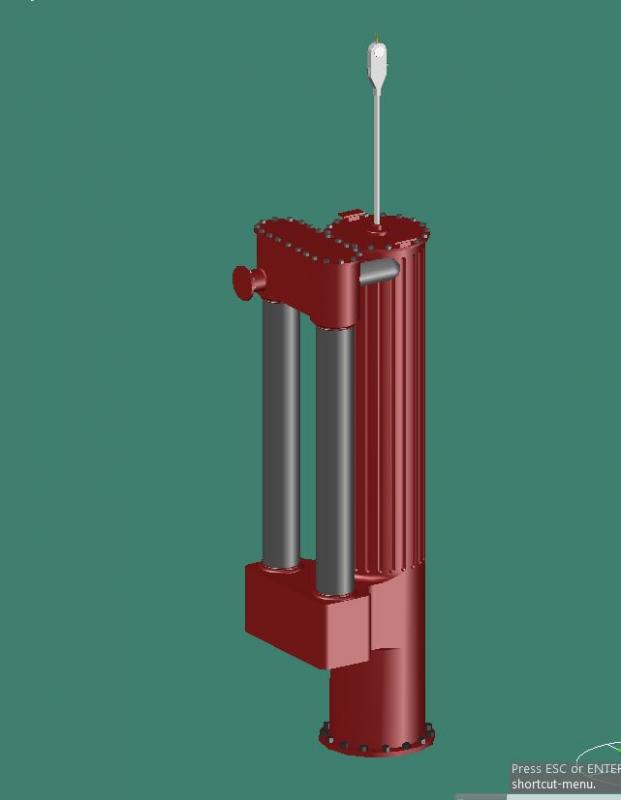

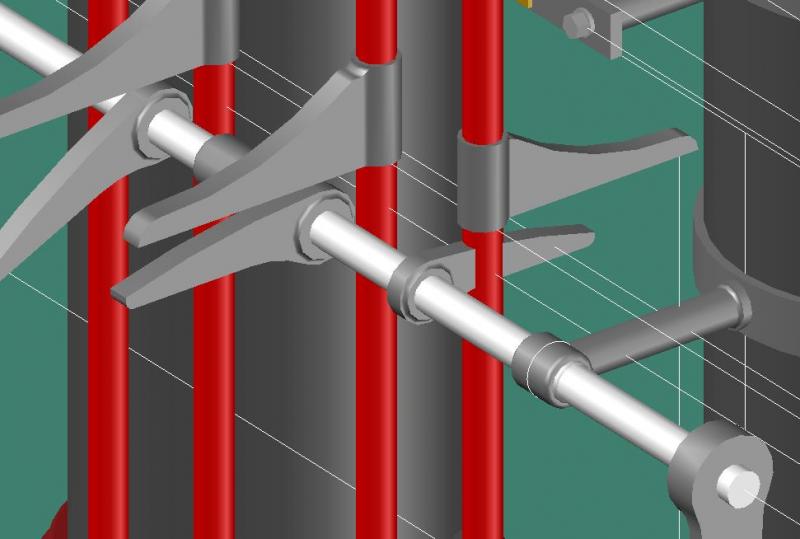

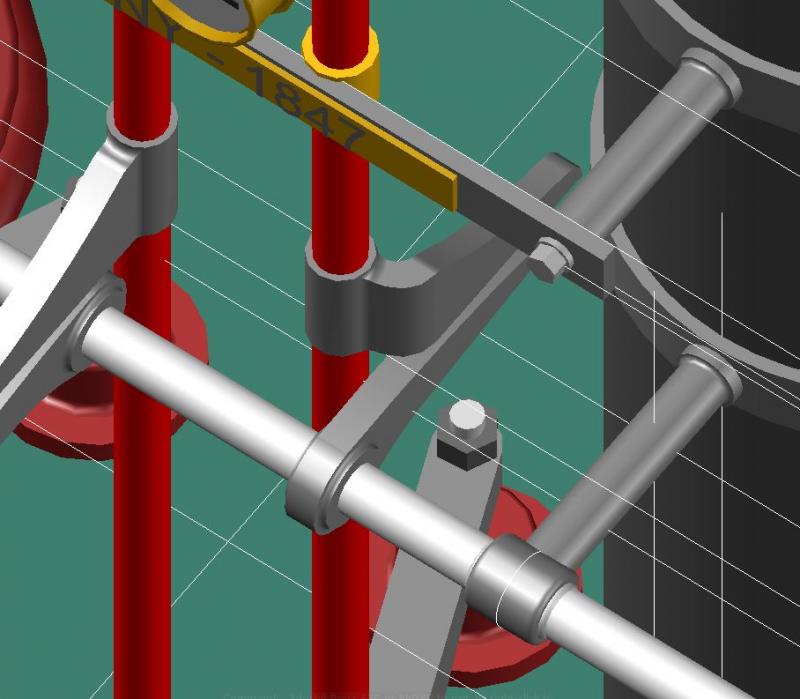

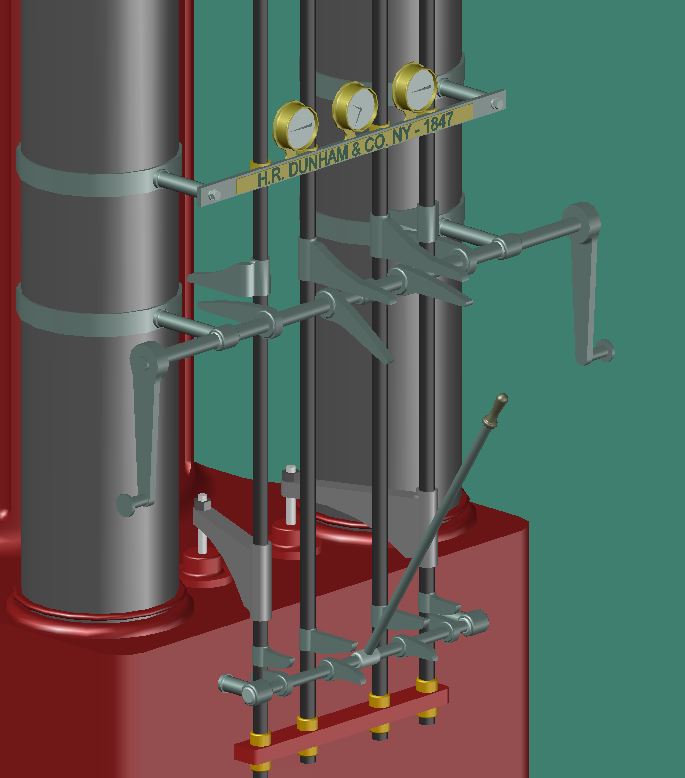

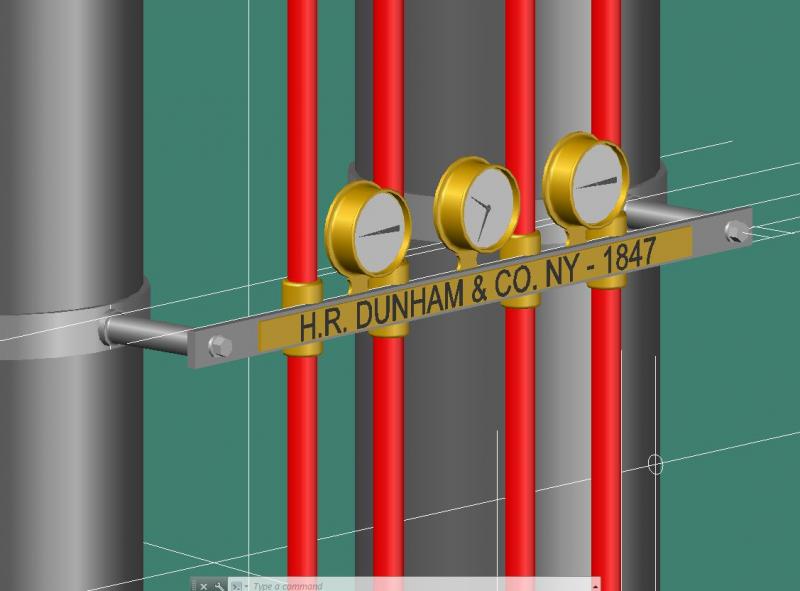

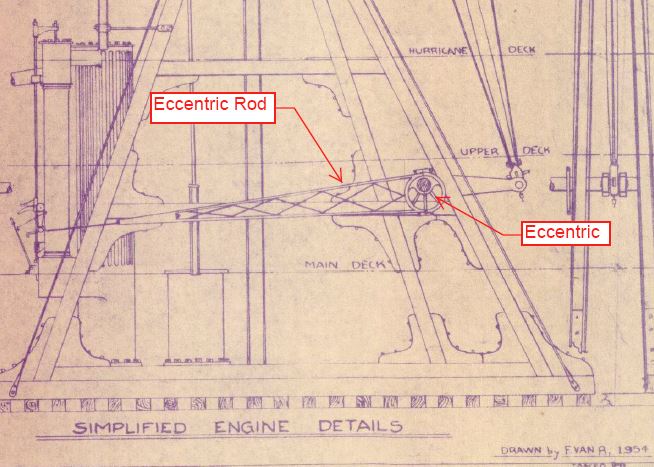

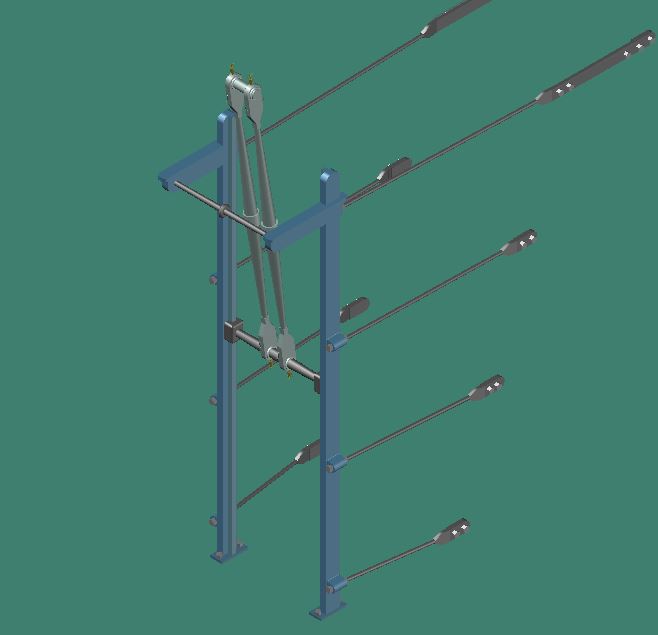

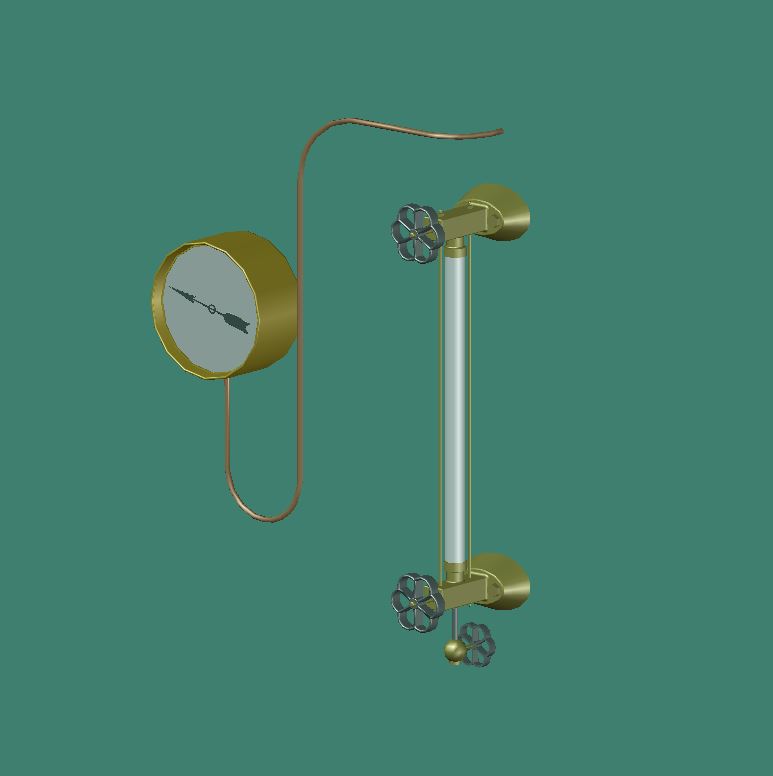

The engine is made up of a few major parts. The first part that I modeled was the air pump. The air pump was connected to the condenser and was used to draw off the condensed water and steam vapor. This was fairly simple to model as a cylinder with a piston rod. The air pump was operated by the two slimmer connecting rods coming down from the walking beam at the beams quarter point. Next I started on the main engine which is comprised of the condenser, cylinder for the main piston rod and the live steam and exhaust steam pipes. Next I modeled the valve lifters for the live steam and exhaust steam. The valve actuating mechanism consisted of a set of large, curved cams called “wipers” which worked against followers called “toes” which were affixed to vertical rods going to the steam and exhaust valves at the upper and lower ends of the two cylindrical vertical steam pipes. The drawing of the engine did not clearly show how these cams were laid out but I did find a good reference. It was on goggle books called “Marine Boilers; Marine Engines; Western River Steamboats” https://books.google.com/books?id=4Q9WAAAAMAAJ&dq=marine_boilers_marine_engines_western_ri.pdf&pg=RA1-PA73#v=onepage&q&f=false Even with this diagram I still ran into a little interference with the cams. It’s not clearly shown in the diagrams but I believe the outer cams must have had and offset to operate correctly. Completed valve actuating mechanism. The lower smaller cams with the starting bar was used by the engineer when first starting the engine either forward or in reverse. The rock shafts were two separate shafts supported in the center by a common bushing. The pressure gauges and clock layout was plagiarized from the Ticonderoga. Engine, air pump with eccentrics Engine in place

