-

Posts

1,871 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MEDDO

-

That framing looks really nice. I am sorry if you said before but what are you using to cut all those mortise out with? Are you getting those incredibly tight joints with a chisel/file/blade or are you one of the power people with a fancy mill?

- 889 replies

-

It really is helpful to have others build logs to reference. The new tag system makes finding them much easier than before. I especially used the great log by @JpR62. Also the middle of @Chuck 45 page thread was very nice here

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Those look great Ryland

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ripping Planks - what I've learned from others

MEDDO replied to glbarlow's topic in Modeling tools and Workshop Equipment

I know @kurtvd19 had made one of those "cut outside the blade" jigs and showed it at one of the recent NRG conferences. Seemed like it would work well. -

Also "new" member after a long shore leave

MEDDO replied to SkerryAmp's topic in New member Introductions

Welcome back! -

Many of us have built on dining room tables and it sounds like you have a good plan going forward. Looking forward to the build

-

Welcome aboard! You can search for your ship with the search function to see if anyone else has built this before. If you start. A build log for yourself You can show off your work ask questions etc.

-

Thank you Derek. You certainly should pick up one of these “most excellent” kits. You will to regret it

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

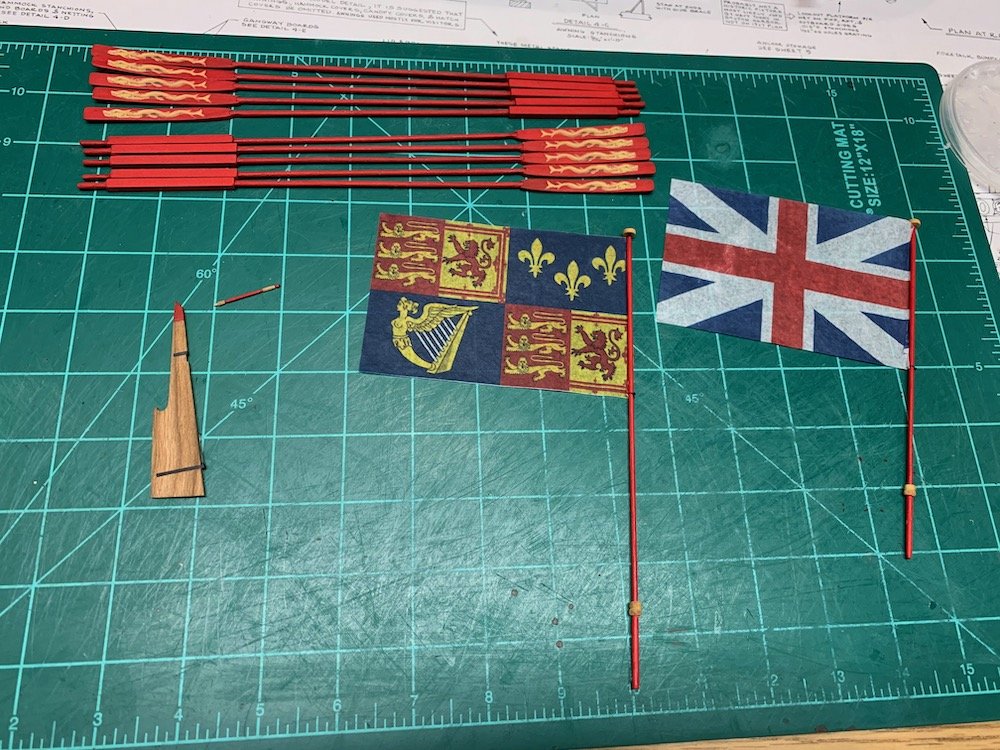

I also had this problem. One of my first attempts basically glued the flag to a paint brush handle and as I was trying to free it it ripped. With more experience I was able to shape them without it getting too sticky.

