-

Posts

685 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captain_hook

-

I like the idea of using CNC-milling instead of laser-cutting very much. Snug joints without the need of sanding char away.

- 67 replies

-

- granado

- cross-section

-

(and 1 more)

Tagged with:

-

Very nice. You‘re close to the finish line..

- 164 replies

-

- first build

- model shipways

-

(and 2 more)

Tagged with:

-

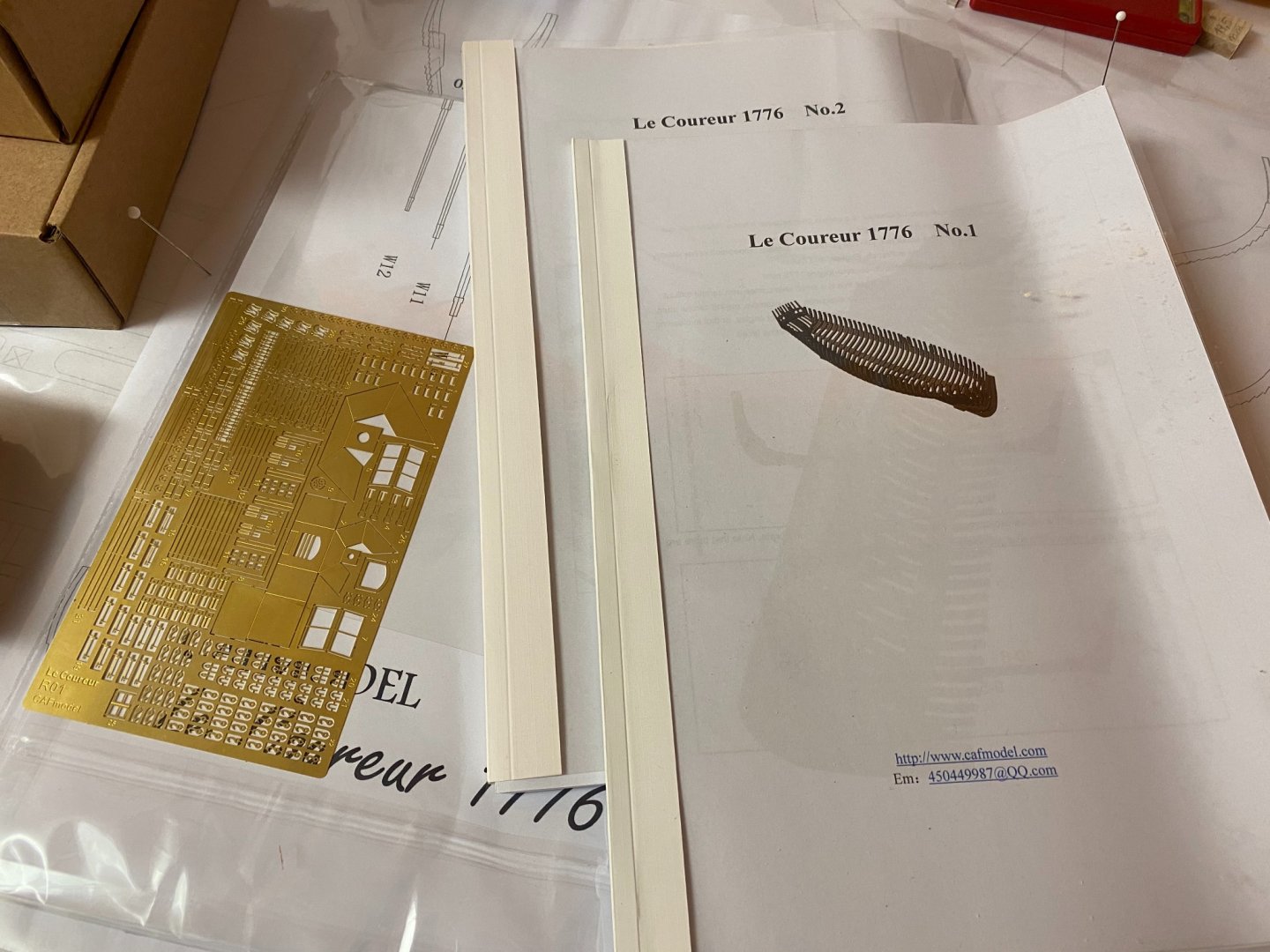

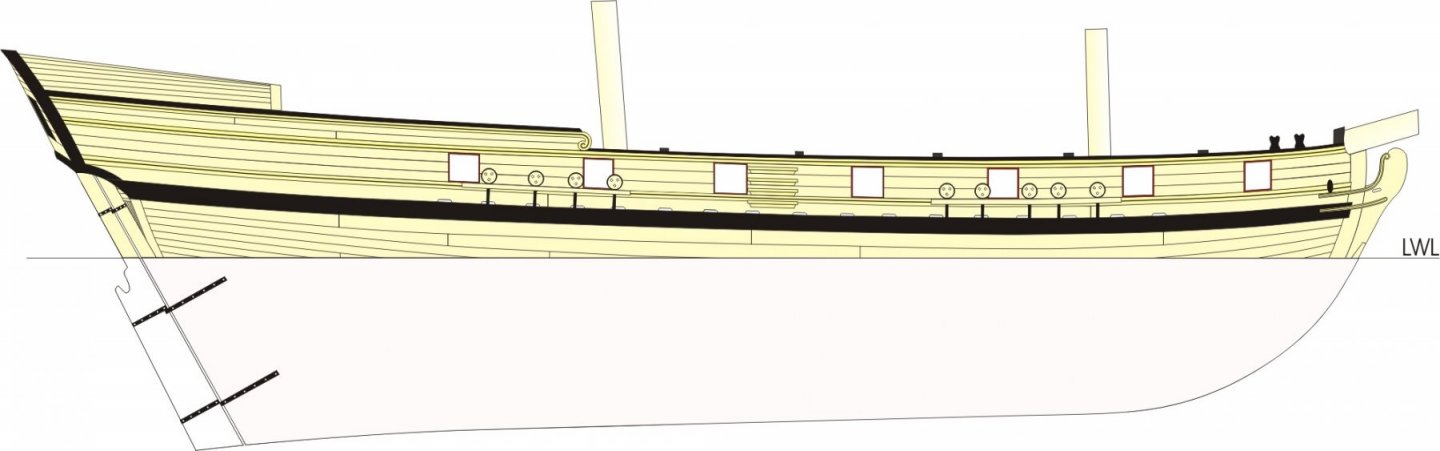

Hello everyone, this is my fourth kit-build and my first POF build. I couldn‘t resist to buy this one because of its beauty and grace. Some months ago I finished my last build and I thought some time about what to build next. There are a lot of beginner kits but I found it difficult to choose the right „intermediate“ kit. I started the Caldercraft 1:64 Granado kit I had in storage for a long time soon to find out that CAF is designing a 1:48 POF kit of the Granado. So I have put that build on hold until CAF has finished the developement. If it will turn out well, I will eventually start that one. But meanwhile? The Badger is more like an experiment, which will take a lot of time researching and I have to think about every step. How about a nice little side-project, that is challenging enough to keep me busy until CAF‘s Granado will be finished? Having followed the banned kits threat for a while I was afraid about buying a Chinese manufacturer‘s kit because I expected less experience with kits than established European and American companies already have. But CAF is something like a startup and I decided if I won‘t give a talented designer like Tom of CAF a try, other Chinese companies that still sell pirated kits in the first will never get encouraged to chance their attitude. So I ordered the kit, a barrel box and a cutter and got all items three days ago. My first impression was - wow! I have also ordered the Le Coureur book from Ancre and will use it as another source for reference, but it will take some more days to arrive here. James H. already did a nice and substantial kit review, so there is little left to say about the kit. It comes in two medium boxes, but both stuffed with lasercut wooden parts, stripe wood, accessoires and plans. As far as I can see, the quality of all parts is excellent, although cherry is not my favorite wood this might be my first kit it won‘t be necessary to substitute any wood. The keel is to be assembled first and then the cradle has to be done next. I made a small step first to assemble the bottom of the cradle and fixed that to a plain MDF-board with some screws. Will begin assembling the keel within the next days. Stay tuned...

