-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RichardG

-

Cookwoods have holly on sale at the moment. I have got wood from them in the past and have been pleased with the quality. Never bought holly from them though and my wallet is a bit empty at the moment. https://www.cookwoods.com/collections/holly

-

New spar-tapering tool from Bridge City Tools!

RichardG replied to Bob Cleek's topic in Modeling tools and Workshop Equipment

And if you want to spend even more money, Bridge City have an anniversary stainless steel/Titanium alloy version for $299. In a choice of 3 colors! -

New spar-tapering tool from Bridge City Tools!

RichardG replied to Bob Cleek's topic in Modeling tools and Workshop Equipment

I will take that as a vote of confidence 😀 -

New spar-tapering tool from Bridge City Tools!

RichardG replied to Bob Cleek's topic in Modeling tools and Workshop Equipment

I got the plane for precisely this reason. It's original price was too much but it was $89 when I ordered it. I'd seen it recommended and thought the price was reasonable for a quality plane. I have only had time to briefly try it (I received it 2 weeks ago). It is very sharp out of the box and more importantly the blade adjustment is very precise. I have yet to try the thicknessing part. I will need to make a jig first since I'll need the wood at an angle. -

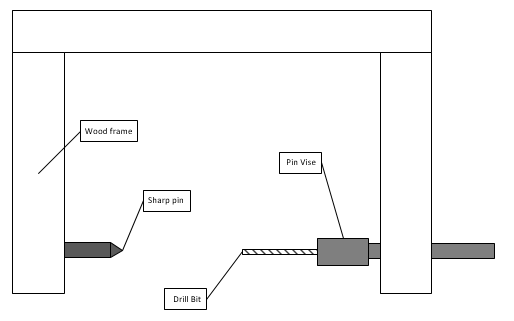

My thought is a jig like this: You use the pin to hold the location on one side then locate and drill the hole using the pin vise on the other side. I think I'd initially put tape on the pin side and measure and mark the position. The drill side I'd just eyeball. I really like making jigs. If it wasn't so cold in my garage, I'd be tempted to go make one. I'll need hawse holes at some time in the future.

-

Miniature Drill Bit Chuck for Dremel Tool?

RichardG replied to turangi's topic in Modeling tools and Workshop Equipment

How does anyone manage without 3 hands? I always have problems. With my Dremel I have 1 hand on the bit, 1 hand on the chuck, and my 3rd hand pressing the button to stop the drill rotation. What am I missing? -

Tool and Raw Material Source

RichardG replied to Charles Green's topic in Modeling tools and Workshop Equipment

I understand that moving such a large product catalog online is a big task and paying someone to do it would not be cheap. However, they must be losing sales without an online presence. It might be nice if they at least gave the catalog price and how to order it on their website. That should be a minimum level of online service. I still like printed catalogs because sometimes you see stuff you didn't know existed. I would spend $12 if it were easy to order. -

I have no problem with the conversion, I can't just go to my big box store pick up an 8mm forstner bit, fortunately my 5/16" bit works (just). I have a 5mm hole, do I try an find a 5mm machine screw or will a #10 be close enough? For my 8mm threaded rod, only a metric nut will work. Show me a piece of wood and I can get pretty close just by looking that it's 2 1/2" wide. To tell you it's 63mm, I need to convert in my head. Something that's 6mm, I can visualize without converting.

-

I agree except my inflection point is an inch. Bigger than an inch I visualize in feet and inches, smaller than that mm is easier. I can "see" 4mm much easier than 5/32 (and 0.15625 inches is impossible). I grew up in the UK and was totally non-metric until an adult. Working in the construction industry moved me to metric. I then moved to the US which is still mostly non-metric. I'm currently making something where the core parts are metric but the tools need to put the parts together are not. So I have an 8mm rod - but what size drill in inches will work?

-

No Ratlines on Revenue Cutter Dallas?

RichardG replied to RichardG's topic in Masting, rigging and sails

Wow, 6 years later 🙈 I shouldn't have looked - it just reminds me how little progress I've made. However, I have made some progress and still haven't given up - so I'm calling that a win. I also have some radical plans for the rigging. So here's to 2021 😀. -

Maybe you could insert one or more metal pins into the wood that would touch the motor and transmit the heat to the outside. When they get hot, you know it's time to take a break. Copper rod could be quite decorative.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

I coppered my current build. This was done mostly to cover up poor planking but only after I was able to find a way to make plates that were reasonably accurate. I'm also planning to not do the rigging as per the kit plans because it's too simplified. So historical accuracy is important to me. However, just to be inconsistent I probably won't do it again! I'm building ship models in wood because I like sailing ships and I love wood as a material. These are items I find enjoyable to build and to look at. I would not build a modern warship model because I like neither the subject or material (although I see some amazing models here). So I'm hoping that my future models will be close to historical accuracy but also show off my improved skills in wood. As to other people saying it's not accurate if not coppered, ignore them. No model is 100% accurate. Most of the materials we use do not match the original. The plans we use are not always correct. So enjoy the hobby and build what you want in the way you want it.

-

I certainly wasted quite a few initially and occasionally later when I wasn't paying attention. I found that bending the paper almost into a U shape when I got the first 1/4" peeled off worked best. So I'd hold the peeled end of the copper between finger and thumb of my left hand (I'm right-handed). Then support the copper with the middle finger (to keep it flat). Finally peel the paper off using my right hand finger and thumb.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.