-

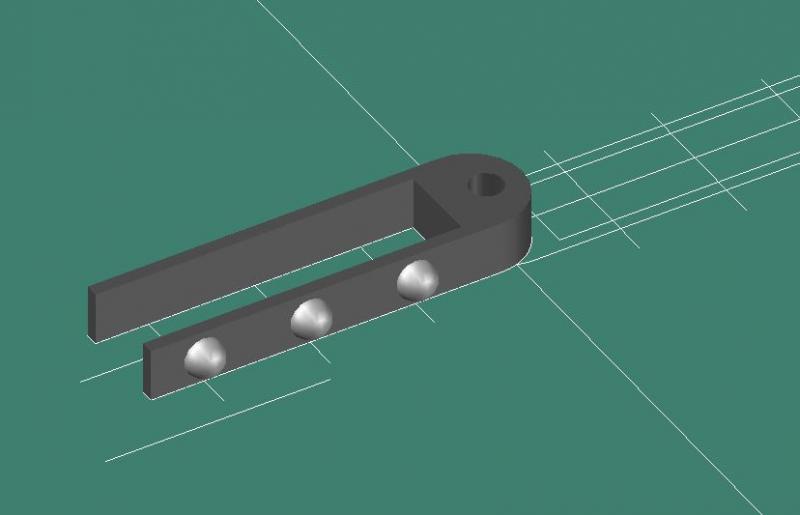

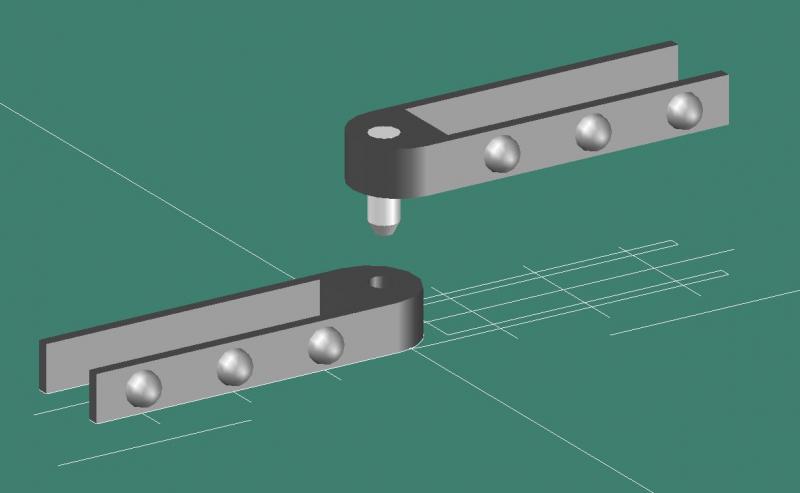

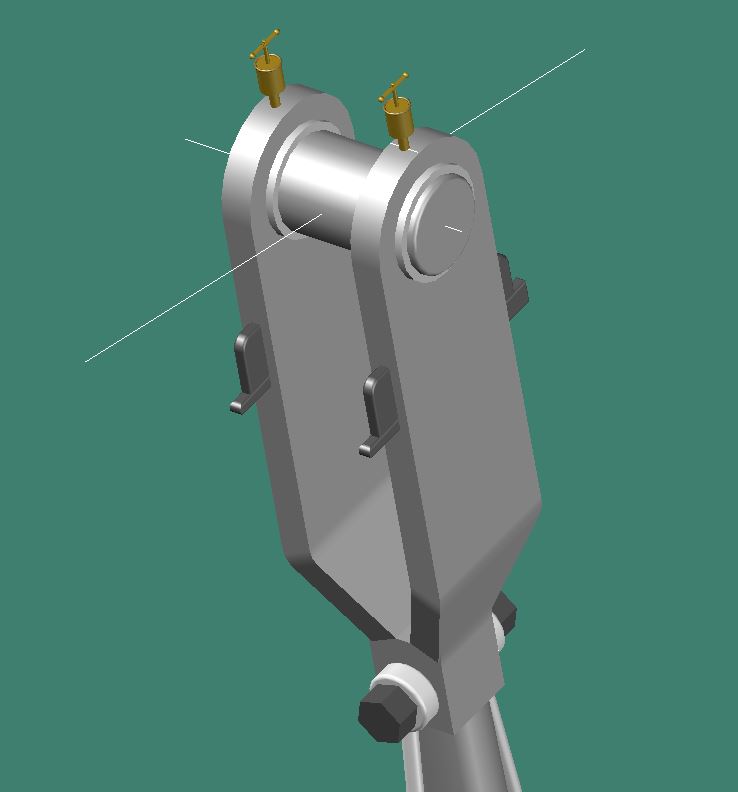

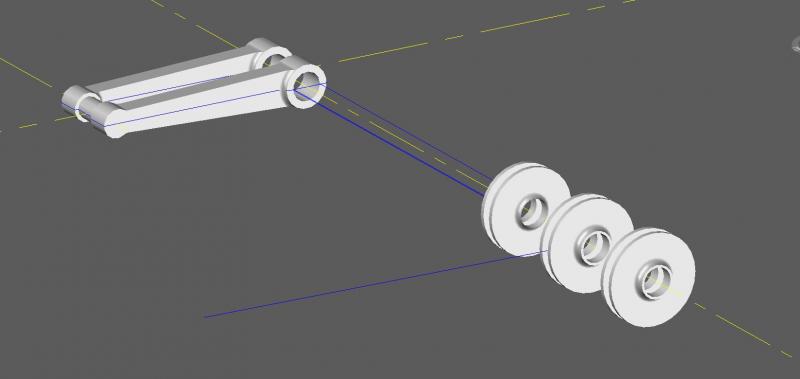

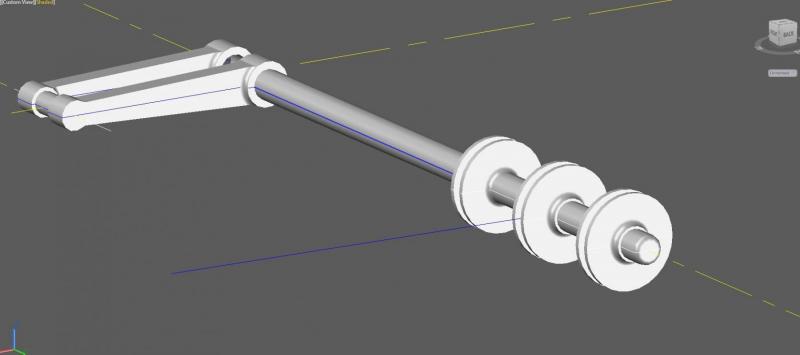

There were eccentric rods on either side of the engine that once the ship was under way would be engaged onto a rock shaft which operated the steam intake and exhaust valves (more on those to come). The eccentrics are connected to the paddle-wheel shaft and have off-centered hubs which produce a back and forth movement in the eccentric rod. Eccentric This is how I believe the eccentric rod mounted to the eccentric. Eccentric pair Mounted to the paddle-wheel shaft.