-

Very nice. You did a wonderful job so far. I like the colour of the wood and the paintscheme as well.

- 238 replies

-

- sloop

- providence

-

(and 1 more)

Tagged with:

-

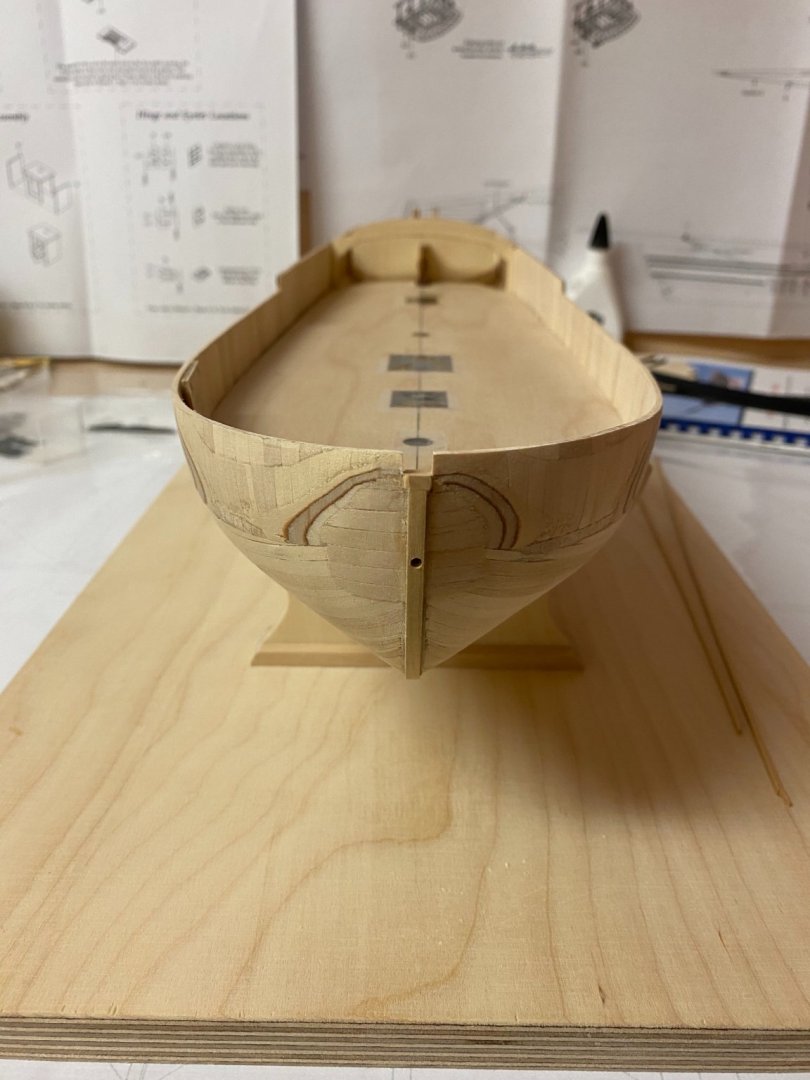

Thank you Mark. I sanded the bulwarks to equal height, following the deck and used a template as reference. Have to cut new gunports and then I‘m ready to add the keel.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you barkeater. Yes, I will leave it open. Have to redesign the galley to enlarge the opening a bit.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