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hope that helps and Thanks

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

First thing I would do is to practice a few times with some tissue and some scrap poles. You don't even have to print the pattern for the practice runs. A few attempts and they really started to look better. I used regular tissue paper that the wife had for wrapping presents. I cut a piece out and then just used scotch tape to tape all the edges to a piece of regular printer paper. I then printed the design with a normal ink jet printer. After cutting it out (11 blade scalpel) I used some thread to attach it to a pole. I used Krylon matte fixative in the big spray can. My first few attempts ended up using too much and apparently was doing it in too high humidity. Too much spray resulted in a whitish frosting on the tissue when it dried. It also wetted it so much that it became very fragile and tore. I did do it in my office/workshop (very smelly not recommended) as it was in the 90's today with really high humidity. After spraying both sides lightly I gently shaped it with my fingers as well as the roundish tips of a pair of hemostats and the end of a round paint brush. The spray has about 10-15 minute wet time so there was plenty of time to shape it. I was able to spray again if it did not dry in a nice enough shape. After a few tries I then proceeded to make the final ones which I think came out pretty well. Here is a picture of the white frosting on the practice runs

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Jean-Paul My thoughts exactly Maybe soon although the wife really likes the Echo cross section

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Do it!!! After this kit I am giving the big ol side eye to the other kits in my stash. They simply cannot compete

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks much better that way.

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Getting there. Need to decide on final mounting. Still leaving the rudder off until finished with the carvings. Carvings are still being practiced. I do want to try one with a rotary tool as so far have only been using the 11 blade scalpel and carving knife. These are the first flags I attached to the poles. I had an epic fail when trying to shape them. Turns out you can use too much of a good thing (krylon fixative). So after printing out a few more on some tissue paper I was able to practice enough and get 2 to come out looking fairly decent. Now just on to the carvings... Deo Volente

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome Chris! Plenty of people here to help you out if you have any questions. A build log is a great way to show what your re working on and to connect to the community.

-

Byrnes Sander or saw, that is the Question?

MEDDO replied to Nirvana's topic in Modeling tools and Workshop Equipment

I was surprised how much I started to use this once I had one. -

That is an excellent presentation for an unusual boat. The added details really make it come to life

- 17 replies

-

- martha

- chesapeake bay maritime museum

- (and 2 more)

-

Dios mio! Cant complain about the amount of carving I have to do after seeing those ones. Marvelous!