-

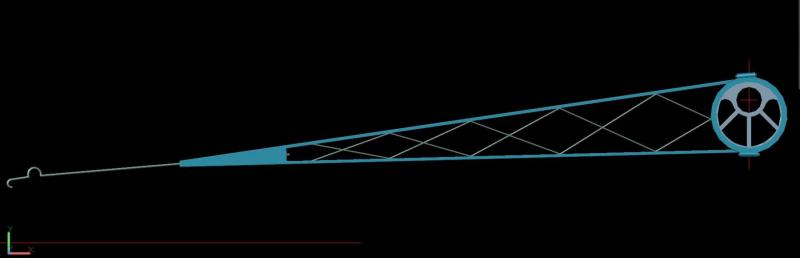

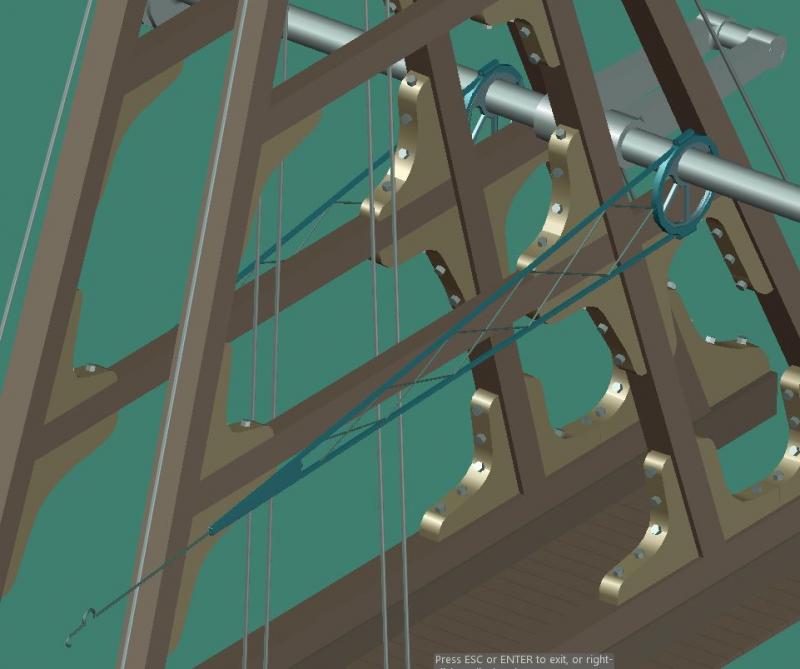

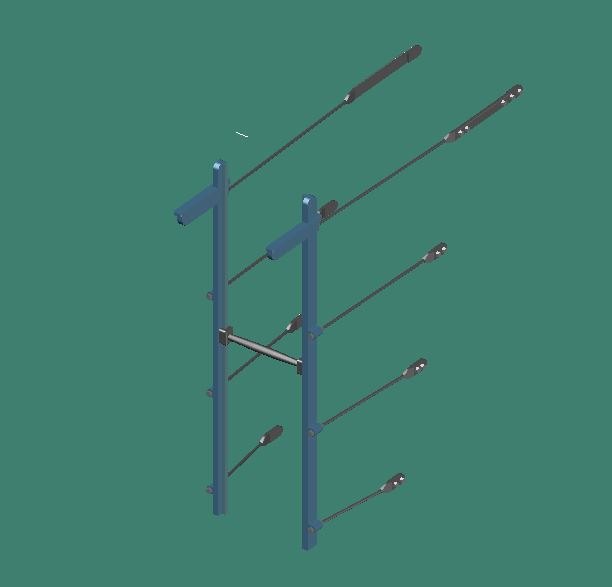

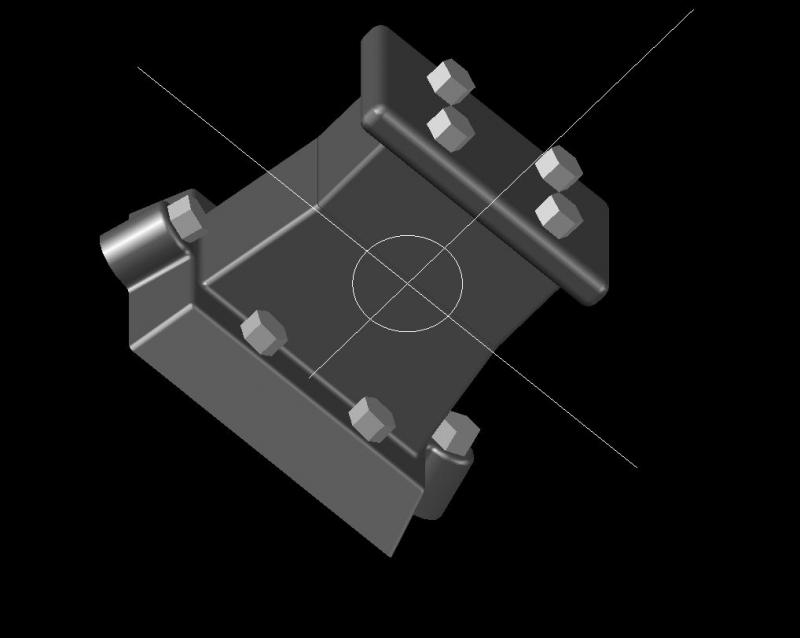

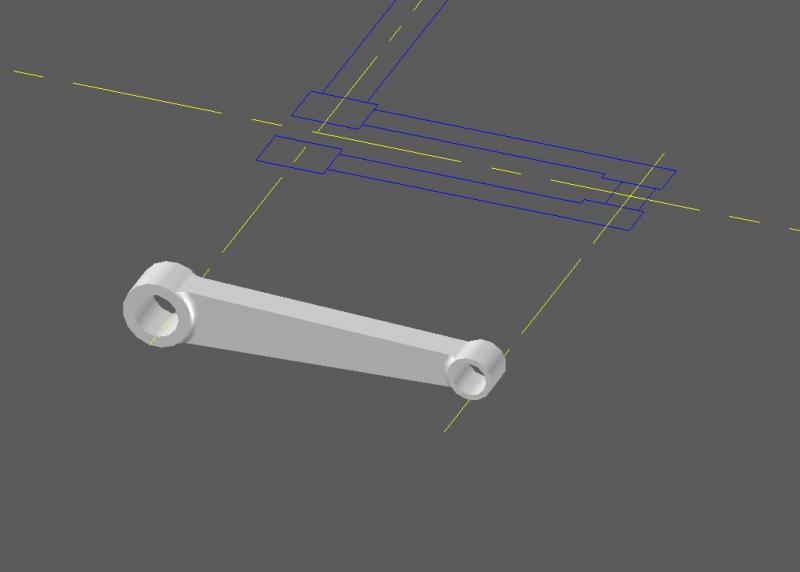

After the frame I started work on the engine’s connecting rods and please forgive me if I don’t use the correct terminology for some of these parts as I’m not a machinist or ME, so please, feel free to correct me. The first one is the braced connecting rod that links the walking beam to the paddlewheel crank. This wrought iron rod is approximately 30’ long by 10” in diameter and is stiffened at its midsection by supplementary rods which bear against braces affixed to its midsection. The bearings were of the plain type and made of brass or bronze. The bearing would be adjusted by means of tapered gibs. What I’m not too sure of is the function of the two brass fitting shown on top of the bearings that you can see in the pictures I took of the Tiaconderoga’s connecting rods (previous post). I’m thinking they’re some kind of grease fitting to lubricate the bearings. Not sure of their name. The next set of connecting rods are located at the other end of the walking beam and connect the beam to the crosshead which connects to the piston rod of the engine. These rods are roughly 10’-6” long and 6” in diameter. Crosshead guide which sits on top of the engine's cylinder and is braced back to the frame. Crosshead guide with connecting rods. The next set of connecting rods are for the air pump. These two slimmer rods are connected to the beam close to its quarter point. All rods in place.

-

Wayne, thanks for the reference. I always enjoy studying the old engineering reference books, they're so much more simplified than today's text books since it was all hand calculations and not the pages and pages of computer generated calculations. I thought the beam must have been made in different pieces but just wasn't sure how it was pieced together. Your reference and explanation helps a lot. I took a few pictures of the walking beam on the Ticonderoga at the Shelbrune Museum in Vermont this past summer, now it makes more sense.

