-

Posts

1,308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Kevin Kenny

-

-

Allan I actually have a feather board but it only works with absolutely square stock. it was not as close as it looks. I always end up with a large piece at the end because of the risk of cutting my finger. I keep the end pieces and if I need additional stock I do use a piece of wood to push it close to the fence.

-

-

I will do as you suggest Greg but I have been bending wood this way for some years now with little or no spring back. Most wood contains moisture in it. Even dried wood. Here in the tropics there is a great deal of moisture in dried wood as compared to very little if you lived in a desert. My experience has shown me that it’s of no benefit to wet or steam wood because of the relative thickness of the wood we use. The heat gun works wonders and almost 99,999% of the pieces I have bent hold their shape. I’ll be away for two weeks and will check it when I return.

-

-

The problem was also on the starboard end which was out to much. After getting the port end sorted i beefed up the support on the port side by adding a stiffener, then used a clamp to pull in the starboard end to the correct position on the plan, then i took out the blow dryer and heated the starboard end back into the correct position based on the plan. After it cooled, it held its position. Leaving the clamp in place i restuck the stern. It worked. Thank you Greg. Please continue to keep an eye on the Thorn.

-

-

-

I fixed the YouTube problem. Seems it made a change to key setting on its own. Not sure how that happened but I have corrected the feed.

Back to the correction on the stern, I will have completed reinstalling the stern this evening. This time it is PERFECT. thank goodness. The inners are installed. once the glue dries I will instal the middle counter timbers.

-

-

-

The error was on the port stern end that had come in too much. I have since sanded it down so both ends are now equi distance. Ill take a breath. Remake the transom piece. Establish the center line and then cut the mortises. Yea, that Greg fella is a pain. Thank goodness. This would have been horrible to fix later on. Thanks. K

-

- dvm27, No Idea, GrandpaPhil and 3 others

-

6

6

-

-

-

-

-

-

-

Looks great. You are making good headway.

- shiprookie and mtaylor

-

2

2

-

-

I Just checked Greg and i have the old model mill. . Next time i go up to the US ill bring the piece up and get it reamed. Looks like a nice attachment.

