-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RichardG

-

First time rigging - being organized

RichardG replied to RichardG's topic in Masting, rigging and sails

Thanks everyone for your feedback. I see this as an organizational and learning tool. Organizational because it will help me keep track and hopefully avoid having to do too much rework. Learning because I will have to work out and enter data, then actually do the rigging. I'm not planning to get 100% of the data done before I start work - I will start with the bowsprit along with any lines from the foremast in that area. Then continue with collecting/entering data in logical sections then rigging that section. The actual software writing will be the easy bit for me - I'm not going to make it very complicated. I really am looking forward to doing the rigging even though it's a bit daunting at the moment. Brian - splits and 'virtual' points will be interesting - I might need to make some changes at that time or may just end up putting stuff in notes, Wayne - not only trying to reach an eyebolt but finding I've completely missed putting the eyebolt in! Druxey - the people on this forum are wonderful - I'm sure I will need help. Jay - no I do not know what a leechline is . Hopefully by the time I've finished all this I will. wq3296 - I'm trying to balance the over thinking and actual work. I'm not a big fan of analyzing and planning everything up front in my work as a developer. I will be doing the same here - plan a bit, do a bit, rinse and repeat until everything is done. Tony - I have both of the spreadsheets and did use one of them to work out the rope sizes I ordered from Chuck. I will need to order some smaller blocks though. Henry - I am definitely planning to be a lot more knowledgeable at the end the process. As you and Jay point out, these are not just a set of random ropes. I am glad I don't have item 6 on your list though. Thanks again. Richard. -

I am about to start rigging my first model - an 1815 1/50 scale US Revenue Cutter. This for me is the scariest part so far. I read posts here and they might as well be in Latin (which I did at school 45 years ago and even then wasn't any good). As well getting each line, knot, and fitting right, they also need to be in the correct order. For help I have: This site and the people on it :) :). A handful of books: A Visual Encyclopedia of Nautical Terms Under Sail Ship Modelling Simplified Steel's The Art of Rigging 2nd Edition Petersson's "Rigging Period Fore-and-Aft Craft" (on order) The AL kit plans (which I believe are simplified) One of the reasons I originally chose this model all those years ago was the rigging was not too complicated. However "not too complicated" does not mean easy. The only real expertise I have is in software development. Now I can't write a program that will rig the model for me but I'm thinking that I can still get some organizational help. I am planning to write a simple database program for me to keep track of the details and help me stay organized. These are the data I'm planning to store for each line: Name Starting point (including picture(s)) Ending point (including picture(s)) Running/Standing Line size Fittings (types [blocks, hooks, etc] + sizes) Notes Once the data is entered I would then be able to move the items around in a list so I can get the right order and keep track of progress. So what does anyone think? Thanks, Richard

-

Thanks druxey and Joel. Chuck's windlass is definitely an inspiration. The scale is close enough to mine that I had considered just buying one from him. However unless something I need is beyond my skill level and/or I don't have the equipment needed, I will try to build it myself first. In this case mine won't be as good but hopefully it will be good enough, if not, I can change my mind (again!). I have already purchased rope and blocks from Chuck, so I know the quality is there. Richard.

-

I'm still a little undecided I am leaning towards having a windlass, partly for the practice of building one (and if it turns out badly I can always change my mind!). I will probably not attach it permanently yet, I still need to work out a rigging plan and this may effect any final decision. Thanks again everyone. Richard.

-

grsjax, That would be simpler. I've been looking to see if I could find the weight of each anchor - that would be useful to see how much effort would be needed - but so far I haven't been successful. Joel, What you have on post #12 is what I was thinking of, a bit simpler than the example from Tadeusz, which might be more likely for a smaller 1815 vessel. Wayne, I see you've provided the answer to my question about weight . So using the simple rule of 5cwt per hundred tons gives about 400 pounds per anchor. Definately more than a couple of men and a rope! In Chapelle's "History of American Sailing Ships", there are drawings of a Top-Sail schooner "Marble Head" which is slightly smaller than the Dallas and a bit older (1767). The drawings show almost no deck detail but on the perspective drawing pp 225, there does seem to be a windlass immediately behind the foremast . Having so little information about this particular ship is both a blessing and curse! Unless I do something stupid, it won't be completely wrong, but I have no way to know how close I am. For my next project I'm planning to use one of the ships in the AOTS series - still not perfect but better. Thanks everyone for your help. Richard.