-

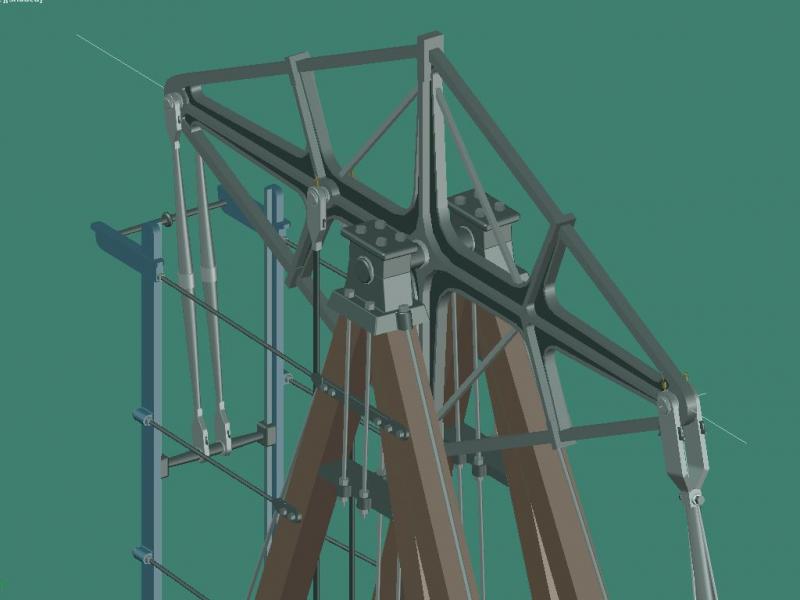

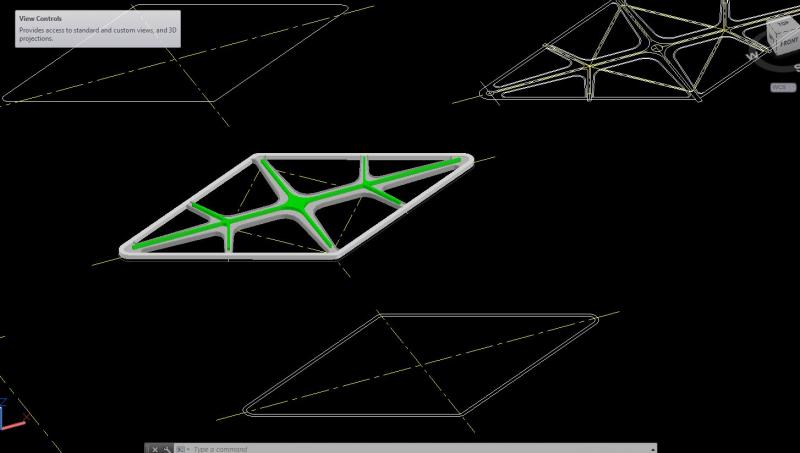

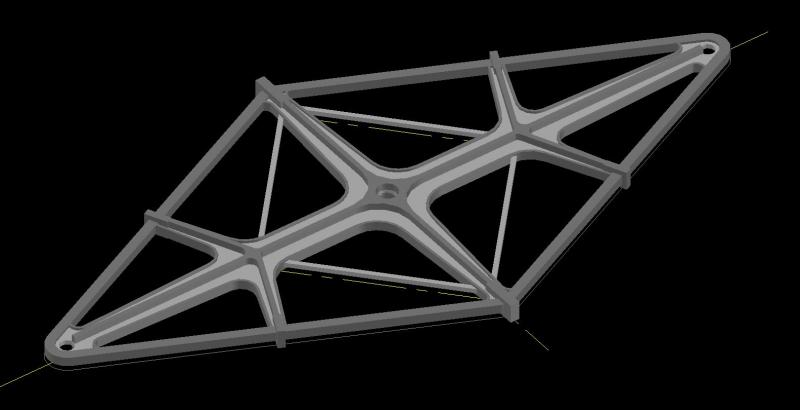

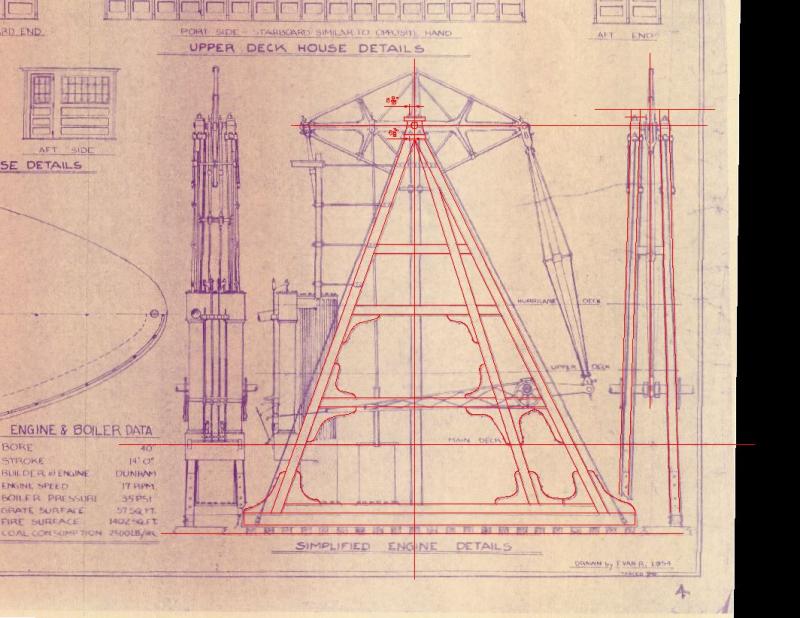

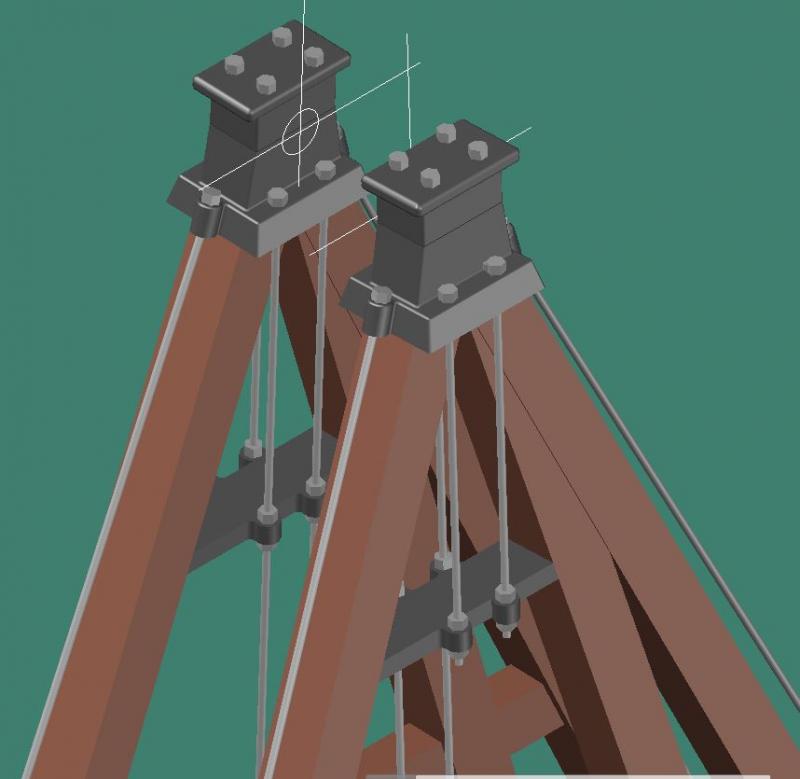

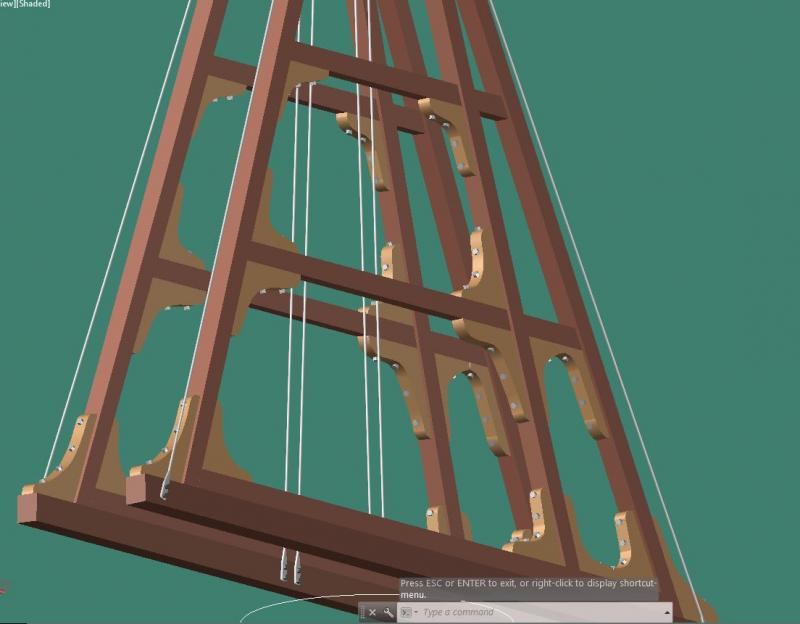

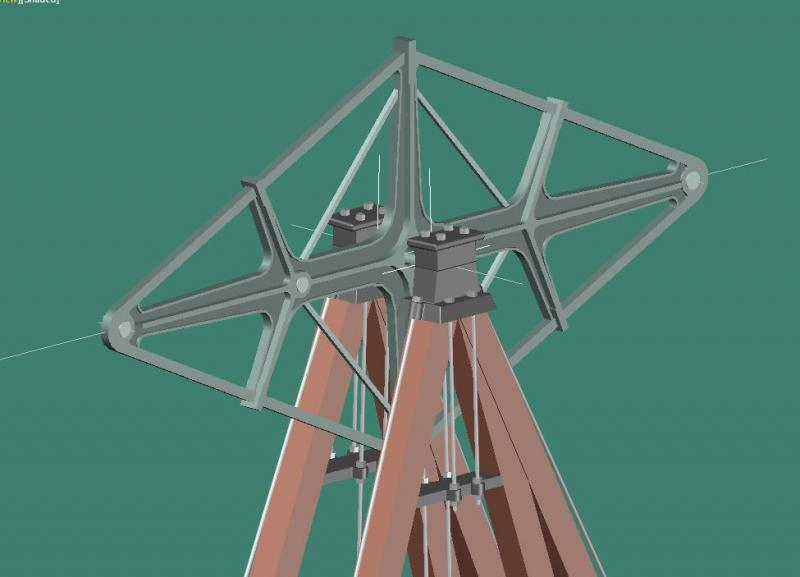

I started working on the walking beam engine by first modeling the walking beam. The dimensions were taken by scaling the drawing. Building the model laying flat Nice thing about 3D models is that you can build parts in any order and put them in place. Next I modeled the support frame for the beam based on the drawing dimensions. Bearings at the top of the frame that supports the beam. The main vertical members are 12”x12” timber. For the bracing tie rods I used 1 ½” diameter rods. beam in frame, still need to add the main support shaft. As a side note I made a little virtual walkthrough around the relief valve that I posted but you couldn't play it, so I deleted it. I guess you can’t post videos here.

-

Nice work Elijah, deadeyes and chain plates look great. Hope you're feeling better

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Wayne, thanks for looking and all good questions. They probably did use the valve to blow off steam, bypassing the engine, for both reasons you mentioned. I didn't notice until you asked but the outside ball does scale a bit smaller than the inside one. I'm not sure if that was intended or if they were suppose to be equal. It probably did work like an arm scale where the weights are movable to get the correct relief pressure they wanted. As for the rope, straight I can do, going around the sheave... a different story.