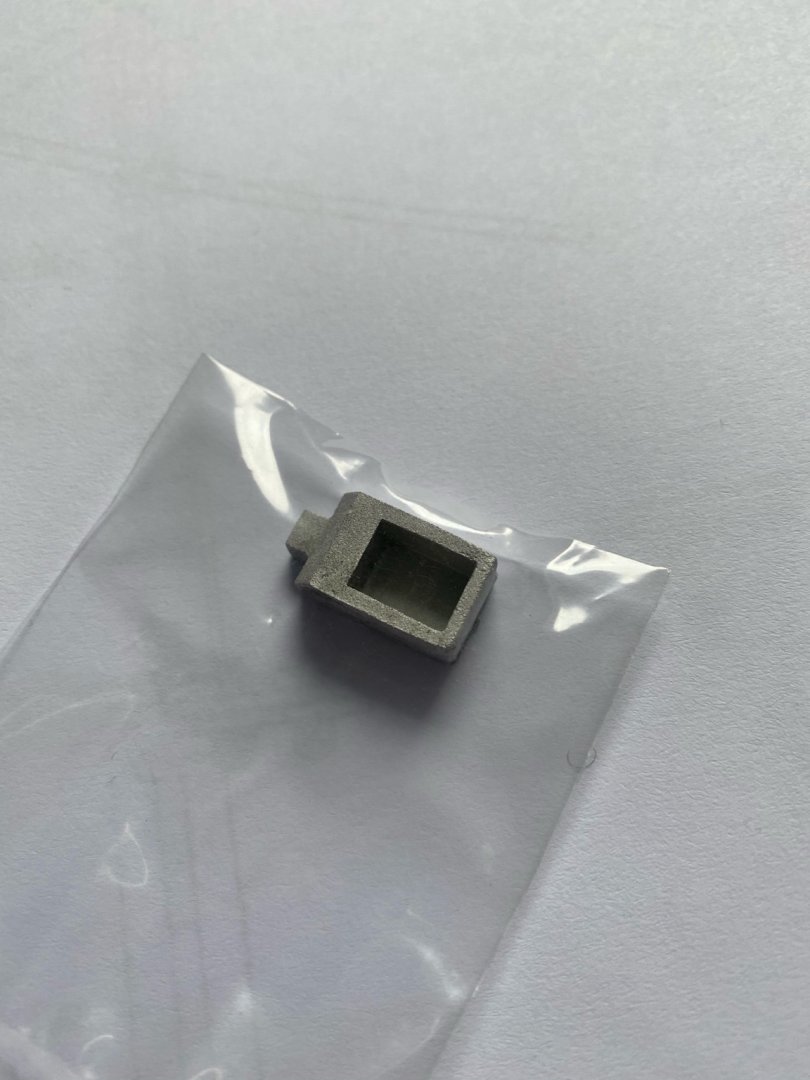

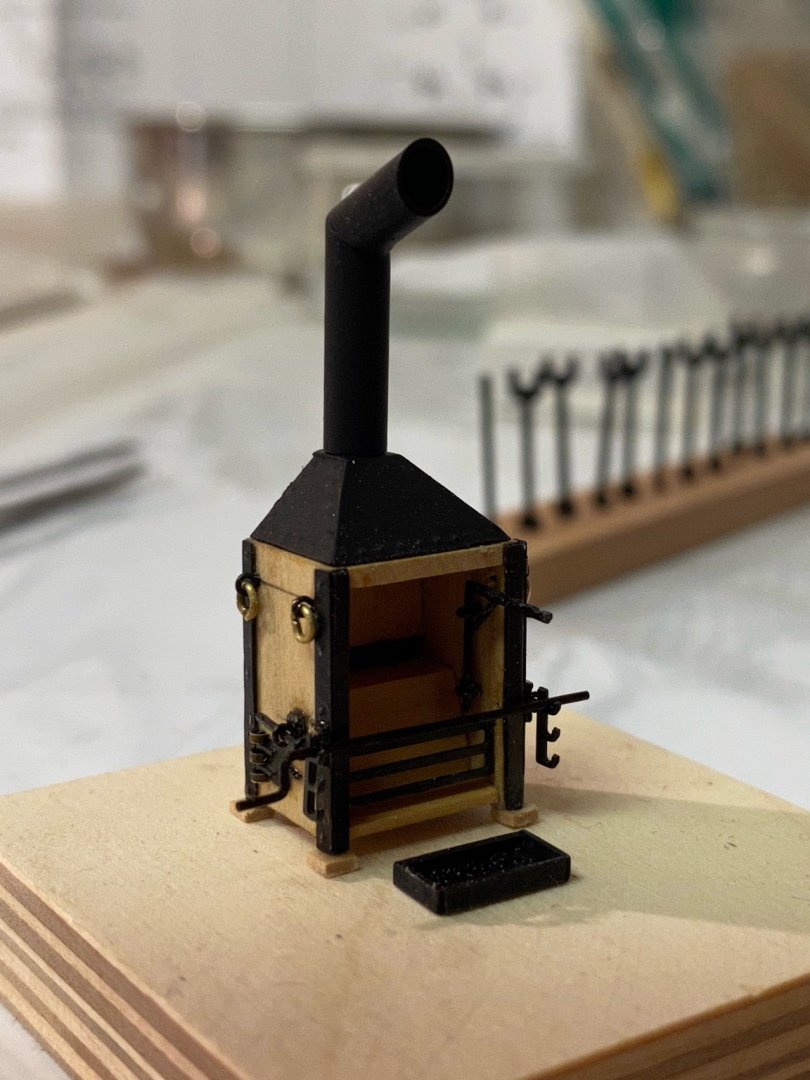

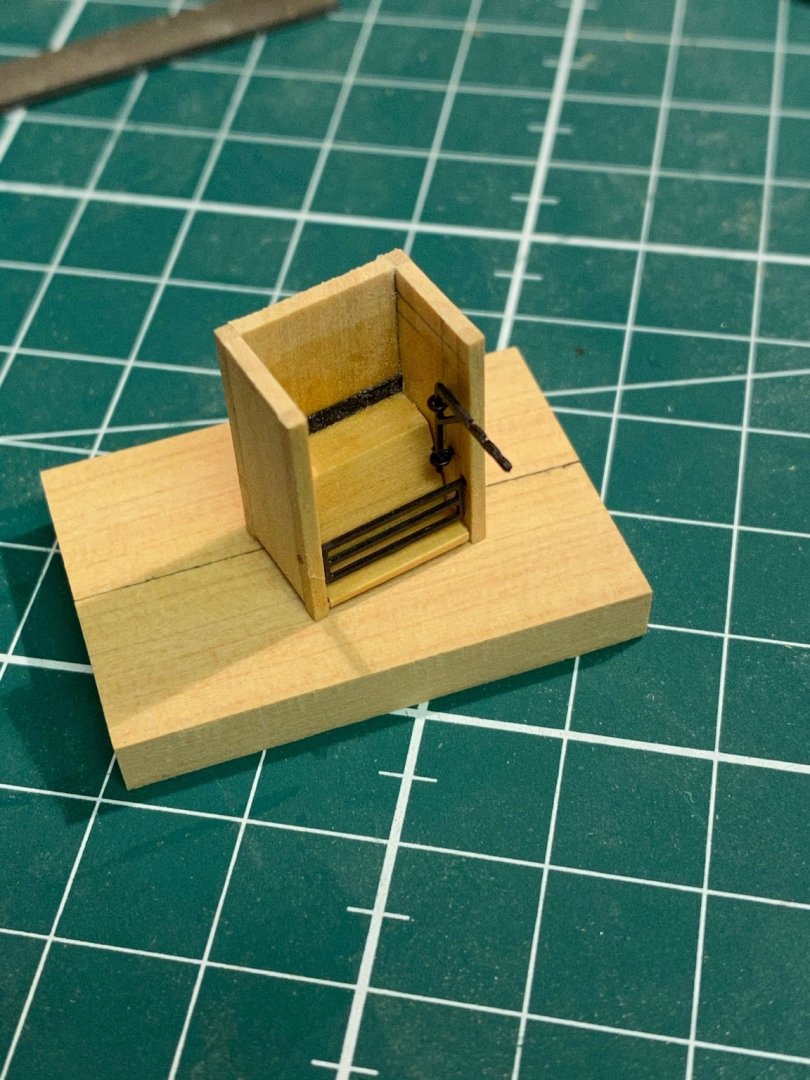

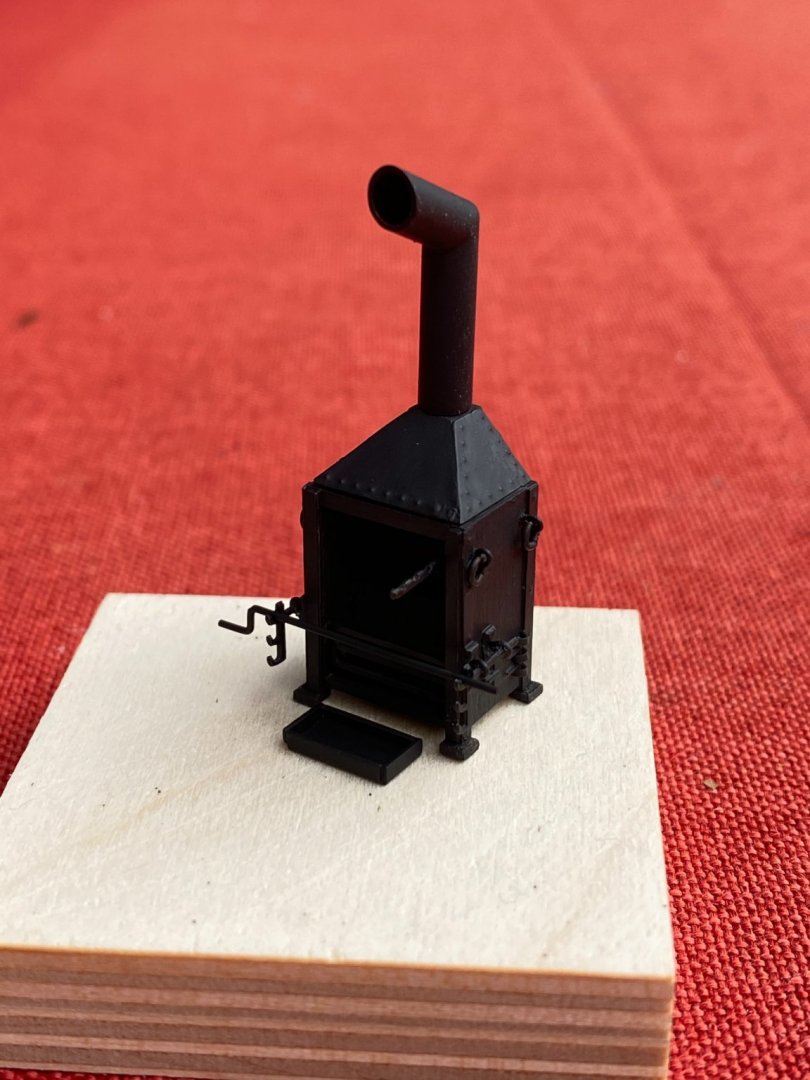

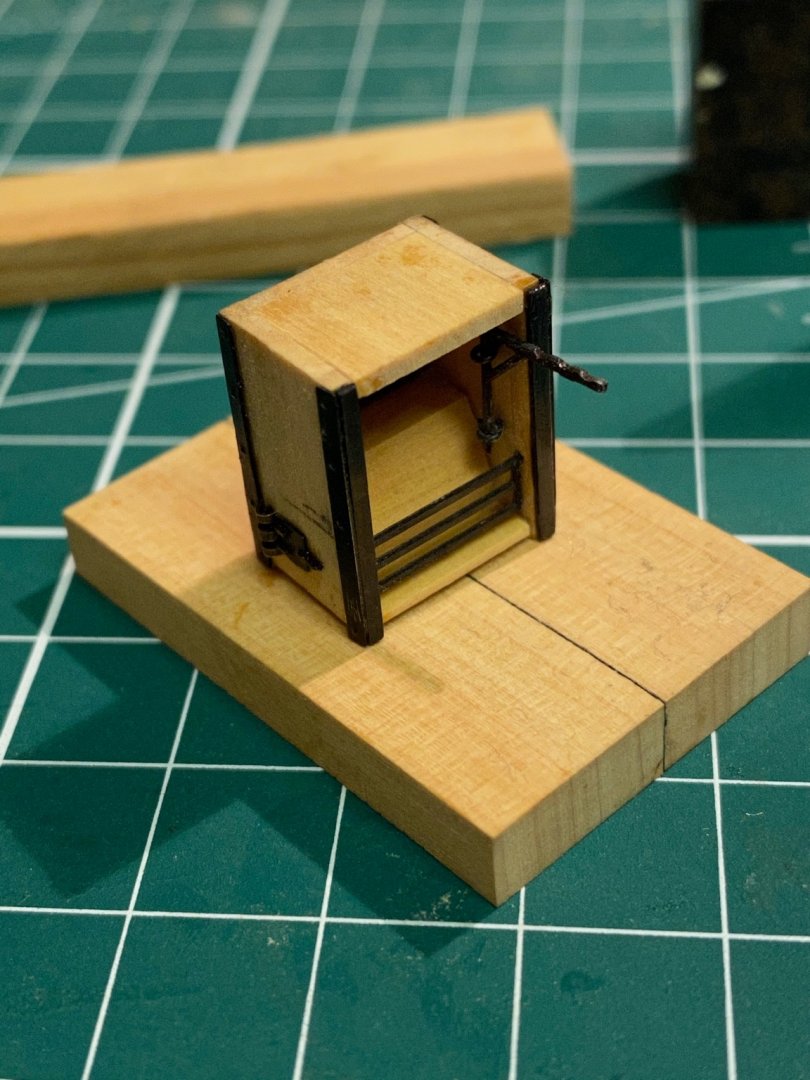

Thank you Jean-Paul. The supplied oven is nothing more than a box. But scratchbuilding a more scale one in 1/64 scale would have been tough... BTW this is the place where the oven will be placed later. It will be surrounded by a galley as well.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

Prepairing all fittings slowed me down during my last build but this time I have already prepaired them all. Now back to the hull. I glued all subdecks in place and then the false deck.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

