-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RichardG

-

Seeing booklet takes me back about 50 years 😀

-

My most recent order was placed on Oct 13th and arrived yesterday. Unfortunately we've all been spoiled by Amazon and their billions of dollars investment. I can see the mail arrive from my "working from home office". Yesterday I could see him put the mail in the box but noticed he had a flat cardboard package as well. He drives a couple of feet to the end of our driveway. I then manage to get downstairs and beat him to our front door. This is what passes for excitement in these times.

-

What do I want for Christmas

RichardG replied to Worldway's topic in Modeling tools and Workshop Equipment

The Byrnes thickness sander is next on my list of "expensive" tools. However, that will also mean improving my dust collection system. Fein vacuum cleaners are supposed to be amongst the quietist, so that's on my list too. But there's also the space issue. One option I have considered is some good pre-planning and just using the sander outdoors as weather and season permits. This is not a simple hobby 🤔 -

What do I want for Christmas

RichardG replied to Worldway's topic in Modeling tools and Workshop Equipment

I find the disk sander I have (unfortunately not the Byrnes one) very useful. Also do you have the cross-cut sled for the saw? I'm using this a lot. -

What do I want for Christmas

RichardG replied to Worldway's topic in Modeling tools and Workshop Equipment

I just one of these to help the filter on my shop vac clogging up so quickly Haven't bought the bucket for it yet though. -

What do I want for Christmas

RichardG replied to Worldway's topic in Modeling tools and Workshop Equipment

My first response when my wife asks me this "How much can I spend?" -

A "like" on the pear and a big "sorry to hear that" on the accident. Unfortunately you can never domesticate power tools. I hope it heals quickly and well. All the best

- 475 replies

-

My wife is teacher who is currently doing remote learning because of the pandemic. She's been finding all the sitting makes her very stiff, so we purchased a nice adjustable desk with a 42"x24" top. I've just realized this would make a really nice bench when she retires in 3 years or Covid ends (whichever is sooner). I won't mention it to her yet though. We ordered it from Amazon https://www.amazon.com/gp/product/B08L5JZ6J5. It was not cheap ($300) but it is very sturdy.

-

Byrnes Table Saw making a 1mm by 1mm strip

RichardG replied to CharlieZardoz's topic in Modeling tools and Workshop Equipment