-

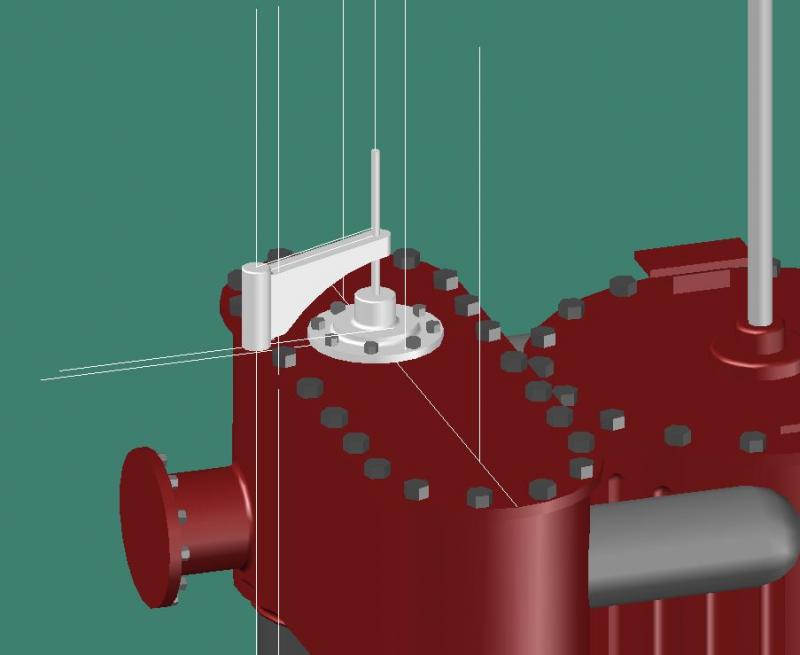

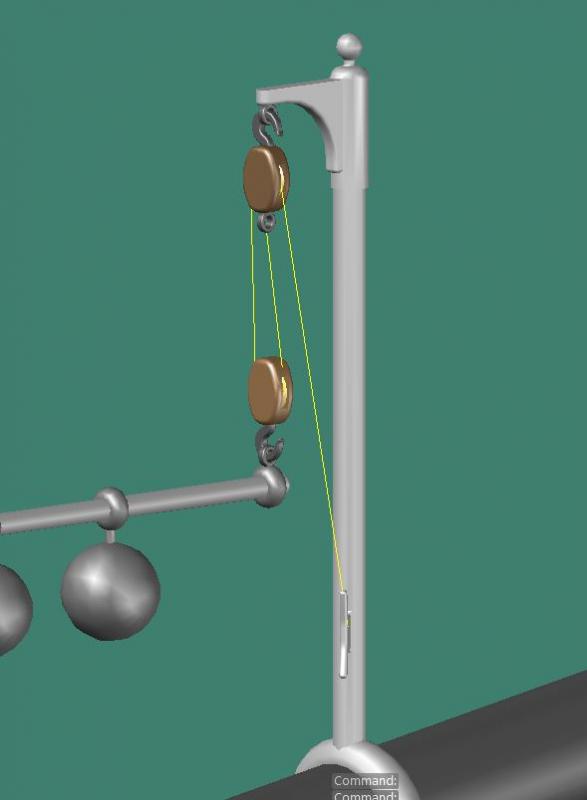

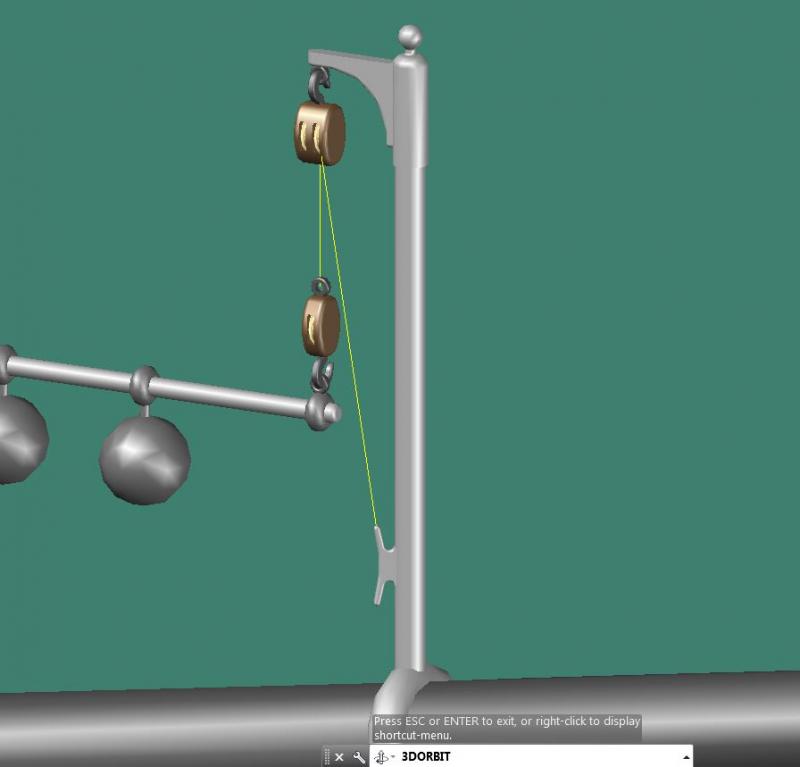

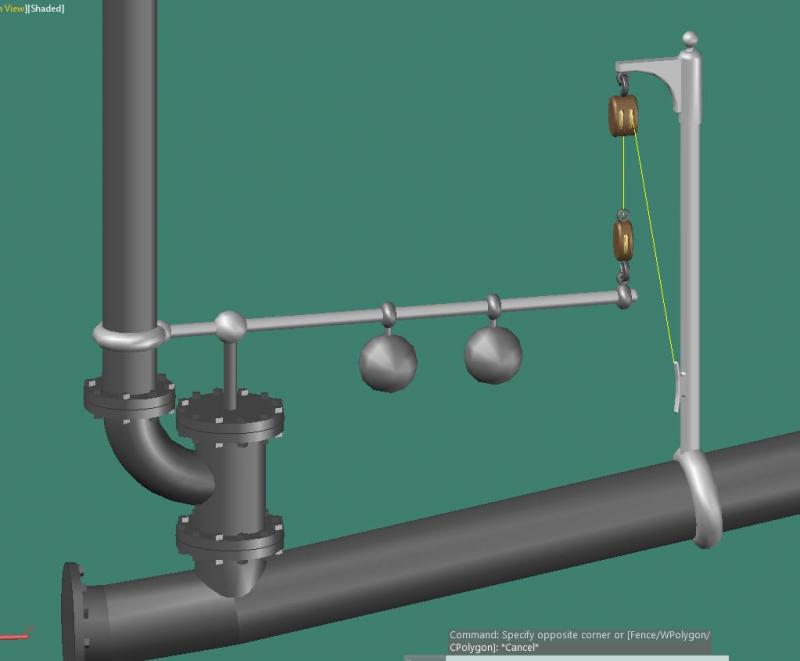

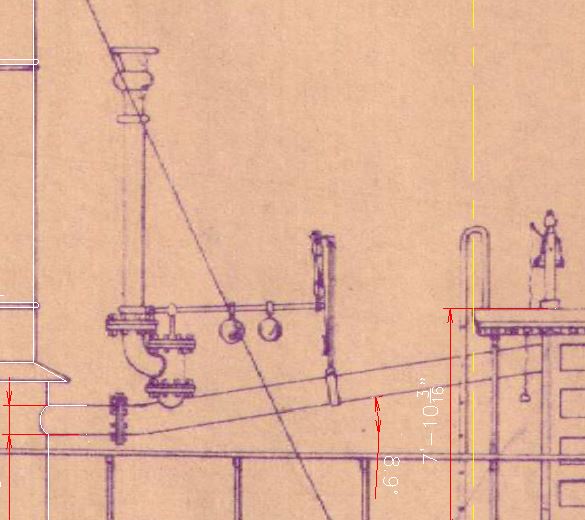

The next part I worked on was what I think is some sort of pressure relief valve in the main steam line from the boiler to the engine. From the drawings it appears to be a weighted lever with a plunger type valve that if too much pressure builds up would be forced up allowing the steam to be bypassed to a blow off stack. I’m not too sure what the purpose the block and tackle at the end would serve other than setting how far the plunger would need to rise before the steam was bypassed. Original drawing layout Modeled relief valve Weighted lever. Block & Tackle The rope in the blocks are just two separate lines, I haven't tried making realist looking rope reeved through the blocks yet (well, actually I tried but the results weren't pretty). Valve in place off of stack

-

Thanks EJ, I was thinking about doing that but at the moment I don't know how. I'll need to do research on the subject. Thanks Wayne, I think the boiler has one large relief valve that I'm working on now. Thanks Nils and I agree with you in that although 3D design drawings are nice and you can show the client a pretty picture you can't really building anything from them. You still need simple 2D drawings showing plan views and elevations. Maybe I'm too old fashion and that's why it took me 30 years to learn 3D.