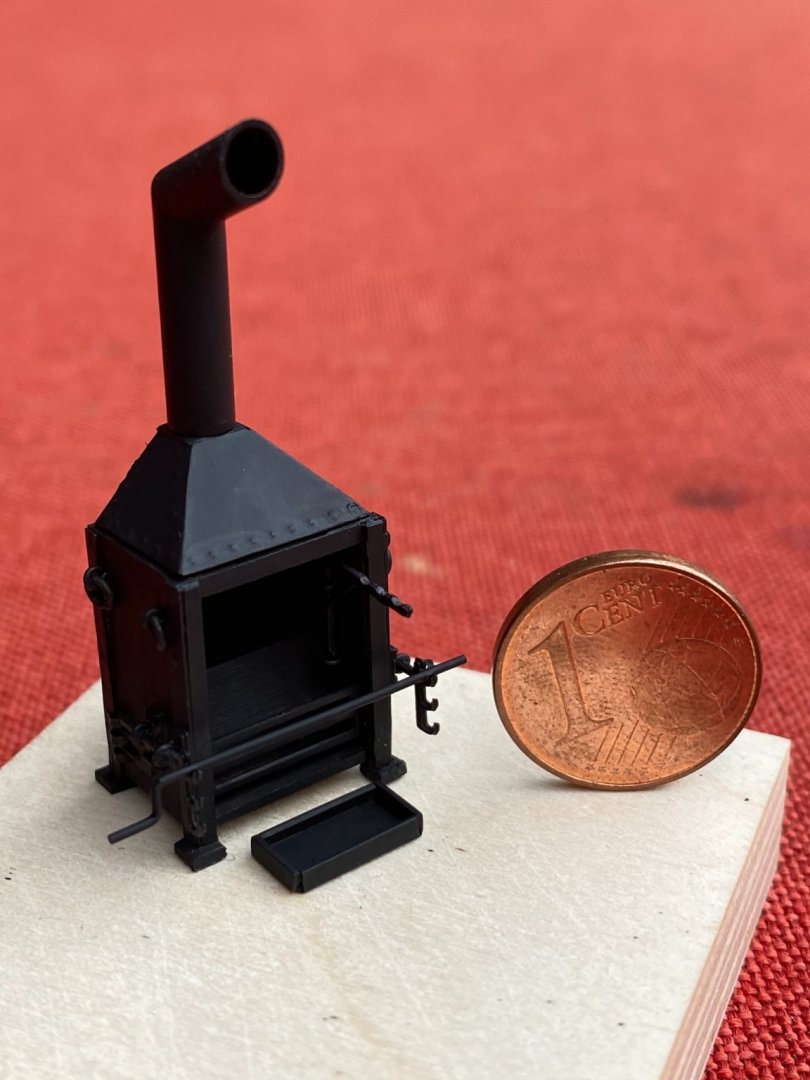

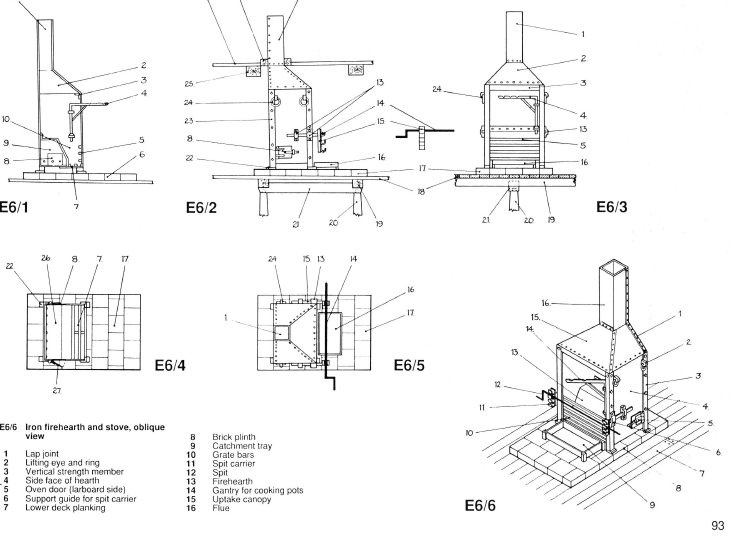

Building time is limited these days so before I start more work on the hull I wanted to do a little side project, the ship‘s oven. As a reference I used a picture I found on MSW in another thread. It was rescaled to match the scale of the build. The original kit supplied one is just a box made of britannia casting and the chimney is attached to it. I started with building the basic structure made of wood. The assembly is basically made of boxwood sheets with some brass parts attached to it with epoxy. Then the brass parts were attached. Put the whole assembly in my electrical stove after attaching the parts to each side and heated it for 10 min. (100 C Celsius) to reduce the cure time of epoxy. Instead of an angular chimney I decided to use a rounded one to match the one in my plans. The whole assembly with all parts attached to it but without paint. ... and after painting it with oxid black acrylic. Will add some clear vanish just before final installation.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