k- mtaylor, KentM and Ryland Craze

-

3

3

-

-

-

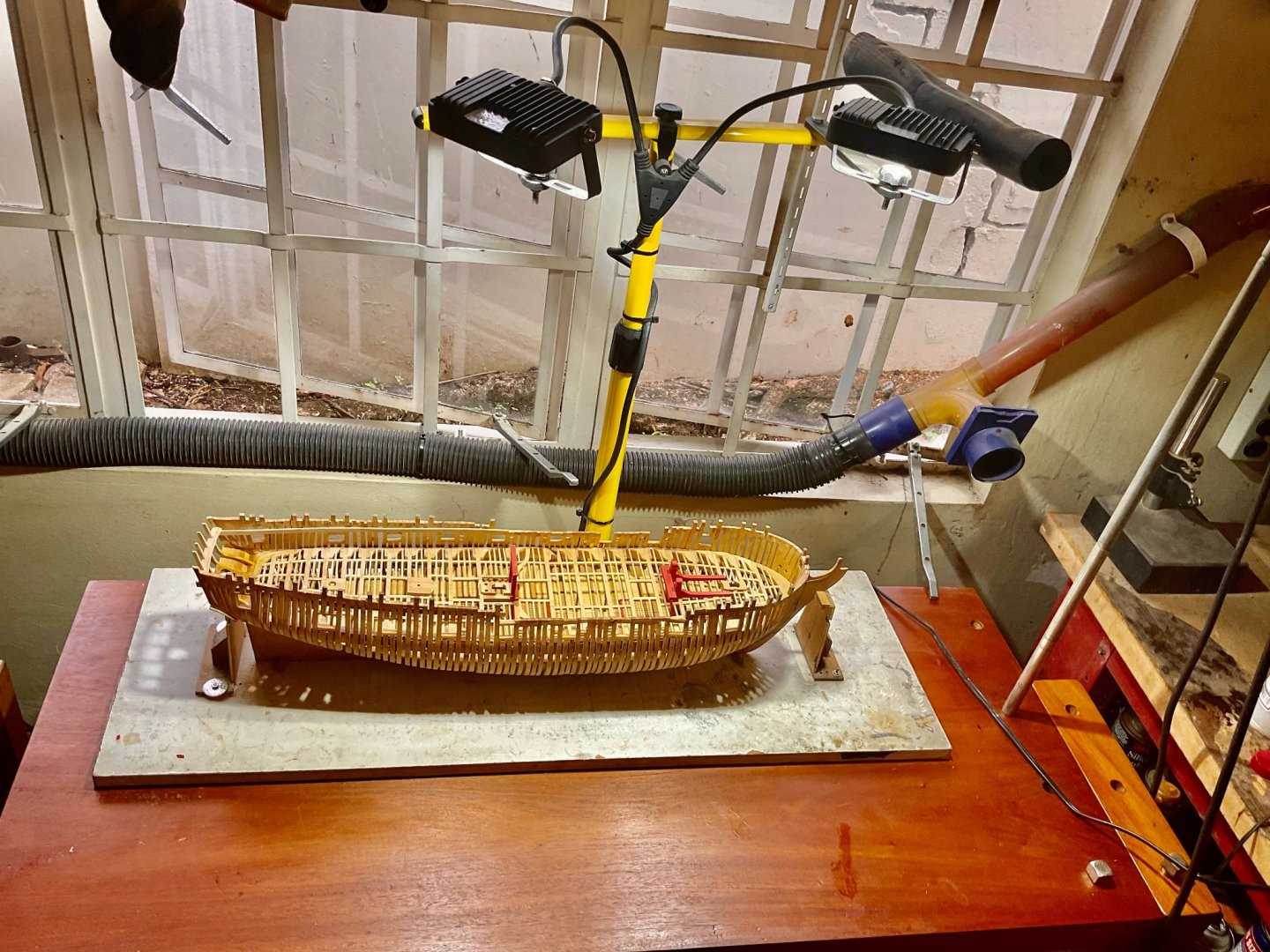

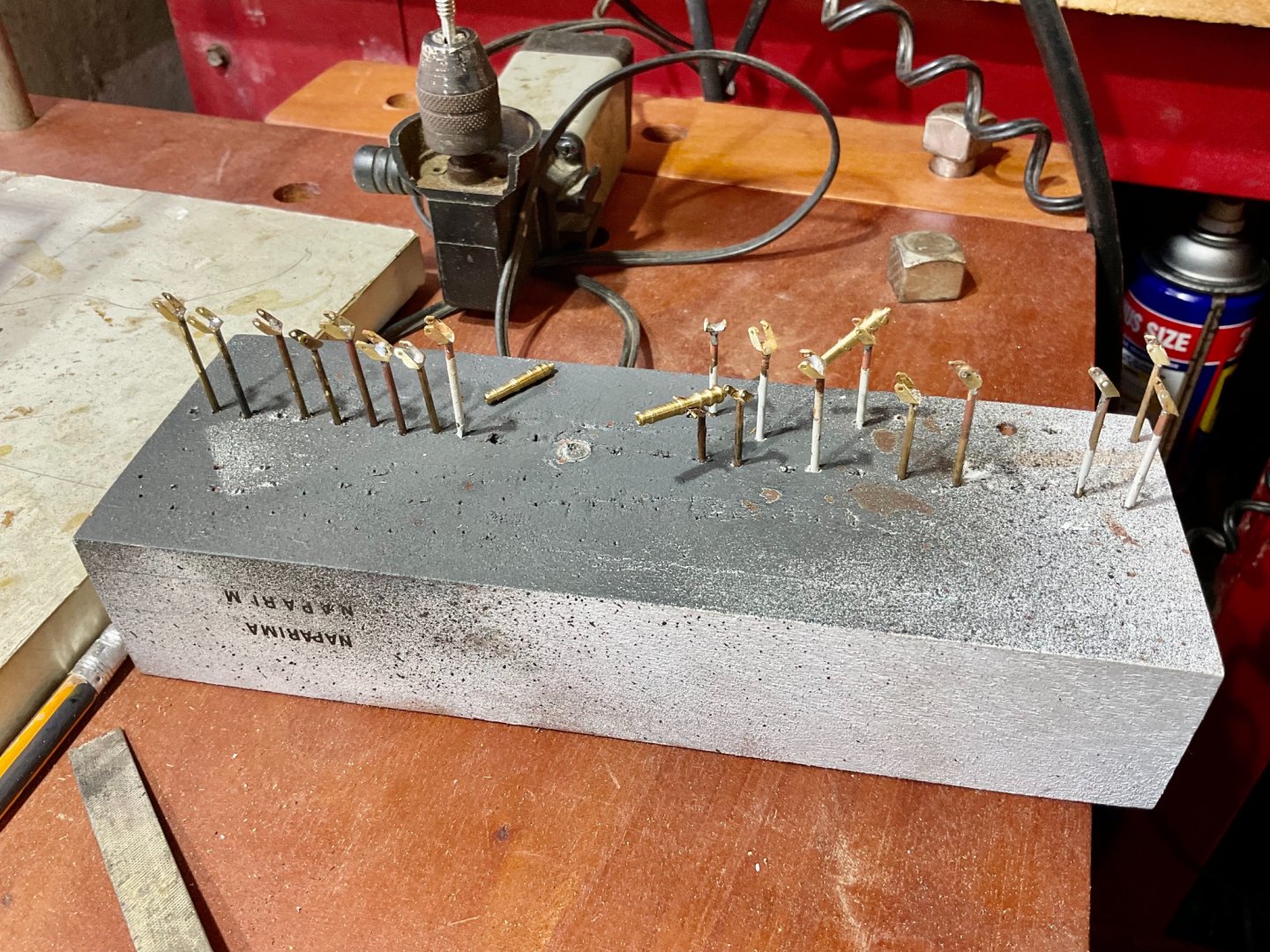

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

in - Build logs for subjects built 1751 - 1800

Posted

I completed 17 gratings from which we will need 8. Just waiting on the termite fluid to dry and cover with rub on poly and then cut and fit with the respective frames.