-

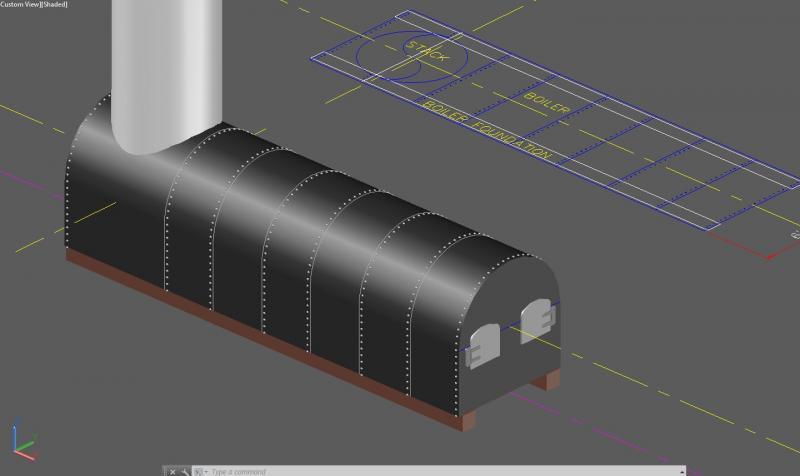

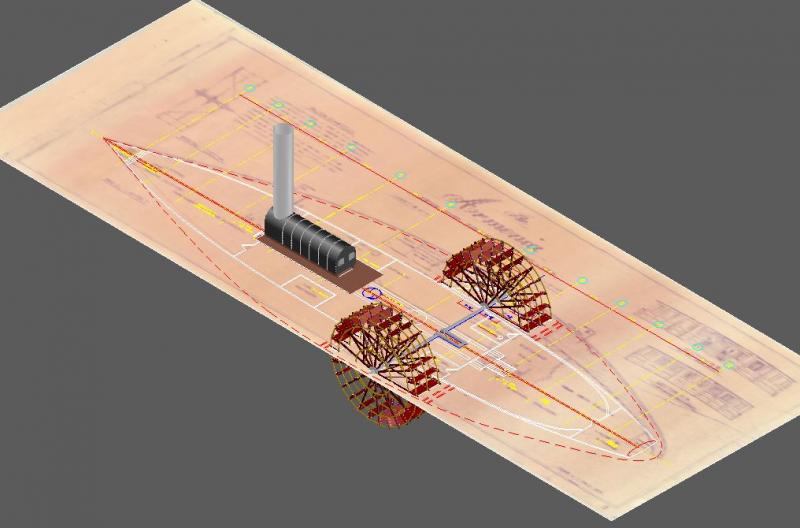

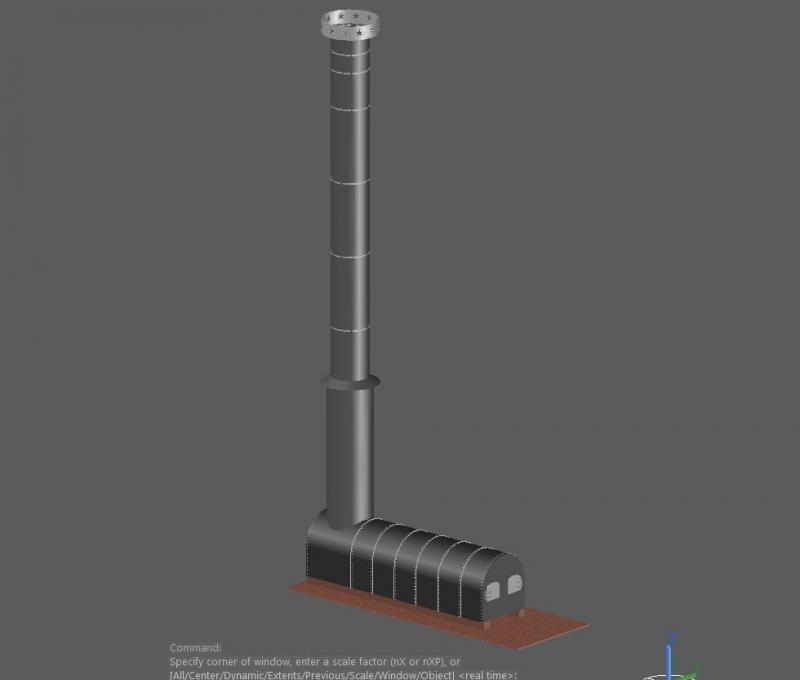

I couldn’t find too much information on what the boiler would look like so I took some artist liberties. From the drawings I knew its diameter and length, stack location and the stack height and diameter. I wasn’t sure about the number or location of the doors used to load the coal so I guessed at two. I also took some liberties and added a pressure gauge and sight glass. I always made fun of the designers at work when they added nuts and bolts to pieces of equipment that would never be seen when you printed out the drawing but now I know why they did it, it's fun. Boiler fit on the plans Boiler in the ship

