-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RichardG

-

Size of blocks & rigging thickness ?

RichardG replied to Senior ole salt's topic in Masting, rigging and sails

The books that Bruce and Tadeusz mention are the ones I'm using to work out the rigging of the 1816 US Revenue Cutter I'm building. I'm finding it slow going but that's me learning not the books! I would recommend both. I will be using blocks and rope from Chuck. Richard. -

At least in Chrome, you can right click on the page and select Translate to English. Richard

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

I like both suggestions . However, maybe the red would be too much (although it is a standard way of indicating a cutaway). Perhaps a light brown, enough to highlight the edge but not too distracting. Whatever you do this is a wonderful example of a cross-section. Richard.

- 268 replies

-

Beautiful! It's a pleasure to see this coming together. Richard

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Here's a couple of links that might be of interest: https://www.uscg.mil/history/webcutters/CUTTERLIST.asp - List of named vessels of the Revenue Marine, Revenue Cutter Service, Coast Guard and Lighthouse Service. https://www.uscg.mil/history/articles/USRCS1789-1849.pdf - Early History of the US Revenue Marine Service 1789-1849 I'll be following your build Richard

- 83 replies

-

- revenue cutter

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Shop-made filing-machine

RichardG replied to wefalck's topic in Modeling tools and Workshop Equipment

I really like the "retro" look. And I'd absolutely want the filer as well ;-) Richard. -

Cutter Cheerful 1806 by rafine - FINISHED

RichardG replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Bob, I wish I could press "like" multiple times. Really good work. Richard.- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Bob, I did a "like" earlier today but wanted to add a few words. This really is a excellent build that shows off both your skills and the "style" of these ships. I wish I lived close by and could come and just look at it for an hour or two. All the best. Richard p.s. What's next .

- 196 replies

-

- higaki kaisen

- woody joe

-

(and 1 more)

Tagged with:

-

Nice bolts. And yes it was too cold to go out unless you really needed to .. Your Atalanta is looking really good. Richard.

- 1,449 replies

-

Very good. I like the look when Ro is stowed, otherwise it looks out of proportion (and it's a lot less likely to get broken). This just makes me want to make another Japanese model (for me this time instead of my daughter!). However with 2 full and 2 partial builds in the queue I really must wait. Please keep building these - I can a least get the pleasure second-hand . Ok, now I've scrolled up the page and looked at the picture again. It's so clean, so elegant, so Japanese. All the best, Richard.

- 51 replies

-

- wasen

- thermal studio

-

(and 1 more)

Tagged with:

-

Lettering

RichardG replied to chborgm's topic in Painting, finishing and weathering products and techniques

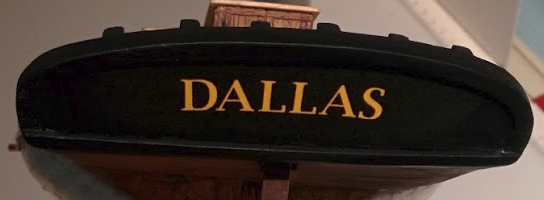

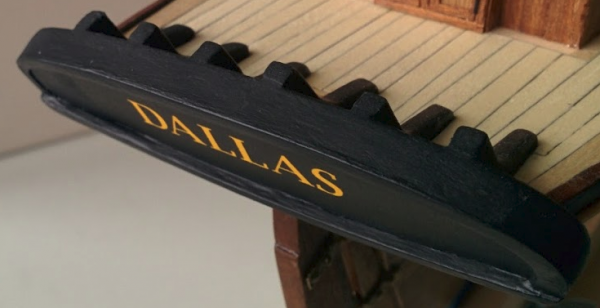

Yes, that's a single piece of paper. It was printed on white paper (black background/yellow letters). It was glued using an Elmer's Extra Strength glue stick (which is acid-free). I then put a coat of the same matte polyurethane varnish (Varathane brand) used on the rest of the ship. Getting the font, color, curve, and size took a lot of tries. To get it looking just right (to me anyway), I also had to fiddle with the kerning (letter spacing) for the 'D' and 'S'. I had considered using individual letters but decided that the chances of getting them lined up correctly was exactly zero (although I know some people here have achieved that feat). The letters are also flat which I felt was probably correct because they were most likely just painted on). Richard. -

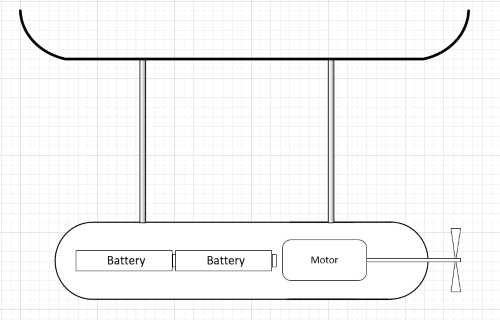

I think the propulsion needs to be spooky quiet and not very fast (I assume he didn't zip across the Styx at 50 knots). My suggestion is a motor and prop below the water with Charon having a single oar for steering. This would be quiet and add stability. I look forward to seeing this build (I enjoyed your last one ). Richard.

-

Lettering

RichardG replied to chborgm's topic in Painting, finishing and weathering products and techniques

I used Word for my Revenue cutter. In this case the whole piece was printed with a black background. Getting the "right" curve and letter-spacing took a lot of fiddling - I'm a bit of a perfectionist with this stuff (and it's easier to redo 20 times on a computer and printer ). Richard. -

New mini-mill... CNC and impressive

RichardG replied to mtaylor's topic in Modeling tools and Workshop Equipment

$4000 and it makes a mess. The admiral would not be happy . Richard. -

Fascinating. Like all good craftsmen they make it look so easy. Now I understand why they are not cheap. Something to add to my ever growing tool list. Richard.

-

Clare, She looks very clean and crisp. Richard.

- 51 replies

-

- wasen

- thermal studio

-

(and 1 more)

Tagged with:

-

Julie, It's only snowed twice this winter so far ! I do find myself disliking the cold more and more. I moved here from England almost 25 years ago and I'd never experienced weather as hot or as cold. Richard.

-

It's funny, I never wanted to retire until I got into this hobby! Even when I do retire, I don't think I'll be doing builds as fast as you though. Your boat is looking good and I will continue to follow along while I slave away at my desk Richard.

-

The nice thing about the internet is there's plenty of room for front row seats. So if nobody minds I'll join too. Richard.

- 51 replies

-

- wasen

- thermal studio

-

(and 1 more)

Tagged with:

-

Wonderful! I'm still amazed by the detail at such a small scale. I had trouble with my last build breaking things that were 10 times as big the fittings here. Thank you for posting your build. Looking forward to the next one. Richard.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.