I'm curious, what size blade did you use? -

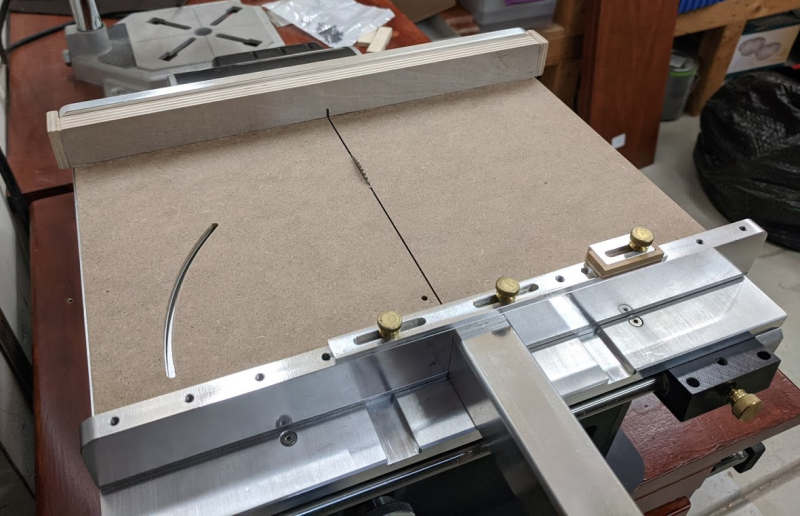

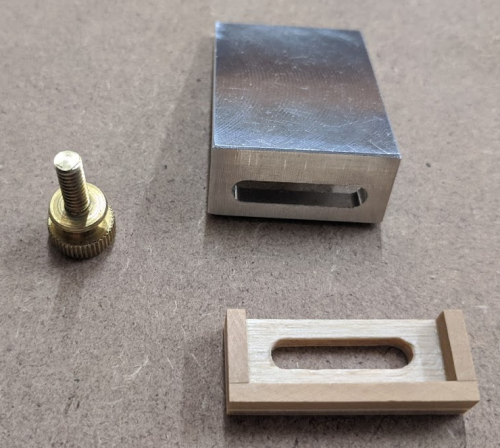

As I was beginning to use my new saw, I was getting some tear-out when using the cross-cut sled with a 3" 70T blade. So I decided to make a zero clearance insert. Using some 1/8" hardboard and plywood, I came up with this: I made a quick jig for my scroll saw to allow me to cut the slot for the angle fence. The fixture just lifts in and out, the base is a snug fit front to back and the plywood at the rear stops any sideways movement. The stop was then 1/8" too a tall so I made a small fitting from 1/16" plywood and boxwood to raise it up. The original thumbscrew was too short so I replaced it with a new brass one. Although I didn't need to, I replaced the others to match. I also needed a longer pivot screw for the angle fence but the main adjusting screw was fine. This of course means I've lost 1/8" from the maximum thickness of cut. Most of the time this will not be an issue but I have additional 4" blade if I need it.

-

Byrne's saw for cutting thin brass???

RichardG replied to CPDDET's topic in Modeling tools and Workshop Equipment

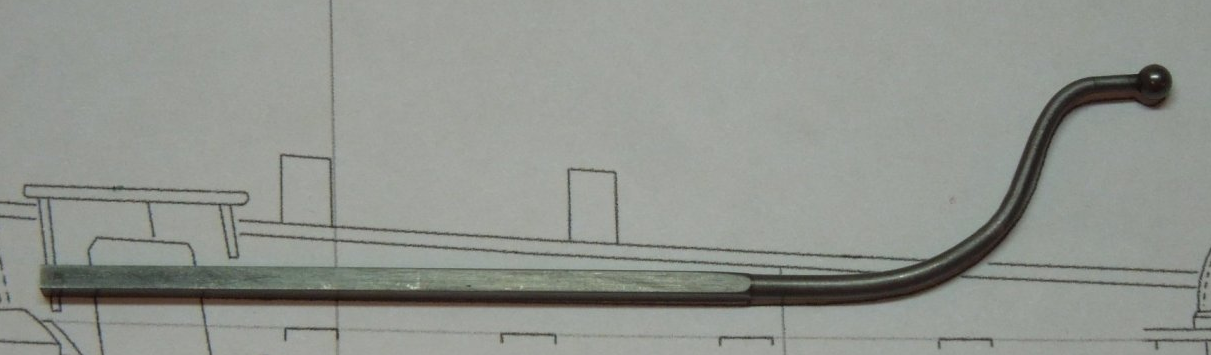

Apparently the saw will cut "larger" stock as well. Greg Herbert used the saw to help make this tiller. https://modelshipworld.com/topic/370-speedwell-by-dvm27-greg-herbert-ketch-rigged-sloop-1752/page/7/?tab=comments#comment-654207 -

Byrnes Table Saw making a 1mm by 1mm strip

RichardG replied to CharlieZardoz's topic in Modeling tools and Workshop Equipment

I've used paint stirring sticks. The one gallon size is about right. HomeDepot sell them for about a dollar for 10. -

Byrnes Table Saw making a 1mm by 1mm strip

RichardG replied to CharlieZardoz's topic in Modeling tools and Workshop Equipment

As a newbie to the Byrnes saw (although I've used a larger saw quite a lot), I don't think you need a push stick that small. You would be cutting 1mm strips from a wider strip that is 1mm thick. You keep cutting strips off until the remainder is too narrow to work with. The remaining strip will be wider than 1mm. How narrow a strip would be left will come with practice but I'm assuming several mm. -

I did roughly the same, starting it with a knife and making sure I curved the paper back not the foil. Holding with the knife while peeling is a good idea - that I didn't think of. As to gloves, I didn't use those. I find with working at a small scales, my coordination is difficult enough even without gloves. I did not have any issues with fingerprints. I think this varies from person to person. You might want to try first.

-

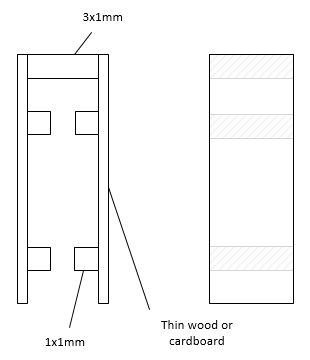

Maybe a small jig made from scrap wood or card. By using a little bit of the 3x1mm and 1x1mm you can get the spacing correct. I'm thinking of something like this This would be flexible enough to use with fingers to hold the spindle in place while gluing. If the top and bottom rails are already in place then just have the 2 pieces without the top strip. If you make the width of the jig the right size, it might also help with spacing.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.