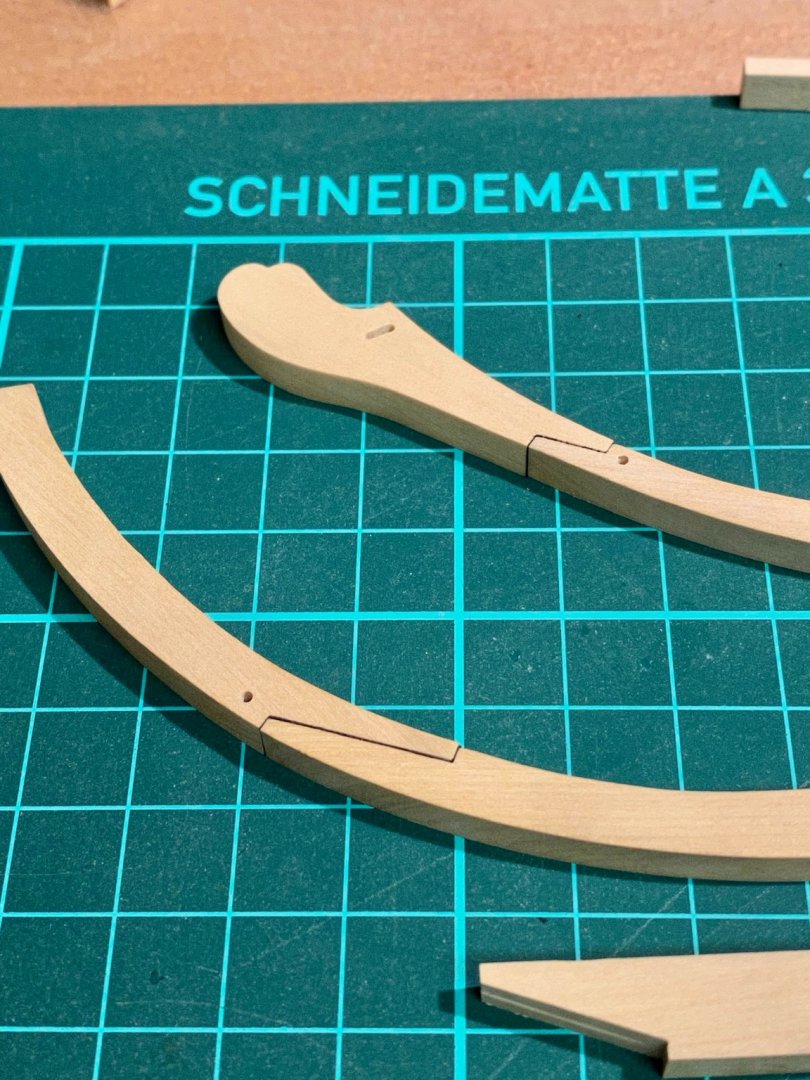

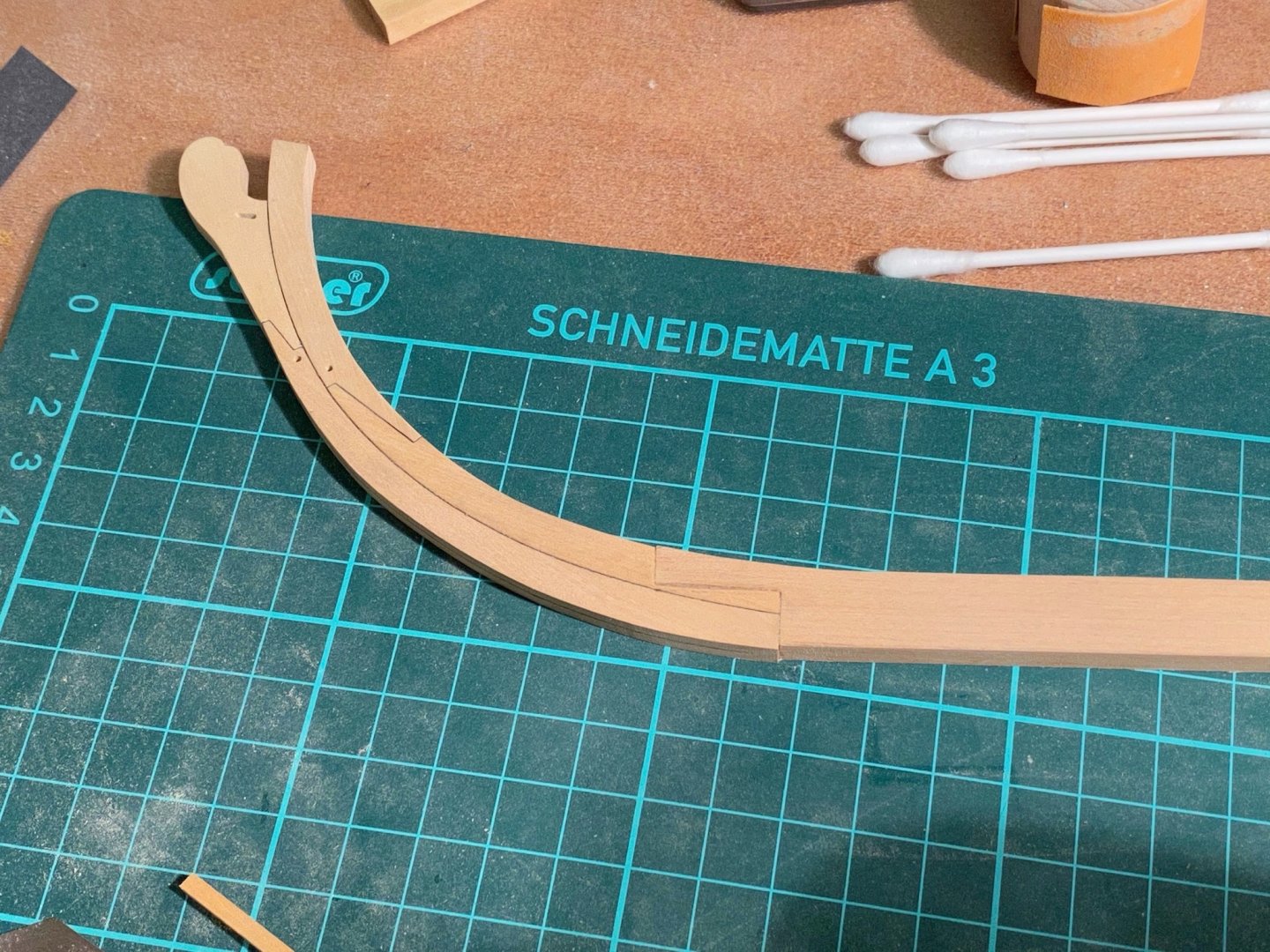

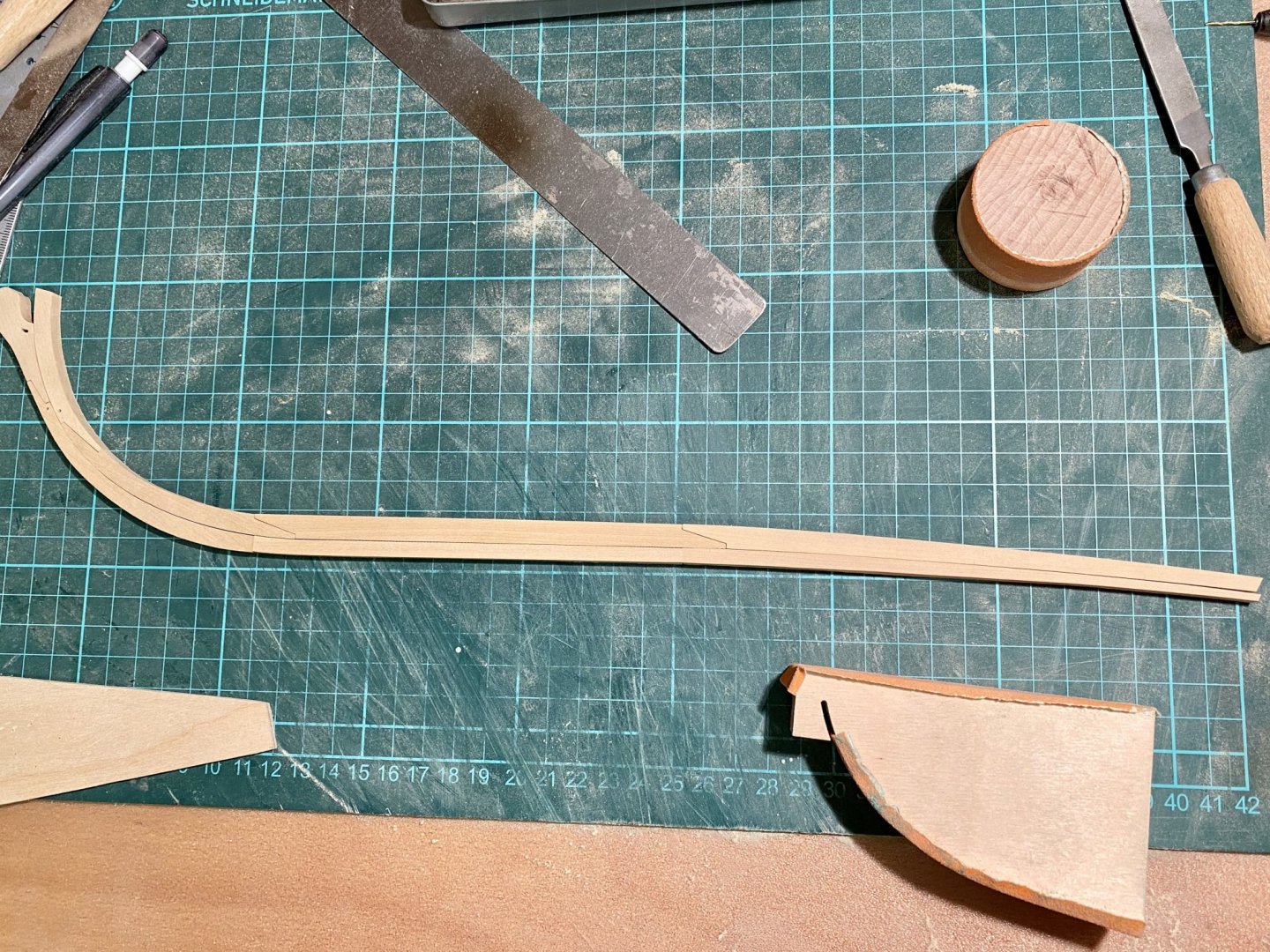

Some weeks have passed and I finally was able to spend more time in the workshop. For simulating tarred joints I first glued the paper on one of the two parts that are joined later. I use two different paper weights (80 gsm and 20 gsm) to simulate different strength of joints. As I haven’t found enough information about all keel parts and how it was build I finally decided to paint the hull white below the waterline so I only have to build the knee. It is exactly shown on the NMM plan. For the keel I will use a single part. Holes were drilled into the paper so the glue can penetrate the wood on the opposite parts. Both parts were then glued together to form a joint. Both sections were then glued together to form the knee. Another layer of paper was used to separate both sections. The keel was added at last. Dry-fit on the model. I still have to taper the knee and cut the gunports before the keel will be glued on.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

Hello everyone, now I have some wood in stock I think about expanding my tools-setup to cut sheets and strips myself. I have already decided to buy a Byrnes saw but I‘m not sure which accessoires are useful too. I will surely add a metric micrometer-stop and another 3‘‘ kerf. I understand that every accessoire has its own usefulness but maybe my english and my knowledge of tools is incomplete. Can anyone tell me please what a Rip Fence, a Rip Taper Gage and a Miter Bar are used for? Best regards, Andreas

-

Very nice, Jean-Paul. I also had to fix one swivel-gun stock, did all of them analog to the plan but unfortunately one interfered with a deadeye.

- 164 replies

-

- first build

- model shipways

-

(and 2 more)

Tagged with:

-

Nice build and rigging! The Cruizer-class brig is one of my favorites.