-

Having seen various beautifully made windlasses here (e.g. on the cutter Cheerful), I'm wondering if the revenue cutter I am building would have had one? Neither the AL plans nor the drawings in Chappelle's book show a windlass. Given its size and weight (70 ft and 80 tons), I'm assuming raising the anchors would not have been done by hand. I'm trying to complete all the deck furniture before starting the rigging and I'd like not to miss anything. Does anyone have any thoughts or suggestions? Thanks, Richard.

-

I hope you're right :) . This is exactly what I was planning to do with the masts on my current and 1st build. I've never rigged anything before, not having the mast fixed would make things even more complicated. Richard.

-

The lower deck looks like you wouldn't be surprised to see someone walking toward you or a group of carpenters working there. Excellent work. Richard.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

MDF for laser-cutting new frames

RichardG replied to rshousha's topic in CAD and 3D Modelling/Drafting Plans with Software

Maybe a better use of the MDF would be to sandwich the plywood keel after manufacturing. It seems that it's usually the keel that's warped. Assuming the plywood was flat when originally cut, a couple of pieces MDF should keep it flat until the kit is started. Or 1 piece could be solid wood to make a base (they never seem to supply that) and the other MDF. My one cents worth. Richard.- 25 replies

-

Specifications for Construction of U.S. Navy Ship Models

RichardG replied to Rob Wood's topic in Nautical/Naval History

Cascamite. Now that immediately took me back many years to mixing the powder with water. It's funny how a single word can take you back (for me it's 40-45 years). Apparently you can still buy it - http://www.amazon.co.uk/Cascamite-Powdered-Resin-Wood-Glue/dp/B0001OZI98 - not sure if it's the same. As to the details of acceptable materials and methods - I found "Hulls shall be built up in lifts of clear, first-grade mahogany or basswood" the most surprising. Where's the boxwood, pear, and holly? My current build (and I fully expect all the others I will hopefully make in the future) will not pass muster. That's fine by me. As to what happens to them after I'm dead - I can truthfully say I don't care. I'm building them for the enjoyment (and frustration); money, posterity, or display in a museum don't enter into it. The only thing I've told my family I'll come back and haunt them for is if they spend too much on my funeral None the less the information was interesting - thanks for posting it Rob. Richard- 16 replies

-

- Specifications

- US Navy ship models

-

(and 1 more)

Tagged with:

-

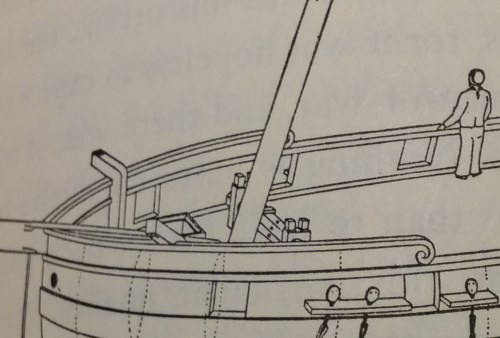

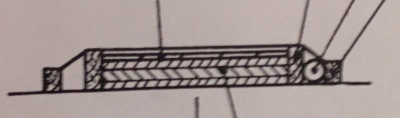

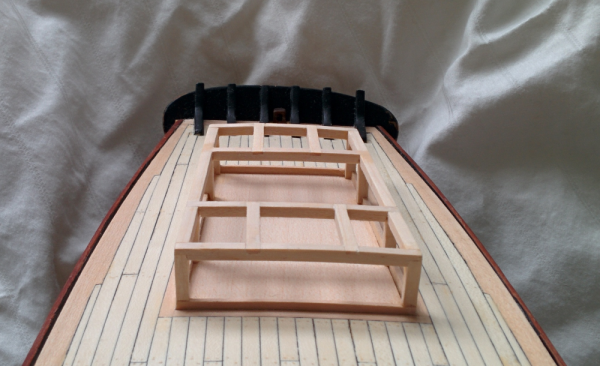

Continuing with carriage roof and deck fixtures. I needed to rebuild the iron pivot gun track. In the original kit this was made from thin ply that didn't make it when I pulled up my original deck. I found a PVC pipe fitting at my local Home Depot that was exactly the right size (only 98 cents!). I first tried using thin basswood strips (the former is 48mm dia). I still can't seem to make tight bends in wood. I tried heat and water. Either it would break or crease. I gave up after 4 or 5 attempts and move to laminating black paper. The results were much better. It's not fixed down yet). I will need to make some wedges to support the track each side where the deck curves. These I'm assuming would also have been iron. I'm using this as a resource http://www.globalsecurity.org/military/systems/ship/sail-armament.htm Richard.

- 78 replies

-

- dallas

- artesania latina

-

(and 1 more)

Tagged with:

-

Interesting, but I have to say your model is way, way, better Richard.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Tilting Table on Byrnes Saw

RichardG replied to jhearl's topic in Modeling tools and Workshop Equipment

I would assume you'd have a sled of some sort to hold the strip down and more importantly keep your fingers out of the way. I always find power saws scary buggers! Richard. -

Tilting Table on Byrnes Saw

RichardG replied to jhearl's topic in Modeling tools and Workshop Equipment

Could you not cut a strip to the width between the red lines without the tilt. Then tilt the table, cut one side, turn over the strip, and cut the other side. Richard. -

Thanks for the information uss frolick. I hadn't thought about the results of enemy fire hitting the bulwark where the shot was stored - nasty. It makes sense that they'd have portable shot boxes - you wouldn't want to carry them from below deck one at a time. You'd also be able to move them around the deck as needed. It's always good when you learn something new that makes perfect sense . Richard.

-

Tadeusz, Thanks for the pictures. The cutter has no bulwarks to speak of so there's no room for the storage in photos 1, 2, and 4. The HMS Warrior racks are very similar to the Constitution's. Wq 3296 (I hope that's not your real name ), I don't think the storage on deck would be permanent, especially during any rough weather, but other than that I don't know either. Since no one is telling me it's stupid, I'm going to go for it. Richard.

-

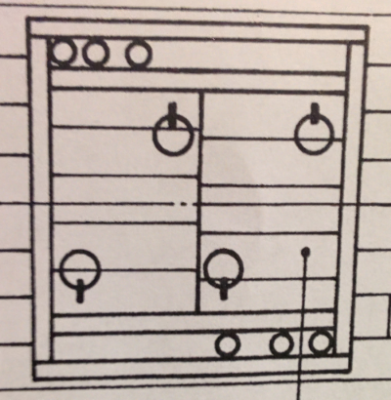

On my 1815 American Revenue cutter (Artesania Latina Dallas), the plans show shot stored either side of a deck hatch just forward of the pivot gun. in cross-section In Chapelle's "The History of American Sailing Ships" there are no details of the hatch except for the outline. I don't like the setup on the kit plans. It strikes me that it is both a trip hazard and a place for sea water to collect and rot the wood (and rust the shot). I think a better option (if they needed shot stored on deck), would be a rack on the end of the hatch. An example you can see on the USS Constitution: Photo from: http://techno-fandom.org/~hobbit/pix/ussc/tour1.html Any thoughts? Thanks, Richard

-

Some progress made. I still need to build the frames up for the skylight and hatchway before I cover it all up. I have no idea how accurate this is to reality but it was fun. Before I start on my next project, I've learnt a few things: I need more practice. I'll need a few more tools - very small chisels, more clamps, a new razor saw. Basswood is too soft (at least for me). Richard.

- 78 replies

-

- dallas

- artesania latina

-

(and 1 more)

Tagged with:

-

Brass Black

RichardG replied to sailor jim's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Jim. You might want to take a look at http://modelshipworld.com/index.php/topic/6977-the-blacken-it-trials/ Richard. -

Tadeusz, Thanks for all the information and pictures. I wonder if it would be possible to grow Bonsai trees to provide a source of bent timbers? photo courtesy of Wikipedia Given the slow growth, you might need to lay down a supply for your children or grandchildren (like vintage wines) I'm also curious - is the grain of the wood "to scale"? Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.