-

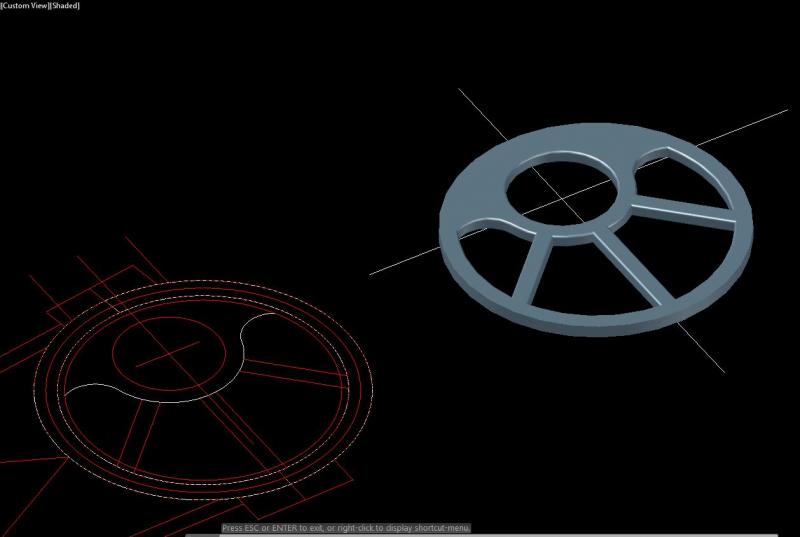

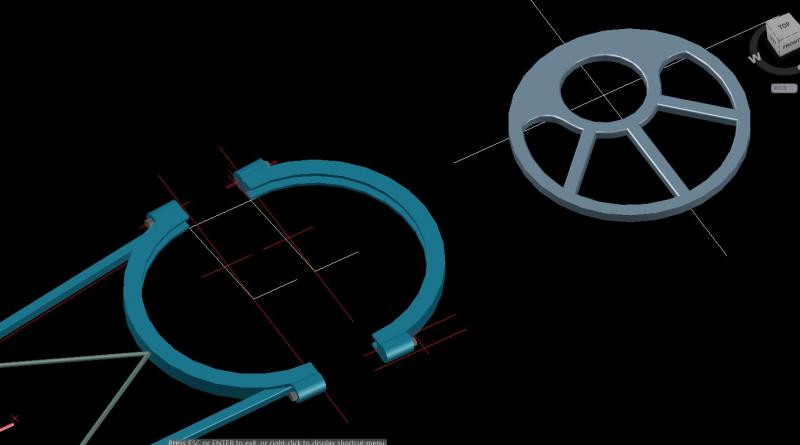

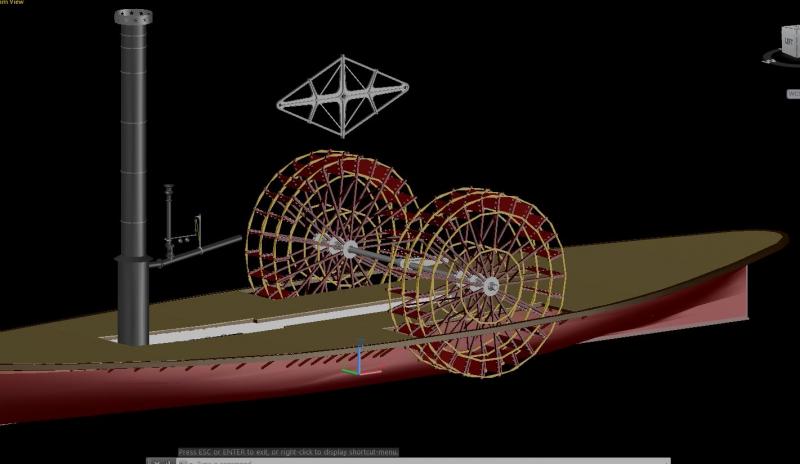

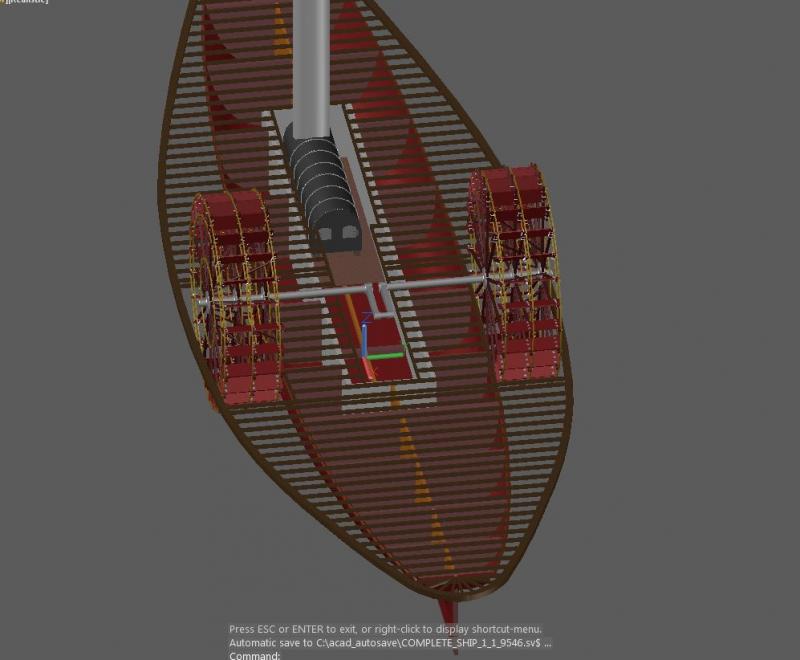

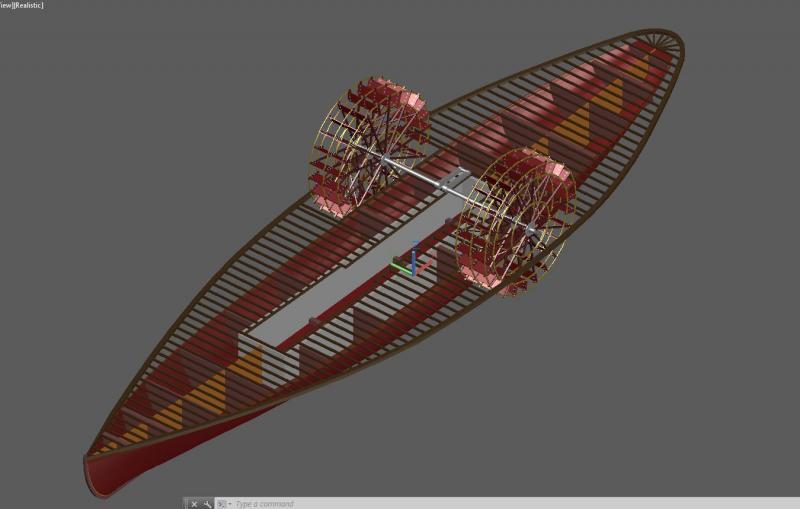

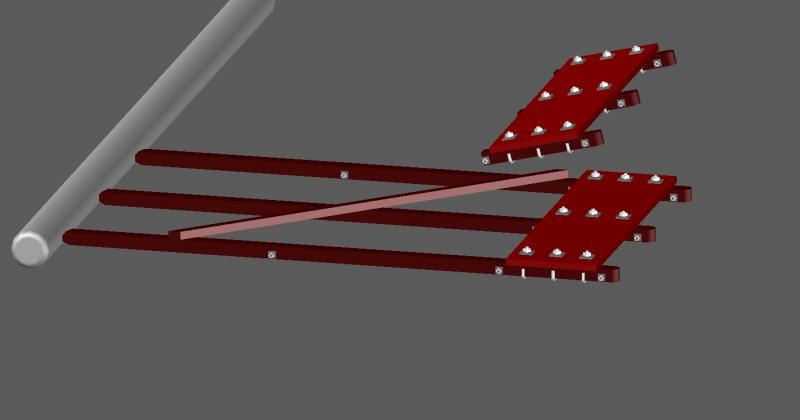

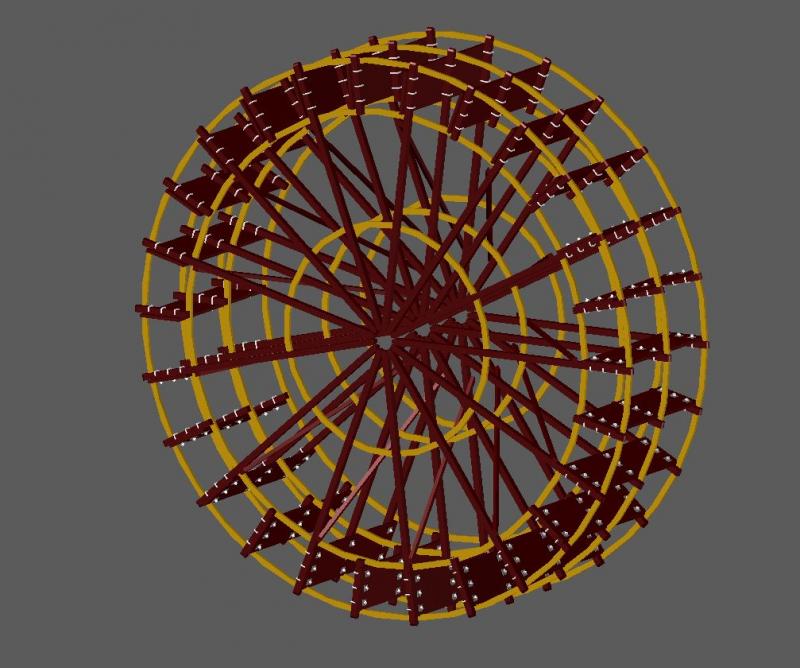

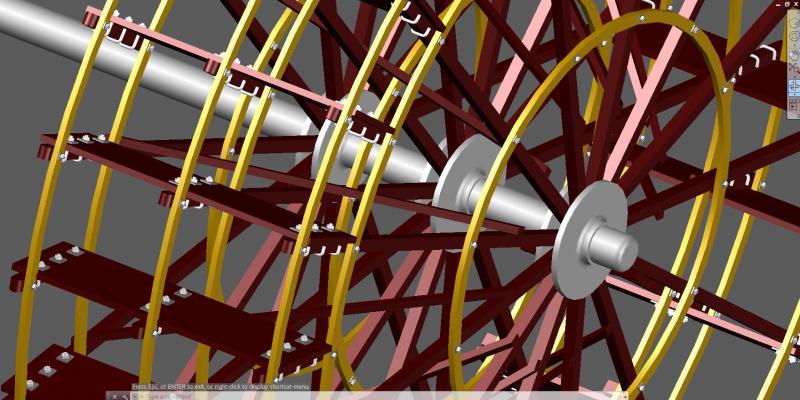

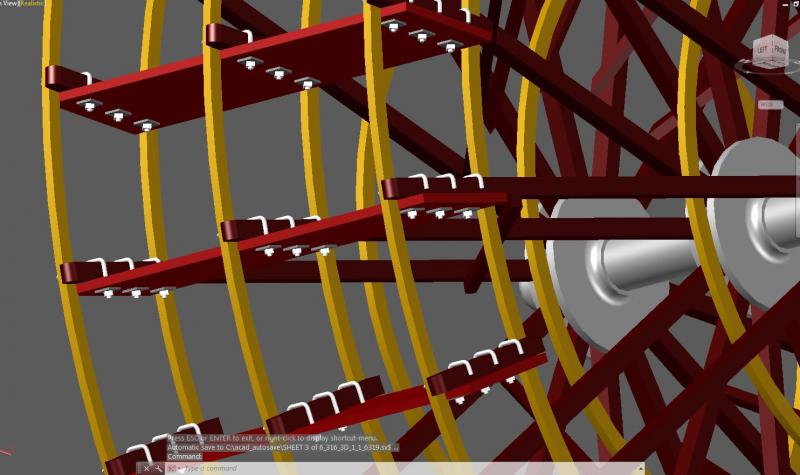

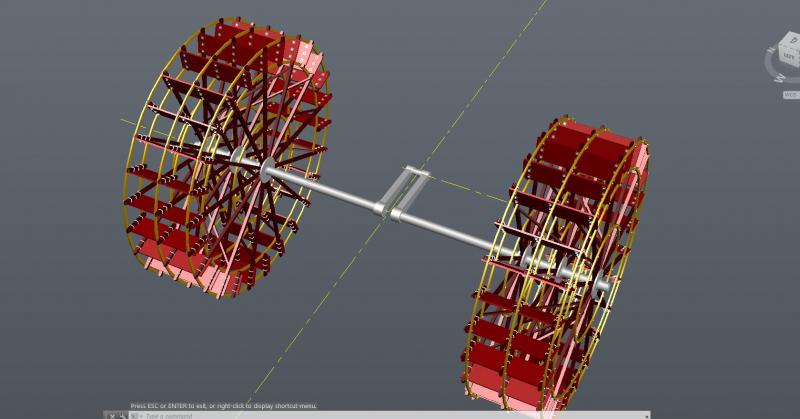

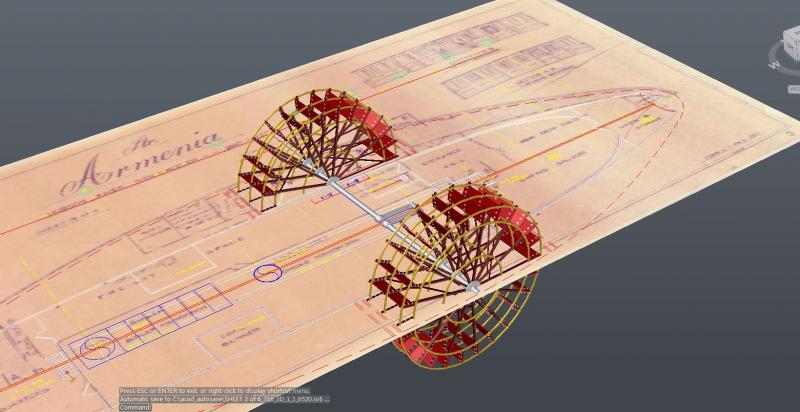

Next I decided to work on the paddlewheels. I started with the crank arm with dimensions taken from the drawing. I also learnt that the length of the arm will be half of the stroke length. So with a stroke of 14’ the arm is 7 feet long. The flanges for the paddlewheel arms were next. Followed by the shaft. The buckets (paddles) on the paddlewheel are 8’-3” long by 2’-4” wide. There are 13 main buckets and 13 intermediate buckets per wheel. The wheel was 29’-4” in diameter and rotated at a speed of 17rpm. One question I had about the buckets is; are they made of one piece of wood 28” wide or of three planks 9 1/4” wide? After making one set of the main and intermediate buckets it was very simple to array (copy) them 13 times around the center hub. Iron bands were added as shown on the drawings. After one paddlewheel was completed it was just a matter of copying it to the other side for the complete paddlewheel assemble I like this view. wheels set in the hull

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.