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you Jean-Paul. A lot of preparation, so there is not much to see yet. I will use the cellulose as it looks more subtile. I have to sand a little more and then glue all parts together and taper the assembly.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

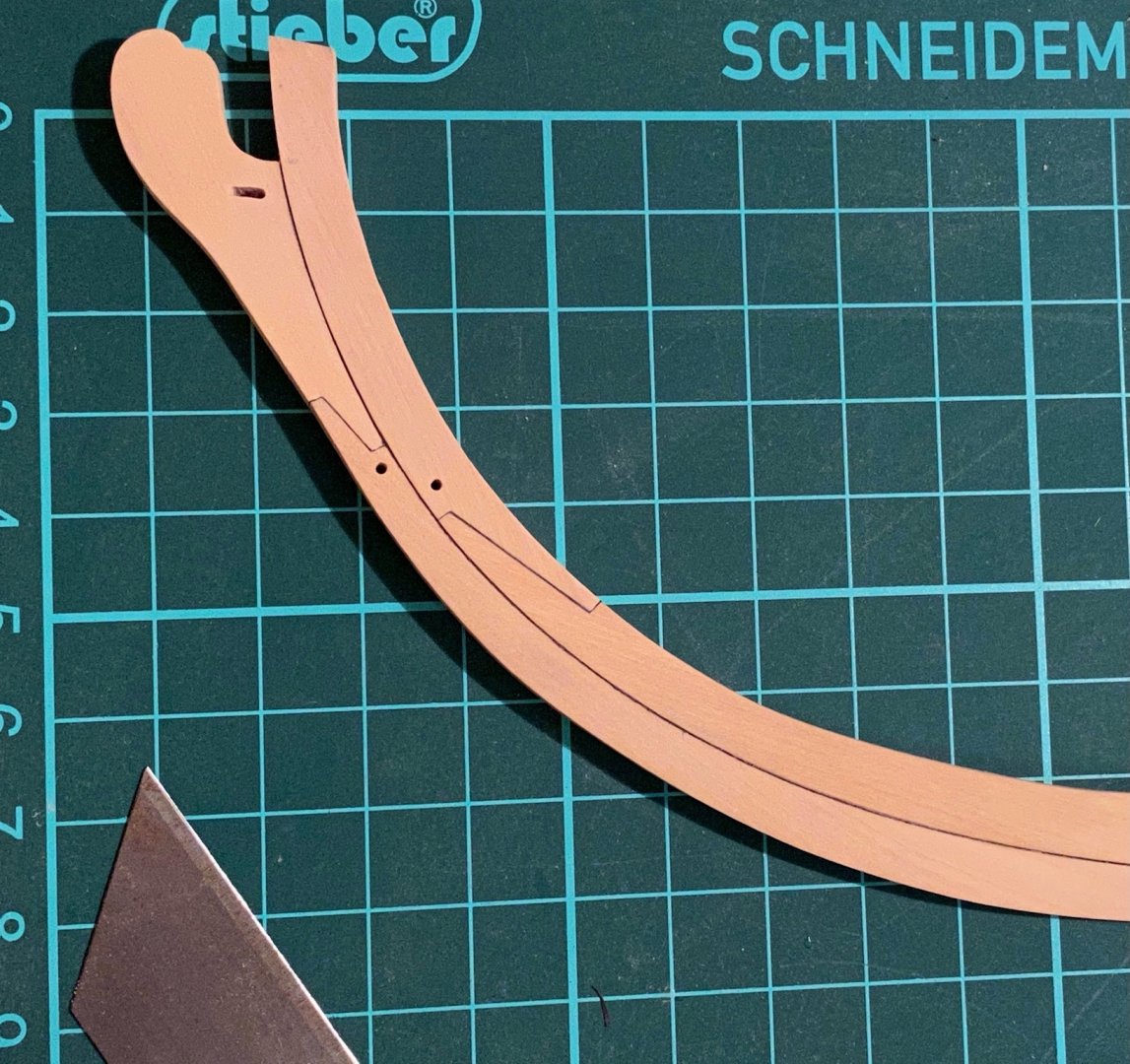

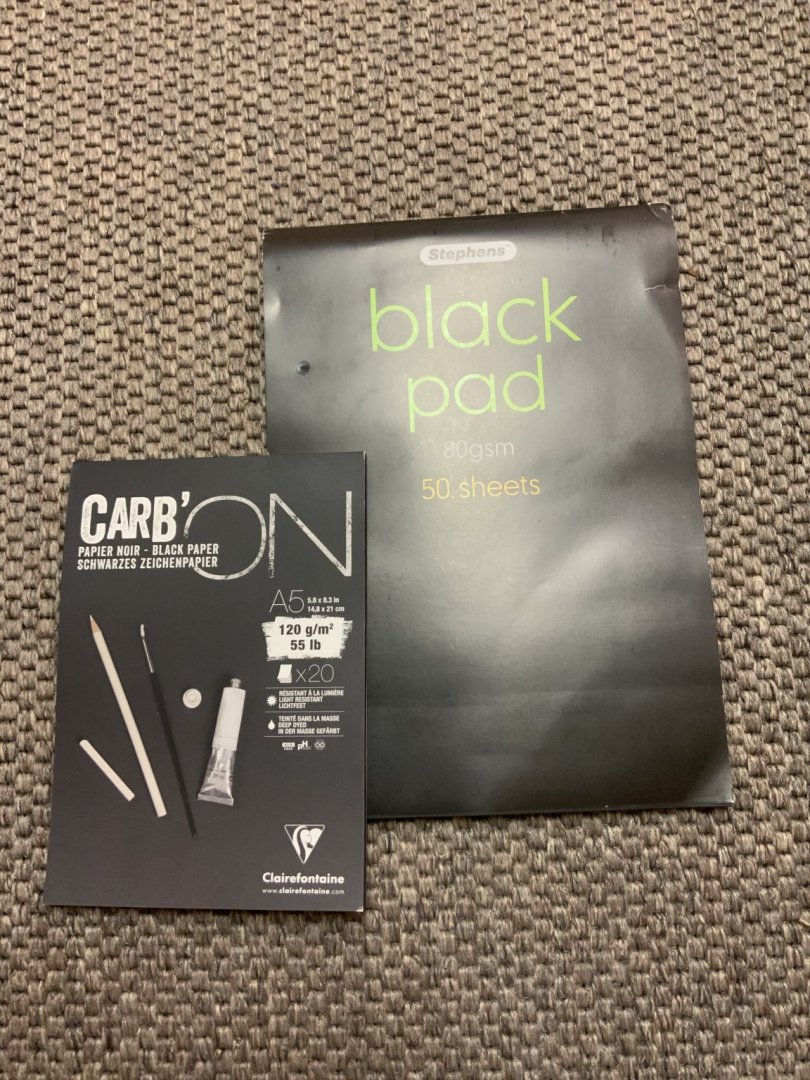

I made two test-joints with scrap. The one in the back is made with black paper (80 gsm), the one in the front is made with black single-sheet cellulose (maybe 30 gsm) I „borrought“ from my daughters desk. Both look very similar but the one in the front looks more discrete. Nitrocellulose-lacquer was used as varnish.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you barkeater, I agree to that. I have finished all eight keel pieces and dry-fitted them. Got some 80 gsm and 120 gsm black acid free paper and I will try the simulated tarred joints on some scrap parts first. Anyone has a suggestion how to taper the „knee of the head“? I have only seen that on some bigger ships before but these ships’s had a different shape. The Speedwell and the Fair American seem to have a similar KOTH, maybe I should use them for reference.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