-

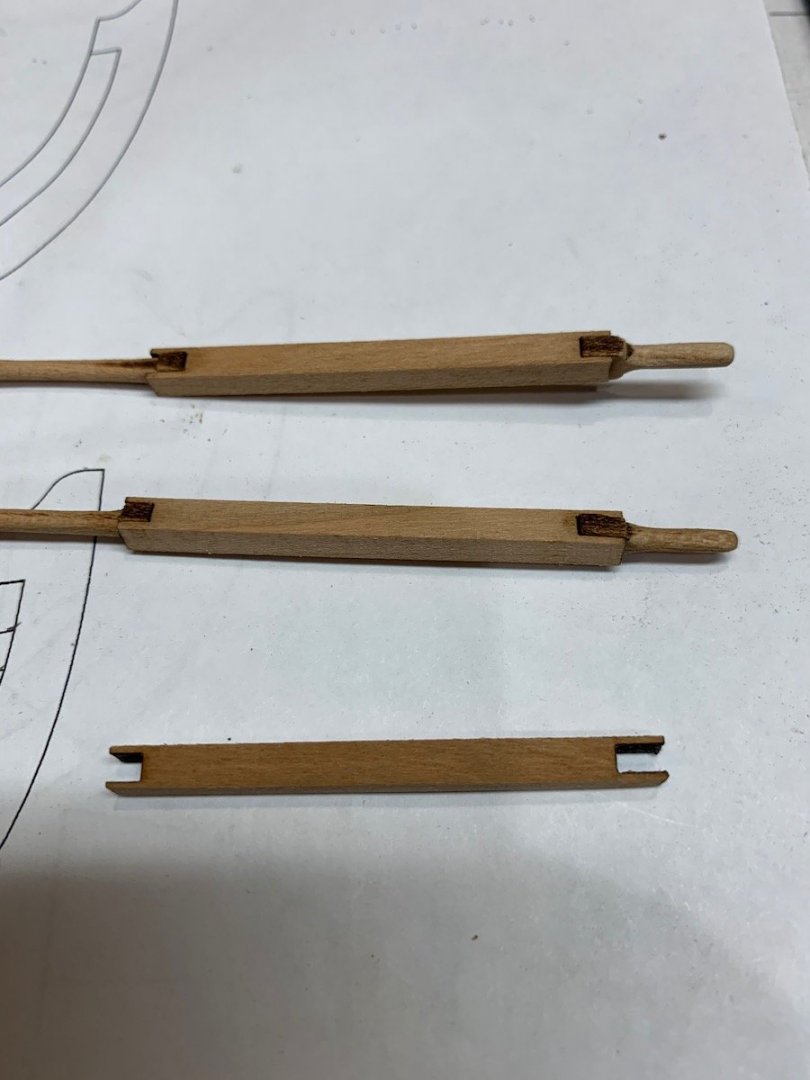

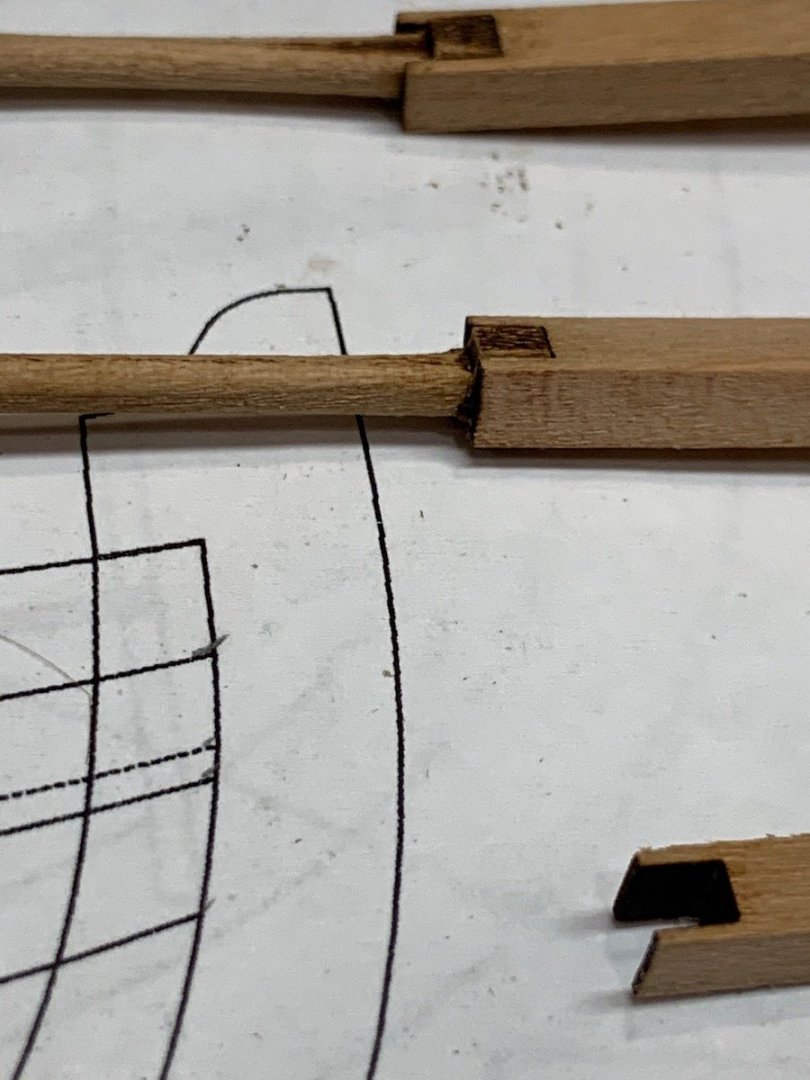

Another reason to not model while tired. I put this post here so maybe will help someone else not be like me.... While putting the sweeps together I ran into this problem as you can see the square part has notches in the end for the handle and the shaft. I wasn't quite paying attention and when putting them together last night ended up with a few like the one pictured at the top. The one in the middle is correct. I didn't even realize this until I came down today and saw something funny on a couple of them. Obviously the plans have them right (another reason to always go back to the plans). The notches are not the same size. Here are a few more close ups Haha had to take them apart and use some of my precious precious isopropyl. Them came apart easily and 'correctly' glued together. Always learning...

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.