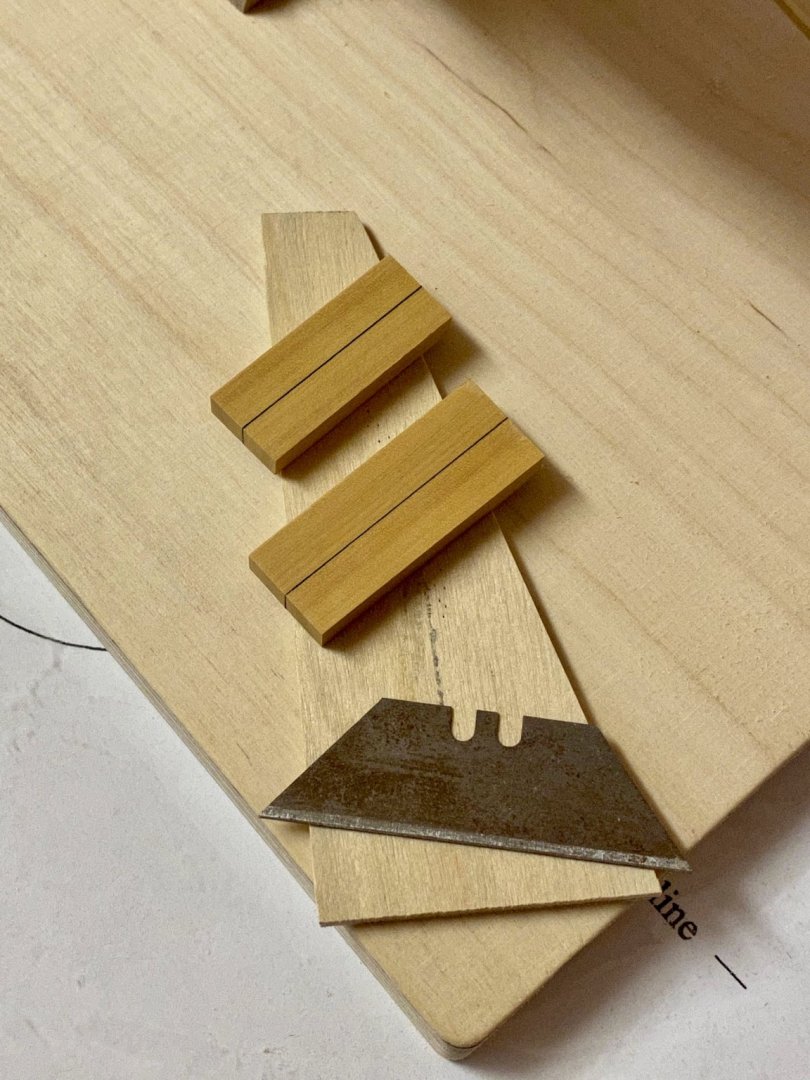

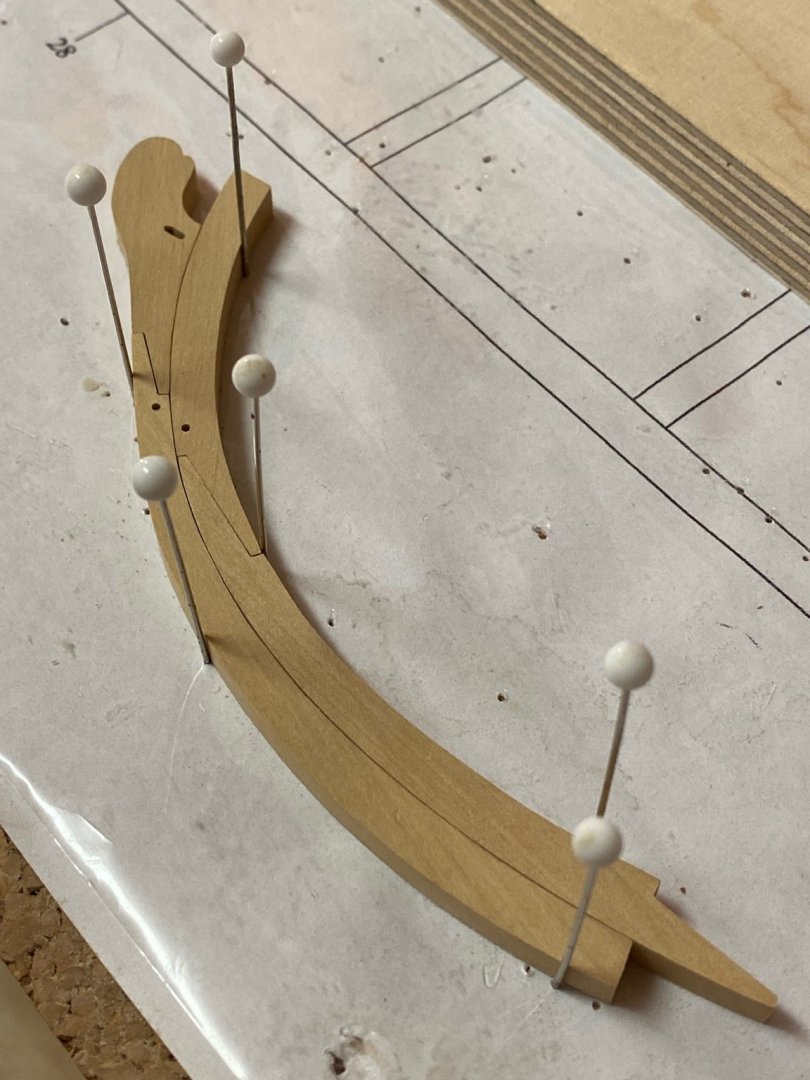

Thank you for the nice comments and the likes. The original kit supplied a simple 2-part keel for the Badger as it is supposed to be painted later. The NMM-plan shows a more complex multi-piece keel and I’m going to prepare both options to choose the final one later and gain more experience for future builds. For the multi-piece solution I first printed all parts on adhesive paper and glued them on 7/32“ boxwood sheets. Then roughly cut the parts with a scroll-saw and sanded them to shape with a Proxxon disc sander. The final sanding to snug fit was done with sanding blocks I made of different wooden blocks. The sanding paper is attached to the blocks with double-adhesive tape and the bottom of the blocks is sanded with the disc-sander so the attached sanding paper is orthogonal to the bottom of the blocks to secure no sloping will occur during sanding the keel parts. As the paper templates are still on I have to use some needles for a test fit. For the tarred joints I might try the paper method dvm27 explained pretty well in his Speedwell log. But before gluing all parts together I still have to find out how to taper the keel correctly. As this is my last day at home working in my workshop might slow down a bit during the next weeks.

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.